,??,**,2), 孟嘉旭??, 刘凯??, 牛迎浩??, 薛睿??, 张鹏??, 丁文杰??, 叶璇???, 凌雪***, 毕颖

,??,**,2), 孟嘉旭??, 刘凯??, 牛迎浩??, 薛睿??, 张鹏??, 丁文杰??, 叶璇???, 凌雪***, 毕颖 ,***,????,3), 夏勇****

,***,????,3), 夏勇****MECHANICAL DESIGN, IMPACT ENERGY ABSORPTION AND APPLICATIONS OF AUXETIC STRUCTURES IN AUTOMOBILE LIGHTWEIGHT ENGINEERING1)

Wu Wenwang*,??, Xiao Dengbao ,??,**,2), Meng Jiaxu??, Liu Kai??, Niu Yinghao??, Xue Rui??, Zhang Peng??, Ding Wenjie??, Ye Xuan???, Ling Xue***, Bi Ying

,??,**,2), Meng Jiaxu??, Liu Kai??, Niu Yinghao??, Xue Rui??, Zhang Peng??, Ding Wenjie??, Ye Xuan???, Ling Xue***, Bi Ying ,***,????,3), Xia Yong****

,***,????,3), Xia Yong****通讯作者: 2) 肖登宝, 副教授, 主要研究方向: 结构冲击动力学. E-mail:xiaodengbao@bit.edu.cn;3) 毕颖, 副教授, 主要研究方向: 轻量化结构设计. E-mail:biying@bucea.edu.cn

收稿日期:2020-09-20网络出版日期:2021-03-18

| 基金资助: |

Received:2020-09-20Online:2021-03-18

作者简介 About authors

摘要

轻量化多功能负泊松比结构由于具有优异的可设计性、拉胀特性、剪切模量、断裂韧性、抗冲击吸能、减震降噪等特性,在车辆吸能结构设计和多功能优化方面具有巨大的应用潜力.本文详细综述了负泊松比结构的力学设计及其在车辆工程中的典型应用:(1)负泊松比基本概念及其力学特性, 以及近几十年来的快速发展趋势;(2)负泊松比材料与结构构型设计方法的基本分类、负泊松比泡沫材料微结构特征及制备工艺、负泊松比复合材料设计方法的基本发展历程以及前沿人工智能设计方法;(3)针对典型负泊松比结构的力学设计进行详细介绍, 主要包括手性结构、方格旋转结构、双箭头内凹结构、内凹蜂窝结构、拉伸扭转效应负泊松比结构等;(4)负泊松比材料与结构的冲击吸能特性及相关的实验、理论和模拟研究;(5)负泊松比材料与结构在汽车轻量化设计领域的典型应用, 主要包括汽车吸能盒、B柱、发动机罩、安全带、悬架、免充气轮胎等典型吸能结构件;(6)负泊松比结构在汽车工程中的应用前景, 所面临技术挑战和巨大应用潜力.

关键词:

Abstract

Lightweight and multi-function structures with negative Poisson's ratio have excellent auxetic mechanical properties, and have been demonstrated promising industrial application potentials as energy absorption structures and multifunctional devices in automobile industry due to their enhanced indentation resistance, shear modulus, fracture toughness, impact energy absorption, shock absorption, noise reduction performances and so on. This paper mainly summarizes the mechanical properties of structures with negative Poisson's ratio effect, and their typical structural design and applications in automotive engineering. The contents could be classified into six parts: (1) The concepts and mechanical characteristics of different materials and structures with negative Poisson's ratio are introduced firstly, and the rapid developments in recent decades are also discussed; (2) main design method of materials and structures with negative Poisson's ratio are performed, corresponding manufacturing technologies of foams with negative Poisson's ratio effect are summarized, the design developments of composite materials with negative Poisson's ratio and the frontier artificial intelligence design method for advanced structure with negative Poisson's ratio are also presented; (3) mechanical designs of typical cellular structures with negative Poisson's ratio are introduced in detail including: chiral structure, rigid node rotation structure, double-arrow structure with negative Poisson's ratio, re-entrant honeycomb structure, structure with tensile-torsion effects and so on; (4) many experimental, theoretical and finite element simulation results about the energy absorption characteristics of materials and structures with negative Poisson's ratio are presented; (5) typical industrial applications of advanced materials and structures negative Poisson's ratio as high performance energy application structures in the field of lightweight vehicle design are demonstrated, mainly including: automobile energy absorption box, B-pillar, engine hoods, seat belts, suspension structures, and non-pneumatic tires and so on; (6) industrial application prospects of advanced materials and structures with negative Poisson's ratio (NPR) in automotive engineering, and the technical challenges and promising industrial application potentials are also pointed out.

Keywords:

PDF (82814KB)元数据多维度评价相关文章导出EndNote|Ris|Bibtex收藏本文

本文引用格式

吴文旺, 肖登宝, 孟嘉旭, 刘凯, 牛迎浩, 薛睿, 张鹏, 丁文杰, 叶璇, 凌雪, 毕颖, 夏勇. 负泊松比结构力学设计、抗冲击性能及在车辆工程应用与展望1). 力学学报[J], 2021, 53(3): 611-638 DOI:10.6052/0459-1879-20-333

Wu Wenwang, Xiao Dengbao, Meng Jiaxu, Liu Kai, Niu Yinghao, Xue Rui, Zhang Peng, Ding Wenjie, Ye Xuan, Ling Xue, Bi Ying, Xia Yong.

引言

泊松比$\nu $是以法国科学家Sime' on Denis Poisson (1787 — 1840)的名字命名的. 泊松比也称横向变形系数,用于表征材料在垂直于作用力方向上的横向变形特性, 可以定义为材料在弹性加载方向上的横向应变$(\varepsilon_{t})$和纵向应变$(\varepsilon_{l})$比值的负数, 即$v=-\varepsilon_{t} /\varepsilon_{l}$. 传统材料受到外力挤压时,在垂直于压力的方向会发生膨胀, 其泊松比值一般大于零. 不同于传统材料, 拉胀材料是一类具有负泊松比效应的材料,在外部载荷作用下会沿着垂直于压缩方向发生膨胀变形效应. 1982年, Gibson等[1-2]以二维硅橡胶或铝蜂窝的形式制造了具有负泊松比效应的蜂窝结构, 这些蜂窝由于肋的弯曲而变形[1].Kolpakov[3]于1985年从理论角度探讨了负泊松比蜂窝结构的力学性能. 同样在1985年, Almgren[4]提出了一种由棒、弹簧和滑块组成的负泊松比二维、三维宏观结构, 能够实现负泊松比值为$-1$的宏观各向同性负泊松比效应. 1987年, Lakes[5]将普通聚氨酯泡沫放入75 mm$\times$25 mm$\times$25 mm的铝制模具中进行三维压缩后再对其进行加热、冷却和松弛处理, 得到负泊松比值为$-$0.17的拉胀材料. 随后Evans等[6]将这类具有负泊松比性能的材料和结构称为“Auxetics”, 该词来源于希腊

对于弹性固体来讲, 通常只需要有4个物理常数来描述材料的弹性行为, 分别是: 拉伸(杨氏)模量($E)$、剪切模量($G)$、体积模量($K)$和泊松比($v)$. 对于各向同性材料来讲,4个物理常数之间存在如下关系

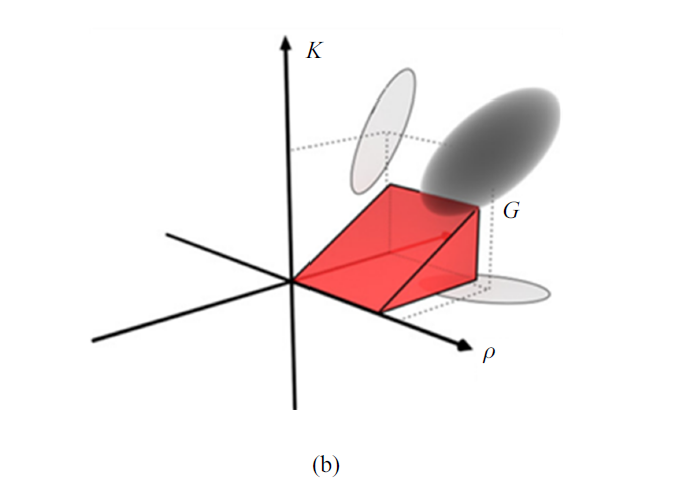

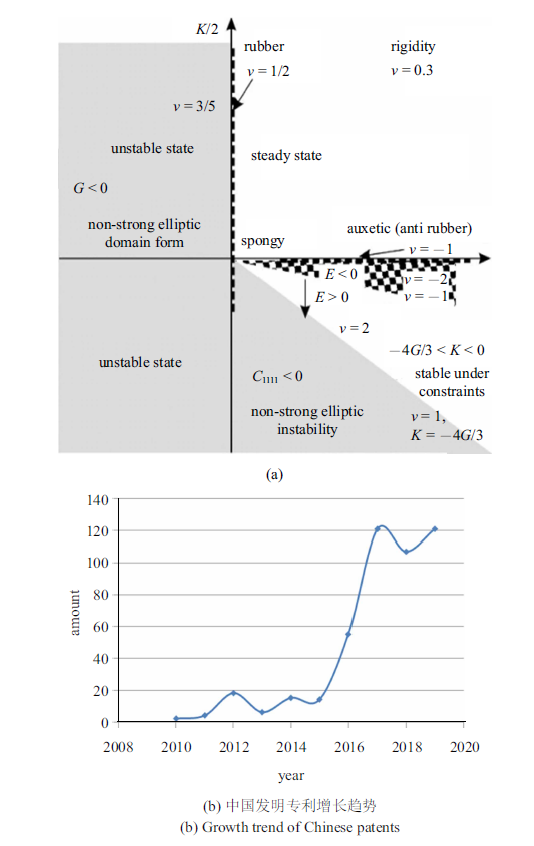

为了比较直观反映固体材料弹性阶段的基本特性,Milton[7]提出基于体积模量和剪切模量的四象限图来描述人工和天然材料的多样化弹性特性和稳定性,其泊松比范围和材料特性差异在图1所示的密尔顿图中得到充分反映[7-11].图1(a)所示(图中具体细节请查阅文献[7])材料稳定区域和不稳定区域的边界与材料相变有关,图上的右象限的“拉胀区域”由Milton首先明确阐述[7]. 在图1(b)中,通过将Milton图(体积模量$K$与剪切模量$G)$和Ashby图(一个弹性模量与质量密度$\rho )$组合起来, 可以清晰反映负泊松比材料的材料区域范围[12].

图1

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图1(a) Milton图(具体细节请查阅文献[7])展示的材料体积模量$K$、剪切模量$G$、泊松比$v$和稳定性之间的关联关系[7];(b) Milton-Ashby图所展示的材料体积模量$K$、剪切模量$G$、材料密度$\rho$之间的关系[12]

Fig. 1(a) Milton diagram (please refer to Ref.[7] for details) showing the correlation between material bulk modulus $K$, shear modulus $G$, Poisson's ratio $v$ and stability[7]; (b) relationship between the material bulk modulus $K$, shear modulus $G$, and material density $\rho$ shown in the Milton-Ashby diagram[12]

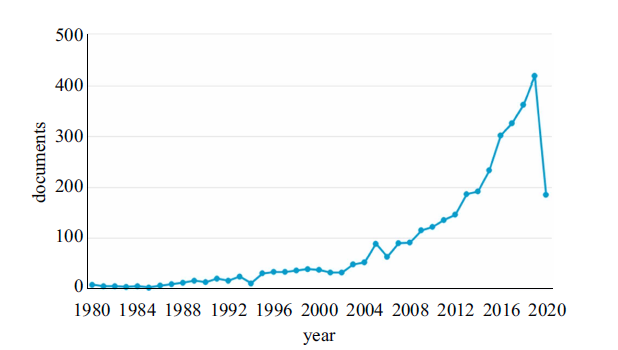

截至2020年5月, 从负泊松比概念被明确定义开始算起, 根据Scopus数据库分析,针对“负泊松比材料与结构”设计及性能的研究论文大约3587篇, 中国发明专利471项,如图2所示.

图2

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图2负泊松比材料与结构研究发展历程分析

Fig. 2Analysis of the development process of NPR material and structure

图2

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图2负泊松比材料与结构研究发展历程分析(续)

Fig. 2Analysis of the development process of NPR material and structure (continued)

1 负泊松比材料及力学性能

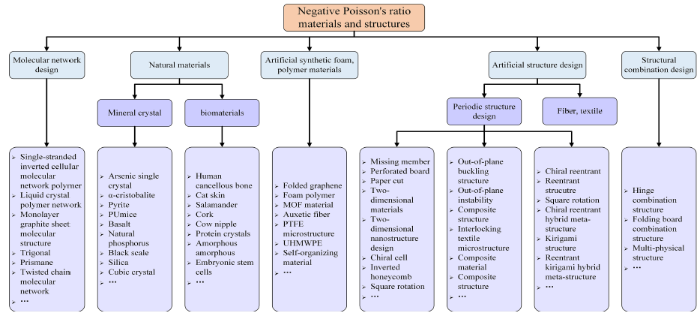

随着Lakes[13]在1987年成功制备出负泊松比泡沫, 各种新型负泊松比材料和结构概念和设计方法得到快速发展. 天然和人工负泊松比材料和结构的分类如图3所示, 主要包括: 负泊松比分子网络、天然负泊松比矿物晶体、天然负泊松比生物材料、人工合成负泊松比聚合物及泡沫材料、负泊松比复合材料、负泊松比纤维及纺织物、负泊松比人工结构、负泊松比结构组合体等[1-14].图3

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图3负泊松比材料与结构分类[1-13]

Fig. 3Negative Poisson's ratio material and structure classification[1-13]

1.1 人工合成负泊松比多孔泡沫材料

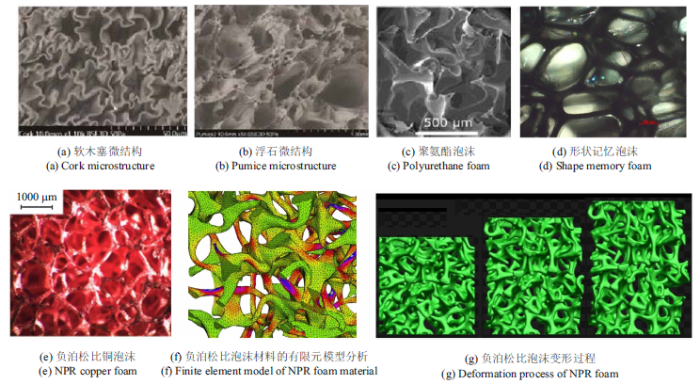

20世纪80年代, 科学家们在泡沫和复合材料领域取得新的理论成果,主要有Gibson和Ashby[15]、Almgren[16]和Kolpakov[17],贾然和赵桂平对泡沫材料的研究进行了详细的综述[18]. 他们的研究成果表明,一种自然界中还未出现的内凹或者内凹式蜂窝, 具有拉胀性.Lakes[13]在1987年通过将聚氨酯泡沫放入铝制模具中, 从三个方向整体压缩,然后升温到材料的软化温度, 再快速冷却松弛固化,得到了泊松比为$-$0.7左右的负泊松比聚氨酯泡沫. 1989年,Caddock和Evans[19-20]发现了一种经过特别加工的多孔聚四氟乙烯树脂具有拉胀特性,泊松比可以达到$-$12, 并提出“纤维-节点”理论模型来解释其拉胀机理. 随后,Friis等[21]利用类似的方法先后制得了另外几种聚合物拉胀泡沫和金属拉胀泡沫.此后, 科学家们进一步改进工艺制备出多种新型拉胀材料,提升了负泊松比聚合物和泡沫材料的可恢复性、吸能特性等[22-26].特别是Grima等[27]对制备工艺进行了重大的改进,用特殊溶剂软化泡沫微结构的方法来代替传统工艺中的加热过程,使拉胀泡沫的制备成为了一个可逆过程, 即拉胀泡沫经过“浸润溶剂-三向拉伸-干燥”的逆向处理后又可以变成正泊松比的普通泡沫,具有“记忆特性”, 两种物性状态相互转化在次数上是无限制的,图4展示了一些典型的负泊松比材料及其变形过程.图4

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图4具有多孔泡沫及随机微结构特征的典型负泊松比材料[14-31]

Fig. 4Typical NPR material with porous foam and random microstructure characteristics[14-31]

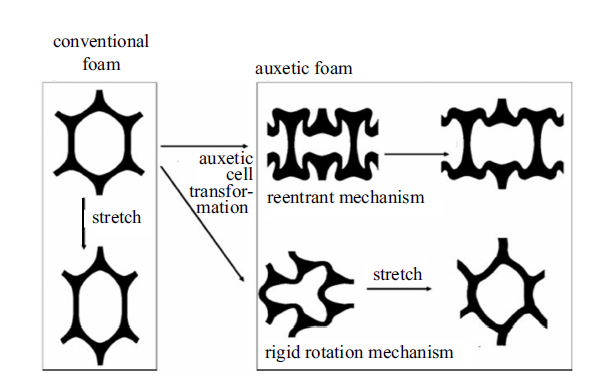

此后, 国内外****针对负泊松比泡沫材料设计和制造工艺、结构优化和力学性能探究方面做了广泛而又深入的研究.相关研究成果表明: 具有软化点的聚合物泡沫、微孔聚合物、延展性金属泡沫,以及某些热固性聚合物泡沫, 均可制成负泊松比材料.拉胀泡沫的秘密在于其内部微观尺度上微结构空间排列特征,并且有一些定性的力学模型用于变形机理解释. 比如,Smith等[28]于2000年提出杆件缺失模型来解释拉胀泡沫的负泊松比变形机理.Grima等[29-30]进一步提出拉胀蜂窝的内凹变形模式等来解释具有负泊松比开孔泡沫的拉胀力学行为,如图5所示. Rodney等[31]设计了具有负泊松比效应的缠绕金属丝三维骨架网络,其力学性能介于连续介质和离散介质之间,这种不寻常的拉胀行为主要由于线圈伸长和位阻效应相互作用引起的.

图5

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图5拉胀泡沫负泊松比变形机制[29-30]

Fig. 5Deformation mechanism of auxetic foam [29-30]

早期的负泊松比发展主要是基于多层级结构设计思想,通过控制不同尺度、不同空间取向的纤维叠层秩序,理论上可以得到具有负泊松比效应的复合材料[32-34].Milton[34]通过多层级结构设计和微观胞元设计,可以在纤维增强复合材料中实现复合材料负泊松比效应,设计出各向同性二维、三维多层次结构负泊松比复合材料,并通过不同层级组分结构的几何尺寸和组元类型调控,可以实现泊松比值接近于$-$1的复合材料负泊松比效应,并通过实验验证了该设计方法的可行性,有力推动负泊松比复合材料设计从理论走向实际应用.随着多孔固体材料力学理论和复合材料设计思想的发展,可以含有微孔结构组元的纤维增强复合材料[35],进一步实现含有分散相、夹杂相、孔洞等负泊松比复合材料的设计[36-40].目前一般认为, 可通过两种方式来使复合材料具有负泊松比特性,第一种是在复合材料中选择恰当的铺设方式, 且要求铺层材料具有高度各向异性.第二种是在复合材料中添加负泊松比增强纤维,使材料受到拉伸外力时延缓纤维的拔出, 并在拔出时发生横向膨胀.

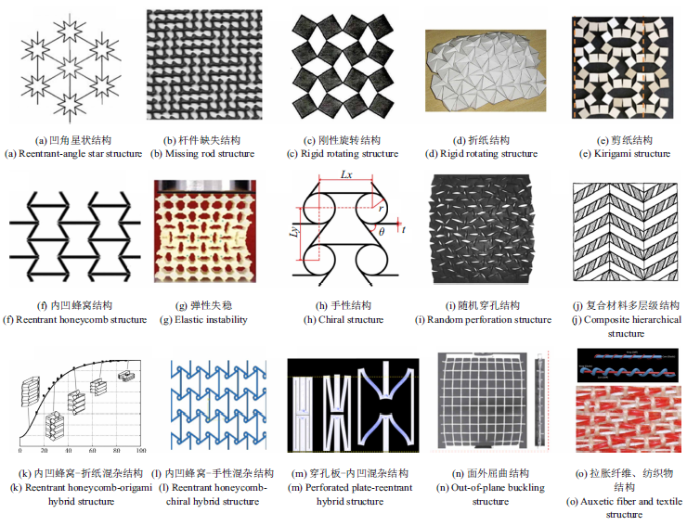

2 负泊松比结构设计方法

自Lakes[13]首次人工合成负泊松比泡沫以来,各种新型先进负泊松比材料与结构得到快速发展,相关基础研究和工业应用开发越来越广泛.各种新型负泊松比材料与结构设计逐渐从1D过渡到4D, 从原子尺度到宏观尺度,性能研究也从准静态力学性能拓展到多物理化学场耦合性能,并实现从概念创新、理论模型、制造工艺到工程应用实践的快速拓展. 近年来,随着力学超材料新概念、设计方法、制造技术的快速发展和进步,特别是各种先进结构设计思想和理论的创新,许多新型负泊松比结构设计体系得到丰富和深度发展. 根据变形机理特征,可以把主要的负泊松比结构分为:内凹多边形结构、旋转刚体结构、手性结构、穿孔板结构、节点-纤维结构、扭转结构、折纸(剪纸)结构、拉张结构、锁链结构、弹性失稳和屈曲结构以及其他结构形式[41-60],见图6所示.图6

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图6负泊松比结构的分类[41-60]

Fig. 6Classification of NPR structures[41-60]

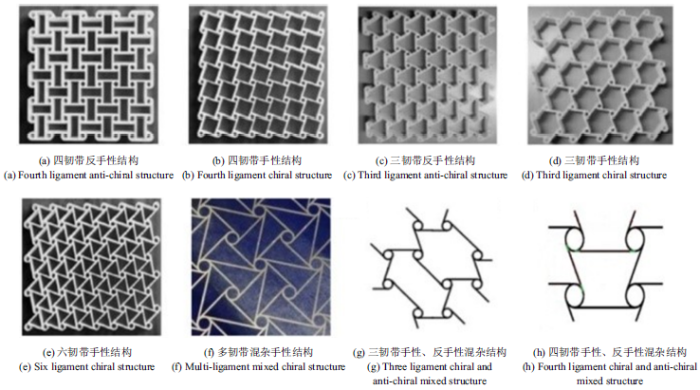

2.1 手性结构

威廉$\cdot$汤姆森爵士在1893年5月16日在牛津大学青少年科学俱乐部举办的RobertBoyle讲座中首次用“手性”术语来描述晶体分子结构所具有的手性属性.手性几何特征主要在于: “对于一个几何图形或者一组点的集合, 如果他们与其理想的平面镜像不能完全重合, 那么我把这样的几何图形或者点集称为“手性的”, 结构手性是指具有镜像对称而又不能完全重合的结构特性, Kelvin[61]在巴尔的摩讲座附录中关于手性有更为普适性的描述“如果一个物体不能通过单独的旋转和平移与其镜像重合时,那么就称其为手性物体”. 自然界天然物质、动物、植物和人工合成材料中通常存在各种手性结构, 例如:螺旋山羊角、海贝壳、DNA、手性碳纳米管、扭曲花瓣和茎、植物攀缘卷须和扭曲的叶子、手性纤维素等.1989年Wojciechowski[62]首次提出了基于可旋转圆形节点的手形结构的概念.1997年Prall和Lakes[63]设计了六角手性蜂窝结构并研究了其面内力学性能.手性超结构是由具有周期性分布的圆环状和弹性韧带切向连接形成的蜂窝型拓扑结构,如果韧带两端所连接的圆环处于韧带的两侧, 称之为手性超结构;如果韧带两端所连接的圆环处于韧带的同一侧, 则称之为反手性超结构.根据每一个圆环切向连接韧带数目不同,主要有三韧带手性/反手性、四韧带手性/反手性和六韧带手性超结构等五种类型[64].如图7所示,Alderson等[65]研究了三韧带手性蜂窝结构、三韧带反手性蜂窝结构、四韧带手性蜂窝结构和六韧带手性蜂窝结构等结构的弹性性质,得出面内弹性模量和泊松比与结构的几何参数的关系,发现节点的旋转和韧带的弯曲在变形中占主导地位.Grima等[66]提出了新的手性结构设计思路,将四韧带手性与反手性结构混杂、三韧带手性与反手性混杂的结构进行研究.Ha等[67]提出基于胞元拉伸旋转机制的三维手性泊松比可调控结构,可以实现正负泊松比范围内的结构性能调制. 在面内载荷作用下,反手性超结构的韧带发生弯曲形成半波长变形特征,手性超结构的韧带弯曲形成全波长变形特征,反映出角点旋转和韧带弯曲变形之间的耦合作用.Wu等[68]在基础手性胞元基础上,进一步提出具有几何梯度特征、多层级结构特征的新型手性结构,并研究了其面内力学性能和拉胀力学行为、面内和面外冲击吸能特性.和多孔泡沫金属、晶格点阵、格栅等轻量化结构周期性胞元中的杆、板、梁承受拉/压、弯曲相比,手性超结构环形角点的旋转变形为胞元增加了结构设计参数,能够调控和优化手性超结构的多功能性,比如结构轻量化、负泊松比拉胀、抑振、吸声降噪、抗冲击吸能等[68].

图7

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图7手性蜂窝结构[61-68]

Fig. 7Chiral honeycomb structure[61-68]

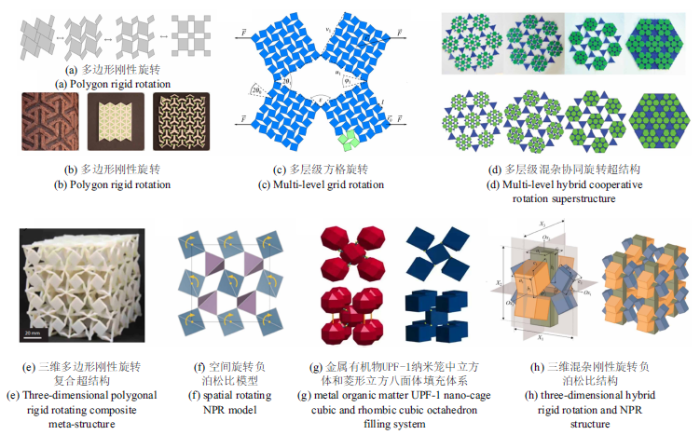

2.2 方格旋转结构

负泊松比旋转二维多边形、三维多面体结构是负泊松比材料的另一大类.多边形、多面体旋转结构一般由刚性多边形、多面体通过相互铰接起来,在拉伸作用下相邻多边形、多面体之间协同变形, 通过刚性旋转产生拉胀响应,形成二维、三维负泊松比效应. 如图8所示, 二维刚性旋转结构主要有:三角形、正方形、菱形、六边形、多边形混杂结构、多层级多尺度旋转结构等.三维刚性旋转结构主要有: 四面体、正方体、十二面体、混杂多面体、多层级多面体结构以及由二维多边形空间旋转排布构建的三维拉胀超结构等[69-77].图8

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图8基于多边形旋转形成负泊松比效应设计[69-77]

Fig. 8Design of NPR effect based on polygon rotation[69-77]

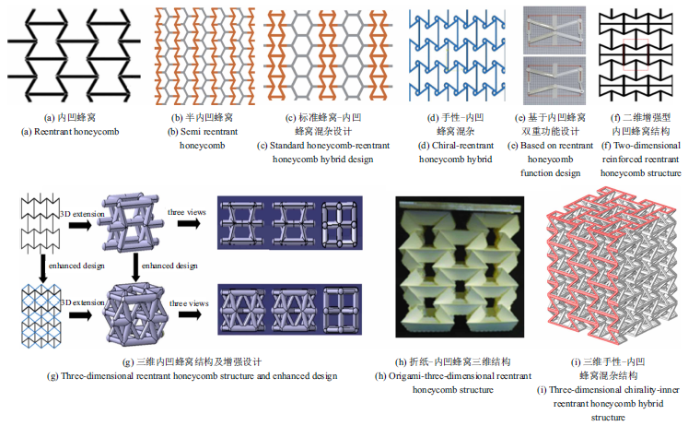

2.3 内凹蜂窝结构

Gibson和Ashby[2]在1982年首次提出了二维内凹六边形蜂窝结构,当蜂窝胞元受到外部拉伸载荷时, 倾斜取向蜂窝壁杆件会沿着垂直于拉伸方向运动,发生面内旋转, 从而使结构表现出负泊松比特性. 如图9所示, 通过利用空间旋转、平移等对称性操作,科学家们进一步设计出具有空间负泊松比效应的新型二维、三维内凹点阵结构, 主要有:二维、三维半内凹、全内凹、内凹混杂结构、增强型内凹负泊松比结构[78-84].图9

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图9内凹蜂窝结构设计[78-84]

Fig. 9Reentrant honeycomb structure design[78-84]

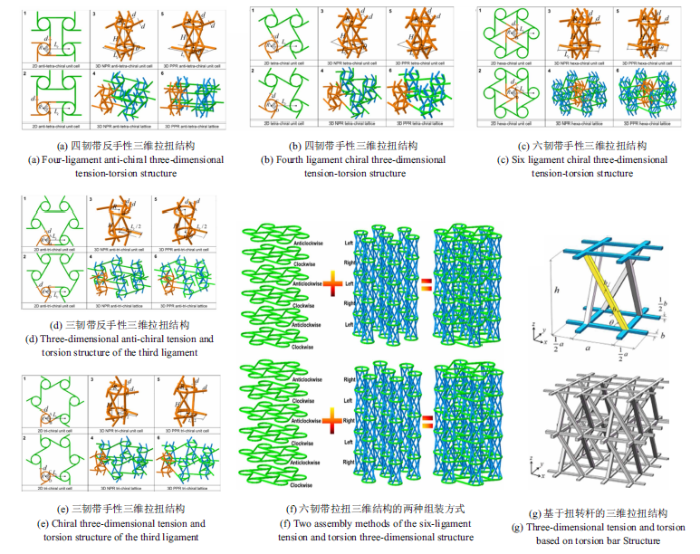

2.4 拉伸扭转效应负泊松比结构

通过利用二维手性结构角点旋转、韧带弯曲的变形特性,Fu等[85-88]设计了具有压缩-扭转效应的三维手性结构,并能够产生负泊松比效应. 如图10所示,Duan等[89-90]基于二维多边形胞元结构空间平移、旋转、镜像等几何操作,通过沿着面外垂直方向进行平移并旋转一定的角度,并将沿着垂直平移方向相邻的胞元用倾斜杆件连接起来设计出一系列新型负泊松比结构.图10

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图10基于拉扭效应的负泊松比三维结构设计[85-90]

Fig. 10Design of the three-dimensional NPR structure based on the tension-torsion effect[85-90]

2.5 拓扑优化负泊松比结构

拓扑优化作为结构设计领域的重要方法在汽车交通等领域得到广泛应用. 近年来,不同的拓扑优化方法被应用于具有负泊松比特性的新型结构设计优化中, 主要包括:均匀化方法[91], 密度法[92], 双向渐进结构优化法(BESO)[93-96],水平集法(LSM)[97-99], 移动组元法(MMC)[100-101]以及等几何拓扑优化法[102-104].Sigmund[105-106]首先采用拓扑优化技术来定制具有性能任意定制的专用材料,包括负泊松比材料等. 随后,研究人员针对负泊松比材料分别在理论研究和工程应用领域开展一系列研究工作.Zhang等[107]通过将独立的点密度插值与双材料模型相结合,提出了一种可用于手性负泊松比材料结构优化设计的新方法.基于SIMP方法, Xia等[108]开发出用于具有极端特性的材料设计程序包,可以设计负泊松比超材料.Zhang和Khandelwalb[109]提出了一种基于非线性均匀化理论的负泊松比超材料设计新方法,该方法是在基于密度的拓扑优化框架下实现的.Gao等[110]提出基于等几何拓扑优化方法的2D和3D负泊松比超材料的性能最优化方法,并通过shepard插值和B样条曲线构造的密度分布函数用于表示微观结构的拓扑变化规律.Vogiatzis等[111]提出了一种基于水平集的多材料设计方法来设计负泊松比超材料,该方法使用Merriman-Bence-Osher(MBO)运算符对水平集分布场进行调控.Wu等[97]提出了一种基于水平集的高性能拓扑优化方法,可以用于复合不确定性条件下的负泊松比超材料的结构设计[97],其中基础材料的泊松比被认为是区间变量, 而杨氏模量被认为是随机变量.Schwerdtfeger等[112-113]采用拓扑优化方法获得各向同性3D负泊松比结构,并通过实验验证了其拉胀特性.Clausen等[114]研究了大变形条件的3D负泊松比材料的力学性能和变形机理.2.6 基于人工智能技术的数据驱动负泊松比结构

近年来, 随着海量科学数据的激增,研究人员将数据科学、人工智能计算方法和结构设计优化方法结合起来,进而可以对结构的宏观力学性能进行优化、实现性能可定制化,并成为新结构类型发现的一种新型技术手段[115-120].Chen等[118]提出了一种超材料设计四步计算法: 第一步,在给定一组基础材料的情况下估算微结构属性范围; 第二步,确定属性区域边界附近的微结构常见几何特征类型; 第三步,为每个微结构族建立参考模板. 第四步,通过参数简化允许在材料属性空间中搜寻最优的微结构设计,用于自动发现具有极端宏观特性的微结构族. 最后,通过控制一组参数自动发现并设计出五种负泊松比微结构族来展示该方法的强大能力.为了克服传统负泊松比材料设计方法局限和大规模计算负荷,基于数学上的最佳变形设计原则,Wilt等[119]将机器学习方法用于预测负泊松比结构柔顺性设计中的误差.通过有限元分析和实验对比, 验证了特定负泊松比构型的力学行为,并展示了通过增材制造负泊松比结构的变形结果来训练回归模型,并预测与最佳力学行为的偏差.Liu等[120]描述了一种数据驱动的方法来预测带有随空间取向切口的负泊松比折纸超材料的力学性能.该方法使用有限元方法生成数据集, 引入卷积神经网络训练这些数据.3 负泊松比材料与结构的冲击吸能特性

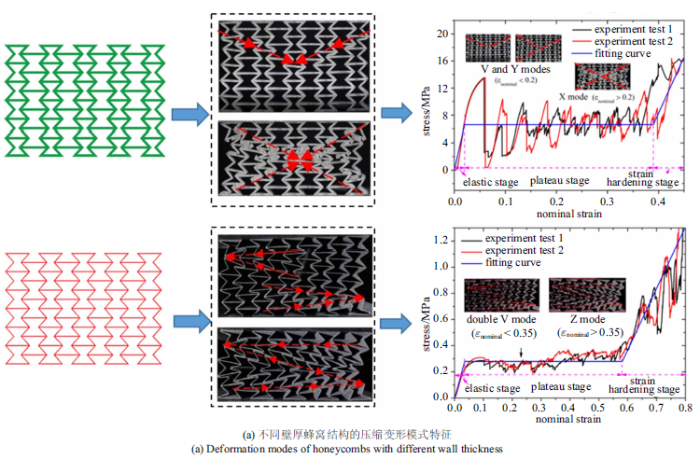

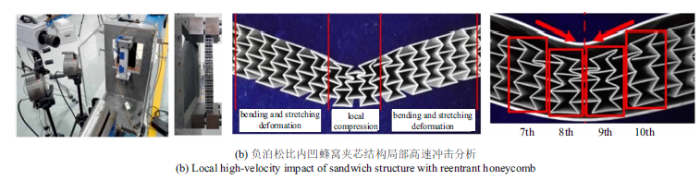

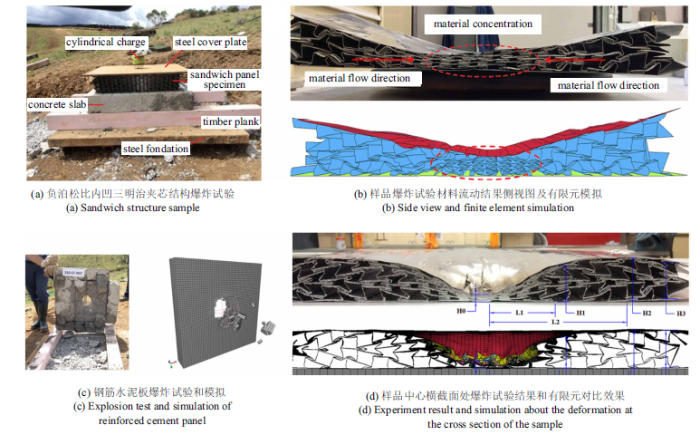

传统材料在承受冲击载荷的时候会发生压缩,垂直于冲击载荷的方向上会向承受冲击的部位四周膨胀;而负泊松比材料在受冲击载荷影响下向冲击部位收缩, 材料的局部密度因此增大.该现象使得负泊松比材料能够吸收部分冲击产生的能量,从而发挥更有效的抗冲击作用. 在所有负泊松比蜂窝结构类型中,内凹六角形蜂窝的构型相对简单且具有代表性. 因此,许多研究人员分别基于数值模拟和理论分析方法相结合的思路研究内凹六边形蜂窝结构的压缩变形行为和吸能规律[121-132].Mukhopadhyay和Adhikari[121]建立分析理论模型用于预测结构不规则对内凹蜂窝结构的面内弹性模量和泊松比特性的影响规律.Boldrin等[122]讨论了具有梯度结构特征的六角形内凹蜂窝结构的动态力学行为,发现具有特定梯度结构的内凹蜂窝能够表现出动态吸能特性的梯度几何形状敏感性.Xiao等[123]对梯度增材制造内凹六角形蜂窝开展了压缩变形行为实验分析,发现梯度结构内凹蜂窝结构在压缩过程中呈现出V型和I型变形模式.Harkati等[124]提出基于势能理论的内凹蜂窝结构力学性能精细分析模型,并在模型中考虑了细胞壁的变形机理.Zhang等[125]建立有限元模型用于揭示胞元几何形状对内凹蜂窝的变形模式和压缩过程中的峰值应力、平台应力等结构吸能特性的影响规律.结果表明, 内凹蜂窝在低速压缩下的变形模式类似于常规正泊松比蜂窝[126],负泊松比蜂窝在最终致密化之前会表现出不一样的V型和X型失效模态.Hou等[127]通过采用理论模型和数值模拟方法相结合,研究了内凹蜂窝的冲击变形规律,发现负泊松比内凹蜂窝的冲击应力大于常规六边形蜂窝的冲击应力. 另外,在准静态压缩过程中, 蜂窝主要表现出V型变形模式, 而没有X型变形模式发生.Liu等[128]研究了内凹六边形蜂窝结构的能量吸收特性,发现由于发生致密化阶段的临界压实应变提前,内凹六边形蜂窝在相同的压缩应变下会比常规蜂窝吸收更多的冲击能量.通过理论、实验和有限元分析相结合,许多研究人员[129-130]研究了内凹蜂窝结构在大变形条件下的应力应变曲线、冲击峰值应力、平台应力的变化规律.基于有限元模拟分析技术,Hu等[131]研究了负泊松比蜂窝的胞元构型对其压缩过程中的收缩变形行为的影响规律.此外, Hu等[132]通过有限元分析发现,负泊松比内凹蜂窝结构的变形模式类似于传统蜂窝结构,并发现负泊松比内凹蜂窝在模拟中会在样品边界处表现出局部膨胀和收缩变形行为.Lee等[133]设计了内凹负泊松比蜂窝筒体,开展了相关冲击吸能实验和有限元分析,并与传统正泊松比蜂窝的冲击吸能特性进行比较.通过结合实验方法、理论分析和有限元计算,Dong等[134-137]针对内凹负泊松比结构的静动态力学性能、负泊松比夹芯结构的冲击动力响应问题,研究了具有不同孔壁厚度的负泊松比内凹六角形蜂窝在准静态压缩下的压缩行为,探讨了负泊松比内凹蜂窝的变形模式和胞元几何特征(胞元数目、胞元壁厚度等)之间关系,以及负泊松比对压缩应力和能量吸收效率的影响规律. 研究结果表明:具有厚壁的内凹负泊松比蜂窝结构胞元会发生破裂并朝着三明治夹芯板外部爆炸载荷中心区域移动,左右边界发生收缩并产生三种变形模式, 即: 垂直V和X模式. 与厚壁胞元不同,薄壁蜂窝在左右边界上均表现出局部收缩和膨胀特征,从而导致水平双V模式和Z变形模式, 如图11(a)所示. 此外,负泊松比效应对压缩平台应力阶段的应力水平影响不大,在应变硬化阶段则具有明显效应. 对于具有厚壁的负泊松比蜂窝来说,与压缩过程中的塑性应变能相比, 其弹性应变能和断裂能所占比例可以忽略. 然而,对薄壁蜂窝来讲, 弹性应变能对于三明治夹芯板结构的冲击吸能能力的贡献不可忽略,需要充分考虑. 其次, 通过发现负泊松比结构高速压缩下存在新的收缩变形机制,开展了动态压缩理论分析; 基于实验和数值相结合,研究了内凹负泊松比蜂窝夹芯梁和夹芯拱结构在高速爆炸冲击波作用下的动力学响应特性.结果表明, 内凹负泊松比蜂窝胞元并非一直发生收缩变形、流向加载中心,同时内凹负泊松比蜂窝芯质也会发生局部膨胀变形, 如图11(b)所示.内凹六边形负泊松比蜂窝结构在受到爆炸载荷作用时,其内部结构单元会发生塑性大变形实现能量吸收. 此外, 由于具有负泊松比效应,内凹六边形蜂窝材料会向外部爆炸载荷中心作用区域流动聚集,可以进一步增强结构的能量吸收能力,在爆炸防护结构、轻质装甲防护结构等方面具有优异的应用前景. 如图12所示,裴连政等[138-139]设计并加工了内凹六边形蜂窝夹芯三明治复合板,并通过开展场地爆炸实验和有限元分析对比研究其对混凝土结构的爆炸防护效果.传统混凝土结构的实验和模拟结果如图12(c)所示,作为与新型负泊松比结构防护效果对比的参考样品. 研究结果表明:铝制的内凹六边形负泊松比夹芯板在场地爆炸实验中表现出了良好的抗爆性能,有效地保护了位于夹芯板背爆面的混凝土板, 混凝土结构没发生贯穿破坏.当结构单元壁厚小于等于0.5 mm时, 夹芯板在爆炸过程中会出现致密化现象;当结构单元壁厚大于0.5 mm时, 夹芯板在爆炸过程中不会出现致密化现象.当夹芯板出现致密化现象时,可以通过增大结构单元壁厚来实现夹芯板的比吸能增大并能降低全局最大峰值力;当夹芯板未出现致密化现象时, 可以通过増加结构单元壁厚,实现夹芯板的比吸能减小而全局最大峰值力的增大.图11

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图11内凹六边形蜂窝结构实验[134-137]

Fig. 11Sandwich structure with reentrant hexagonal honeycomb[134-137]

图11

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图11内凹六边形蜂窝结构实验[134-137](续)

Fig. 11Sandwich structure with reentrant hexagonal honeycomb[134-137] (continued)

图12

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图12内凹六边形负泊松比夹芯板在场地爆炸实验[138-139]

Fig. 12Blasting experiment of the sandwich panel with reentrant honeycomb core[138-139]

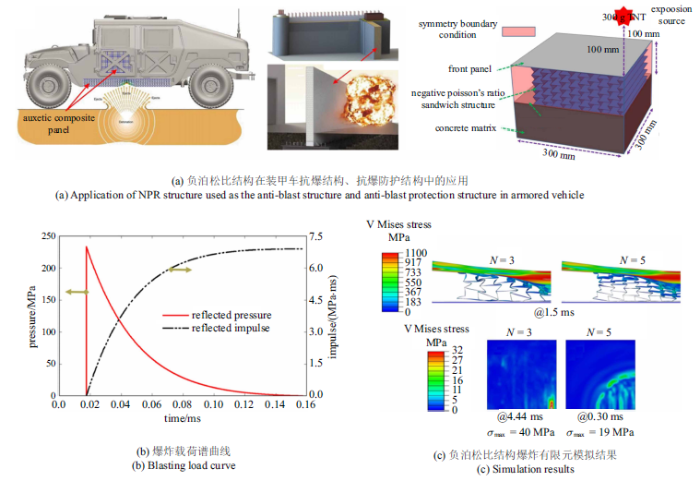

基于Reid和Peng等[140]提出的一维冲击波理论,Imbalzano等[141-142]采用数值模拟方法研究了负泊松比夹芯板结构在高速冲击压缩下作用下的动力学行为和失效机理,采用Johnson-Cook模型描述结构在高应变率载荷作用下的动力响应.进一步基于胞元几何尺寸的解析模型推导了夹芯板在不同冲击速度下的抗压强度,并评估不同夹芯板在外部脉冲载荷下的力学性能. 模拟结果显示:负泊松比夹芯板在外部脉冲载荷作用下,通过将四周材料拉入载荷作用中心局部区域来有效地增强局部抵抗外部冲击的能力,从而增强了负泊松比三明治夹芯板的抗冲击性能.而常规蜂窝板只是整体发生塑性变形, 并没有出现局部刚度增强效应, 如图13所示.

图13

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图13内凹负泊松比夹芯板强脉冲载荷下的变形模拟[141-142]

Fig. 13Deformation simulation of sandwich panel with NPR core[141-142]

针对手性超结构的面外力学性能和抗冲击吸能特性,Lorato等[143]给出了三韧带手性/反手性、四韧带手性/反手性和六韧带手性结构的离面力学性能的解析解,主要包含: 离面弹性模量、Voigt和Reuss等效离面剪切刚度范围等特性.基于薄板和壳体线性屈曲经典解析解,Spadoni等[144]研究并比较了三韧带手性超结构、拉胀结构、六边形蜂窝结构的离面力学性能,发现三韧带手性超结构的整体和局部屈曲临界载荷均高于具有相同面密度的拉胀材料和蜂窝材料.Miller等[145]分别采用解析解和有限元模拟技术研究了四韧带手性超结构和六韧带手性超结构的离面力学性能,发现韧带对圆环角点结构的失效具有强化效应, 能够提升手性超结构的整体屈曲强度.Airoldi等[146]制备、测试并比较了塑料和碳纤维树脂基复合材料手性超结构在轴向低速冲击下的失效模式和能量吸收效率.Scarpa等[147]采用3D打印技术制备了六韧带塑料手性超结构,并研究了结构在离面载荷作用下的线弹性曲屈行为,发现手性超结构的圆环角点变形模式和独立中空圆柱的轴向压溃变形模式类似,仅仅是圆环局部体现高阶半波长变形特征,韧带则对手性超结构的整体失效具有强化效应.

4 负泊松比材料及结构在汽车轻量化设计领域应用

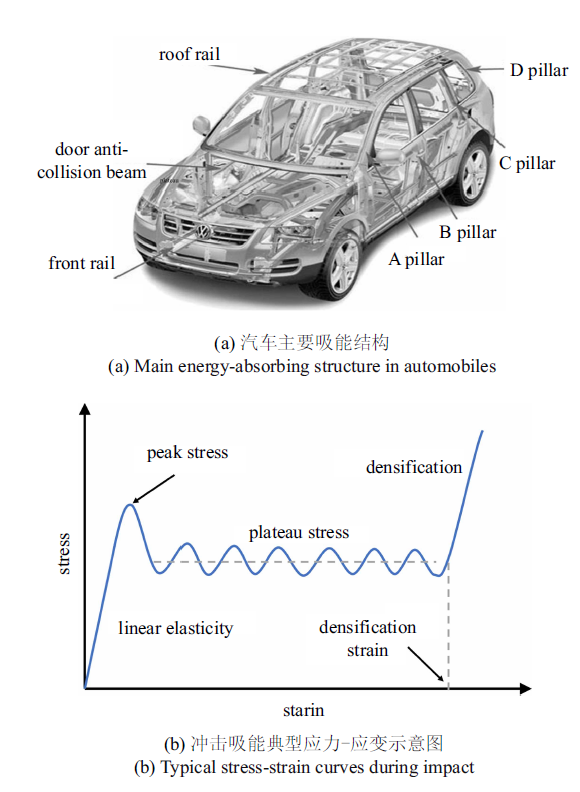

4.1 汽车轻质结构吸能指标

如图14(a) 所示, 现代汽车中的安全带、气囊、保险杠系统、吸能盒、A 柱、B 柱、C柱、车顶纵梁、发动机罩等先进结构在正面碰撞、侧面碰撞和追尾碰撞事故中发挥着能量吸收和保护乘员和行人等重要作用.为有效评价汽车主要吸能结构的抗冲击吸能效果, 提升结构安全防护效果,需要针对冲击压缩过程中应力-应变曲线(或者力-位移曲线)进行定量化的分析,并提取相应的吸能特性评价指标, 主要包括: 峰值应力, 平台应力, 总吸能, 比吸能,冲击吸能效率[148], 如图14(b) 所示.图14

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图14汽车结构主要吸能构件, 以及轻质材料与结构吸能性能指标

Fig. 14Main energy-absorbing components of automobile structure, aswell as the energy-absorbing performance indicators of lightweight materialsand structures

通常, 轻质材料与结构在压缩过程中的应力应变曲线可以划分为三个区域, 包括:初始弹性区、应力平台区和应力迅速提升的密实化区.碰撞法向应力和应变可以表达为

其中, $F$是压缩力, $A$是结构的初始横截面面积, $\delta $是碰撞引起的结构位移量,$\delta _{0} $是吸能结构的初始长度. 平台应力$\sigma_{m}$是应力-应变曲线平台阶段的平均值, 可以通过如下公式进行计算

其中, 应变$\varepsilon_{y} $是屈服应变, 对应着峰值应力$\sigma_{p} $. 密实化应变$\varepsilon_{d}$可以通过压缩应力应变曲线和如下公式获得

结构在冲击过程中吸收的总能量$EA$可以表示为吸能过程中压缩位移的函数, 对应力-位移曲线所围成的面积, 可以写成

其中, $\delta $是压缩过程的轴向位移, $F\left( \delta \right)$代表轴向冲击载荷.

平均冲击载荷是与结构吸收外部冲击能量所需要的轴向位移量相关的吸能指标, 通过总体吸收能量$EA\left( \delta \right)$除以结构轴向变形量$\delta $得到

比吸能 (SEA)是指单位质量的吸能结构所吸收的冲击能量, 可以表达为

其中, $M$是吸能结构的重量, $U_{V} $单位体积材料的吸能能力, 并可以通过$U_{V}={U}/{V}=\int_0^\varepsilon {\sigma \left( \varepsilon \right){d}\varepsilon}$进行计算. 比吸能越高, 代表结构吸能能力越强. 为了比较不同工程结构的吸能特性, 结构吸能效率(CLE)指标较为合理, 可以表达为

其中, $PCL$代表着结构在冲击过程中的峰值冲击力, 并定义为

其中, $F\left( \delta \right)$代表着冲击过程中的力的大小. 通常,工程师倾向于选择具有更高冲击吸能效率指标$CLE$的结构来实现更好的碰撞防护性能.吸能结构需要由峰值应力来触发结构塑性变形冲击吸能过程,工程师们会根据不同的吸能结构设计出不同触发机制来引导整个结构的吸能过程,进而提高结构的吸能效率和碰撞冲击防护效能.

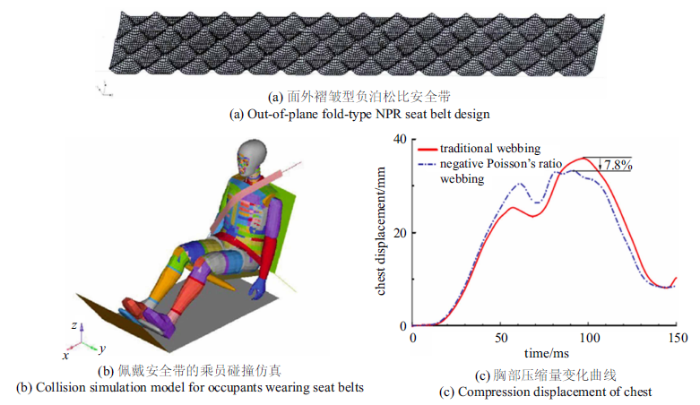

4.2 负泊松比安全带

安全带是汽车、公共交通、民用航空、战斗机等先进运载车辆及装备上最常用的安全防护设施,可以有效保护驾驶员和乘员的生命财产安全.安全带主要有编织防护带、锁扣、功能调控组件及相关固定结构件等构成,通过及时响应外部的碰撞事故或者紧急刹车状况,稳步拉紧编织防护带将驾驶员和乘员“束缚”在座椅上,避免头部、胸部等关键身体部分撞击到汽车结构件,也可以避免驾驶员或者乘员被甩尾脱离座椅、甚至甩出车外, 危及生命安全. 然而,传统的正泊松比安全带在汽车碰撞事故中越勒越紧, 安全带受力面积减小,乘员或驾驶员身体受力急剧上升, 容易造成骨折等机械伤害.为了有效缓解安全带勒紧过程中应力急剧上升问题,可以通过利用负泊松材料与结构在拉紧过程中的拉胀变形特征增大人体有效受力面积,实现受力分散或者应力水平降低.如图15所示, 安文姿等[149-150]提出了通过面外褶皱结构设计实现负泊松比特性的安全带织带设计方法,建立了包含人体胸部简化结构的安全带-乘员耦合有限元分析模型,分析了负泊松比安全带织带设计对乘员安全的保护效能,进一步讨论了负泊松比值调控范围、安全带-乘员系统的摩擦系数对负泊松比织带保护效能的影响规律.有限元模拟分析结果如下: 负泊松比褶皱结构在安全带拉紧过程中宽度会增大,有利于扩大乘员胸部受力面积, 能够在发生膨胀事故时有效减小乘员胸部压缩量;随着负泊松比值的进一步变小, 安全带织带在拉进过程中的接触宽度会迅速增大,可以大幅提升接触受力面积, 减少乘员胸部压缩量. 此外,负泊松比安全带与乘员胸部受力部位之间的摩擦力会阻碍织带在宽度方向充分展开,弱化了织带的负泊松比变形效应, 降低了安全带的真实保护效能.

图15

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图15负泊松比安全带设计[149-150]

Fig. 15NPR seat belt design[149-150]

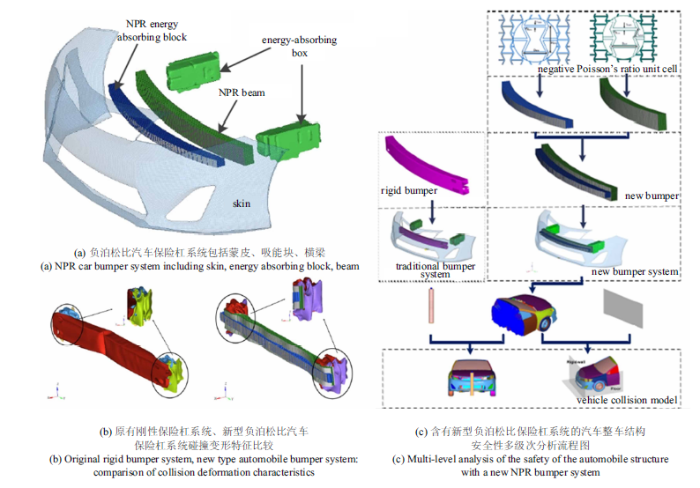

4.3 负泊松比汽车保险杠系统及碰撞吸能盒设计

汽车前保险杠系统在汽车正面碰撞事故中,主要起到吸收碰撞动能、保护行人身体和生命安全,以及降低交通事故经济损失等作用. 在保险杠系统设计的过程中,需要考虑结构耐撞性、碰撞能量吸收、对行人小腿保护效果和轻量化设计等不同方面的性能和指标要求,可以在低速碰撞条件下通过自身的连续塑性变形吸收碰撞动能,减低对行人下肢的冲击损伤, 有效保护行人生命安全. 如图16所示,通过利用负泊松比结构的协同变形特征和吸能效率优势,王崴崴等[151-152]提出了一种由负泊松比夹芯横梁结构和吸能块组合成的新型保险杠结构协同设计方法,建立参数化建模保险杠系统碰撞吸能分析与性能优化模型,并可以在模型中进一步嵌入行人小腿模型以及整车碰撞系统模型,开展行人小腿保护效果分析, 并基于行人安全、结构力学的多学科协同优化设计技术,实现新型负泊松比保险杠系统的结构吸能特性的最优化设计. 研究结果表明:所设计的新型负泊松比保险杠复合结构充分利用保险杠系统横梁和保险杠蒙皮之间的空置区域,提高了保险杠系统在和行人发生碰撞时对行人小腿的保护作用.图16

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图16新型负泊松比汽车保险杠系统设计及整车性能分析[151-152]

Fig. 16New design of NPR car bumper system and the analysis of its performance[151-152]

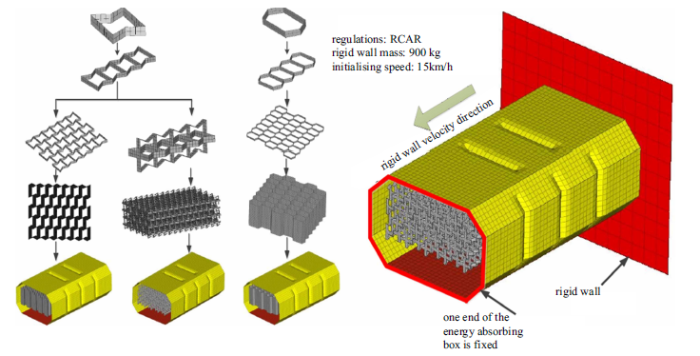

汽车碰撞吸能盒通常被设计成薄壁结构形式, 安装在汽车前段防撞梁和车体纵梁之间,可以在汽车发生碰撞时有效吸收碰撞能量. 在进行汽车吸能盒设计时,较为理想的吸能盒应拥有较大的平均碰撞力和总吸能能力,且要求峰值碰撞力不能超过设计允许值. 近年来,通过利用负泊松比材料与结构的独特变形机理和吸能模式,科研人员提出新型负泊松比吸能盒结构设计方法,可以改善传统薄壁管保险杠和吸能盒的吸能特性. 和传统吸能盒相比,负泊松比吸能盒具有更大的刚度, 中速碰撞下拥有更明显的能量吸收优势,可以为汽车碰撞能量吸收和乘员加速度下降过程提供更长的缓冲时间,其吸能能力、吸能效率等指标均优于传统吸能盒.王陶[153]研究了由负泊松比内凹蜂窝胞元构成的薄壁吸能盒结构的吸能特性,开展理论分析、有限元模拟和冲击吸能实验的对比验证,应用于汽车吸能盒结构设计和性能优化. 随后,通过结合某商用车型进行结构耐撞性分析,发现负泊松比吸能盒结构可以显著改善该车型在正面碰撞中的被动安全性能.研究结果表明: (1) 所设计的新型负泊松比吸能盒在低速碰撞时,吸收相同的碰撞能量所需要的压溃行程及时间均小于传统吸能盒结构;负泊松比结构吸能盒的平均碰撞力、能量吸收能力和吸能效率均优于传统吸能盒;此外, 负泊松比吸能盒的峰值应力较高、平台应力相对偏低,在进一步提升乘员安全防护效果方面具有一定局限. (2)开展了负泊松比吸能盒结构吸能特性的多学科协同优化设计,实现结构的比吸能最大化. 如图17所示,通过利用具有双箭头结构特征的负泊松比胞元的变形特征,张伟等[154-156]提出了一种具有负泊松比效应的汽车前纵梁吸能盒结构,并分析压溃过程中的应力平台区的胞元失效模式和平台应力.周冠[157]分别在给定初始速度、恒定碰撞速度和整车正面碰撞3种工况下,分析和比较了具有双箭头胞元特征的负泊松比结构吸能盒、传统吸能盒和泡沫铝填充吸能盒的吸能特性,主要包括: 能量吸收、碰撞力、比吸能、压溃位移等主要吸能指标. 随后,进一步开展吸能盒内双箭头形负泊松比胞元几何拓扑结构优化设计,并将比吸能(SEA)和最大碰撞力(PCF)作为负泊松比吸能盒结构优化目标函数,实现了新型负泊松比结构(双箭头型)的最优化拓扑、形状和厚度设计,成功实现了某车型负泊松比结构吸能盒的多目标优化设计.

图17

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图17新型双箭头负泊松比结构吸能盒模型[156]

Fig. 17Double-arrow NPR structure energy-absorbing box[156]

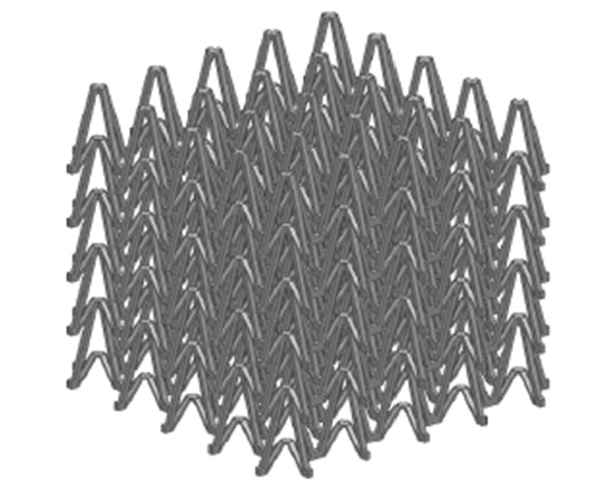

如图18所示, 为了改善传统吸能盒的缺点,邹松春[158]通过利用负泊松比结构的质量轻、吸能效果好、缓冲特性优良等优点,将其填充在传统吸能盒中来改善吸能盒的耐撞性能,从而降低乘员在碰撞过程中受伤害的程度. 研究发现:采用三维负泊松比胞元填充的吸能盒具有较大的总吸能和平均碰撞力,以及较小的压缩位移, 有利于提升吸能盒的耐撞性能.

图18

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图18三维负泊松比吸能盒设计[158]

Fig. 18Three-dimensional NPR energy-absorbing box[158]

通过利用具有双箭状胞元结构特征的独特变形模式产生负泊松比效应,Ma等[159-163]开发了新型负泊松比吸能盒,建立了负泊松比参数化优化模型提高结构吸能效率, 并与传统有限元模型进行比较,验证了参数化模型的准确性,通过与传统防撞箱和泡沫铝填充吸能盒进行吸能性能比较来研究负泊松比吸能盒的吸能性能优势.进一步建立了负泊松比吸能盒的多目标优化模型,开展吸能盒结构优化和吸能性能优化分析.

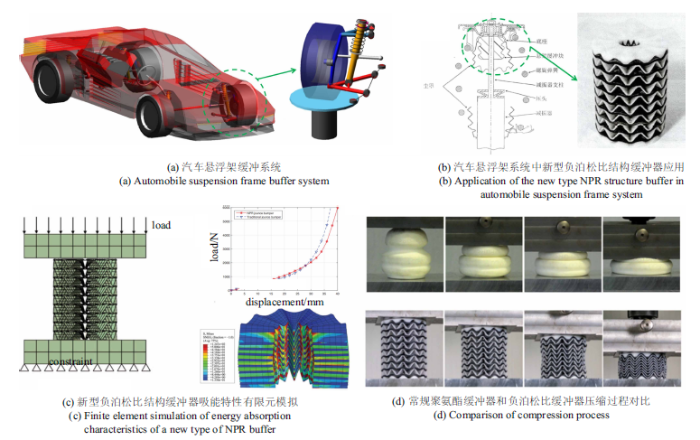

4.4 汽车悬架缓冲吸能结构

汽车悬架在外部冲击载荷作用下的力学性能对于车辆的操纵稳定性、行驶平顺性和安全性至关重要.汽车悬架结构中的悬架缓冲块通常由聚氨酯材料制备而成,发挥着限位、缓冲、阻尼、辅簧等作用.汽车悬架结构设计要求缓冲块的载荷-位移曲线应满足初始段刚度和曲线过渡区域的双重要求.传统缓冲块的载荷-位移曲线过渡区域通常难以很好满足上述要求,其应力-应变过渡区域常常提前发生, 初始阶段应力幅值偏低,且会出现后过渡区的应力水平快速增长等问题,导致过渡区前后阈值偏离理想缓冲区域范围, 限制了汽车行驶平顺性的提升潜力.负泊松比材料/结构具有优异的冲击吸能、减震降噪等特性,在提升悬架结构综合性能方面具有广泛的应用潜力.如图19所示,王源隆等[164-169]提出了基于双箭状负泊松比结构的新型悬架缓冲结构设计方法,并以缓冲块的载荷-位移目标曲线和典型凸台障碍物环境下整车加速度峰值作为结构优化目标,对负泊松比缓冲块冲击响应性能优化,并进行了整车驶过凸台路面和凹坑路面的平顺性分析. 结果表明:优化后的缓冲块设计能够实现在典型凹凸不平脉冲路面环境下整车行进的平顺性的提升,显著降低了整车加速度峰值, 提高整车在复杂路面环境下的行驶平顺性.

图19

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图19新型负泊松比汽车悬浮架缓冲吸能块的力学设计及吸能特性[164]

Fig. 19Mechanical design and energy absorption characteristics of the NPR automobile suspension frame buffer energy absorption block[164]

4.5 负泊松比汽车B柱侧面碰撞冲击吸能

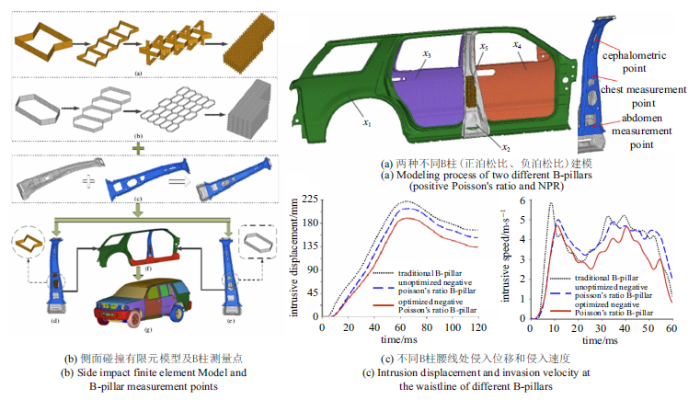

汽车B柱起到支撑车体空间结构,在车翻或者侧撞事故中起到支撑车体空间、吸收碰撞冲击能量和保护乘员免受严重机械变形挤压的作用[170].在汽车侧面碰撞测试标准中,将B柱中部的侵入速度和侵入量作为评价侧面碰撞安全的重要指标.董庆战等[171-172]将泡沫铝材料填充在汽车 B柱内来提升其在侧面碰撞过程中的碰撞能量吸收能力,从而提高了车辆的耐撞性和安全性. 如图20所示,邹松春等[158]基于RCAR法规和ECE R95法规,分别对传统结构B柱和负泊松比B柱结构进行侧碰撞吸能特性研究. 结果表明:所设计的负泊松比结构填充B柱可以有效减少传统B柱结构的侧面碰撞侵入位移和侵入速度.最后, 基于非支配排序遗传算法对负泊松比B柱结构的吸能效果进行优化,进一步提升了负泊松比B柱结构的侧面碰撞条件下的耐撞性能.图20

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图20含有负泊松比填充芯层新型汽车B柱设计及性能分析[158]

Fig. 20Design and performance analysis of a new automobile B-pillar with a NPR filled core layer[158]

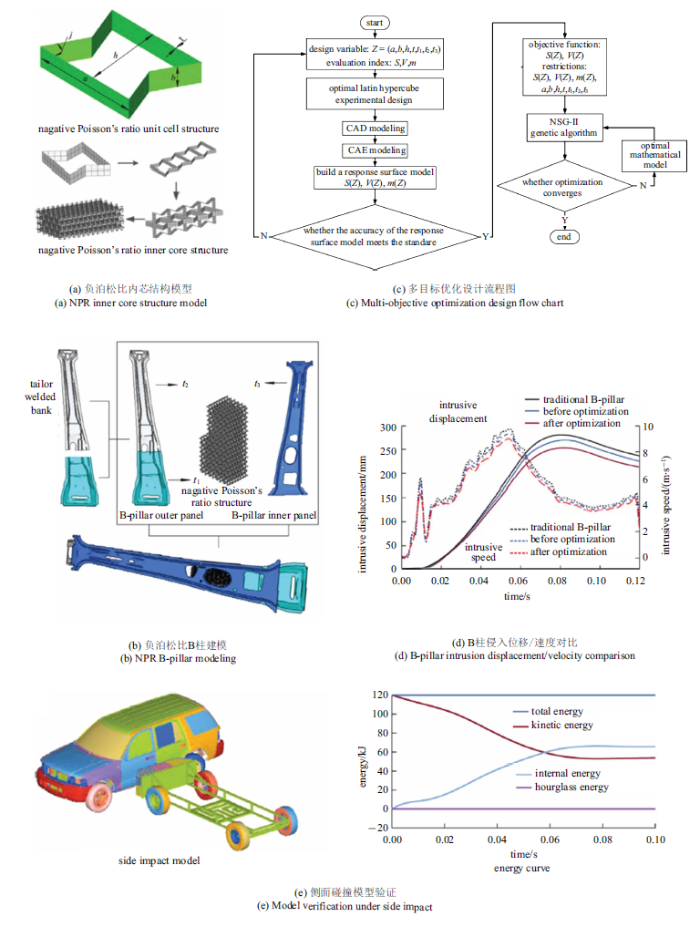

如图21所示, 在传统B柱基本结构基础上,赵万忠等[173]提出了一种负泊松比芯质填充的新型B柱结构.根据我国新车评价规程C-NCAP要求, 建立基于新型B柱结构的整车侧面碰撞有限元模型,并以B柱侵入位移和侵入速度为优化目标,采用NSGA-II优化算法对新型B柱结构进行多目标优化设计. 结果表明:新型负泊松比填充B柱结构可以实现整车侧面碰撞的侵入位移和侵入速度的明显降低,进而显著改善汽车的侧面耐撞性能[173].

图21

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图21负泊松比B柱防侧面碰撞冲击吸能研究[173]

Fig. 21Impact energy absorption characteristic of NPR B-pillar against side impact[173]

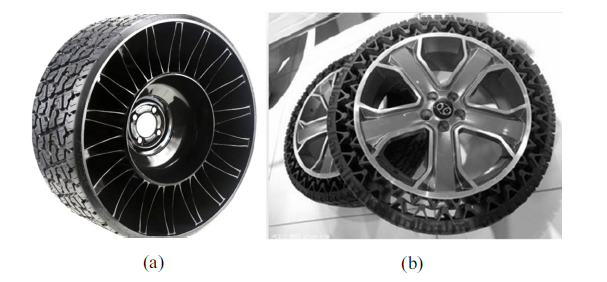

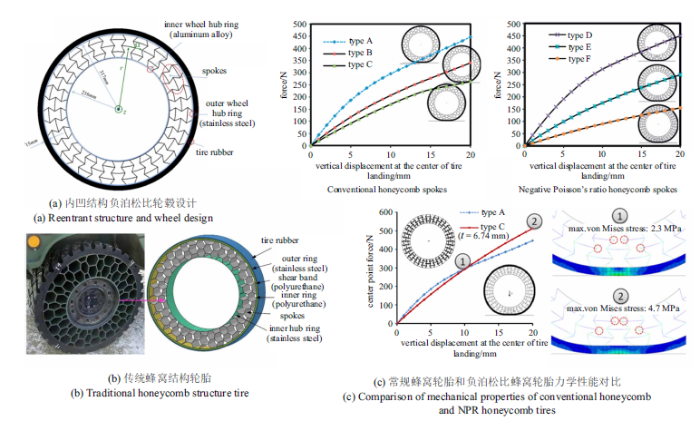

4.6 负泊松比免充气轮胎

非充气轮胎有不爆胎、耐磨损、减震性好、承载能力强、智能可操纵性好等优势,将会给自行车、家用轿车、卡车等交通工具带来全新的使用理念. 19世纪20年代,美国发明家詹姆斯$\cdot$马丁率先发明了免充气轮胎,并申请相关专利. 在免充气轮胎发展过程中,最为著名的是米其林美洲研发中心在1997年设计开发出TWEEL免充气子午线轮胎,并在2005年成功推出TWEEL免充气轮胎样胎, 如图22(a)所示. 近年来,随着非充气轮胎设计理念的发展, 工程师们提出利用负泊松比结构受压收缩的特性将其应用于汽车免充气轮胎设计,进而实现不同路况和驾驶方式下的主动控制及针对性适应. 如图22(b)所示,密歇根大学机械工程系马正东教授和北汽集团在2014年合作开发了一种新型负泊松比免充气轮胎,这种防爆免充气的轮胎可以保证汽车始终处于最佳行驶状态.图22

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图22(a) 米其林开发的TWEEL免充气轮胎; (b) 北汽新能源开发的负泊松比免充气轮胎

Fig. 22(a) TWEEL non-pneumatic tire developed by Michelin;(b) non-pneumatic tire developed by BAIC New Energy company

免充气轮胎的辐条在循环拉伸压缩载荷下必须具有可靠的整体刚度和优异的变形回弹特性.材料高模量、刚度和回弹力是相互矛盾的, 常规材料难以满足需求,但是可以通过蜂窝胞元构型设计和几何优化来克服这些固有的矛盾. 如图23所示,Ju等[174]提出了采用负泊松比蜂窝轮辐的免充气轮胎代替传统充气轮胎的设计方法,并开展相关刚度、接触力、蜂窝变形特征模拟分析, 研究结构表明:负泊松比蜂窝几何结构尺寸设计是免充气轮胎的面内柔韧性的关键因素,可以通过调节负泊松比蜂窝角度来实现免充气轮胎的接触面积的有效调控,进而改变地面接触力的分布, 也可以优化轮胎的抗疲劳性能.

图23

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图23负泊松比免充气轮胎[174]

Fig. 23NPR pneumatic tire[174]

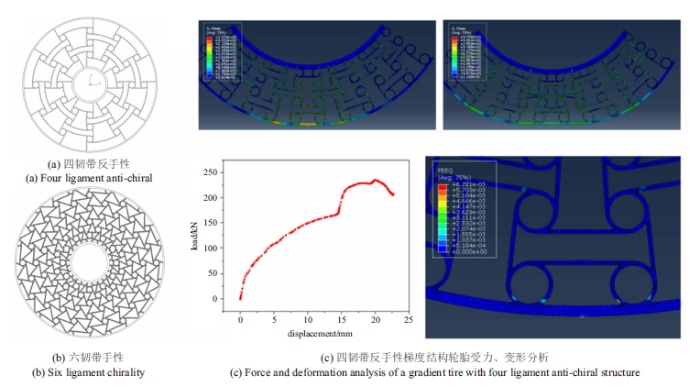

如图24所示, Wu等[175]开展了具有手性胞元夹芯的非充气轮胎力学设计,并通过有限元模拟研究了其力学性能. 结果表明,梯度四手性结构胞元与基于梯度结构的免充气轮胎在变形模式上具有一定的相似性,具有梯度反四手性结构的非充气轮胎具有良好的承载能力, 具有广阔的工程应用潜力.

图24

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图24手性超结构免充气轮胎力学设计及性能分析[175]

Fig. 24Mechanical design and performance analysis of a chiral meta-structure non-pneumatic tire[175]

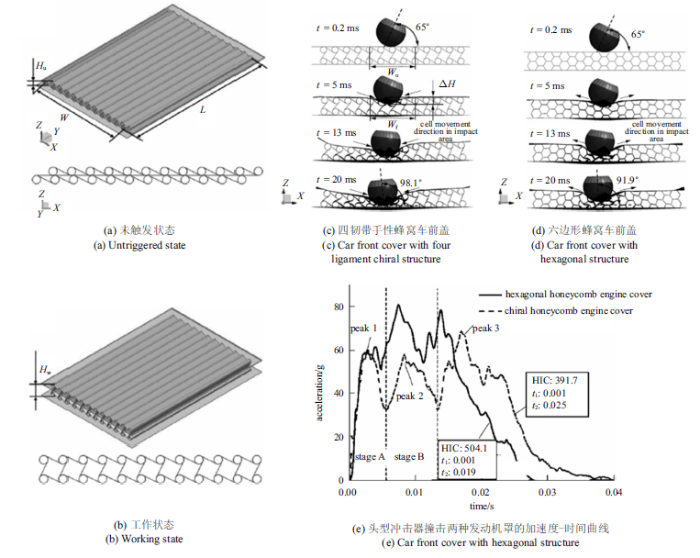

4.7 负泊松比汽车发动机罩行人保护设计

行人安全保护一直是汽车安全的重要内容, 而行人在与汽车发生碰撞时,头部伤害的特殊性以及大概率的致死性使得行人头部保护成为行人安全保护的重中之重.碰撞安全设计要求较高的汽车,要求发动机罩能够充分吸收碰撞过程中行人头部的冲击能量,进而可以降低对行人头部的损伤.为了提高汽车发动机罩在碰撞过程中对行人头部的保护效能,国内外的研究机构和相关****对发动机罩的结构进行了大量的研究与探索,并提出了多种基于新材料和新结构技术的新型发动机罩.特别是具有新型轻质夹层材料与结构芯层的发动机罩,能够通过芯层结构的设计和优化实现吸能能力和吸能效率的优化,在保护行人头部具有巨大的应用潜力[176].通常可以采用HIC值来比较和评价不同构型的发动机罩设计对行人头部的保护效果.为了有效降低行人头部与汽车发动机罩相撞过程中的峰值应力,并延长碰撞相互作用过程的脉冲行程, 进而有效降低HIC数值,清华大学周青教授研究团队在国内率先开展新型发动机罩夹层结构设计、制造和行人头部保护效果评价研究[177].

如图25所示, 通过利用韧带弯曲吸收弹性能的特性,杨姝等[178]提出新型手性夹芯结构发动机罩设计理念,通过利用手性结构的负泊松比吸能特性和弯曲-旋转耦合变形机理来吸收碰撞动能,可以有效保护行人头部.结果表明手性夹芯结构发动机罩在受到行人头部撞击时韧带首先发生弯曲和圆环旋转变形、然后出现圆环屈曲、压溃和层叠,可有效降低行人头部的HIC值.

图25

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图25手性负泊松比汽车发动机罩行人保护性能分析[149]

Fig. 25Pedestrian protection performance analysis of car hood with NPR chiral structure[149]

5 负泊松比结构在车辆结构中工程应用展望

综上所示, 可以看出负泊松比结构在汽车结构多功能化方面具有巨大应用潜力,目前还处于工业应用的初期, 应用开发还比较有限.为了推动负泊松比结构在汽车工业中的进一步发展,需要在如下几个方面开展系统深入研究:(1) 各类负泊松比结构的力学行为、变形机理、冲击吸能特性以及减震降噪机理有待进一步深入理解,需要开展相关理论和实验研究.

(2) 需要针对各类负泊松比结构的大规模、低成本制造技术和工艺优化开展系统研究,比如金属增材制造、复合材料成型工艺、机械切割组装、铸造、焊接等制造工艺.

(3) 目前, 负泊松比结构在汽车吸能盒,B柱、发动机罩、安全带、悬架、免充气轮胎方面的应用研究还是零碎的,难以得到较为全面的结论. 因此,需要针对负泊松比结构在这些典型汽车结构件上的应用开展系统研究.

(4) 基于负泊松比结构在汽车应用的结构优化研究工作还比较少, 优化方法较为局限.需要结合人工智能、多学科多目标拓扑优化方法、大数据等技术, 开展深入研究,进一步优化其性能.

(5) 目前,针对负泊松比结构在汽车安全气囊、天窗、新能源电池箱体等结构方面的应用研究还很少,可以进一步拓展负泊松比在这些结构方面的应用潜力.

(6)可以进一步将负泊松比结构和智能材料(形状记忆合金、形状记忆聚合物、介电弹性体、铁电材料、磁流变材料等)结合,实现汽车结构的智能化应用. 比如:设计出负泊松比形状记忆免充气轮胎来实现崎岖路面的平稳行进,负泊松比自适应形状记忆汽车后视镜来提高驾驶安全性、智能形状记忆负泊松比天窗来维持车内温度恒定等.

6 总结

本文首先分别从负泊松比的概念、负泊松比泡沫材料及复合材料、典型负泊松比结构设计方法、负泊松比结构的冲击吸能特性角度系统论述负泊松比材料与结构的力学设计方法和性能优势.其次通过负泊松比结构在车辆典型结构件中的应用,来展示负泊松比结构设计的巨大优势.最后对负泊松比结构在车辆工业中的应用前景进行了展望,并剖析了负泊松比结构在车辆工业应用所面临的技术开发难题和巨大机遇.参考文献 原文顺序

文献年度倒序

文中引用次数倒序

被引期刊影响因子

[本文引用: 5]

[本文引用: 2]

[本文引用: 1]

[本文引用: 1]

DOIURLPMID [本文引用: 1]

A novel foam structure is presented, which exhibits a negative Poisson's ratio. Such a material expands laterally when stretched, in contrast to ordinary materials.

[本文引用: 1]

[本文引用: 8]

DOIURLPMID [本文引用: 1]

In comparing a material's resistance to distort under mechanical load rather than to alter in volume, Poisson's ratio offers the fundamental metric by which to compare the performance of any material when strained elastically. The numerical limits are set by (1/2) and -1, between which all stable isotropic materials are found. With new experiments, computational methods and routes to materials synthesis, we assess what Poisson's ratio means in the contemporary understanding of the mechanical characteristics of modern materials. Central to these recent advances, we emphasize the significance of relationships outside the elastic limit between Poisson's ratio and densification, connectivity, ductility and the toughness of solids; and their association with the dynamic properties of the liquids from which they were condensed and into which they melt.

[本文引用: 3]

URLPMID [本文引用: 5]

[本文引用: 3]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 3]

[本文引用: 3]

DOIURLPMID [本文引用: 3]

Designing structures that dilate rapidly in both tension and compression would benefit devices such as smart filters, actuators or fasteners. This property however requires an unusual Poisson ratio, or Poisson function at finite strains, which has to vary with applied strain and exceed the familiar bounds: less than 0 in tension and above 1/2 in compression. Here, by combining mechanical tests and discrete element simulations, we show that a simple three-dimensional architected material, made of a self-entangled single long coiled wire, behaves in between discrete and continuum media, with a large and reversible dilatancy in both tension and compression. This unusual behaviour arises from an interplay between the elongation of the coiled wire and rearrangements due to steric effects, which, unlike in traditional discrete media, are hysteretically reversible when the architecture is made of an elastic fibre.

[本文引用: 1]

[本文引用: 2]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 3]

DOIURLPMID

DOIURL

DOIURLPMID

Perforated systems with quasi-disordered arrays of slits are found to exhibit auxetic characteristics almost as much as their traditional ordered

DOIURL

Flat knitting is a widely used fabric manufacturing technology. Compared with warp knitting and circular knitting, flat knitting is characterized by its higher process flexibility and greater fabric structure variety. In this work, flat knitting technology was exploited to fabricate auxetic fabrics which laterally expand when stretched. Three kinds of geometrical structures, i.e. foldable structure, rotating rectangle and reentrant hexagon, were employed as basic reference structures for the development of these kinds of auxetic fabrics. The weft knitting processes based on these structures were specially developed and auxetic fabrics were fabricated using the computerized flat knitting machines. The Poisson's ratio-strain curves of the developed fabrics were plotted and compared with those calculated using existing models to demonstrate the variation trends of Poisson's ratio with the axial strain. The results reveal that except the folded fabric formed with the face loops and reverse loops in a rectangular arrangement, of which the auxetic effect firstly increases and then decreases with the axial strain, the auxetic effects of all other fabrics decrease with an increase of the axial strain. The work also shows that auxetic fabrics can be realized based on knitted structures and that flat knitting technology can provide a simple, but highly effective way of fabricating auxetic fabrics from conventional yarns.

URLPMID

DOIURLPMID

We investigate the unique mechanical properties of reentrant 3D origami structures based on the Tachi-Miura polyhedron (TMP). We explore the potential usage as mechanical metamaterials that exhibit tunable negative Poisson's ratio and structural bistability simultaneously. We show analytically and experimentally that the Poisson's ratio changes from positive to negative and vice versa during its folding motion. In addition, we verify the bistable mechanism of the reentrant 3D TMP under rigid origami configurations without relying on the buckling motions of planar origami surfaces. This study forms a foundation in designing and constructing TMP-based metamaterials in the form of bellowslike structures for engineering applications.

DOIURLPMID

Perforated systems with quasi-disordered arrays of slits are found to exhibit auxetic characteristics almost as much as their traditional ordered

[本文引用: 3]

[本文引用: 3]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 4]

[本文引用: 3]

URLPMID

URLPMID

DOIURLPMID

In this work, we investigate the deformation mechanism of auxetic hierarchical rotating square systems through a dynamics approach. We show how their deformation behaviour, hence their mechanical properties and final configuration for a given applied load, can be manipulated solely by altering the resistance to rotational motion of the hinges within the system. This provides enhanced tunability without necessarily changing the geometry of the system, a phenomenon which is not typically observed in other non-hierarchical unimode auxetic systems. This gives this hierarchical system increased versatility and tunability thus making it more amenable to be employed in practical application which may range from smart filtration to smart dressings.

[本文引用: 3]

[本文引用: 3]

[本文引用: 3]

[本文引用: 3]

[本文引用: 1]

[本文引用: 1]

[本文引用: 3]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 3]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

URLPMID [本文引用: 1]

[本文引用: 1]

URLPMID [本文引用: 1]

[本文引用: 1]

URLPMID [本文引用: 1]

[本文引用: 1]

[本文引用: 2]

[本文引用: 2]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 2]

[本文引用: 1]

[本文引用: 5]

[本文引用: 5]

[硕士论文].

[本文引用: 3]

[Master Thesis].

[本文引用: 3]

DOIURL [本文引用: 3]

DOIURL [本文引用: 1]

[本文引用: 3]

DOIURL [本文引用: 3]

[本文引用: 1]

DOIURL [本文引用: 1]

DOIURL [本文引用: 1]

AbstractThe flatwise compressive behaviour of tetrachiral and hexachiral honeycombs is analysed, using analytical and Finite Element simulations, both with explicit and implicit formulations. The tetrachiral and hexachiral cells are composed by cylinders connected by four and six tangent ligaments respectively. The ligaments act as mixed stiffeners-elastic foundations during flatwise compressive loading, providing different buckling mode shapes during deformation. The models are compared with experimental results obtained using RP-based honeycombs tested according to ASTM C 393-00 and ASTM C365-00.]]>AbstractThe flatwise compressive behaviour of tetrachiral and hexachiral honeycombs is analysed, using analytical and Finite Element simulations, both with explicit and implicit formulations. The tetrachiral and hexachiral cells are composed by cylinders connected by four and six tangent ligaments respectively. The ligaments act as mixed stiffeners-elastic foundations during flatwise compressive loading, providing different buckling mode shapes during deformation. The models are compared with experimental results obtained using RP-based honeycombs tested according to ASTM C 393-00 and ASTM C365-00.]]>AbstractThe flatwise compressive behaviour of tetrachiral and hexachiral honeycombs is analysed, using analytical and Finite Element simulations, both with explicit and implicit formulations. The tetrachiral and hexachiral cells are composed by cylinders connected by four and six tangent ligaments respectively. The ligaments act as mixed stiffeners-elastic foundations during flatwise compressive loading, providing different buckling mode shapes during deformation. The models are compared with experimental results obtained using RP-based honeycombs tested according to ASTM C 393-00 and ASTM C365-00.]]>AbstractThe flatwise compressive behaviour of tetrachiral and hexachiral honeycombs is analysed, using analytical and Finite Element simulations, both with explicit and implicit formulations. The tetrachiral and hexachiral cells are composed by cylinders connected by four and six tangent ligaments respectively. The ligaments act as mixed stiffeners-elastic foundations during flatwise compressive loading, providing different buckling mode shapes during deformation. The models are compared with experimental results obtained using RP-based honeycombs tested according to ASTM C 393-00 and ASTM C365-00.]]>

[本文引用: 1]

[本文引用: 1]

[硕士论文].

[本文引用: 1]

[Master Thesis].

[本文引用: 1]

[硕士论文].

[本文引用: 5]

[Master Thesis].

[本文引用: 5]

[本文引用: 3]

[本文引用: 3]

[硕士论文].

[本文引用: 3]

[Master Thesis].

[本文引用: 3]

[本文引用: 3]

[博士论文].

[本文引用: 1]

[PhD Thesis].

[本文引用: 1]

DOIURL [本文引用: 1]

提出了一种具有负泊松比效应的汽车前纵梁吸能盒(NPRC)结构, 通过对元胞平台区的失效模式和平台应力的分析, 研究了此结构在失效时的力学性能, 即等效弹性模量和平台应力在面内加载过程中均能得到一定程度的增强, 表现出较好的能量吸收能力。根据NPRC元胞在平台区的力学模型, 分别建立了发生弹性屈曲和塑性塌陷时的临界应力公式, 得出塑性塌陷是该结构的主要失效模式。通过Matlab程序建立了NPRC元胞的参数化有限元模型, 研究了元胞几何参数与平台应力的关系, 即元胞的平台应力与长度系数和元胞夹角呈反比, 与厚度系数呈正比。通过NPRC结构3×3样件的面内轴向准静态压缩实验验证了有限元分析结果, 实验结果表明: NPRC样件等效负泊松比为-11.97, 产生密实化现象, 平台应力的峰值随着应变的增加逐渐增大, 这对提高能量吸收性能具有重要的研究意义。

[本文引用: 1]

[本文引用: 3]

[博士论文].

[本文引用: 1]

[PhD Thesis].

[本文引用: 1]

[硕士论文].

[本文引用: 6]

[Master Thesis].

[本文引用: 6]

//

[本文引用: 1]

DOIURL [本文引用: 1]

[博士论文].

[本文引用: 3]

[PhD Thesis].

[本文引用: 3]

DOIURL

DOIURL

DOIURL

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[硕士论文].

[本文引用: 1]

[Master Thesis].

[本文引用: 1]

[本文引用: 4]

[本文引用: 4]

DOIURL [本文引用: 3]

Non-pneumatic tires (NPTs) have been introduced with a compliant cellular solid spoke component which functions as the air of the pneumatic tire. In this paper, hexagonal honeycomb spokes for a high fatigue resistance design are investigated by seeking compliant hexagonal structures that have low local stresses under macroscopic uni-axial loading. Using the honeycomb mechanics, two cases of hexagonal honeycombs are designed: (i) the same cell wall thickness and (ii) the same load carrying capacity. The elastic limits of the hexagonal honeycombs are obtained from the ABAQUS finite element code considering the geometric nonlinearity of a cellular structure associated with the cell wall buckling and bending. The compliant cellular structures having low local stress values are applied to the honeycomb spokes of an NPT for the structural validation and the local stresses of the honeycomb spokes are investigated under the same vertical loading conditions. Hexagonal honeycombs with a highly positive cell angle have low local stresses and low mass under the same vertical load carrying capability; the Type C honeycomb spokes in this study. (c) 2012 Elsevier Ltd.

[本文引用: 3]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]