全文HTML

--> --> --> 矿产资源开采与冶炼、污水灌溉、污泥回用,以及肥料与农药的使用,均会导致土壤污染问题[1-2]。城市工业遗留场地以有机污染为主,具有种类多、浓度高、分布不均等特点[3]。热脱附技术能够快速高效去除土壤中汞、挥发性和半挥发性有机污染物,具有不受场地传质条件限制、二次污染可控等优点[4-6]。热脱附技术分为原位和异位2类。其中,异位热脱附技术所使用的设备一般由进出料系统、热脱附系统和废气处理系统(含废水处理)构成[7]。相比原位修复过程在地下的“黑箱”状态,异位热脱附设备中控端可直接调控温度和停留时间,整个修复过程更加直观和可控。根据热源与污染土壤是否直接接触,异位热脱附又可细分为直接式和间接式。直接热脱附使用单层炉,炉内土壤和热源直接接触,污染物加热到沸点后从土壤中分离并向气相中转移。直接热脱附尾气包括高温烟气和脱附气体,尾气流量大,温度和含尘量高,尾气处理系统须配有二燃室和除尘系统[8]。间接热脱附则采用内筒和外筒组成的夹套式双层炉,通过内外管之间的高温烟气间接加热内筒中的土壤,从而实现土壤中有机物的脱附。外筒中的高温烟气由排气筒直接高空排放,内筒中热脱附尾气由挥发性有机污染物、水蒸气、颗粒物和抽提气组成,可通过规模较小的尾气处理系统净化[9]。

异位热脱附是一项装备与工艺并重的应用型技术。通过引进吸收,结合自主研发等方式,热脱附技术在国内发展迅速,本土化异位热脱附装备不断涌现,对于热脱附技术的研究则主要集中在热脱附效率影响因素与处理能力、尾气处理技术和节能降耗等方面[10-12]。现有自研异位热脱附设备仍存在处置规模小、能耗高、模块化程度低等缺点,在运行过程中存在返厂率高、稳定性差、处理能力不达设计量等问题[13]。此外,现有文献中异位热脱附设备和工艺在工程实践应用方面的报道较少。

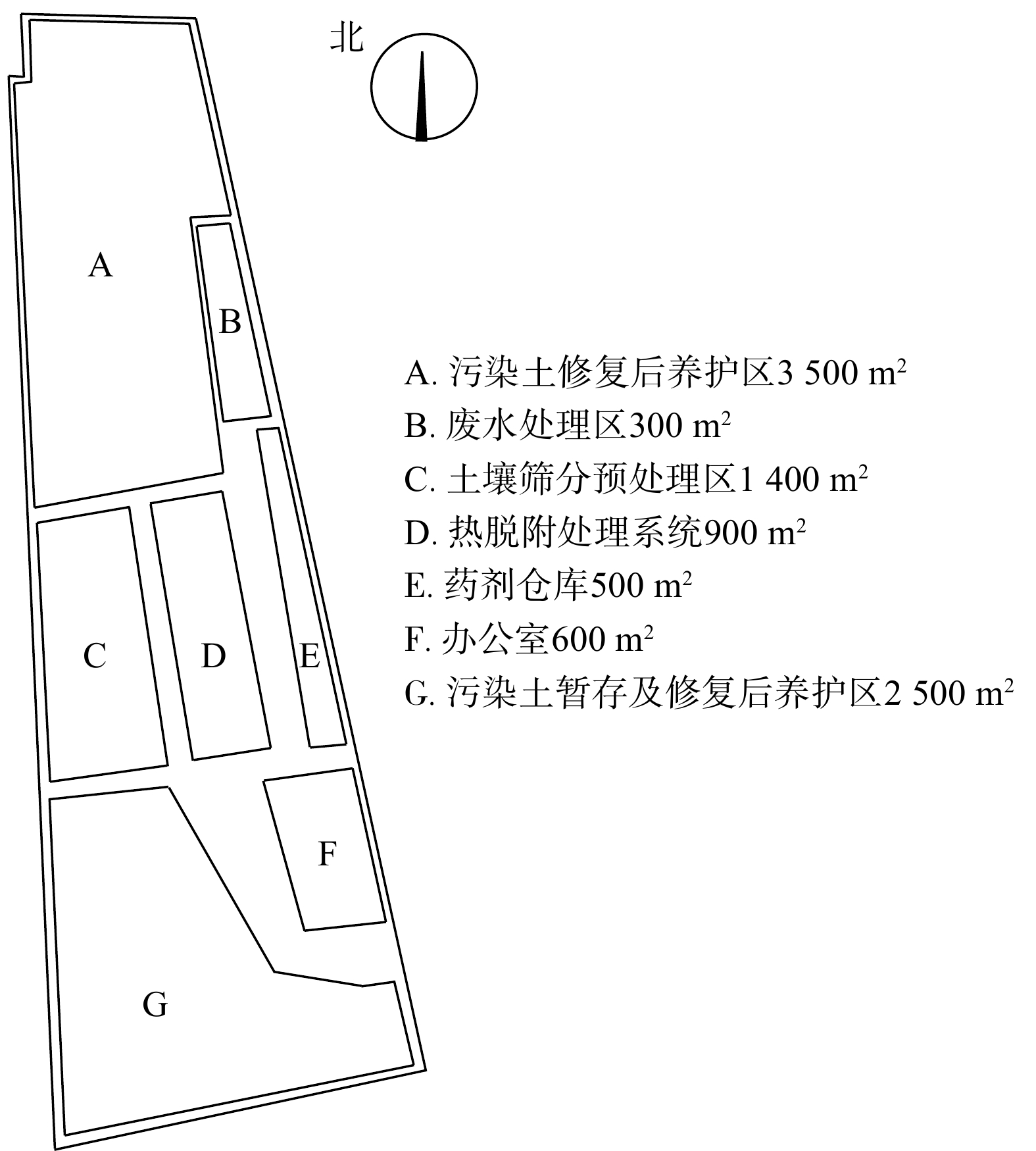

本研究以上海某异位间接热脱附修复有机污染土壤工程为例,依托自研间接两级热脱附设备和前期技术经验积累,在污染物去除、温度控制和尾气净化等方面开展了现场实验研究,并对技术工艺进行了分析总结,以期为异位热脱附技术在修复有机污染土壤的工程应用提供参考。

1.1. 供试土壤的理化性质

需异位处置的污染土来自于上海某树脂厂用地,为具有40多年树脂生产历史的化学工业用地。该厂的生产工艺中主要原料为甲苯、二甲苯、苯醚和苯乙烯等,主要产品有环氧树脂、醇酸树脂和聚氨酯树脂等。该厂的储罐区曾发生过化学品溢出事故。场地地层条件依次由杂填土层(深度至2.5 m)、粉质砂土层(深度至4 m)、粉质粘土层(深度至5 m)、粉质砂土层(深度至7 m)和粉质粘土层(深度至10 m)组成。堆土主要理化性质为:pH为7.6,含水率32.9%~33.9%,以粉粒和沙粒为主,渗透系数为3.33×10?6~1.48×10?4 cm·s?1,有机质含量为6.9%~ 15.8%。

1.2. 场地污染的特征

所需修复污染土总体积约为26 250 m3,包括4个污染区域,具体污染范围和深度见表1。场地土壤中特征有机污染物种类较多,为复合型有机污染场地。土壤中超标有机污染物主要为总石油烃类、挥发性有机物(苯、甲苯、乙苯和1,2,3-三氯丙烷),以及半挥发性有机物(苯并(b)荧蒽、苯并(a)芘、二苯并(a,h)蒽、邻苯二甲酸双(2-乙基己基)酯)。该地块被规划为敏感性用地,根据污染场地风险管控值和场地污染筛选值中敏感用地的要求,确定了本场地的修复目标值。污染浓度范围及最大超标倍数等信息见表2。本项目采用自主研发的异位间接两级热脱附装备对污染土进行修复[14]。设备主要由进出料系统、热处理系统、燃烧系统、尾气处理系统(含废水处理)和监测控制系统等组成,其主体装置参数和功能特征见表3。

间接热脱附设备一般采用回转窑或螺旋推进炉,目前其单套处理能力普遍较低(设计处理量约1~5 t·h?1)[9]。本工程的设备热处理系统为螺旋推进炉,主要特征为上下2层串联连接的一级和二级热处理系统,每一层又均使用2个并联的夹套式双层炉管。其中,内外管之间为高温烟气通道,内管运送污染土和热脱附尾气。该套装置设计处理能力为5 t·h?1,污染土在炉膛内停留时间通过调节绞龙轴体转速进行控制,加热烟气与污染土逆向换热,热量利用率较高。作为对比,浙江宁波某污染场地项目[9]采用3套并联的两级间接热脱附窑,单套设备设计处理量为5 t·h?1。本项目中的设备与之相似,均采用撬装设计,模块化和集成化程度较高。

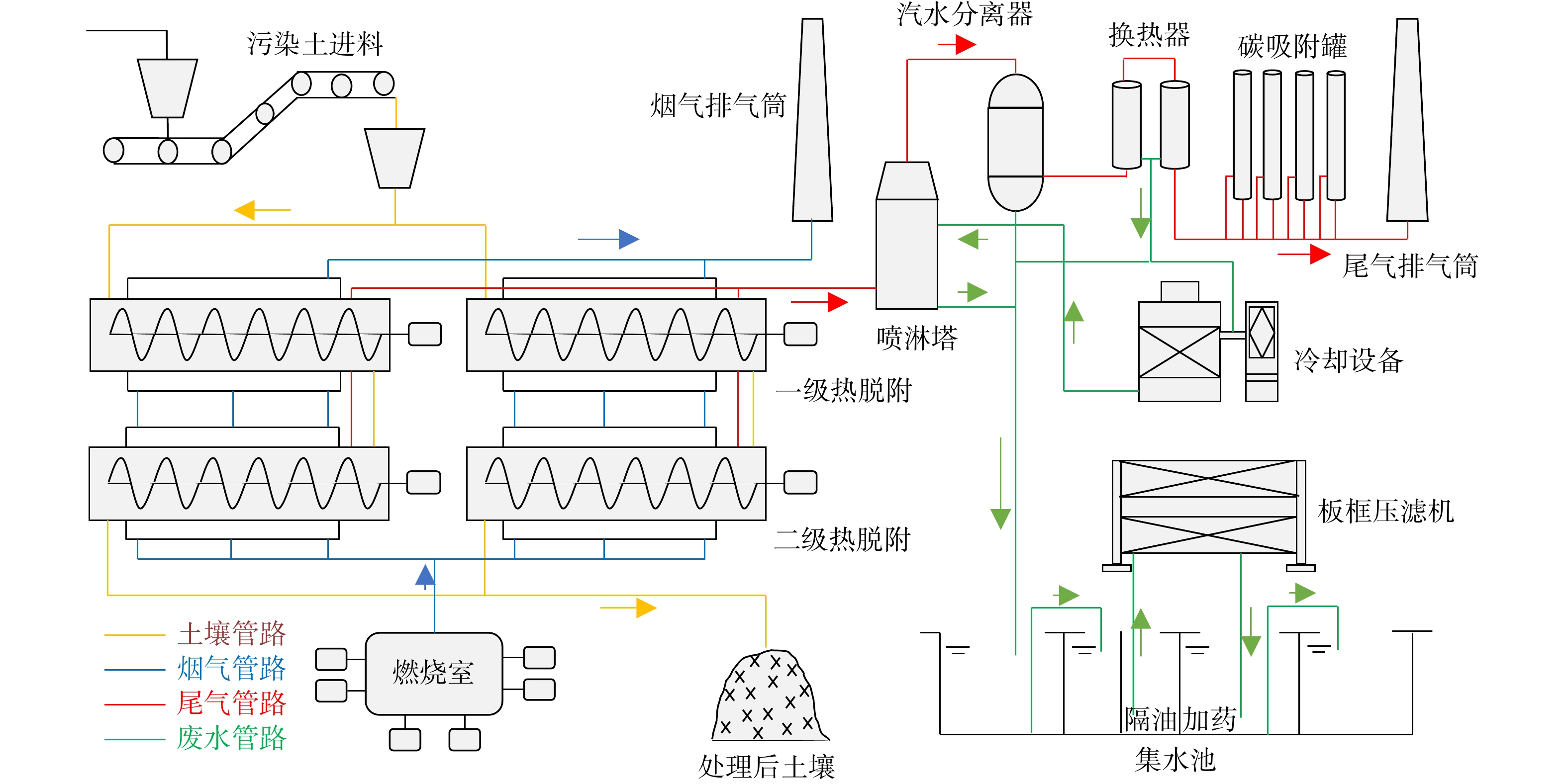

本工程中,设备的燃烧系统采用清洁燃料,燃烧产生的高温烟气依次通过二级和一级热处理系统后通过排气筒直排。尾气处理系统则依次由喷淋塔、换热器、炭吸附罐、引风机和尾气排气筒连接组成。热脱附尾气由2台引风机从内管中抽提而出,整个尾气处理系统维持在微负压状态。与之配套的废水处理装置主要有集水池和板框压滤机。

2.3. 工艺流程

2.3.1. 土壤的预处理

土壤预处理环节包括铺散和分筛。铺散环节加快了土壤干化,使含水率降低到15%,以满足进土要求,并有助于污染土在一级热脱附系统中的快速升温。机械分筛过程中,剔除大块土或杂质,保证给料的均匀性,避免系统阻塞。预处理过程在棚内进行,施工人员均佩戴呼吸保护面罩[15]。2.3.2. 有机污染物的热脱附

污染土在热处理系统内由绞龙螺旋轴体推动前进,依次经过一级和二级炉膛。燃烧室产生的高温烟气在外管内先后经过二级和一级热处理系统,加热内管升温污染土。因高温烟气与土壤逆向换热,热量利用率较高,在中高温下污染土中有机物能够充分热解脱附。通过比例调节控温,二级热处理炉膛温度在500~600 ℃,一级热处理炉膛温度为260~350 ℃。该设定温度下,污染土先在一级炉膛充分预热,此时甲苯、乙苯和短链石油烃等沸点相对较低的挥发性污染物先行脱附出来。随后,污染土被匀速推进二级热处理炉膛,在高温下实现高沸点、难挥发的多环芳烃类污染物和长链石油烃的分离[16]。土壤在每一级热处理系统的停留时间为15 min,以确保有机污染物的分离效果。土壤经高温热脱附后结构遭到破坏[17],喷淋加湿后施加土壤养护剂,以对土壤进行养护,使其能再次资源化利用。主要工艺流程见图2。2.3.3. 尾气及废水的处理

尾气主要包含气态特征污染物、水蒸气、土壤颗粒物及抽提气,具有流量小、含尘量低、无氯代产物和酸性气体[18]。热脱附尾气首先经过喷淋塔进行急冷和降尘处理,尾气与喷淋冷却水进行直接热交换,其温度大幅度下降。此时,沸点较高的挥发性有机物发生液化,与换热后的废水、尘土形成泥水混合物,其温度较高。泥水直接从喷淋塔底部流出进入暂存池,并用空冷器持续降温,泥水再经过隔油、氧化后使用板框压滤进行泥水分离。板框压滤机出水经絮凝沉淀处理后,可用作循环水或排入污水处理系统。急冷后的尾气仍带有大量水气,经过气水分离器、换热器进一步降温和除湿后可得到活性炭吸附的最佳条件[19],不凝气在炭罐中被吸收。处理后的尾气由引风机抽提至15 m高排气筒排放。3.1. 对温度的监测结果

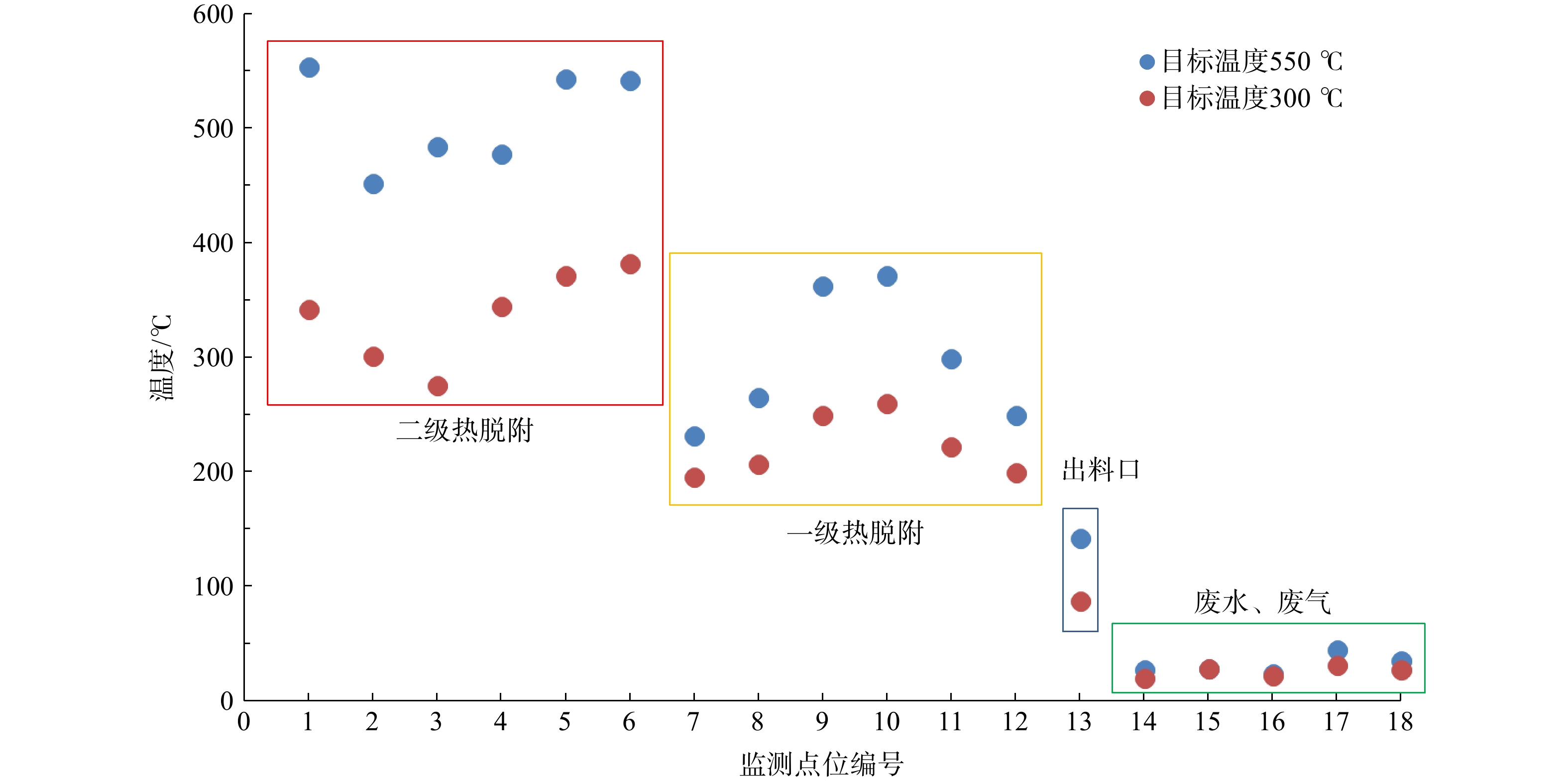

监制系统的自动化和智能化是热脱附设备的发展方向,实现精准控温对于设备运行的稳定和污染物的分离尤为关键,故监测和研究异位热脱附实际工程温度数据意义重大。本项目中的热脱附设备配备K型热电偶温度传感器,用于热处理系统和废气、废水温度监测。在二级热处理系统设置12个热电偶(编号1~12),在一级热处理系统设置6个热电偶(编号13~18),出料口设置1个热电偶(编号19),废水监测单元设置3个热电偶(编号为20~22),废气监测单元设置6个热电偶(编号23~28)。为验证设备控温效果,将燃烧器温度分别设定在550 ℃和300 ℃进行实验。2种工况下监测了18个点位温度变化(见图3)。从图3中的温度点位数据可看出二级热处理系统的温度基本能达到设定温度,一级热处理系统温度则相对低100~200 ℃。这是由于烟气先经过二级热处理炉膛,损失了部分热量;此外,热处理系统中各个监测点位温度存在差异,但基本都在预设温度范围;废水、废气部分温度无明显差异,主要由冷却水换热效果而非初始尾气温度决定。

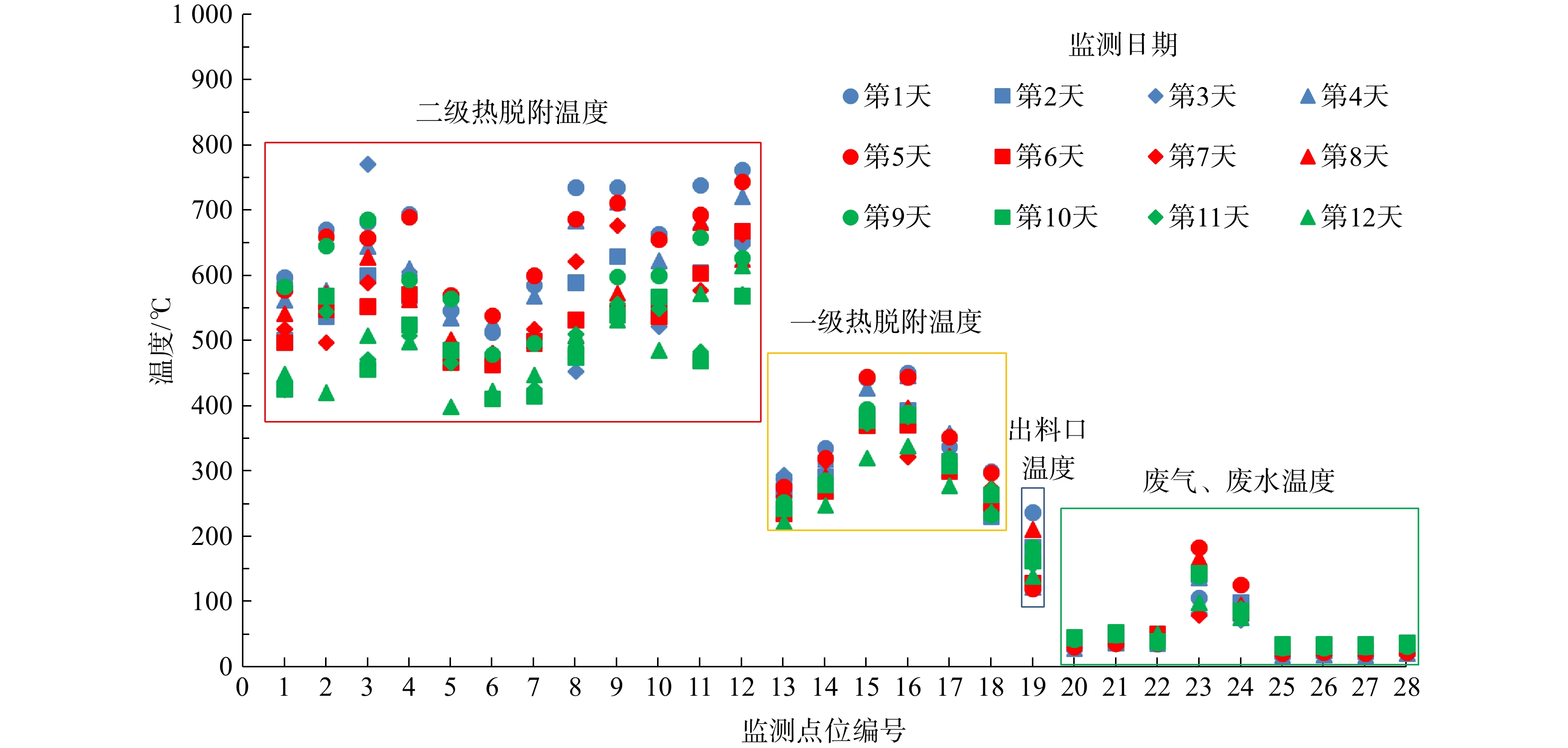

将燃烧器温度设定为550 ℃,对系统连续运行12 d的温度监测结果进行统计分析,得出全部28个热电偶监测点位温度变化实际情况(见图4)。图4说明,二级热处理系统温度为400~800 ℃,其中6号点位的温度不达标;一级热处理系统中13号和18号点位温度不达标。出料口的温度为120~230 ℃,表明处理后土壤温度下降较快,远低于热处理系统。热脱附尾气出口处温度在100~200 ℃(点位23和24),经喷淋塔后温度快速下降至40 ℃以下(点位25)。此外,废水的温度则维持在约40 ℃,变化并不明显。

热脱附温度的选择大多以污染物沸点为依据。徐飞等[20]在采用异位间接热脱附处理多环芳烃污染时,研究了4种热脱附温度对污染物去除效果的影响,并指出550 ℃时能满足多种多环芳烃的达标去除。邢汉君等[21]开展的有机氯农药污染土壤异位热脱附实验的结果表明,温度为450 ℃时,污染土壤中五氯苯酚的质量浓度低于检出限。相比于场地温度变化过程[22],有关异位热脱附设备实际运行温度特征的研究较少。本研究结果能较好地反映出异位间接热脱附设备的温度特征。

3.2. 对尾气的处理效果

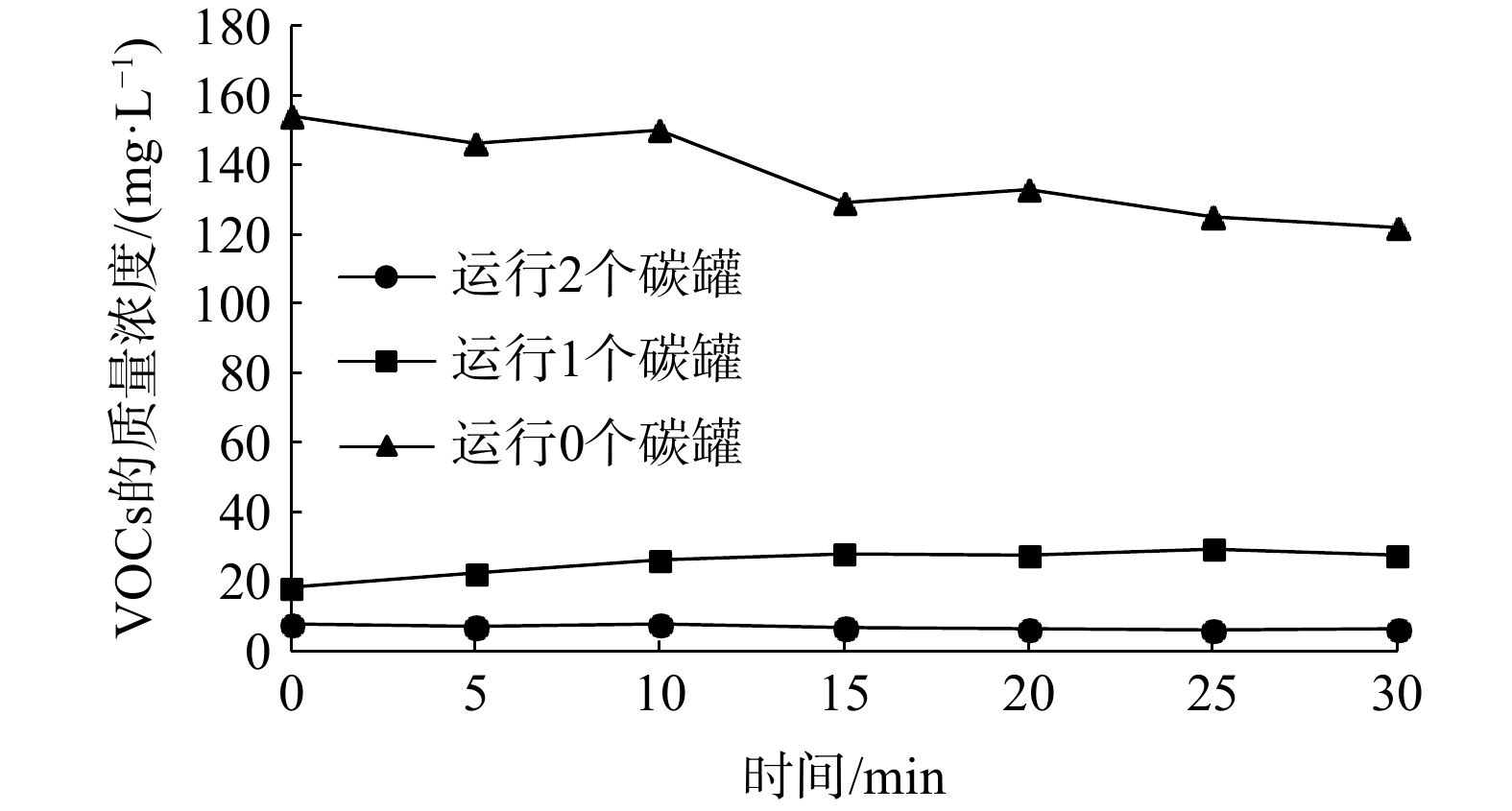

尾气及伴生废水是主要的二次污染源,选用适合现场应用的处理工艺尤为关键。现场采用C600挥发性有机物监测仪对碳吸附后的尾气进行有机物浓度监测(见图5)。结果表明,监测时间30 min内,经单罐活性炭净化尾气中挥发性有机物质量浓度由120~155 mg·L?1降至低于30 mg·L?1,去除率为75%~80.6%,而经过双罐净化后去除率可进一步提升至95%~97%。与此同时,对尾气进行了气体采集送检,分析了其残留污染物组分(见表4)。尾气吸附处理前非甲烷总烃为116 mg·m?3,特征污染物苯、甲苯、二甲苯有检出且浓度较高。经吸附后,尾气中非甲烷总烃、苯、甲苯、二甲苯浓度分别为12.3、0.6、2.1、1.04 mg·m?3,低于地方排放标准(DB 31/933-2015)中的限值。尾气中的多环芳烃类物质均低于检出限,其原因是此类高沸点有机物在冷凝阶段已从尾气中分离[11]。

目前,炭吸附工艺是处理热脱附尾气中不凝组分的主流手段,采用价格低廉的工业级粗粒活性炭即可实现较好的处理效果。相关研究表明,活性炭对苯系物的吸附效率在90%以上[23]。美国Terratherm公司在原位热传导修复含氯有机物污染场地时采用了车载式尾气处理系统,其尾气处理也采用类似的两级串联炭吸附床进行[24];孟祥帅等[10]研究了某焦化场地原位热脱附污染排放及控制,热脱附废气采用活性炭吸附去除污染物后进行排放。吸附工艺简单高效,在尾气乃至工业废气处理中使用率高[25],可进一步应用并推广无害多孔的吸附材料。

本工程采用清洁燃料作为热源,经检测分析,烟气中二氧化硫、氮氧化物和颗粒物的出口浓度均低于排放标准(见表5),故采用15 m高排气筒进行直排。

3.3. 对工艺废水的处理效果

废水由循环冷却水和尾气经换热后产生的冷凝水组成,含少量油泥,产生量约为10 m3·d?1。对油泥进行板框压滤脱水,对废水进行油水分离、氧化和混凝的强化处理后,取总排口废水进行监测(见表6)。检测项目中石油烃、苯、甲苯和乙苯均有检出,但质量浓度均低于排放标准;多环芳烃类有机物在废水总排口未检出,其原因可能是多环芳烃类物质经氧化和混凝步骤得到了有效去除[26],或是仍储存于油相和脱水污泥中。处理达标后的废水可用作循环冷却水回用。3.4. 土壤修复效果

采集2个处理后的土壤样品进行送检,结果见表7。在2个送检的土壤样品中1,2,3-三氯丙烷、二苯并(a,h)蒽和邻苯二甲酸双(2-乙基己基)酯未有检出;石油烃、苯、甲苯、乙苯、苯并(b)荧蒽和苯并(a)芘均有检出,但浓度均低于修复目标值。该结果证明了异位间接热脱附设备对复合有机污染土壤治理的有效性。同时,修复过程中不同批次的污染土可能存在异质性,导致出料中有机物含量存在波动,故必要时可采取增加停留时间和回烧等措施,以强化修复效果。和丽萍等[27]运用异位高温间接热脱附设备修复云南地区红壤土污染场地,多环芳烃的去除率在90%以上。胡孙等[28]在氯苯污染场地开展中试试验,结果表明,异位间接热脱附可实现土壤中二氯苯和六氯苯类污染物的高效去除。结合本研究的结果可见,间接热脱附技术适用于土壤中各类复合有机污染物的去除。

参考文献

下载:

下载:

点击查看大图

点击查看大图