全文HTML

--> --> --> 厨余垃圾是指产生于居民小区经大类粗分后的有机垃圾。近年来,生活垃圾中厨余垃圾的比例逐渐增加,甚至高达70%~80%[1-2]。因厨余垃圾具有有机成分多、含水率高、易腐烂、热值低、有害成分少等特点[3],高湿的厨余垃圾给收集、运输以及末端的处理处置都带来一定的难度。另外,高含水率厨余垃圾还使得生活垃圾不同组分间相互粘连,机械分选效果差,也限制了通过分选实现垃圾处理过程优化的可能性[4]。生物干化是近几年来逐步兴起的一种生活垃圾预处理技术,与热干化不同,它无需消耗外界热能,而利用垃圾中可生物降解的有机物好氧分解释放的热量,使垃圾中水分汽化,通过强制通风对流,将汽化后的水蒸气带出,从而降低生活垃圾水分[5]。生物干化技术追求的目标是通过最小的有机质降解实现最大水分去除,快速去除有机物料中水分。经生物干化过程预处理后含水率较低的厨余垃圾仍保留了大部分的有机物,具有较高的热值,可以进行直接焚烧处理,或经过进一步加工后制备垃圾衍生燃料[6]。由于厨余垃圾含水率高、C/N低、物料致密,通常在厨余垃圾堆肥或生物干化过程中通过添加辅料来调节理化性质。秸秆、木屑、稻壳、菌糠等不同的生物质辅料已被用于调节厨余垃圾好氧生物转化的含水率、C/N比和孔隙率[7-10]。这种添加辅料的联合生物干化方式既可以处理生物质废弃资源,同时也可将厨余垃圾高效地转化为垃圾衍生燃料(RDF)。目前, 生物干化技术主要用于干化脱水污泥[11-12]。GEA等[7]发现脱水污泥中添加20%的玉米棒作为辅料,可获得较高的水分去除率。CAI等[13]使用木屑作为辅料调节污泥的含水率进行生物干化。不同种类的辅料可以用来调节厨余垃圾生物干化的理化特性,同时也会改变物料的降解特性和组成,从而影响厨余垃圾燃烧热特性。

目前,大部分研究集中于利用生活垃圾中的塑料、纸质以及纤维等高热值的组分制备垃圾衍生燃料(RDF),这些组分的热解特性以及动力学参数已有报道[14-16]。LI等[17]研究了厌氧消化对污泥热解特性的影响,发现与原始污泥相比,经厌氧发酵后的沼渣的质量损失在180~550 ℃时较低,但在550~900 ℃时较高。ZHANG等[18]研究了混合生活垃圾生物干化过程的燃烧特性,发现生物干化过程可使混合垃圾的热值和表观活化能提高,这主要是由于有机质的降解使混合垃圾中的塑料占比增加,也意味着生物干化过程会使混合垃圾的燃烧更难。然而,生活垃圾的组成比较复杂,主要包括可降解和不可降解组分。目前,我国已经大力倡导生活垃圾源头分类,厨余垃圾需要被单独分离出来并进行单独的运输和处理处置。经生物干化后的厨余垃圾作为生物质能源的燃烧特性以及不同的辅料添加对厨余垃圾生物干化产品热特性的影响引起人们的广泛关注。

本研究以厨余垃圾为研究对象,研究了不同碳源的辅料添加对厨余垃圾生物干化产品燃烧热特性的影响,为厨余垃圾生物干化技术提供参考。

1.1. 材料与实验设计

厨余垃圾取自北京市南城地区马家楼转运站筛分的0~80 mm粒径段垃圾,经人工大类粗分去掉其他垃圾和可回收垃圾后的有机部分。厨余垃圾的物理组成为(湿基):蔬菜30.3%,主食38.9%,果皮17%,果壳5.1%,骨头4.2%,肉类2.4% 和蛋壳2.2%。玉米秸秆取自中国农业大学上庄实验站,经粉碎机切割为3 cm左右的秸秆段。木本泥炭是一种主要由树木、灌木和其他木本植物组成的泥炭,取自印度尼西亚,由中国香港中项国际有限公司提供,供试的木本泥炭为粉末状,粒径约5 mm。原材料的基本性状见表1。实验共设置3个处理,以厨余垃圾单独进行生物干化作为对照,分别添加玉米秸秆和木本泥炭2种辅料,使其与厨余垃圾联合进行生物干化。玉米秸秆为黄贮玉米,将收割后粉碎为3 cm左右的秸秆段直接与厨余垃圾进行混合。木本泥炭经晾晒至含水率低于15%后,将其直接与厨余垃圾混合。玉米秸秆的主要组成为纤维素和半纤维素,木本泥炭主要组成为木质素,因此,二者作为辅料所提供的碳源并不相同,前者可代表纤维素类碳源的辅料,后者代表木质素类碳源的辅料。厨余垃圾单独进行生物干化,不添加任何辅料为对照处理(CK),添加玉米秸秆辅料的处理简称为CS,添加木本泥炭的处理简称为WP。2种辅料的添加量均为初始物料总质量的15% (湿基)。辅料添加比例是综合考虑混合物料C/N比、含水率和好氧发酵温度确定的。将充分混匀后的初始物料堆置于容积为60 L同时具有鼓风和排风的密闭式发酵罐中,再进行生物干化实验。通风方式采用连续通风,通风速率为0.3 L· (kg·min)?1,实验周期为21 d,每隔3 d翻堆1次。生物干化实验装置见图1。生物干化发酵罐为60 L不锈钢圆柱形罐(内径0.36 m,高0.6 m),发酵罐采用2层不锈钢制成,之间为绝热层,防止热量损失。距离发酵罐底部5 cm处装有不锈钢的筛,筛板上为3 mm的气孔,便于气流输送。发酵罐底部设有2个口,1个用来鼓风通气,1个用来收集渗滤液。发酵罐的顶端装有可密封的不锈钢盖,顶盖中间部位有2个孔:1个密封连接温度探头,可在线连续监测生物干化过程中温度的变化;1个孔用来收集测定发酵罐内气体含量和组成。同时发酵罐盖设有直径50 mm的排气口,与冷凝器相连,将发酵罐中水蒸气冷凝,并收集于玻璃中。

1.2. 测定项目和分析方法

在生物干化开始和结束时,采集固定样品约200 g,分2部分保存:一部分为新鲜样品,用于测定含水率,4 ℃条件下保存备用;另一部分自然风干,粉碎后过0.5 mm筛,用于测定挥发性固体(VS)、有机质组分(淀粉、脂肪、蛋白质、纤维素、半纤维素和木质素)、元素含量以及热重分析。含水率采用烘箱干燥法,105 ℃烘干至恒重;固相挥发性固体VS含量采用马弗炉灼烧法,在550 ℃灼烧6 h至恒重。纤维素、半纤维素和木质素含量采用范式洗涤法[19]测定;淀粉含量测定采用蒽酮比色法[20];脂肪含量测定采用乙醚索氏提取法[21];蛋白质含量测定采用凯氏定氮法[20]。各固体指标均测定了3个平行样。

样品(C、N、S和H)含量采用元素分析仪(Elementar Analysensysteme, Hanau, 德国)测定,采用差减法计算O含量。

使用日本 HITACHI 公司的 STA7200 型热重分析仪进行工业分析。测定条件为:升温速率为10 ℃·min?1,进气总流量为 375 mL·min?1,进气中 N2 与 O2 流量之比是 4∶1,在 25~950 ℃进行线性程序升温,每隔 0.5 s 进行一次测定。最后,对所得到的 TG和 DTG曲线使用热重分析仪自带软件 TA7000 Job Gallery 进行分析。根据热重分析仪输出的质量随温度变化的结果,从室温到110 ℃失重率为水分含量,在110~550 ℃失重率为挥发分含量,固定碳的含量为整个过程中质量总损失扣除分析水和挥发分后的含量[22]。

在进行热特性分析时,分析了每个失重段的最大燃烧温度,最大燃烧速率、温度范围和失重率。确定了燃点和燃烬点[23-24],计算了燃烧过程的可燃性指数、综合燃烧指数以及活化能。

可燃性指数C直观地反映试样发生燃烧反应前期的能力。C越大,燃料的着火燃烧稳定性越好[25]。C可按式(1)进行计算。

式中:C为可燃性指数,10?3 μg·(min·℃2)?1;(dw/dt)max 为最大燃烧速率,μg·min?1;Ti为燃点,℃。

与反映燃料前期反应能力的可燃性指数C相比较,综合燃烧特征指数S则全面反映燃料着火和燃烬的综合性能[25],S越大,表明燃料的燃烧性能越佳。S可按式(2)进行计算。

式中:S为综合燃烧特征指数,10?4 μg2·(min2·℃3)?1;(dw/dt)max 为最大燃烧速率,μg·min?1;(dw/dt)mean为平均燃烧速率,μg·min?1;Ti为燃点,℃;Th为燃烬点,℃。

对剧烈燃烧温度范围内的 TG 曲线进行拟合,计算活化能 E,指前因子A和R2[26-28]。活化能越大,说明物料反应越困难。R2越接近1,说明所选用的动力学方程拟合效果越好。动力学方程如式(3)和式(4)所示。

式中:w0为样品初始质量,mg;wt为反应t时刻样品质量,mg;w∞为反应结束最终的样品质量,mg;A为指前因子;E为活化能,kJ·mol?1。

表观活化能(Em)反映每个燃烧阶段对总反应活化能的贡献,Em可按式(5)进行计算。

式中:Em为表观活化能,kJ·mol?1;F1~Fn为每个反应区域所反映的质量分数,根据各个温度段的活化能和反应的质量分数,可计算试样的平均表观活化能。

2.1. 可降解组分含量和贡献率

随着生物干化的进行,堆体中有机质在好氧微生物的活动下逐渐降解产生热量,产生的热量使物料温度升高,在通风的携带作用下,水蒸气被带出堆体,物料含水率也逐渐降低。袁京等[29]详细分析说明了在整个生物干化周期内不同处理的温度变化、含水率变化以及水分去除情况。玉米秸秆富含纤维素和半纤维素,而木本泥炭富含木质素,由于木质素较难降解,纤维素较木质素容易降解,但是比脂肪和淀粉等易降解的有机质组分难降解。因此,经过21 d生物干化后,厨余垃圾单独生物干化后的VS降解率最高,添加木本泥炭处理的VS降解率最低。生物干化过程各有机质组分含量以及各组分对总VS损失的贡献率见表2和表3。有机物料中可降解组分主要包含淀粉、脂肪、蛋白质、纤维素、半纤维素和木质素。与生物干化前相比,所有处理中淀粉、纤维素和半纤维素的含量经过生物干化后均有所降低,脂肪和蛋白质的含量变化较小。但是所有处理中的木质素含量经生物干化后有所增加,主要是由于木质素不容易降解,因此,比其他组分降解速率慢,其他组分的降解速率大于木质素的降解速率,会使木质素的含量浓缩。对于CK处理,对VS损失贡献较大的组分主要为淀粉(27.45%)、纤维素(25.3%)和脂肪(17.44%),占总有机质损失的70.2%。然而,对于CS和WP处理,纤维素、半纤维素和淀粉是主要的贡献组分。但是,WP处理木质素的贡献率明显高于其他2个处理(P =0.001)。2.2. 燃烧特性

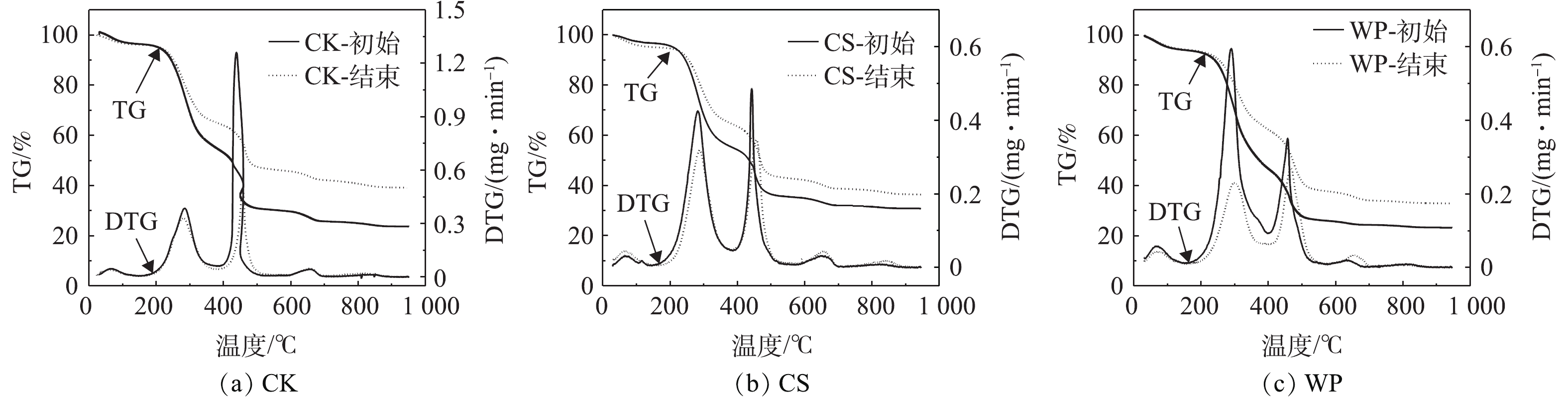

对各处理生物干化前后的样品进行热重分析(TG)和微分热重分析(DTG),CK,CS和WP处理的热特性图谱分别如图2(a)~图2(c)所示。燃点可用于评价物料的着火性能[30]。最大燃烧速率、最大燃烧速率对应的温度、燃烬点、燃烧率、挥发分(VM)、固定碳(FC)和VM/FC均可以用来表征物料的燃烧热特性。热重曲线(TG)出现4个失重段,YE等[31]也发现了相似的失重曲线。第1失重段的温度为30~110 ℃,该温度范围内主要是物料中分析水的损失,失重率较少,约为2.5%~5.3%;第2失重段的温度为110~400 ℃,主要为淀粉、脂肪、蛋白质、纤维素、半纤维素和少量的木质素物质的损失,这一失重段的失重率较高,为30%~46%;DTG曲线的第1峰出现在这个燃烧段。生物干化前,3个处理的最大燃烧温度为282.03~289.8 ℃,差异不大,但是添加辅料的处理对应的最大燃烧速率(CS处理为525.15 μg·min?1,WP处理为595.08 μg·min?1)明显高于CK 处理(385.69 μg·min?1)。这主要是由于辅料的添加增加了初始物料的挥发分含量,主要增加了纤维素、半纤维素以及木质素的含量。有研究[32]表明,纤维素、半纤维素和木质素的燃烧温度分别为225~325、300~380和380~525 ℃。经生物干化后,各处理的最大燃烧速率均有所降低,为231.5~331.55 μg·min?1,但是最大燃烧温度基本保持不变(279.6~301.3 ℃)。生物干化过程对第2失重段的燃烧温度范围和最大燃烧温度影响较小,但是生物干化后物料的最大燃烧速率明显低于生物干化前,这主要是由于生物干化过程中有机质的降解导致第2失重段的质量损失减少。图2有2个明显的峰,根据温度可以判断其为TG曲线第2和第3失重段物质剧烈燃烧反应峰。第3失重段的温度为380~570 ℃,主要为其他剩余的挥发分以及固定碳的析出,失重率为17%~24%;第2个明显的DTG 峰出现在这一失重段。蒲舸等[24]用城市生活垃圾混合样品得到的DTG 曲线也出现明显双峰峰形。CK处理中的原始物料在这一失重段的最大燃烧速率为1 261.7 μg·min?1,高于添加辅料的CS(485.75 μg·min?1)和WP(351.1 μg·min?1)处理,这主要是由于厨余垃圾较高的固定碳含量(6.55%)造成的。生物干化过程使第3失重段的最大燃烧温度提高,同时最大燃烧速率降低,这意味着物料在第3失重段的燃烧较生物干化前相比变困难了。第4失重段的温度为580~710 ℃,这一温度范围内主要为较难分解物质的析出,失重率为1.5%~4%。随着生物干化反应的进行,有机质不断降解,固定碳以及难降解物质所占的比例有所增加,因此,生物干化后物料在第4失重段的最大燃烧速率高于生物干化前。

由表4及表5可以看出,第2和第3失重段为主要的失重段,90% 以上的质量损失发生在这2个阶段。各处理生物干化前后物料燃烧率约为60%~77%,燃烬温度为780~852 ℃。ROBINSON等[33]将垃圾衍生燃料(RDF)的 TG 曲线分为2次水分散发阶段(80~180 ℃)、纤维素分解阶段(180~380 ℃)、塑料分解阶段(400~560 ℃)和难分解的挥发分(>580 ℃),这与本研究结果相似。但是添加玉米秸秆和木本泥炭提高了物料的燃点,添加木本泥炭处理的燃点最高可达到285~288 ℃,这可能与木本泥炭含有大量的木质素有关,添加玉米秸秆增加了物料中纤维素的含量,导致燃点与CK处理相比也有所增加。随着生物干化反应的进行,与初始物料相比,各处理最后生物干化产品燃点基本保持稳定,有机质的降解并不会影响物料的燃点。但是随着有机质的降解,各处理的燃烬点延后了。生物干化过程会导致燃烧率降低以及燃烬点推后。ZHANG等[18]发现,生物干化各时期物料的燃烧率与有机质降解有关,但是燃点与有机质降解无关。这与本研究的结果相似,生物干化对于燃点的影响较小,燃点主要由物质的组成和性质决定。

可燃性指数(C)可以直观地反映物料燃烧前期的燃烧特性,可燃性指数越高,说明燃料的着火和燃烧稳定性越好[25]。综合燃烧指数(S)可用来综合评价着火和燃烬性能,S越高,说明燃烧越活跃。生物干化过程使得各处理的C和S均有所降低。随着生物干化反应的进行,VM含量降低,但是FC的含量增加,因此,VM/FC比值有所降低。这一比值高于5,说明物料在低温区域有较高的质量损失[18](110~340 ℃)。在本实验中,各处理在生物干化前后的VM/FC比值均高于5,这与物料无论是在生物干化前还是干化后,在第2失重段质量损失率最高的结论是一致的。由物料热值变化可以看出,厨余垃圾进行干化前的高位热值较高,但是低位热值仅为266 kJ·kg?1,这主要是由于过高的含水率影响了物料的低位热值。CK处理经生物干化后的热值提高至1 331 kJ·kg?1,但仍无法达到自燃的要求,需要添加助燃剂。但是在添加辅料的CS和WP处理中,经生物干化后,物料的低位热值提高至6 327~8 404 kJ·kg?1,辅料中碳源的补充一方面增加了物料的热值,另一方面提高了生物干化效率,进而增加了最终物料的低位热值。

2.3. 燃烧动力学参数

Coats-Redfern 模型已被广泛用于计算一阶动力学反应和指前因子[34-35],在本研究中,采用Coats-Redfern 模型计算各燃烧阶段的动力学的参数。同时,也可计算获得活化能(E)和表观活化能(Em)[36]。各处理在生物干化前后的燃烧动力学参数见表6。可以看出,一级动力学方程的拟合效果较好, R2 =0.86~0.97。活化能越高表明发生反应更为困难。随着生物干化反应的进行,CK处理中的第2失重段的活化能有所增加,但在CS和WP处理中的第2失重段的活化能均有所降低。与此相反,在第3失重段,CK处理的活化能降低,但是CS和WP处理的活化能增加。对于CK处理,生物干化过程使第2失重段反应变难,第3失重段反应变易。然而对于CS和WP处理,生物干化处理使第2失重段反应变易,第3失重段反应变难。总体而言,生物干化过程使各处理的表观活化能(Em)显著降低(P=0.006),与生物干化前相比,各处理生物干化后产品的表观活化能降低了15.9%~29.4%,从而使得厨余垃圾的燃烧更加容易。

ZHANG等[18]报道了在生物干化过程中,厨余垃圾和纸质的混合物的表观活化能基本上保持不变,主要是由于原料中包含了20%的纸质。然而,对于混合垃圾的活化能,ZHANG等[18]发现,随着生物干化反应的进行,混合垃圾的活化能增加了。这可能主要是由于有机质的降解浓缩了混合垃圾中的塑料组分。因此,不同的原材料对于生物干化过程表观活化能的影响不同。浮爱青等[37]发现纸类的活化能为85.04 kJ·mol?1,橡胶塑料类的活化能为101.41 kJ·mol?1。本研究中的厨余垃圾经过人工分选去除了大部分的纸类和塑料,因此,活化能低于单一物料的活化能。煤在温度<300 ℃ 的条件下进行燃烧,活化能为80 kJ·mol?1,而本研究中生物干化前后物料在200~350 ℃时,活化能基本均低于50 kJ·mol?1,这表明与煤相比,厨余垃圾经生物干化后作为燃料的低温燃烧反应更容易发生[38]。

2)随着生物干化反应的进行,物料的燃烧速率和燃烧率均有所降低,同时燃烬点推后。但燃点基本保持不变。添加木本泥炭的处理燃点最高,燃烬点最低,燃烧率最高。

3)生物干化过程使CK处理中的第2失重段反应变难,第3失重段反应变易。然而,对于添加辅料的处理,第2失重段反应变易,第3失重段反应变难。总体而言,生物干化过程使各处理的表观活化能(Em)降低了15.9%~29.4%,从而使得厨余垃圾的燃烧更加容易。

参考文献

下载:

下载:

点击查看大图

点击查看大图