,*, 勾玲

,*, 勾玲 ,*石河子大学农学院 / 新疆生产建设兵团绿洲生态农业重点实验室, 新疆石河子 832003

,*石河子大学农学院 / 新疆生产建设兵团绿洲生态农业重点实验室, 新疆石河子 832003Temperatures of promoting rapid leaf abscission of cotton in Xinjiang region

TIAN Jing-Shan, ZHANG Xu-Yi, ZHANG Li-Na, XU Shou-Zhen, QI Bing-Qin, SUI Long-Long, ZHANG Peng-Peng, YANG Yan-Long, ZHANG Wang-Feng ,*, GOU Ling

,*, GOU Ling ,*College of Agronomy, Shihezi University / Key Laboratory of Oasis Eco-Agriculture, the Xinjiang Production and Construction Corps, Shihezi 832003, Xinjiang, China

,*College of Agronomy, Shihezi University / Key Laboratory of Oasis Eco-Agriculture, the Xinjiang Production and Construction Corps, Shihezi 832003, Xinjiang, China通讯作者:

收稿日期:2018-03-13接受日期:2018-12-24网络出版日期:2019-01-23

| 基金资助: |

Received:2018-03-13Accepted:2018-12-24Online:2019-01-23

| Fund supported: |

作者简介 About authors

摘要

关键词:

Abstract

Keywords:

PDF (385KB)元数据多维度评价相关文章导出EndNote|Ris|Bibtex收藏本文

本文引用格式

田景山, 张煦怡, 张丽娜, 徐守振, 祁炳琴, 随龙龙, 张鹏鹏, 杨延龙, 张旺锋, 勾玲. 新疆机采棉花实现叶片快速脱落需要的温度条件[J]. 作物学报, 2019, 45(4): 613-620. doi:10.3724/SP.J.1006.2019.84068

TIAN Jing-Shan, ZHANG Xu-Yi, ZHANG Li-Na, XU Shou-Zhen, QI Bing-Qin, SUI Long-Long, ZHANG Peng-Peng, YANG Yan-Long, ZHANG Wang-Feng, GOU Ling.

棉花脱叶催熟技术是实现棉花机械采收的重要前提, 不仅能解决棉花生育后期的晚熟问题, 而且加快收获前叶片脱落, 能提高机采棉的采摘率和作业效率[1], 降低机采籽棉含杂率[2]。脱叶催熟效果受品种特性[3]、植株生长状况[4]、脱叶催熟剂喷施时间[5,6]、温度[7,8,9]等多重因素影响。

合理喷施脱叶催熟剂不仅能实现良好的脱叶催熟效果, 而且可以降低对棉花产量和纤维品质的负面影响[5-6,10]。目前, 确定脱叶催熟剂喷施时间主要依据吐絮率(percentage of open boll)、裂铃以上主茎节数(node above cracked boll)、热量积累量(calculating DD60s after NAWF5)、刀切法(sharp knife technique)、马克隆值预测法(Hal Lewis Method)[11], 其中棉铃吐絮率是较为常用的指标[5,12]。一般情况下, 推荐在60%的棉铃吐絮后进行脱叶催熟[5,12-13]。如果脱叶催熟剂喷施时间过早, 将严重影响成铃和纤维发育[14], 增加不成熟棉铃和纤维的比例[12,15], 特别是铃龄45 d以下棉铃的铃重明显下降[16], 导致棉花产量下降和纤维品质变劣[12,15]。喷施时间推迟虽对棉花产量和品质都有利[6], 但是药效不大, 失去了催熟的意义, 又会增加遭遇霜冻和恶劣天气的风险[8], 出现叶片干枯而不脱落现象(sticking), 导致籽棉含杂率增加[2]。因此, 何时喷施脱叶催熟剂非常关键, 但也较难确定[5], 需考虑棉花产量和纤维品质之间的平衡关系[17]。

通常喷施脱叶催熟剂后的温度变化是影响脱叶效果的重要因素[18,19], 较高的温度可促进药剂快速渗入叶片、利于药剂发挥[20], 以实现快速脱叶[9]。研究表明, 要取得良好的脱叶效果, 应确保施药后> 20.0°C的最高气温持续数日[7]、最低温度>12.0°C [21]。喷施脱叶催熟剂后一个较短时间范围内的气温变化趋势对脱叶率也有很大的影响, 施药5 d的温度与脱叶率呈显著正相关[22], 施药后10 d脱叶率则受温度影响较小[18]。另有研究表明, 脱叶效果与施药当天和施药后5 d内气温无显著相关, 与施药后6~10 d的温度关系最密切, 是脱叶率的气温决定期[19]。此外,也有****认为有效积温(growing degree days, GDD)也是影响化学脱叶催熟剂效果的重要因素[8,23]。

在新疆棉花生育后期, 一天内气温>20°C的时间逐渐减少, 夜间温度急剧下降[24]。为确保机械采收, 部分棉田植株顶部棉铃尚未完全发育就喷施脱叶催熟剂, 这势必严重影响棉铃发育[14,16]。因此, 确定脱叶催熟剂喷施时间时不仅要考虑气温变化, 还应观察棉铃发育状况。为此, 本研究采用分期喷施脱叶催熟剂的方式, 探讨温度变化对棉花叶片脱落的影响及实现叶片快速脱落需要的温度条件, 以期为降低机采籽棉含杂率提供技术支撑。

1 材料与方法

1.1 试验设计

试验于2013—2014、2016—2017年在新疆生产建设兵团第八师一四九团三连(44°52′N, 86°09′E)、石河子大学农学试验站(45°19′N, 86°03′E)和新疆乌兰乌苏农业气象试验站(44°17′N, 85°49′E)进行, 选用生产中曾大面积种植过或目前主栽的“新陆早”系列棉花品种, 包括新陆早6号、新陆早13号、新陆早33号、新陆早45号、新陆早59号; 分期喷施脱叶剂, 以不喷施脱叶剂为对照(CK), 脱叶剂为噻苯隆(80%可湿性粉剂), 并复配乙烯利(40%水剂), 每公顷用量分别为450 g、1350 mL; 随机区组设计, 小区面积为长×宽 = 10.0 m × 4.6 m, 留苗密度18~23万株 hm-2, 田间管理措施按当地大田管理模式进行。不同年份和试验点具体种植的棉花品种、播种日期、脱叶剂喷施时间和叶片数调查时间见表1。Table 1

表1

表1脱叶催熟剂试验中的棉花品种、播种日期、脱叶催熟剂喷施时间和调查时间

Table 1

| 年份 Year | 试验地点 Experiment plot | “新陆早”系列品种序号 No. of “Xinluzao” cotton cultivars | 播种日期 Bowing dates (month/day) | 脱叶催熟剂 喷施时间 Defoliation times (month/day) | 叶片数调查时间 (喷施脱叶剂后天数) Investigation times of leaf number (days after defoliant application) |

|---|---|---|---|---|---|

| 2017 | 石河子大学农学试验站 Shihezi University Experiment Station | 33, 59 | 4/22 | 8/8, 8/16, 8/24 | 8, 16, 23, 29, 36 |

| 2016 | 石河子大学农学试验站 Shihezi University Experiment Station | 6, 13, 33, 45 | 4/21 | 8/18, 8/25, 9/4 | 6, 13, 19, 26 |

| 新疆乌兰乌苏农业气象试验站 Wulanwusu Agrometeorological Experiment Station | 33 | 4/15 | 8/11, 8/20, 8/27 | 6, 13, 20, 28 | |

| 59 | 4/8, 4/15 | 8/11, 8/20, 8/27 | 6, 13, 20, 28 | ||

| 59 | 4/22 | 8/20, 8/27, 9/3 | 7, 14, 21, 29 | ||

| 2014 | 新疆兵团第八师一四九团三连 Third company Regimental Farm 149, the Eighth Division | 45 | 4/20 | 9/12, 9/19 | 7, 14, 20, 28 |

| 2013 | 新疆兵团第八师一四九团三连 Third company Regimental Farm 149, the Eighth Division | 45 | 4/20 | 9/8, 9/15 | 7, 14 |

新窗口打开|下载CSV

1.2 叶片脱落率的调查与计算

选取每小区有代表性且连续的棉株10~20株定点调查, 从喷施脱叶剂当天开始, 每隔6 d左右调查单株叶片数。棉花叶片脱叶率(Di)是指喷施脱叶剂当天的单株叶片数(L0)与喷施后第i天(Li)的差值占L0的百分比, 计算方法见公式(1)。为了明确喷施脱叶剂后叶片脱落率的变化规律, 采用分段计算的方式, 根据调查时间和次数将叶片脱落过程划分为4个时间段, 即7.0±1.0 d (6~8 d)、15.0±1.6 d (13~17 d)、21.0±1.6 d (19~23 d)、29.8±3.8 d (26~36 d), 不同时间段的叶片脱落率是第n+1次调查的脱落率与第n次之间的差值, 喷施脱叶剂当天至第1次的脱落率可根据公式(1)计算。

1.3 温度资料的采集

用HOBO (Onset, 美国)空气温湿度记录仪自动采集石河子大学农学试验站的温度数据, 新疆生产建设兵团第八师一四九团三连和新疆乌兰乌苏农业气象试验站的温度数据由石河子气象局提供。选取叶片脱落的不同时间段的平均温度、最低温度、最高温度、日温差和每日≥12°C有效积温(GDD)作为影响该时间段叶片脱落率的温度因子; 每日≥12°C有效积温根据公式(2)计算, 各时间段≥12°C有效积温是该时间段每日有效积温的总和。2 结果与分析

2.1 脱叶催熟剂喷施时间对棉花脱叶效果的影响

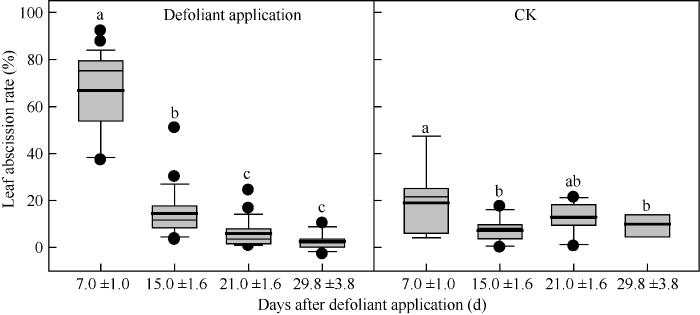

由图1可看出, 喷施脱叶催熟剂后, 叶片脱落率随时间推移而显著下降。在喷施脱叶催熟剂后(7.0±1.0) d左右时叶片快速脱落, 平均叶片脱落率高达65.7%, 较对照增加了3倍。之后, 叶片脱落率显著降低, 且变化趋于平缓; 在喷施后(7.0±1.0)~ (15.0±1.6) d期间叶片脱落率显著降低至15.6%, 仅有(7.0±1.0) d时的1/5; 喷施后(15.0±1.6) d后叶片脱落率逐渐降至10%以下。图1

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图1喷施脱叶催熟剂后不同时间段棉花叶片脱叶率的变化

图中粗实线表示该组数据的平均值, 标以不同小写字母的值在0.05水平差异显著。

Fig. 1Changes of leaf abscission rate by defoliant application during different time period

The thick solid line represents the average value of the defoliant treatment, values followed by different letters are significantly different at P < 0.05.

2.2 温度变化对棉花脱叶效果的影响及其关系

由表2可知, 喷施脱叶催熟剂后的时间段不同, 影响叶片脱落率的温度因子亦有所不同。在喷施脱叶催熟剂后(7.0±1.0) d内, 叶片脱落率受温度的影响较为明显, 均呈正相关; 其中, 与平均温度、最高温度和≥12°C有效积温的P < 0.01, 达到极显著性水平, 与最低温度呈显著正相关。在喷施后(15.0±1.6) ~(21.0±1.6) d期间, 叶片脱落率与平均温度、最低温度和每日≥12°C有效积温呈显著负相关; 而在喷施后(7.0±1.0)~(15.0±1.6) d期间则受温度的影响不显著。Table 2

表2

表2喷施脱叶催熟剂后不同时间段的温度与叶片脱落率的方差分析

Table 2

| 喷施脱叶剂后天数 Days after defoliant application (d) | 0 to (7.0±1.0) d | (7.0±1.0) to (15.0±1.6) d | (15.0±1.6) to (21.0±1.6) d |

|---|---|---|---|

| 样本数 n | 27 | 29 | 25 |

| 平均温度 Average temperature (°C) | 0.0013 | -0.9367 | -0.0162 |

| 最低温度 Minimum temperature (°C) | 0.0163 | 0.6753 | -0.0176 |

| 最高温度 Maximum temperature (°C) | 0.0001 | -0.6865 | -0.2982 |

| 日温差 Diurnal temperature range (°C) | 0.2399 | -0.3817 | 0.2174 |

| 各时段≥12°C有效积温 GDD accumulation baseline 12 °C (°C) | 0.0078 | -0.3337 | -0.0807 |

| 每日≥12°C有效积温 GDD baseline 12 °C (°C day) | 0.0013 | -0.9367 | -0.0162 |

新窗口打开|下载CSV

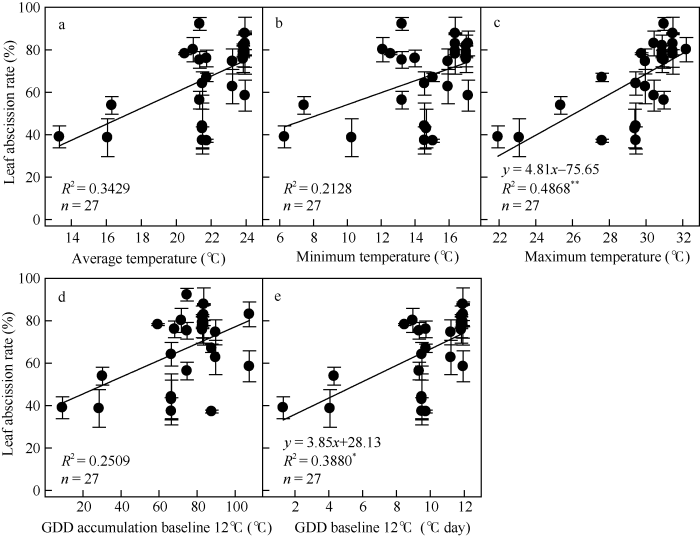

对喷施脱叶催熟剂后(7.0±1.0) d内的叶片脱落率与最低温度、最高温度、平均温度和≥12°C有效积温进行曲线拟合(图2)可看出, 最高温度与叶片脱落率呈线性正相关, 决定系数为0.4868, 达到极显著水平; 叶片脱落率与每日≥12°C有效积温亦呈显著的正线性关系, 决定系数为0.3880。最低温度和平均温度与叶片脱落率的决定系数分别为0.2128和0.3429, 均未达到显著性水平。

图2

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图2脱叶催熟剂喷施后(7.0±1.0) d内叶片脱落率与平均温度(a)、最低温度(b)、最高温度(c)和有效积温(d, e)变化的关系

Fig. 2Relationships of average temperature (a), minimum temperature (b), maximum temperature (c), and growing degree days (d, e) with leaf abscission rate during the period within (7.0±1.0) days after defoliant applicationGDD: growing degree days.

通过联立叶片脱落速率与最高温度和每日≥12°C有效积温的拟合曲线(图2-c, e), 计算出实现叶片脱落速率>55%、>60%和>65%所需要的最高温度和每日≥12°C有效积温, 再根据最高温度和每日≥12°C有效积温可计算出最低温度的适宜范围。由表3可看出, 在喷施脱叶催熟剂后(7.0±1.0) d内, 若要实现叶片脱落速率>55%需要期间的最高温度大于27.2°C、每日≥12°C有效积温大于7.0°C·日、最低温度大于10.8°C。实现更高的叶片脱落速率就需要更高的温度条件, 实现>65%以上的叶片脱落速率则应满足喷施脱叶催熟剂后(7.0±1.0) d内的最高温度不低于29.2°C、每日≥12°C有效积温大于9.6°C·日、最低温度大于13.9°C。

Table 3

表3

表3喷施脱叶催熟剂后(7.0±1.0) d内实现>55%叶片脱叶速率所需要的温度条件

Table 3

| 项目 Item | 叶片脱落率 Leaf abscission rate | ||

|---|---|---|---|

| > 55% | > 60% | > 65% | |

| 最高温度Maximum temperature (°C) | 27.2 | 28.2 | 29.2 |

| 每日≥12°C有效积温GDD baseline 12 °C (°C day) | 7.0 | 8.3 | 9.6 |

| 最低温度Minimum temperature (°C) | 10.8 | 12.4 | 13.9 |

新窗口打开|下载CSV

2.3 新疆棉区适宜喷施脱叶催熟剂时间的估算

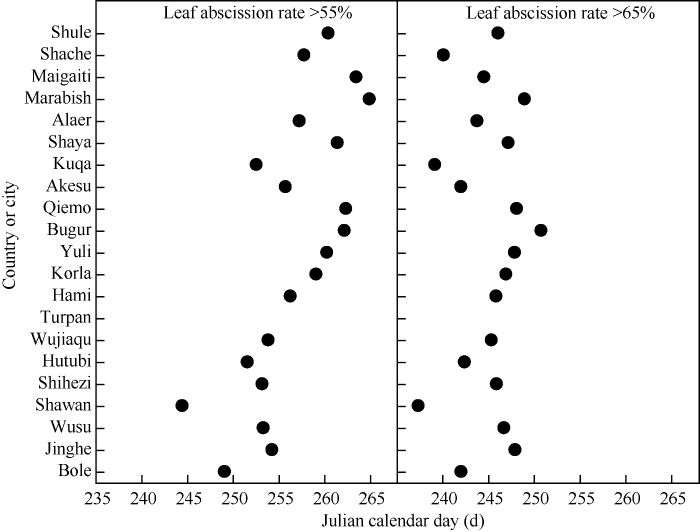

根据新疆2010—2015年的棉花播种面积[25,26]选择了疏勒县、莎车县、博乐市等21个市县, 并收集各市县的温度资料(中国气象数据网http://data. cma.cn/site/index.html), 计算出最高温度和≥12°C有效积温在2008—2017年的平均值, 代表该市县温度条件一般的年份。通过对21个市县9月1日至30日的最高温度和每日≥12°C有效积温与日序进行线性拟合, 结合表3中最高温度和每日≥12°C有效积温的阈值计算出对应的日期(日序), 即各市县适宜喷施脱叶催熟剂的时间。由图3可看出, 若在喷施脱叶催熟剂后(7.0±1.0) d内实现叶片脱落速率>55%, 各市县的喷施时间基本在9月9日至17日。其中, 沙 湾县喷施脱叶催熟剂的时间最早, 为8月31日; 博乐市、呼图壁县、库车县、石河子市、精河县、乌苏市和五家渠市则在9月5日至10日, 轮台县、且末县、麦盖提县和巴楚县喷施脱叶催熟剂的时间可延迟至9月18日至20日; 吐鲁番市喷施脱叶催熟剂的时间最晚, 为10月7日。若在喷施脱叶催熟剂后(7.0±1.0) d内实现叶片脱落速率>65%, 各市县基本在9月1日左右就需喷施脱叶催熟剂。其中, 沙湾县、库车县、莎车县、阿克苏市、博乐市和呼图壁县的喷施时间最早, 为8月24日至29日; 精河县、且末县、巴楚县和轮台县喷施时间较晚, 为9月3日至6日; 吐鲁番市喷施时间最晚, 为9月27日。图3

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图3新疆棉区各市县适宜喷施脱叶催熟剂的时间

市县的选择依据是2010-2015年各市县的棉花平均播种面积占新疆总播种面积的比例>1%。横坐标是日序, 244为9月1日。

Fig. 3Optimal schedule of applying defoliant in Xinjiang Region

Cities or countries accounted for more than 1% of Xinjiang’s cotton areas in 2010-2015 were chosen. the abscissa is the Julian calendar day, 244 is 1st September.

3 讨论

3.1 最高温度和≥12°C有效积温是实现良好脱叶效果的关键气象因素

发展机采棉有利于实现规模化经营、大幅降低植棉成本和提高劳动生产率, 推动棉花生产方式向现代农业的快速发展。然而, 机采棉在新疆棉区的快速发展过程中, 现有的原棉品质变劣问题日益突出[27], 其原因在于机采籽棉含杂率过高, 导致加工过程中清理工序多, 造成不必要的纤维损伤[28]。良好的脱叶效果既可以有效降低机采籽棉含杂率, 又能减少机械采收和清理加工对纤维的潜在损伤。在新疆棉区, 棉花生长发育后期既要催熟又要脱叶, 脱叶催熟技术需要协调棉铃发育状况和气温变化之间的关系; 适宜的脱叶催熟剂喷施时间既要促使棉株顶部棉铃基本发育成熟, 又要满足脱叶所需的气温条件。有关脱叶催熟剂对棉花脱叶效果及与温度的关系已有大量的报道, 研究表明, 喷施脱叶催熟剂后不同时段的温度是影响棉花脱叶效果的关键因素[18-19,22], 明确指出了温度变化与叶片脱落率之间存在显著相关性。本研究发现, 在喷施脱叶催熟剂后(7.0±1.0) d内, 叶片脱落率受温度(平均温度、最高温度、最低温度、≥12°C有效积温)的显著影响, 且随最高温度和≥12°C有效积温升高而直线增加; 然而, 在喷施脱叶催熟剂后(7.0±1.0)~(15.0±1.6) d, 温度对脱叶脱落率的影响很小。因此, 喷施脱叶催熟剂后(7.0±1.0) d内是实现良好脱叶效果的关键时间段, 期间的最高温度和每日≥12°C有效积温是影响的关键因素。

多数研究者虽然确定了喷施脱叶催熟剂的适宜时期[7, 21], 但多为生产经验总结, 温度变化与叶片脱落率之间的定量关系尚不清晰。本研究表明, 喷施脱叶催熟剂后(7.0±1.0) d内要求达到的叶片脱落率越高, 则就需要更高的温度条件, 若要实现>65%的叶片脱落率就需要最高温度>29.2°C。新疆植棉区域分布广泛, 气候变化亦存在明显的地域性, 脱叶催熟剂喷施时间理应有所差异。在喷施脱叶催熟剂后(7.0±1.0) d内, 若实现叶片脱落率>65%, 新疆各市、县应在8月29日至9月3日左右喷施脱叶催熟剂。然而, 新疆棉区棉花生长后期的热量资源有限, 温度下降快[24], 8月29日至9月3日喷施脱叶催熟剂时部分地区, 尤其是南疆棉区棉花顶部棉铃尚未发育完全, 这势必严重影响纤维品质; 再者, 此时喷施脱叶催熟剂将会缩短棉花发育期, 不能充分利用后期的温度资源。若在喷施脱叶催熟剂后(7.0±1.0) d内实现叶片脱落率>55%, 新疆各市、县可在9月9日至17日喷施脱叶催熟剂。本研究认为, 在喷施脱叶催熟剂后(7.0±1.0) d内, 新疆棉区应至少实现55%的叶片脱落率, 此时要求该时间段的最高温度大于27.2°C、每日≥12°C有效积温大于7.0°C·日。

3.2 如何实现棉花叶片快速脱落

根据行业标准NT/T 113-2006 《采棉机作业质量》的要求, 叶片脱落率≥80%时就可进行机械采收[29]。在本试验条件下, 棉花叶片大量脱落集中在喷施脱叶催熟剂后(7.0±1.0) d内, 期间的平均脱落率是喷施脱叶催熟剂后(7.0±1.0)~(15.0±1.6) d的4.2倍; 在喷施脱叶催熟剂后(7.0±1.0) d内, 叶片脱落率虽存在较大波动, 约37%~92%, 但仍有1/5试点的叶片脱叶率>80%。可见, 喷施脱叶催熟剂后(7.0±1.0) d内是实现棉花叶片快速脱落的重要时间段。除温度因素影响外, 脱叶剂种类[30]和喷施量[31]也是影响棉花叶片脱落的重要因素。脱叶剂喷施量应根据喷施时间、天气条件和棉花长势而定, 坚持“适量偏少、适量偏多”原则[21], 喷施量过高易造成叶片迅速干枯而不脱落[32]。机采棉杂质包括叶、茎杆、铃壳、尘土、杂草等[33], 其中以叶含杂量最高[34], 据调查新疆机采籽棉中以叶杂含量最高, 占总杂质的53%~93%。根据喷施脱叶催熟剂后单株残留叶片的状况, 可将叶杂的来源分为干枯叶(指离层未形成, 干枯在茎枝上的叶片, Drying)、挂枝叶(指离层已形成, 脱落留在茎枝或吐絮铃上的叶片, Hanging) 2类[35]。在新疆北疆棉区的调查结果显示, 棉花单株干枯叶数平均为4.1个, 较挂枝叶显著高出1.2个 株-1。可见, 实现棉花叶片快速脱落, 首先要解决喷施脱叶催熟剂后棉花叶片干枯问题, 这就需要明确噻苯隆喷施量、温度条件与叶片脱落率之间的关系, 根据温度变化和棉田状况随时调整脱叶催熟剂的喷施量。

目前, 我国批准登记并在有效期内的棉花脱叶剂产品共有68个, 有效成分仍以噻苯隆为主[36]。脱叶剂复配往往能获得更好的脱叶效果, 且更为安全[37], 其中, 敌草隆是一种触杀型化合物[38], 常与噻苯隆复配[36], 用于提高低温条件下的脱叶效果[39], 但喷施量过高也很容易形成干枯叶。因此, 实现棉花叶片快速脱落的另一途径是, 改良脱叶剂配方以增强棉花叶片的附着性和吸收能力, 避免触杀型复配剂带来的负面影响。

机采棉自身杂质高[40], 棉花加工厂一般采用多道清理工序, 以提高机采棉清杂效率和皮棉等级[41], 过多增加清理次数势必造成纤维损伤[42]。机采籽棉清理过程中叶片特性是决定纤维损伤程度的关键因素之一[43,44], 研究表明, 棉花叶片表面光滑的品种机采籽棉含杂率较茸毛多的品种明显减少[43,45], 棉花加工过程只需较少的清理工序即可获得高等级、损伤较小的原棉[46]。Anthony等[46]认为光滑叶品种的机采籽棉经4道籽棉清理后比多茸毛叶品种多清除17%的杂质, Smith[47]认为籽棉含杂率受叶片茸毛的影响大于脱叶剂的影响。李雪源[48]、李蒙春等[49]提出, 机采棉品种应具备叶片光滑、茸毛少等特点。因此, 在机采棉品种选育及推广中, 更应注重有无茸毛叶片的筛选。

4 结论

在喷施脱叶催熟剂后, 不同时间段的叶片脱落率存在显著差异, 以喷施后(7.0±1.0) d内的脱落率最高, 而且影响叶片脱落率的温度因子因时间段不同亦有较大差异。在喷施脱叶催熟剂后(7.0±1.0) d内是实现良好脱叶效果的关键时间段, 期间的最高温度和≥12°C有效积温是影响叶片脱落率的关键因子。在新疆棉区喷施脱叶催熟剂后(7.0±1.0) d内至少实现叶片脱落率>55%, 要求该时间段的最高温度大于27.2°C、每日≥12°C有效积温大于7.0°C·日。参考文献 原文顺序

文献年度倒序

文中引用次数倒序

被引期刊影响因子

[本文引用: 1]

URL [本文引用: 2]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

DOI:10.1016/0378-4290(94)90042-6URL [本文引用: 5]

In general, defoliant treatments should not be applied prior to 60% open bolls in order to safeguard against potential losses in yield and undesirable changes in fiber quality. Yield losses and quality reductions occurred due to improper timing, irrespective of defoliant used.

DOI:10.2134/agronj2002.1004URL [本文引用: 3]

Excessive weathering may diminish cotton lint yield and fiber quality to the extent that economic losses occur for the producer. The objective of this investigation was to determine the effects of systematic delayed harvest on cotton lint yield, fiber quality and profitability. Experiments were conducted from 1998 to 2000 at the Coastal Plain Experiment Station in Tifton, GA. The treatments consisted of a standard harvest-aid combination applied at weekly intervals over a thirteen-week period beginning at first open boll. Harvest aids were applied to each plot according to its week after first open boll designation and machine harvested two weeks thereafter. After ginning, fiber quality was determined on lint samples from each plot. High volume instrument (HVI) fiber length uniformity was greatest in 1999 and 2000 when harvest aids were applied between 58 and 88% open boll while the Advanced Fiber Information System (AFIS) short fiber content were lowest when harvest aids were applied from 40.1 to 46.8% open boll. The HVI upper half mean fiber length and the AFIS mean fiber length by number were greatest when harvest aids were applied between 39.1 and 56.7% open boll. In 1999 and 2000 lint yield and adjusted gross income were greatest when harvest aids were applied from 76.5 to 89.0% open boll. Thus, results from this study indicate optimum fiber quality is established earlier during boll opening than lint yield and profitability.

[本文引用: 3]

[本文引用: 3]

URL [本文引用: 3]

Producers need methods to determine the relationship between early defoliation and net revenues for cotton (Gossypium hirsutum L.) in a short-season environment. This study evaluated the effects of alternative defoliation timing and harvest-aid strategies on lint yields, prices adjusted for fiber quality, and net revenues. 'Stoneville 474' or 'Stoneville 4892 BR' was planted in May 1998, 1999, and 2000, and the crops were monitored using the COTMAN Expert System. Harvest-aid treatments were (i) a tank mixture of thidiazuron (N-phenyl-N-1,2,3-thiadiazol-5-ylurea), tribufos (S,S,S-tributyl phosphorotrithioate), and ethephon [(2-chloroethyl)phosphonic acid]; and (ii) a prepared mixture of cyclanilide { 1 - [ [ ( 2 , 4 - dichlorophenyl)amino]carbonyl]cyclopropanecarbo xylic acid} plus ethephon. These treatments were applied at 361, 417, 472, and 528 degree-d (base 15.6C) after cutout each year. Price differences for fiber quality were calculated using fiber quality measured from the experiment and North Delta spot price quotations from contrasting marketing years. Net revenues were estimated using lint yields, price differences, harvest-aid materials and application expenses, and harvesting costs. Results consistently showed the harmful effects of premature crop termination and the beneficial effects of delayed termination beyond the nominal threshold of 472 degree-d. Additional yield occurred with delayed crop termination. Improved fiber quality and enhanced yields from cotton harvested after defoliation at 528 degree-d maximized cotton crop profitability. Findings suggest that delaying defoliation to 528 degree-d can facilitate a single harvest of cotton. However, the potential advantages of delayed defoliation need to be weighed against the potential risks of later harvest when inclement weather is more probable.

URL [本文引用: 2]

Abstract Successful cotton harvest depends on the use of harvest-aid chemicals, but their performance is often inconsistent because of weather conditions. Our objective was to determine weather factors that most influence responses to various harvest aids. A 5-yr study was conducted at 16 locations across the United States. Responses to three defoliants, applied with and without ethephon, were compared with an untreated check. Response data included defoliation, desiccation, boll opening, and regrowth. Weather data collected prior to and following treatment were precipitation and average daily maximum and minimum temperatures. Data taken at time of treatment included cloud cover, air temperature, relative humidity, and wind speed. Correlation and quartile analyses showed that daily minimum temperatures from planting to treatment dominated the weather factors influencing the defoliation response to all harvest aids. High seasonal night temperatures apparently promoted crop maturity and susceptibility to defoliation. Weather had little influence on desiccation. Daily maximum temperatures from planting to treatment, and daily maximum and minimum temperatures after application were the main weather factors influencing the boll opening response to ethephon-based treatments. Although boll opening was promoted by warm weather after treatment, ethephon had a proportionally greater boll opening response under cooler conditions in which boll opening of untreated cotton apparently slowed. Terminal regrowth responses were most evident with relatively moist conditions before treatment and mild temperatures after treatment, which apparently promoted vegetative regrowth in untreated relative to treated cotton. These findings may help improve selection of harvest aids for different weather conditions and climatic regimes.

DOI:10.2135/cropsci2004.0165URL [本文引用: 1]

ABSTRACT The timing of certain cotton (Gossypium hirsutum L.) management practices varies according to the yield potential and quality characteristics associated with a variety. A defoliation timing study was performed to (i) determine if certain cultivars respond differently to defoliation timings and (ii) compare the use of the open boll percentage at defoliation (OBPD), nodes above cracked boll (NACB), and micronaire readings at defoliation for their effectiveness in timing defoliation. The study was conducted in 1999, 2000, and 2001. Treatments consisted of two proprietary cultivars (ST 474 and DP 5409), each defoliated on the basis of OBPD measurements. At the time of defoliation, NACB was recorded and lint samples were retained for later high volume instrumentation (HVI) analysis. Neither variety produced consistently higher yields than the other in this study. In 2000, delaying defoliation from 40 to 60 OBPD would have resulted in a significant addition of approximately 75 kg lint ha1 for either variety. Stoneville 474 micronaire was highest in all years suggesting that timely defoliation is more critical to ST 474 cotton compared with DP 5409 in years when overall conditions are favorable for high micronaire. DP 5409 fiber length (UHM) values were consistently higher than ST 474 and UHM was unaffected by changes in OBPD values regardless of variety. Stoneville 474 had higher uniformity index (UI) values in all three years and delaying defoliation produced mixed results. The data demonstrate that proper defoliation timing strategies aimed at optimizing quality can vary across varieties. Proper defoliation timing in the two varieties examined in this study varied little with respect to yields. Both NACB and micronaire readings taken at defoliation were more effective for timing defoliation to optimize micronaire readings than OBPD.

URL [本文引用: 1]

DOI:10.2134/agronj2009.0454URL [本文引用: 4]

Immature cotton (Gossypium hirsutum L.) fibers and neps in ginned cotton will affect textile quality and thus can affect overall industry reputations. This study conducted three field studies that systematically varied the timing of harvest aid application to generate differences in the amount of immature fiber and levels of neps in crops at harvest. The aim was to ascertain what crop conditions (percent open bolls, number of immature bolls, percent immature bolls, and percent immature lint mass) at the time of application contribute to these differences, and assess whether these outcomes are influenced by 0, 1, 2 lint cleaning passes. Earlier harvest aid treatments increased neps and the level of neps was best related to fiber linear density (r2 = 0.78). All measurements of crop condition at harvest aid application explained changes in yield and fiber properties well, although the percent immature bolls (r2 > 0.67) can be applied when crops are nonuniform in their maturity, and when they contain fruiting gaps. Relationships between lint cleaning passes and crop condition at harvest aid application showed an interaction between earlier harvest treatments and lint cleaning passes. One lint cleaning pass contributed between 95 and 141 count 1 more neps, while a second pass added between 101 and 181 count 1 more neps. This information will be valuable in refining strategies that aim to optimize both yield and fiber quality (including less neps). This study also supported the current recommendation of applying harvest aids at 60% open bolls.

DOI:10.2135/cropsci2004.0158URL [本文引用: 1]

Stresses during cotton (Gossypium hirsutum L.) square and boll formation can result in fruit abscission from several continuous nodes, resulting in a fruiting gap on the plant. This gap may cause a shift in benchmarks for timing various agronomic practices aimed at maximizing cotton yield and optimizing quality. A cotton defoliation timing study was performed in 1999, 2000, and 2001 to (i) see if the creation of a fruiting gap would influence defoliation timing and to (ii) compare the use of the open boll percentage at defoliation (OBPD), nodes above cracked boll (NACB), and micronaire readings at defoliation as tools for timing defoliation. In late July or early August each year, a fruiting gap was created by physically removing fruit from several continuous nodes on plants. Plots were defoliated on the basis of various OBPD values. Upon defoliation, OBPD and NACB were taken and lint was retained to determine the micronaire at defoliation. In both 1999 and 2000, there was a yield advantage to delaying defoliation beyond 60 OBPD in treatments containing a gap. However, in 2001 there was no yield advantage to delaying defoliation. This may have been due to optimal late-season growing conditions experienced in 2001. In years when micronaire readings are high, data suggested cotton not containing a fruiting gap is more likely to be above discount levels for high micronaire and should not be defoliated past 60 OBPD. In both 1999 and 2000, trends confirmed a direct relationship between OBPD and both yield and micronaire. Overall, these studies demonstrated that in some years, where no fruiting gaps exist, it might be possible to terminate cotton before the 60% open boll recommendation without sacrificing yields. These results would allow farmers to shift defoliation, and hence harvest, to a time when there are fewer risks of quality-based discounts. While a significant interaction prohibited the examination of the use of micronaire at defoliation as a technique for timing defoliation, there did not appear to be a significant advantage to using either NACB or OBPD for timing defoliation.

DOI:10.1016/j.fcr.2011.01.008URL [本文引用: 2]

Immature cotton fiber will negatively impact textile processing. Three field experiments were undertaken that applied chemical harvest aids to upland cotton ( Gossypium hirsutum L.) crops at varying times with the intention of manipulating the maturity of bolls and fibers. The aim was to quantify the effects of these treatments on the textile performance of the harvested cotton and relate these differences to the status of the crop at the time of treatment application. Although earlier treatments produced less mature fiber that was lower in linear density, yarn and fabric strength was not affected. However less mature cotton from a cooler growing season produced stronger yarns (by 3 cN tex 611) and fabric (by 0.39 N (g m 612) 611) which was partly attributed to the smaller ribbon width of this fiber affecting more fiber packing density and inter-fiber friction. Yarns made from this immature cotton also contained more neps. Micronaire and linear density were equally well related, and more strongly related than maturity ratio, to dyed fabric color dimensions, which were greatly influenced by treatments. Percent immature bolls at the time of harvest aid application related well to changes in the degree of fabric blueness ( R 2 = 0.89). Knowing the status of a crop in the final stages of production will help cotton producers and the supply chain to predict some of the processing performance aspects of harvested fiber.

DOI:10.1016/0378-4290(82)90011-9URL [本文引用: 2]

Cotton ( Gossypium hirsutum L.) plants that had approximately 65% open bolls were sprayed with DEF (S,S,S-tributyl phosphorotrithioate), ethephon [(2-chloroethyl)phosphonic acid], arsenic acid, and paraquat (1,1-dimethyl-4,4-bipyridinium ion) to determine the effects of the chemicals on boll dehiscence, seedcotton yield, and quality of seed and fiber. All chemicals except DEF increased boll dehiscence rate and first harvest percentage. The greatest effect on these two parameters occurred in the ethephon-treated plots. Total seedcotton yield was not affected by either DEF or ethophon, but was reduced significantly by treatments with either arsenic acid or paraquat. In addition, the fiber micronaire readings of the lint gathered at first harvest was reduced by arsenic acid and paraquat treatments. All chemical treatments had an adverse effect on one or more of the components of bolls that were unopened at treatment time. Boll size and fiber micronaire were reduced by treatments with ethephon. DEF caused a reduction in boll size only, whereas arsenic acid and paraquat caused reduction in boll size, seed index, lint index, fiber micronaire, and seed germination. These results indicate that growth regulator chemicals can be used to accelerate boll dehiscence and increase firsth harvest percentage, though the quality of the harvested product may be lowered if treatments are made when many immature bolls are present.

[本文引用: 2]

,

URL [本文引用: 1]

DOI:10.1007/BF02358358URL [本文引用: 3]

A laboratory study was conducted to determine the effects of two adjuvants and temperatures at time of treatment on efficacy, absorption, and translocation of thidiazuron defoliant on cotton. Five days after treatment at 30/21 C day/night temperatures, leaf drop was 17% with no adjuvant, 37% with addition of crop oil concentrate, 40% with ammonium sulfate, and 75% with two adjuvants combined. At 21/13 C day/night temperatures, there was less than 10% leaf drop with all treatments. At 10 d after treatment, leaf drop drop was not different among treatments at the high or low temperatures. Shoot regrowth at high and low temperature was reduced 55 to 60% with addition of both adjuvants and 44 to 50% with each adjuvant or with no adjuvant when compared to plants defoliated by hand. Absorption of -thidiazuron was not affected by variations in temperature during the time of treatment but was affected by adjuvants. With no adjuvants, absorption was 7 to 10%. With 1.25% by vol crop oil concentrate, absorption was 33 to 46%. Addition of ammonium sulfate resulted in 18 to 19% absorption, and the combination of ammonium sulfate and crop oil concentrate increased absorption to 65 to 68%. There was no movement of radiolabel away from treated leaves as determined by autoradiographs of treated plants.

[本文引用: 3]

[本文引用: 3]

[本文引用: 1]

.

[本文引用: 3]

[本文引用: 3]

[本文引用: 2]

[本文引用: 2]

DOI:10.1016/S0378-4290(00)00093-9URL [本文引用: 1]

The indeterminate growth of cotton ( Gossypium hirsutum L.) often results in a boll population at various stages of maturity when the crop is harvested. Boll opening compounds can be used to facilitate harvest by accelerating the opening of green bolls. Field trials were conducted at two locations in 1996 and 1997 to test the efficacy of four commercially available boll openers that stimulate ethylene production or desiccate the plant. Two of these boll openers are new to the marketplace: Finish64, ethephon+cyclanilide (2-chloroethyl phosphonic acid+1-(2,4-dichlorophenylaminocarbonyl)-cyclopropane carboxylic acid), and CottonQuick64, ethephon+AMADS (2-chloroethyl phosphonic acid+1-aminomethanamide dihydrogen tetraoxosulfate). Open bolls were hand harvested at 3–7 days intervals after application of the boll openers, and environmental conditions in conjunction with these harvests were recorded. The desiccant, paraquat (1,1′-dimethyl-4,4′-bipyridinium dichloride), was found to have erratic boll opening activity. Two products that contain ethephon plus the synergists cyclanilide or AMADS were found to have equal or higher rates of boll opening than ethephon alone. The rate of boll opening of all compounds was influenced more by the accumulation of heat units than by the amount of time following the application of boll openers. Although erratic, boll opening activity from paraquat application can be significant. Moreover, the reliability of ethephon based products, which are consistent boll openers, may be enhanced by formulations that contain a synergist. Heat unit accumulation may be used to predict and model the efficacy of boll opening with these harvest aides.

[本文引用: 2]

[本文引用: 2]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

.

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

URL [本文引用: 1]

Changes in fiber quality and attachment forces between foreign-matter particles and fibers were studied at different stages from the time of harvest through lint cleaning to develop new and less damaging methods for removing foreign-matter particles from fiber. The study involved 75 samples collected from five field locations near College Station, Texas, including three replications and five harvesting and processing treatments: (1) hand picked and hand ginned, (2) machine picked and hand ginned, (3) machine picked, seed-cleaned, and hand ginned, (4) machine picked, seed-cleaned, and machine ginned, and (5) machine picked, seed-cleaned, machine ginned, and one-stage lint-cleaned. A microscope was used to identify foreign-matter particles in each sample. Physical characteristics of the particles and their attachment to fibers were investigated and classified. Results indicated that each machine-fiber interaction during the harvesting through ginning process had the net effect of decreasing the size of foreign-matter particles. The particles had no obvious difference in shape across the processing stages. The tightness of particle-fiber attachment, the number of neps, and the short-fiber content differed significantly as a function of mechanical interactions: they increased as the number of mechanical interactions increased. Processing through the gin stand was a major contributor to the increase in short fiber content. The majority of the foreign-matter particles were leaves, but proportions of the particle categories changed with stages of processing. With an increased number of mechanical interactions the proportion of leaf particles decreased and the proportion of seed-coat fragments and stems increased.

DOI:10.13031/2013.26826URL [本文引用: 1]

One goal of lint cleaning at a cotton gin is to reduce the non-lint material to an acceptable level with minimal fiber damage. In an effort to improve lint cleaner performance, an initial study was conducted on lint collected before and after lint cleaning at nine commercial gins across the cotton belt to characterize non-lint content. Samples from this study were first processed with an MDTA-3 (Micro Dust and Trash Analyzer 3, SDL Atlas, Stockport, U.K.) to determine trash, fiber fragment, and dust content. The trash portion was retained for additional manual fractionation to determine the percent of material classified as seed coat fragments (SCF), motes, funiculi, sticks, leaf bark, lint, and "other" material. Leaf SCF, and sticks were the largest fractions, accounting for 81% of the total trash sample. Overall, total trash decreased by 57% due to lint cleaning, and trash fractions remained consistent in samples before and after lint cleaning. Lint cleaning efficiency in terms of SCF was less than the overall cleaning efficiency, and lint cleaning efficiency for bark, mote, and other (all minor components) was higher than the overall cleaning efficiency. The lint cleaning efficiency for SCF was increased significantly when higher SCF levels were found before the lint cleaner, but this trend was not found for other fractions. Results of this experiment will help direct future studies to improve lint cleaning.

[本文引用: 1]

[本文引用: 1]

[本文引用: 2]

[本文引用: 2]

DOI:10.1016/0378-4290(92)90018-5URL [本文引用: 1]

Current chemical defoliants have limitations which are usually magnified by environmental conditions or the nature of the compound. The objective of this study was to evaluate the effectiveness of various chemical defoliants when used in combination at one-half the standard use rate. Tests were conducted from 1986 to 1988 at the Delta Branch Experiment Station in Stoneville, Mississippi and in 1987 and 1988 at the Plant Science Research Center in Starkville, Mississippi. Chemicals evaluated were tribufos (S,S,S-tributylphosphorotriphioate), thidiazuron (N-phenyl-N prime-1,2,3-thi-diazo-5-ylurea), dimethipin (2,3-dihydro-5,6-dimethyl-1,4-dithiin 1,1,4,4 tetraoxide), and ethephon [(2-chloroethyl)phosphonic acid]. Standard rates for each chemical defoliant were 1.26, 0.14, 0.35, and 2.24 kg/ha, respectively. When used in two-way combination treatments, each defoliant rate was reduced by one-half. A non-ionic surfactant at 0.25% (v/v) was added to all dimethipin treatments. Defoliation and regrowth estimates were made by visual observations at 5, 7, and 14 days after treatment.In general, two chemical defoliants tank-mixed at one-half the standard use rate were equal to or superior to either single component applied at the standard use rate. In addition to equal effectiveness, combinations offered additional safeguards against adverse environmental conditions.

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

DOI:10.13031/2013.26284URL [本文引用: 1]

A survey was made of the types and combinations of lint cleaners currently being used in roller gins. Data are presented on the effectiveness of the cleaner and how it affects bale value.

[本文引用: 1]

DOI:10.13031/2013.42427URL [本文引用: 1]

Southern High Plains cotton has improved over the last ten years with regard to yield and HVI (High Volume Instrument) fiber length and strength. In light of increased adoption of picker harvesting to preserve fiber quality and improve harvest productivity, ginning practices are needed which preserve fiber quality and maximize return to the producer. The objective of this work was to investigate the influence of harvest method, number of seed cotton extractor cleaners (e.g., stick machines), and seed cotton cleaning rate on foreign matter content, lint value, and fiber and yarn quality of cotton produced in the Southern High Plains. Compared to using only one stick machine, the use of two stick machines in the seed cotton cleaning system removed more foreign material from both picker and stripper harvested cotton, but more foreign material was removed by the stick machines from stripper harvested cotton because it had higher initial foreign matter content. Seed cotton cleaning rate had no influence on stick machine cleaning performance for picked cotton, but higher cleaning rates reduced stick machine cleaning performance for stripper harvested cotton. Picker harvested cotton exhibited improved HVI and AFIS (Advanced Fiber Information System) fiber quality and higher bale values compared to stripper harvested cotton. The use of two stick machines improved fiber color properties and reduced lint foreign matter content. Seed cotton cleaning rate had a minimal effect on fiber quality and bale value was not influenced by the number of stick machines or seed cotton cleaning rate. Total lint value, on a production area basis, was higher for stripper harvested cotton after both lint cleaners compared to picker harvested cotton due to yield differences. Yarn imperfections were reduced for ring spun yarn produced from picker harvested cotton processed through one stick machine at the high cleaning rate. The findings of this work support a recommendation for using one stick machine in seed cotton cleaning systems processing picker harvested cotton and two stick machines in systems processing stripper harvested cotton.

[本文引用: 2]

DOI:10.2135/cropsci1991.0011183X003100040037xURL [本文引用: 1]

Genetic traits that reduce seed-cotton (Gossypium hirsutum L.) trash or improve cleanability should improve lint grade and preserve fiber quality. Our objective was to evaluate morphological traits that reduce trash and improve cleanability and grade. Twelve near-isolines involving four leaf shapes (normal, semi-okra, okra, and super-okra) in two genetic backgrounds (LA 213-613 and MD 65-11), two bract types (normal and frego), and two leaf-pubescence levels (hairy and semismooth) were grown for 2 yr at three locations in Louisiana. Seed-cotton was harvested with a spindle-picker and ginned on a miniature version of a commercial gin. Amount and type of trash was determined before and after (feeder apron) seed-cotton cleaning, and after zero, one, and two saw-type lint cleaners. Semismooth and super-okra leaf traits reduced motes by 25 and 15% and small-leaf trash at the feeder apron by 47 and 20%, respectively, compared with the check. They produced grades similar to the check with one less lint cleaner. Frego-bract isolines had less leaf and bract trash in lint than the normal-bract check at any level of lint cleaning. Use of genetic traits such as semismooth and super-okra, and to a lesser extent sub-okra and frego bract, can be used to reduce lint trash and improve cotton grade. Reductions in motes could help reduce the seed-coat fragment-white spot (dead fiber) problem in fabric dying.

DOI:10.1177/004051759106100205URL [本文引用: 1]

Abstract Smooth leaf and hairy leaf Midsouth cottons were processed through minimum, two intermediate, and maximum gin cleanings. Based on fiber measurements after mill cleaning, minimum gin cleaning yielded the best fiber quality (i.e., length, low short fiber content). Fiber damage as a result of maximum gin cleaning was evident through all levels of mill cleaning. There were also differences in nonlint content as a result of cleaning machinery and cotton varieties.

[本文引用: 2]

URL [本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]