,*, 侯鹏*, 明博*, 张万旭*, 张国强*, 高尚*, 白氏杰*, 初振东*, 李少昆

,*, 侯鹏*, 明博*, 张万旭*, 张国强*, 高尚*, 白氏杰*, 初振东*, 李少昆 ,*中国农业科学院作物科学研究所 / 农业部作物生理生态重点实验室, 北京100081

,*中国农业科学院作物科学研究所 / 农业部作物生理生态重点实验室, 北京100081Effect of Lodging on Maize Grain Losing and Harvest Efficiency in Mechanical Grain Harvest

XUE Jun, LI Lu-Lu, XIE Rui-Zhi, WANG Ke-Ru ,*, HOU Peng*, MING Bo*, ZHANG Wan-Xu*, ZHANG Guo-Qiang*, GAO Shang*, BAI Shi-Jie*, CHU Zhen-Dong*, LI Shao-Kun

,*, HOU Peng*, MING Bo*, ZHANG Wan-Xu*, ZHANG Guo-Qiang*, GAO Shang*, BAI Shi-Jie*, CHU Zhen-Dong*, LI Shao-Kun ,*Institute of Crop Sciences, Chinese Academy of Agricultural Sciences / Key Laboratory of Crop Physiology and Ecology, Beijing 100081, China

,*Institute of Crop Sciences, Chinese Academy of Agricultural Sciences / Key Laboratory of Crop Physiology and Ecology, Beijing 100081, China通讯作者:

第一联系人:

收稿日期:2018-04-3接受日期:2018-07-20网络出版日期:2018-08-03

| 基金资助: |

Received:2018-04-3Accepted:2018-07-20Online:2018-08-03

| Fund supported: |

摘要

关键词:

Abstract

Keywords:

PDF (498KB)元数据多维度评价相关文章导出EndNote|Ris|Bibtex收藏本文

本文引用格式

薛军, 李璐璐, 谢瑞芝, 王克如, 侯鹏, 明博, 张万旭, 张国强, 高尚, 白氏杰, 初振东, 李少昆. 倒伏对玉米机械粒收田间损失和收获效率的影响[J]. 作物学报, 2018, 44(12): 1774-1781. doi:10.3724/SP.J.1006.2018.01774

XUE Jun, LI Lu-Lu, XIE Rui-Zhi, WANG Ke-Ru, HOU Peng, MING Bo, ZHANG Wan-Xu, ZHANG Guo-Qiang, GAO Shang, BAI Shi-Jie, CHU Zhen-Dong, LI Shao-Kun.

倒伏是玉米生产中普遍存在的现象, 不仅影响产量, 也对收获过程造成一定的障碍。机械收获过程中田间损失率是评价玉米收获质量和决定实收产量的重要指标之一[1,2,3], 玉米收获机械技术国家标准规定田间损失率应≤5%[4]。探索造成田间损失的原因对于推进玉米机械粒收技术的应用具有重要意义。机械收获产量损失包括落穗损失和落粒损失两部分[5,6,7,8,9,10], 前者占72.3%, 后者占27.7%, 即落穗损失大于落粒损失[11]。本研究团队的前期研究也已表明, 田间损失主要与植株倒伏、品种易落穗性、玉米螟、茎腐病等病虫危害、收获时种植行距与收获机行距匹配度及机手操作水平等因素有关[12,13,14,15,16]。玉米整个生育期均存在倒伏风险, 倒伏分为根倒和茎折, 在生理成熟前根倒和茎折同时存在, 生理成熟后以茎折为主[17,18]。玉米倒伏后植株行距错位或匍匐在地面, 使穗位降低或落穗增加, 对机械收获质量和收获效率造成一定影响[18,19]。前人研究玉米倒伏对产量的影响多以人工收获或机械穗收为主[20,21,22,23], 关于机械粒收过程中倒伏率与产量损失率之间的量化关系研究较少, 并且我国玉米种植区域广泛, 不同种植区收获机械类型也不相同, 倒伏对不同区域及机械类型机收过程中落穗、落粒及收获速度的影响尚不清楚。本研究调查多区域、多年份机械粒收前田间自然倒伏率和机械粒收后落穗、落粒的大样本数据, 分析玉米植株自然倒伏与机械粒收落穗、落粒损失之间的量化关系, 并通过模拟倒伏试验分析倒伏对田间产量损失及收获速率的影响, 为降低玉米机械粒收产量损失提供依据。

1 材料与方法

1.1 田间自然倒伏、落穗与落粒调查

2013—2017年, 在新疆、宁夏、内蒙古、河南、山东、安徽、江苏、北京、辽宁、吉林、黑龙江等分布在全国11个省市自治区的41个田块, 于机械粒收时同步调查倒伏和落穗、落粒数据, 共获得364组样本数据。机械收获前, 在田间随机选取长度为10 m, 宽度为一个割幅(4~8行)的样区调查玉米总株数、茎折和根倒株数。总倒伏率(%)=(茎折数+根倒数)/总株数×100, 3次重复。其中, 玉米穗下节间发生折断的为茎折; 穗下节间未发生折断, 植株偏离垂直方向45°以上的为根倒[24]。

在测试的已收割地块随机选取样点, 每个样点取3 m长、一个割幅宽面积, 收集样区内所有落穗和落粒, 记录穗数并脱粒, 分别称落穗、落粒的籽粒重, 结合收获时的籽粒含水率, 按照样区面积计算单位面积含水率为14%的落穗重和落粒重, 3次重复。结合收获田块产量数据计算产量损失率。

1.2 模拟倒伏对玉米机械粒收产量损失影响试验

在位于黄淮海夏玉米区的河南新乡中国农业科学院作物科学研究所综合试验站和位于北方春玉米区的吉林公主岭市双城堡设置倒伏处理试验, 调查人为控制倒伏后玉米机械粒收田间产量损失情况。1.2.1 试验处理 采取人工处理植株、模拟倒伏, 在新乡试点共设置8个梯度处理, 倒伏率分别为0、5%、10%、20%、40%、60%、80%和100%; 在公主岭试点设置7个梯度处理, 倒伏率分别为0、5%、10%、20%、40%、80%和100%。于机械收获前清除小区中的倒伏植株和自然落穗, 然后在玉米穗位处用力将植株推倒, 使其茎秆沿着行向折断, 倒伏植株在群体中均匀分布, 倒伏高度为20~30 cm, 每个处理20 m长、1个割幅宽(新乡为4行, 公主岭为6行)。

1.2.2 供试品种 在新乡试点为中单909 (晚熟高秆类型品种)、户玉3518 (早熟中秆类型品种)、富育5152(中熟矮秆类型品种); 在公主岭试点为泽玉8911。

1.2.3 收获机械与收获方式 在新乡试点收获机械为雷沃谷神GE50, 割幅为4行; 在公主岭试点收获机械为约翰迪尔C110型, 割幅为6行。逆倒伏方向收获。

1.2.4 观测指标 准确记录收割时机车在每个倒伏处理小区的自然行走时间, 计算行走速度; 并在每个处理20 m行长内取3个点调查落穗和落粒数, 分别称落穗、落粒的籽粒重, 每个样区3 m长, 1个割幅宽, 3次重复。

2 结果与分析

2.1 田间倒伏及产量损失

对调查的364组数据分析可知, 黄淮海夏玉米区的平均倒伏率高于北方和西北春玉米区; 同时落粒率、落穗率和总损失率也均高于春玉米。春玉米和夏玉米倒伏率高于国标(≥5%)的样本量占总样本量的比例分别为45.4%和47.6%; 春玉米和夏玉米总损失率高于国标(≥5%)的样本占总样本量的比例分别为22.5%和39.5% (表1)。Table 1

表1

表1玉米田间倒伏及机械粒收产量损失描述

Table 1

| 玉米季 Maize season | 调查指标 Indicator | 样本量 Sample quantity | 平均数 Average (%) | 最大值 Maximum (%) | 最小值 Minimum (%) | 变异 系数 CV (%) | ≥ GB/T-21962-2008样本量 ≥ GB/T-21962-2008 sample quantity |

|---|---|---|---|---|---|---|---|

| 春玉米 | 倒伏率 Lodging rate | 240 | 9.9 | 89.0 | 0.0 | 146.1 | 109 |

| Spring maize | 落粒损失率 Kernel loss | 240 | 0.5 | 5.5 | 0.0 | 142.0 | 1 |

| 落穗损失率 Ear loss | 240 | 2.9 | 31.3 | 0.0 | 157.3 | 49 | |

| 总损失率 Total grain loss | 240 | 3.4 | 33.4 | 0.0 | 139.4 | 54 | |

| 夏玉米 | 倒伏率 Lodging rate | 124 | 13.2 | 89.7 | 0.0 | 156.7 | 59 |

| Summer | 落粒损失 Kernel loss | 124 | 1.1 | 3.6 | 0.1 | 61.2 | 0 |

| maize | 落穗损失 Ear loss | 124 | 5.0 | 26.1 | 0.0 | 120.7 | 43 |

| 总损失 Total grain loss | 124 | 6.1 | 27.8 | 0.2 | 100.2 | 49 |

新窗口打开|下载CSV

2.2 田间自然倒伏与产量损失的关系

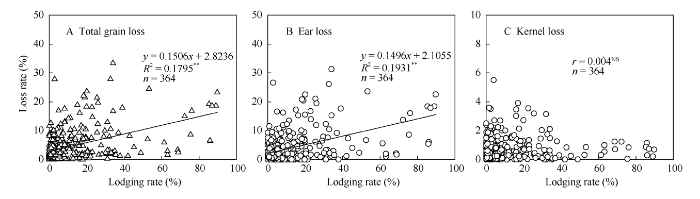

对大田调查的364组样本数据分析表明, 机械粒收总产量损失率与田间倒伏率呈极显著正相关, 拟合方程为y = 0.1506x + 2.8236, R2 = 0.1795**(n = 364, 图1-A)。落穗率与倒伏率呈显著正相关, 拟合方程为y = 0.1496x + 2.1055, R2 = 0.1931** (n = 364, 图1-B), 说明田间自然倒伏每增加1%, 落穗率增加0.15%, 即使田间未发生倒伏, 也会有2.11%的落穗率, 这可能与品种易落穗性、玉米螟、穗腐病等病虫危害、种植行距与收获机行距是否匹配及机手操作水平等因素有关。落粒率与倒伏率之间无显著相关(r = 0.004NS, n = 364)。图1

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图1自然条件下植株倒伏与落穗、落粒率的关系(2013-2017年)

图A为总损失率, 图B为落穗率, 图C为落粒率。** 表示 0.01显著水平, NS表示未达到显著水平。

Fig. 1Relationship of lodging rate with ear loss and kernel loss under natural condition (2013-2017)

Fig. A is total grain loss rate, Fig. B is ear loss rate, and Fig. C is kernel loss rate. ** indicates significance at the 0.01 probability level, NS indicates no significant correlation.

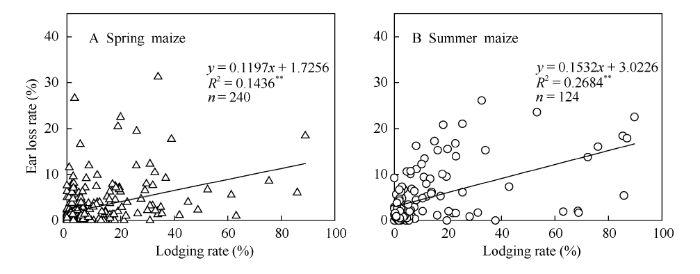

北方和西北春玉米区240组样本数据表明落穗率与倒伏率之间呈显著正相关, 拟合方程为y = 0.1197x + 1.7256, R2 = 0.1436** (图2-A); 黄淮海夏玉米区124组样本表明落穗率与倒伏率间呈显著正相关, 拟合方程为y = 0.1532x + 3.0226, R2 = 0.2684** (图2-B)。由拟合方程的斜率可知, 每增加1%倒伏, 春玉米机械粒收落穗损失率增加0.12%, 夏玉米落穗损失率增加0.15%, 未发生倒伏时, 春玉米和夏玉米的落穗率分别为1.73%和3.02%。

图2

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图2不同玉米种植区倒伏率与落穗率之间的关系

A为北方和西北春玉米区(n=240), B为黄淮海夏玉米区(n=124), **表示0.01显著水平。

Fig. 2Relationship between lodging rate and ear loss rate in different maize regions (2013-2017)

Fig. A is the North and Northwest spring maize regions (n=240), Fig. B is the Yellow-Huaihe-Haihe Rivers Plain summer maize region (n=124). ** indicates significance at the 0.01 probability level.

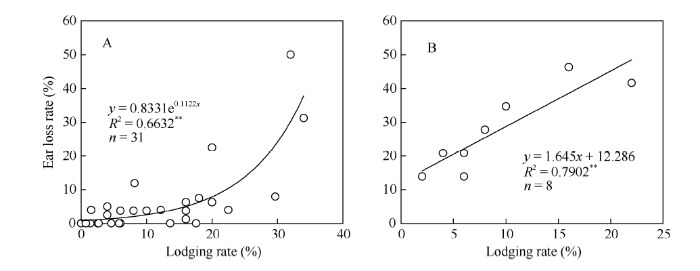

2015年在吉林榆树采用芬兰生产的全喂入式Sampo收获机, 倒伏率较低时可将部分倒伏植株果穗捡拾起来, 倒伏率和落穗损失率之间符合指数递增的关系, 拟合方程为y = 0.8331e0.1122x, R2 = 0.6632** (n = 31, 图3-A)。同年, 在山东茌平采用福田雷沃重工股份有限公司生产的雷沃谷神GE50型半喂入式收获机, 倒伏率和落穗率之间呈直线关系, 拟合方程为y = 1.645x + 12.286, R2 = 0.7902** (n = 8, 图3-B)。由此进一步说明, 当前黄淮海夏玉米区多采用半喂入式机械较北方和西北春玉米区采用全喂入式机械的落穗损失更高。

图3

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图3全喂入式(A, 吉林榆树)和半喂入式(B, 山东茌平)测试机具倒伏率与机收落穗率之间的关系

**表示0.01显著水平。

Fig. 3Relationship between lodging rate and ear loss rate by using whole feed type combine harvester in Yushu, Jilin (A) and a half feed type combine harvester in Chiping, Shandong (B)

** indicates significance at the 0.01 probability level.

2.3 人工倒伏处理对玉米产量损失的影响

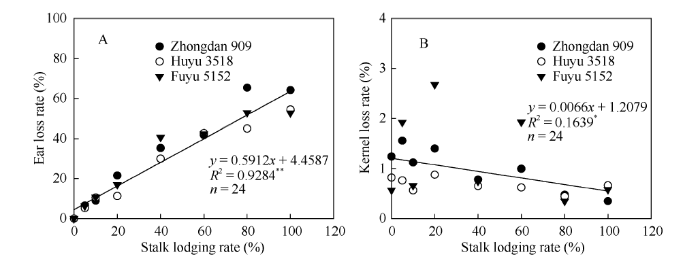

在河南新乡倒伏控制处理中, 排除收获前自然落穗的影响, 落穗率与茎折率呈显著正相关, 拟合方程为: y = 0.5912x + 4.4587, R2 = 0.9284** (n = 24, 图4-A), 说明茎折率每增加1%, 落穗率增加0.59%; 落粒率与倒伏呈显著负相关, 拟合方程为y= -0.0066x+1.2079, R2=0.1639* (n = 24, 图4-B), 这可能与倒伏越多、进入机械的果穗少、落粒少有关。品种之间表现为中单909的落穗率高于户玉3518和富玉5152。图4

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图4模拟倒伏试验中倒伏率和落穗(A)、落粒(B)率之间的关系(河南新乡, 2017)

**和*分别表示0.01和0.05显著水平。

Fig. 4Relationship of lodging rate with ear loss rate (A) and kernel loss rate (B) in implemented treatments of mechanical grain harvest (Xinxiang, Henan, 2017)

**, * indicate significance at the 0.01 and 0.05 probability levels, respectively.

2.4 人工模拟倒伏处理对玉米收获速度的影响

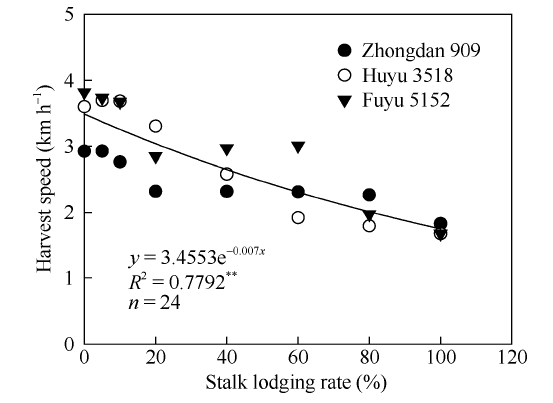

收获速度随倒伏率增加而降低(图5)。在新乡试点, 正常无倒伏田块3个品种机械收获速度平均为3.4 km h-1, 在倒伏率超过20%时收获速度明显下降, 20%和100%植株倒伏时, 收获速度分别下降至2.8 km h-1和1.7 km h-1, 仅为正常速度的82.5%和50.4%, 收获速度与倒伏率呈指数曲线递减, 拟合方程为y = 3.4553e-0.007x, R2 = 0.779**(n = 24)。不同品种间因植株大小等不同而表现出一定的差异, 中单909为晚熟高秆类型, 收获速率较低, 在没有倒伏情况下收获速率为2.9 km h-1, 而中熟矮秆的富育5152收获速度较快, 为3.8 km h-1。图5

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图5倒伏率与玉米机械粒收速度的关系(河南新乡, 2017)

**表示0.01显著水平。

Fig. 5Relationship between maize lodging rate and harvest speed in mechanical grain harvest(Xinxiang, Henan, 2017)

** indicates significance at the 0.01 probability level.

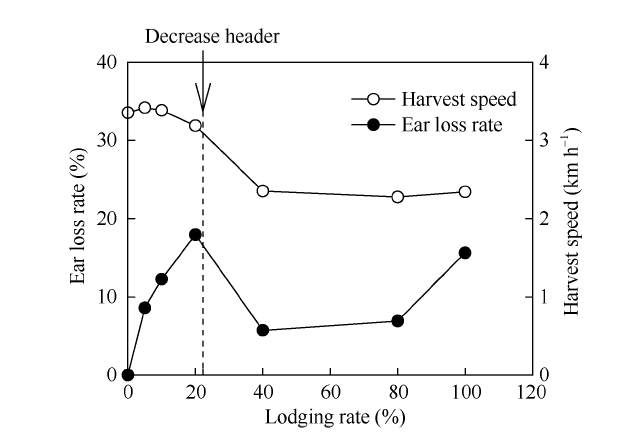

公主岭模拟倒伏处理表明, 不改变收获机割台, 倒伏率由0增加至20%时, 收获速度由3.4 km h-1降低至3.2 km h-1, 落穗率增加至18.0%。降低收获机割台, 倒伏率由20%增至40%时, 落穗率由18.0%降低至5.7%, 收获速度由3.2 km h-1降低至2.4 km h-1; 倒伏率由40%增加至100%时, 收获速度由2.4 km h-1降低至2.3 km h-1, 产量损失由5.7%增至15.6% (图6)。由此说明, 随倒伏率增加, 机械粒收落穗率增加, 但通过降低割台、降低收获行进速度可以明显减少落穗损失。

图6

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图6倒伏和收获速度对玉米机械粒收落穗率的影响 (吉林公主岭, 2017)

Fig. 6Effect of lodging rate and harvest speed on ear loss in mechanical grain harvest (Gongzhuling, Jilin, 2017)

3 讨论

本研究团队曾对1819组田间测试样本分析, 玉米机械粒收总损失率平均为4.76%[11], 略低于国标(GB/T-21962-2008) ≤ 5%的标准, 但田块间差异较大, 特定条件下也出现了较严重的落粒和落穗损失,且各地农户普遍担心机械粒收的损失较大, 是当前制约玉米籽粒机械收获技术推广的一个重要因素[25,26]。在本研究调查的364组田间数据中, 春玉米和夏玉米损失率高于国标的比例分别为22.5%和39.5%。春玉米和夏玉米倒伏率高于国标的比例分别为45.4%和47.6%。分析玉米倒伏和产量损失之间的定量关系可知, 倒伏对玉米产量损失主要表现为落穗率增加, 拟合方程为y = 0.1496x + 2.1055, 由方程斜率可知, 倒伏每增加1%, 落穗率增加0.15%; 由方程的截距可知, 即使田间未发生倒伏也会有2.1%的落穗损失; 由方程决定系数R2 = 0.1931**可知, 倒伏是造成玉米机械粒收落穗损失的重要原因之一, 但倒伏仅能解释落穗损失的19.3%。由此说明, 机械粒收玉米田间落穗损失还可能与其他因素有关[27,28], 张向前等[29]研究表明, 相同倒伏条件下, 品种之间落穗率差异较大; 玉米螟多分布在穗着生节(含穗柄)及其上、下1~3节, 蛀食穗柄, 造成落穗[30]; 种植行距与收获机行距匹配度也影响落穗率, 黄淮海地区夏玉米宜采用60 cm的种植行距[31]; 此外, 田间站秆时间越长, 落穗率也越高[32]; 机手操作水平也是影响落穗的重要因素[16]。本研究人工处理倒伏试验表明, 倒伏每增加1%, 落穗率增加0.59%, 远高于调查数据显示的0.15%, 这是因为调查数据中倒伏率为根倒率和茎折率的总和, 根倒植株发生弯曲而穗位高于收获机割台时雌穗可进入收获机械, 人工处理倒伏全部为茎折, 倒折高度为20~30 cm, 雌穗匍匐在地, 大多数低于割台, 未能进入收获机械, 说明茎折对机械粒收落穗率的影响远高于根倒。此外, 同等倒伏条件下, 晚熟高秆的中单909落穗率高于早熟矮秆的户玉3518。对不同种植区田间调查数据统计的结果显示, 黄淮海夏玉米区落穗率与倒伏率之间拟合方程的斜率为0.1532, 高于北方和西北春玉米区的斜率0.1197, 夏玉米拟合方程的截距3.02也高于春玉米的1.73, 说明未发生倒伏时, 夏玉米区落穗率高于北方春玉米区, 随倒伏程度的增加, 黄淮海夏玉米区造成的落穗损失更大。其原因是, 黄淮海夏玉米区所用籽粒收获机械多以小麦收获机改装成的中小型、半喂入式机械为主, 其割台没有捡拾功能, 倒伏植株果穗几乎不能被收获机捡拾而造成浪费, 倒伏率和落穗率之间呈直线关系; 而北方和西北春玉米区均用大型、全喂入式收获机械, 通过降低割台可将部分倒伏植株果穗捡拾起来, 倒伏率与落穗率呈指数递增关系。

植株倒伏、倒折不仅造成玉米落穗损失, 还严重影响机械收获的效率[19]。新乡试验站倒伏控制处理试验中, 机车收获时行进速度随倒伏率的增加表现出指数曲线递减的趋势。2017年在公主岭开展的倒伏处理收获试验表明, 随倒伏率增加落穗量增加, 通过降低割台可以明显减少落穗损失, 但是也大幅降低收获速度。Hanna等[5]研究认为, 90%以上的机收损失发生在割台部位, 而又主要是落穗损失。2015年10月19日在吉林榆树弓棚子镇荣誉村蒋恩凯合作社田间粒收观测, 使用芬兰产的Sampo收获机械降低割台、放慢速度、逆倒伏方向收获, 可以将80%~90%倒伏植株果穗拾起, 但收割效率大幅下降, 倒伏严重田块收割速度一般在1.5~2.0 km h-1, 正常田块收获速度为6~7 km h-1, 在行直、不倒伏、割台适当抬高的田块收获时机车行进速度可达到8~9 km h-1(调查数据, 未发表)。

综上所述, 机械粒收产量损失和收获效率受多种因素综合影响。品种抗倒性差、易落穗对机械收获田间产量损失影响较大; 病虫害, 特别是生育后期茎腐病易造成玉米倒伏倒折、玉米螟蛀食穗柄和茎秆会造成落穗, 均会造成田间损失; 收获机械类型及机械设置也会影响田间损失和收获效率。因此, 选育抗倒伏、抗病品种, 采取健康的栽培管理, 玉米植株生长健壮, 有利于降低收获损失; 适时收获能减少倒伏和落穗风险, 有效降低田间损失。生产中具体收获时期可根据籽粒水分含量、倒伏风险等因素确定。

4 结论

倒伏对玉米产量损失的影响主要表现为落穗损失, 倒伏率每增加1%, 落穗率增加0.15%; 倒伏对黄淮海夏玉米落穗损失影响高于北方和西北春玉米; 倒伏降低了机械粒收速度; 玉米发生大面积倒伏, 收获时降低收获机割台、放慢行走速度可以将部分倒伏植株果穗捡起, 降低产量损失。参考文献 原文顺序

文献年度倒序

文中引用次数倒序

被引期刊影响因子

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

DOI:10.3864/j.issn.0578-1752.2017.11.009URL [本文引用: 1]

【目的】机械粒收技术是现代玉米生产的关键技术,是国内外玉米收获技术发展的方向和中国玉米生产转方式的关键。明确当前中国玉米机械粒收质量的现状,研究影响收获质量的主要因素,推动玉米机械粒收技术发展。【方法】利用2011—2015年在西北、黄淮海和东北和华北玉米产区15个省(市)168个地块获得的1 698组收获质量样本数据,分析当前中国玉米机械粒收质量的现状及其影响因素。【结果】结果表明,籽粒破碎率平均为8.63%,杂质率为1.27%,田间损失籽粒(落穗、落粒合计)为24.71 g·m~(-2),折合每亩损失16.5 kg,平均损失率为4.12%,破碎率高是当前中国玉米机械粒收存在的主要质量问题。收获玉米籽粒平均含水率为26.83%,含水率与破碎率、杂质率及机收损失率之间均呈极显著正相关。其中,破碎率(y)与籽粒含水率(x)符合二次多项式y=0.0372x~2-1.483x+20.422(R~2=0.452**,n=1 698),在一定含水率范围内(含水率大于19.9%),破碎率随籽粒含水率增大而增大。【结论】当前中国玉米机械粒收时破碎率偏高,而籽粒含水率高是导致破碎率高的主要原因。对此,建议选育适当早熟、成熟期籽粒含水率低、脱水速度快的品种,适时收获,配套烘干存贮设施等作为中国各玉米产区实现机械粒收的关键技术措施。

DOI:10.3864/j.issn.0578-1752.2017.11.009URL [本文引用: 1]

【目的】机械粒收技术是现代玉米生产的关键技术,是国内外玉米收获技术发展的方向和中国玉米生产转方式的关键。明确当前中国玉米机械粒收质量的现状,研究影响收获质量的主要因素,推动玉米机械粒收技术发展。【方法】利用2011—2015年在西北、黄淮海和东北和华北玉米产区15个省(市)168个地块获得的1 698组收获质量样本数据,分析当前中国玉米机械粒收质量的现状及其影响因素。【结果】结果表明,籽粒破碎率平均为8.63%,杂质率为1.27%,田间损失籽粒(落穗、落粒合计)为24.71 g·m~(-2),折合每亩损失16.5 kg,平均损失率为4.12%,破碎率高是当前中国玉米机械粒收存在的主要质量问题。收获玉米籽粒平均含水率为26.83%,含水率与破碎率、杂质率及机收损失率之间均呈极显著正相关。其中,破碎率(y)与籽粒含水率(x)符合二次多项式y=0.0372x~2-1.483x+20.422(R~2=0.452**,n=1 698),在一定含水率范围内(含水率大于19.9%),破碎率随籽粒含水率增大而增大。【结论】当前中国玉米机械粒收时破碎率偏高,而籽粒含水率高是导致破碎率高的主要原因。对此,建议选育适当早熟、成熟期籽粒含水率低、脱水速度快的品种,适时收获,配套烘干存贮设施等作为中国各玉米产区实现机械粒收的关键技术措施。

[本文引用: 1]

[本文引用: 1]

[本文引用: 2]

DOI:10.3969/j.issn.1000-1573.2012.01.022URL [本文引用: 1]

为了降低玉米的收获损失,本研究通过摘穗板式摘穗机构的正交实验的方法,对在玉米摘穗过程中影响籽粒破碎和籽粒损失率的4个因素—摘穗板的型式、拉茎辊转速、籽粒含水率、机具前进速度进行了分析。结果表明:籽粒破碎率受籽粒含水率的影响最大,受摘穗板型式和拉茎辊转速影响次之,受前进速度的影响较小。籽粒损失率受拉茎辊转速的影响最大,受摘穗板型式的影响次之。籽粒的含水率较低(30%左右)、摘穗板的型式为弯板、拉茎辊转速为中速度(600~700r/min)时进行玉米的摘穗作业时,综合指标较好。

DOI:10.3969/j.issn.1000-1573.2012.01.022URL [本文引用: 1]

为了降低玉米的收获损失,本研究通过摘穗板式摘穗机构的正交实验的方法,对在玉米摘穗过程中影响籽粒破碎和籽粒损失率的4个因素—摘穗板的型式、拉茎辊转速、籽粒含水率、机具前进速度进行了分析。结果表明:籽粒破碎率受籽粒含水率的影响最大,受摘穗板型式和拉茎辊转速影响次之,受前进速度的影响较小。籽粒损失率受拉茎辊转速的影响最大,受摘穗板型式的影响次之。籽粒的含水率较低(30%左右)、摘穗板的型式为弯板、拉茎辊转速为中速度(600~700r/min)时进行玉米的摘穗作业时,综合指标较好。

Magsci [本文引用: 1]

为了降低玉米的收获损失,该文通过摘穗板式摘穗机构的正交试验方法,对在玉米摘穗过程中影响籽粒破碎和籽粒损失率的4个因素——摘穗板的形式、拉茎辊转速、籽粒含水率、机具前进速度进行了分析。结果表明,籽粒破碎率受籽粒含水率的影响最大,受摘穗板形式和拉茎辊转速影响次之,受前进速度的影响较小。籽粒损失率受拉茎辊转速的影响最大,受摘穗板形式的影响次之。当籽粒的含水率较低(30%左右)、摘穗板的形式为弯板、拉茎辊转速为中速度(600~700 r/min)时进行玉米的摘穗作业时,综合指标较好。

Magsci [本文引用: 1]

为了降低玉米的收获损失,该文通过摘穗板式摘穗机构的正交试验方法,对在玉米摘穗过程中影响籽粒破碎和籽粒损失率的4个因素——摘穗板的形式、拉茎辊转速、籽粒含水率、机具前进速度进行了分析。结果表明,籽粒破碎率受籽粒含水率的影响最大,受摘穗板形式和拉茎辊转速影响次之,受前进速度的影响较小。籽粒损失率受拉茎辊转速的影响最大,受摘穗板形式的影响次之。当籽粒的含水率较低(30%左右)、摘穗板的形式为弯板、拉茎辊转速为中速度(600~700 r/min)时进行玉米的摘穗作业时,综合指标较好。

[本文引用: 1]

[本文引用: 1]

DOI:10.13031/2013.36128URL [本文引用: 1]

[本文引用: 1]

[本文引用: 2]

[本文引用: 2]

URL [本文引用: 1]

研究玉米品种、子粒水分含量、产量水平、种植密度、种植行距、植株高度、穗位高度及收割速率等因素对玉米机械收粒质量(子粒破碎率、杂质率和损失率)的影响。结果表明,子粒含水量与机收时子粒破碎率、损失率和杂质率呈显著相关,子粒水分含量越高,机收子粒破碎率和杂质率越高,但田间损失率越低。不同来源品种机收质量特性表现出较大差异。

URL [本文引用: 1]

研究玉米品种、子粒水分含量、产量水平、种植密度、种植行距、植株高度、穗位高度及收割速率等因素对玉米机械收粒质量(子粒破碎率、杂质率和损失率)的影响。结果表明,子粒含水量与机收时子粒破碎率、损失率和杂质率呈显著相关,子粒水分含量越高,机收子粒破碎率和杂质率越高,但田间损失率越低。不同来源品种机收质量特性表现出较大差异。

DOI:10.16035/j.issn.1001-7283.2017.02.013URL [本文引用: 1]

子粒破碎率是评价玉米子粒机械收获质量的重要指标。2011-2016年在全国16省(市、区)194个地块开展子粒机械收获质量测试,对获取的2450组样本数据的统计表明,当前玉米子粒机械收获破碎率均值为8.56%,高于国标["玉米收获机械技术条件"(GB/T 21961-2008)]≤5%的要求,破碎率偏高是我国玉米子粒机械收获存在的主要质量问题。破碎率与收获时玉米子粒含水率呈极显著正相关,2450组样本子粒含水率平均值达到26.65%,两者呈二次多项式关系,水分偏高是导致当前我国玉米子粒收获破碎率高的主要原因;不同收获机械及其作业对子粒破碎率也会产生显著影响;此外,玉米生育和收获期间生态环境因素、栽培措施对破碎率也有影响。培育早熟、脱水速率快、收获期含水率低及抗破碎性好的品种,研发推广破碎率低的收获机械和选择最佳收获期收获是解决破碎率高的主要措施,而在收获时根据玉米生长、成熟和子粒水分状况及时检查与调试收获机械参数也有助于降低破碎率。

DOI:10.16035/j.issn.1001-7283.2017.02.013URL [本文引用: 1]

子粒破碎率是评价玉米子粒机械收获质量的重要指标。2011-2016年在全国16省(市、区)194个地块开展子粒机械收获质量测试,对获取的2450组样本数据的统计表明,当前玉米子粒机械收获破碎率均值为8.56%,高于国标["玉米收获机械技术条件"(GB/T 21961-2008)]≤5%的要求,破碎率偏高是我国玉米子粒机械收获存在的主要质量问题。破碎率与收获时玉米子粒含水率呈极显著正相关,2450组样本子粒含水率平均值达到26.65%,两者呈二次多项式关系,水分偏高是导致当前我国玉米子粒收获破碎率高的主要原因;不同收获机械及其作业对子粒破碎率也会产生显著影响;此外,玉米生育和收获期间生态环境因素、栽培措施对破碎率也有影响。培育早熟、脱水速率快、收获期含水率低及抗破碎性好的品种,研发推广破碎率低的收获机械和选择最佳收获期收获是解决破碎率高的主要措施,而在收获时根据玉米生长、成熟和子粒水分状况及时检查与调试收获机械参数也有助于降低破碎率。

URL [本文引用: 1]

设置不同玉米品种和收获时期试验,研究黄淮海地区夏玉米子粒机械收获的可能性及影响收获质量的因素。结果表明,选择适宜品种和收获时期,在黄淮海小麦/玉米一年两作区实施夏玉米机械直接收获子粒是可行的。影响收粒质量的主要因素是子粒水分含量,随含水量增加,机收时子粒损失率、破碎率和杂质率明显上升,适宜子粒收获的含水量建议控制在27%以内。

URL [本文引用: 1]

设置不同玉米品种和收获时期试验,研究黄淮海地区夏玉米子粒机械收获的可能性及影响收获质量的因素。结果表明,选择适宜品种和收获时期,在黄淮海小麦/玉米一年两作区实施夏玉米机械直接收获子粒是可行的。影响收粒质量的主要因素是子粒水分含量,随含水量增加,机收时子粒损失率、破碎率和杂质率明显上升,适宜子粒收获的含水量建议控制在27%以内。

DOI:10.1016/S2095-3119(17)61785-4URL [本文引用: 1]

DOI:10.13597/j.cnki.maize.science.20160119URL [本文引用: 2]

在玉米收获季节,通过6组不同收获机械收获玉米子粒的对比试验与测试,研究不同机械作业对玉米子粒直收质量的影响。结果表明,机械收获子粒后,子粒破碎率普遍较高,大多超过5%的国家标准;杂质率和落粒损失率普遍较低,分别低于3%和5%的国家标准。子粒破碎率和落粒损失率在不同收获机械及其作业之间存在明显差异,杂质率差异相对较小,收获机械作业是造成玉米子粒破碎率的一个重要因素。

DOI:10.13597/j.cnki.maize.science.20160119URL [本文引用: 2]

在玉米收获季节,通过6组不同收获机械收获玉米子粒的对比试验与测试,研究不同机械作业对玉米子粒直收质量的影响。结果表明,机械收获子粒后,子粒破碎率普遍较高,大多超过5%的国家标准;杂质率和落粒损失率普遍较低,分别低于3%和5%的国家标准。子粒破碎率和落粒损失率在不同收获机械及其作业之间存在明显差异,杂质率差异相对较小,收获机械作业是造成玉米子粒破碎率的一个重要因素。

DOI:10.1016/j.fcr.2016.01.003URL [本文引用: 1]

Close planting often increases the lodging rate of maize, but the cause is unclear. Close planting reduces light intensity within the canopy; therefore, we hypothesized that light intensity may be the main factor affecting maize lodging. To test this hypothesis, three field experiments involving plant density, shading and defoliation were designed to explore how the light environment in a maize canopy affects stalk strength formation and lodging rate. The results showed that close planting and artificial shading treatments both reduced light intensity in the lower canopy. This reduced the dry weight per unit length (DWUL) and rind penetration strength (RPS) of the third basal internode and increased the lodging rate. Removal of leaves 10–12 reduced the DWUL and RPS of the third internode and increased lodging rate. This showed that leaves 10–12 play a crucial role both in the formation of RPS of the third basal internode and in lodging resistance. Removal of either all or part of leaf 16 and above not only increased ptotosynthetic active radiation (PAR) at leaves 10–12 but also increased the DWUL and RPS of the third basal internode. This resulted in a decline in lodging. Therefore, we conclude that light intensity is an important factor affecting maize lodging at high plant density. Increasing light intensity at leaves 10–12 can enhance stalk strength and reduce lodging.

DOI:10.2134/agronj2011.0147URL [本文引用: 2]

Many corn (Zea mays L.) growers in Ohio delay harvest as a management strategy for reducing grain drying costs. However, this practice increases the risk of yield loss due to extended crop weathering. Field studies were conducted at three Ohio locations in 2002 to 2004 to determine effects of three harvest date periods, early to mid-October (HD1), early to mid-November (HD2), and early to mid-December (HD3), and four plant densities (59,000; 74,000; 89,000; and 104,000 plants ha611) on the agronomic performance of four corn hybrids differing in maturity and stalk strength. Interactions between harvest date, plant population, and hybrid indicated that decreases in grain yield and increases in stalk rot and lodging associated with harvest delays were influenced by plant population and hybrid characteristics. Significant yield losses due to delayed harvest were evident only after HD2. When harvest was delayed until HD3, yields decreased at the higher plant populations, especially at 104,000 plants ha611. Stalk rot and lodging increased at the higher plant populations, and this effect was magnified by late harvesting. Hybrids with lower stalk strength scores exhibited greater stalk lodging and yield loss when harvest was delayed beyond HD2. Stalk rot showed a greater increase between HD1 and HD2, whereas stalk lodging generally showed a greater increase after HD2. Harvest delays after HD2 achieved little or no additional grain drying. Results of this study indicate that harvest delays should be avoided when using plant populations above 74,000 plants ha611, especially if planting hybrids that are not highly rated for stalk strength.

DOI:10.13031/2013.40887URL [本文引用: 2]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

DOI:10.2135/cropsci1994.0011183X003400060007xURL [本文引用: 1]

Because stalk lodging is an important problem in maize (Zea mays L.) production, improved methods of breeding for stalk lodging resistance are important. The objective of research reported in this paper was to determine the influence of six cycles of selection for rind puncture resistance, measured just prior to anthesis, on postanthesis rind puncture resistance, grain yield, grain moisture, and stalk rot reaction in two maize synthetics, RSL(MPEN) and RSSSC(MPEN), which represent two different heterotic groups. Response to selection was measured in the populations, per se, testcrosses of each cycle of each population to an appropriate inbred tester, and in crosses between cycles of the two synthetics. In all cases, selection significantly increased postanthesis rind puncture resistance. Stalk lodging was significantly reduced for all cases except RSL(MPEN) per se. Stalk rot incidence was significantly reduced in RSSSC(MPEN) per se. Few adverse effects were noted for other traits. Measuring rind puncture resistance just before pollination allowed effective improvement in stalk lodging resistance using a selection scheme which requires only one generation per cycle.

[本文引用: 1]

[本文引用: 1]

URL [本文引用: 1]

Based on sample data of maize producers in Shandong Province, the author focused on the determinants of farmers adoption of mechanized maize harvesting with binary Logistic modeling, an Ordered Probit model was further applied to analyze factors affecting the degree what farmers applied machines to harvest maize. The results showed that: education level, information acquiring ability, proportion of non-agricultural income, planting scale, perceived effectiveness and the subsidy of government were significantly positive with the adoption of maize mechanized harvesting, whereas land fragmentation and serious natural disasters had significant negative effect on it. Among all the farmers who had adopted mechanized harvesting, factors like the frequency of information acquiring, proportion of non-agricultural income, planting scale and perceived effectiveness were significantly positive with the extent of farmers using of machines while harvesting. The author suggested that accelerate the promotion of reasonable land transfer, expand the publication of mechanization, effectively use the subsidy policy tools and actively carry out agricultural mechanization innovation can improve the adoption of mechanized maize harvesting among farmers.

URL [本文引用: 1]

Based on sample data of maize producers in Shandong Province, the author focused on the determinants of farmers adoption of mechanized maize harvesting with binary Logistic modeling, an Ordered Probit model was further applied to analyze factors affecting the degree what farmers applied machines to harvest maize. The results showed that: education level, information acquiring ability, proportion of non-agricultural income, planting scale, perceived effectiveness and the subsidy of government were significantly positive with the adoption of maize mechanized harvesting, whereas land fragmentation and serious natural disasters had significant negative effect on it. Among all the farmers who had adopted mechanized harvesting, factors like the frequency of information acquiring, proportion of non-agricultural income, planting scale and perceived effectiveness were significantly positive with the extent of farmers using of machines while harvesting. The author suggested that accelerate the promotion of reasonable land transfer, expand the publication of mechanization, effectively use the subsidy policy tools and actively carry out agricultural mechanization innovation can improve the adoption of mechanized maize harvesting among farmers.

DOI:10.13031/2013.39361URL [本文引用: 1]

[本文引用: 1]

URL [本文引用: 1]

URL [本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]