HYGROTHERMAL MECHANICAL BEHAVIOR OF A FG CIRCULAR PLATE WITH VARIABLE THICKNESS 1)

Dai Ting, Dai Hongliang2), Li Junjian, He QiCollege of Mechanical and Vehicle Engineering, Hunan University, Changsha 410082, China收稿日期:2018-10-22接受日期:2018-12-20网络出版日期:2019-03-18

| 基金资助: |

Received:2018-10-22Accepted:2018-12-20Online:2019-03-18

作者简介 About authors

2)戴宏亮,教授,主要研究方向:智能材料与结构力学.E-mail:hldai520@sina.com

摘要

功能梯度材料(functionally graded materials, FGM)是组份含量按特定方向连续变化的非均匀复合材料,可有效解决传统复合材料组份之间结合能力弱和不同组份性能难以协调等问题,达到诸如缓和应力集中和优化应力分布等效果,使整体材料在保持细观结构完整性的同时充分发挥各组份材料的性能优势.由于制备技术等原因或出于特殊功能的需要,微孔或孔隙是各类型FGM中的常见缺陷.从细观结构上看,多孔FGM中的孔隙包含了单一组份内的材料孔隙和组份微粒间的结构间隙,这些孔隙将对FGM的力学性能,尤其是在湿热环境下的力学行为产生影响.本文考虑FGM中的两类细观孔隙(材料孔隙和结构孔隙),提出了令各类孔隙依赖于各自组份变化,再线性叠加得到的整体孔隙计算式.考虑组份材料和孔隙填充物(液相水和水蒸气)性质的温度相关性,建立了湿热相关FGM材料模型.针对厚度沿径向变化的旋转圆板结构,应用该FGM材料模型,推导了圆板的非线性稳态湿热控制方程及考虑湿热弹性本构的位移控制方程,采用微分求积法(differential quadrature method,DQM),获得了圆板的湿热场、位移场和应力分布.在数值算例中,利用退化模型的解析解对本文的数值计算方法进行了验证,继而通过改变各关键参数,讨论了两类孔隙率、梯度指数和圆板厚度变化对含孔隙FGM变厚度旋转圆板湿热力学响应的影响规律.

关键词:

Abstract

Functionally graded materials (FGMs) are composed of two or more discrete constituent phases with continuous and smoothly varying components. Due to the distinctive merit comparing with usual composite materials that they can reduce the stress concentration and optimize the stress distribution to make good use of each component, utilizing of FGMs helps to resolve some problems in composite materials such as low bond strength and inharmonious of properties effectively. Because of the preparation technology or for the need of special structures, micropores or pores are commonly found in various types of FGM and play an important role in the influence factors on mechanical properties of FGMs. In addition, the application conditions of FGMs are usually complex or extreme with multiple physical fields, and the mechanical responses of various FGMs under coupling multi-fields will be more complex. On micro scale, the pores in porous FGM include material pores of each components and structural gaps between different particles. These pores will affect the properties of FGM, especially under hygrothermal environments. In this paper, two kinds of micro pores (material pores and structural gaps) in FGM are both considered. An expression to characterize porosity of the whole FGM is proposed, where the porosity of each component is related to its volume fraction and the global porosity is a linear superposition. Considering temperature dependency of the component properties as well as the material properties of pore fillers (liquid water or vapor), a prediction model of the porous FGM is established. Focusing on a rotating circular plate with its thickness varying along the radial direction, and applying the current porous FGM model, governing equations of the nonlinear steady-state temperature and moisture fields as well as displacement field are derived. Solving the governing equations by the differential quadrature method (DQM), distributions of temperature, moisture, displacement and stress of the FG circular plate are obtained. In the numerical examples, analytic solution of a simplified mechanical model is carried out to verify the numerical calculation process of the current study. By changing the key parameters, influences of each porosity, gradient index and thickness change rule on the hygrothermal mechanical responses of the porous FG circular plate with variable thickness are discussed in detail.

Keywords:

PDF (10368KB)元数据多维度评价相关文章导出EndNote|Ris|Bibtex收藏本文

本文引用格式

戴婷, 戴宏亮, 李军剑, 贺其. 含孔隙变厚度FG圆板的湿热力学响应 1). 力学学报[J], 2019, 51(2): 512-523 DOI:10.6052/0459-1879-18-280

Dai Ting, Dai Hongliang, Li Junjian, He Qi.

引 言

功能梯度材料(functionally graded material, FGM)作为组份和性质连续变化的复合材料,常被设计用于具多物理场或环境条件变化剧烈的结构.含孔隙FGM的性能,不仅与组份材料及其变化规律相关,还受到孔隙率的影响,尤其是在会引起孔隙填充物变化的湿热环境中.因此,建立有效的力学模型进行含孔隙FGM性质预测,并据此研究湿热环境下多孔功能梯度(functionally graded,FG)结构的力学响应,对FGM的设计和工程推广应用具有重要的意义.国内外对FG结构静、动力学行为的分析已很丰富.基于高阶剪切变形方法及里兹法,Heydari等[1]研究了Pasternak弹性基础上FG圆板在均匀径向压缩作用下的屈曲行为.通过不同的加载方式,Moita等[2]研究了FG板在不同载荷作用下的屈曲行为和几何非线性行为.基于一阶剪切理论及有限元分析,Yu等[3]研究了FG板在温度和机械载荷作用下的屈曲行为.应用改进的无网格法,Nguyen等[4]研究了FG板的非线性静动态力学行为.借助牛顿-拉夫逊方法以及里兹法,Ashoori和Vanini[5]分析了FG压电板的非线性弯曲和后屈曲响应.基于Kirchhoff-Love理论的无旋度等几何公式,Yin等[6]分析了FG薄板的自由振动和屈曲行为.考虑尺度效应和剪切变形,Thai等[7]采用应变梯度理论和等几何法分析了FG微板的力学行为.基于von Kármán几何非线性理论,张靖华等[8]研究了热冲击作用下具缺陷FG圆板的动态屈曲及后屈曲问题.应用一阶剪切理论及最小势能原理,Dai等[9-10]研究了FG圆板的非线性动态行为和低速冲击作用下的动态响应.基于经典板壳理论,Lal和Ahlawat[11]得到了FG圆板在流体静力学平面力下的屈曲力学行为及圆板的振动特性.应用一阶剪切变形理论,Yousefzadeh等[12]考虑了旋转惯性效应和横向剪切应力,解决了FG圆板与不可压缩流体接触时的自由振动问题.使用微分求积法,Mahinzare等[13]分析了旋转双向FG压电圆板的自由振动,得到了FGM压电圆板的振动特性.考虑热屈曲变形引入的结构几何非线性,夏巍和冯浩成[14]分析了FG壁板的气动弹性颤振.基于单向耦合的热传导理论,许新和李世荣[15]研究了FG微梁的热弹性阻尼.应用有限元法,高晨彤等[16]研究了FGM梁在大范围转动下的刚柔耦合动力学问题.

复合材料在湿热环境下的力学响应及含孔隙复合材料的力学性能也已受到国内外****的关注.基于湿热环境下的力学实验,许良等[17]分析了碳纤维环氧复合材料的力学性能及提高力学性能的方法.利用一阶剪切变形理论和模态叠加法,赵天等[18]研究了复合材料层合板在湿热环境下受简谐激励作用的振动和声辐射特性.运用近场动力学及有限元法,苏伯阳等[19]研究了复合材料湿热环境下的冲击损伤特性.吴振和刘子茗[20]研究了复合材料层合板在湿热环境下的力学行为,探讨了湿热膨胀系数对湿热行为的影响.利用实验的方法,王柏臣等[21]研究了湿热环境对聚甲基丙烯酸甲酯混杂纳米复合材料性能的影响.基于FG构件动力分析的细观元法,曹志远和程红梅[22]研究了材料的宏观性能与微观结构之间的关系,尤其是微观孔隙对宏观性能的影响.根据三维剪切变形理论,Zenkour[23]研究了多孔FG单层板和夹层板的弯曲响应,并且分析了孔隙率对材料性能的影响.应用修正后的混合法则,Boutahar等[24]研究了不同孔隙度下各向同性矩形板的力学性能.应用有限元法,Kiran和Kattimani[25]分析了多孔FG磁弹性板的自由振动特性和静态特性,具体分析了孔隙率对自由振动以及静态性能的影响.利用哈密顿原理和变分法,Rezaei等[26]分析了孔隙率对FG矩形板振动特性的影响.利用修正后的幂律计算公式,Kiran等[27]分析了孔隙度对FG板自由振动以及静力性能的影响.Wang和Zu[28]分析了多孔FG板在热环境中的振动.为快速分析功能梯度材料结构在复杂载荷作用下的动态响应,郑保敬等[29]提出了一种模型降阶方法,并且验证了其准确性和适用性.基于Euler-Bernoulli梁理论和单向耦合的热传导理论,许新和李世荣[15]分析了功能梯度梁的热弹性阻尼的变化.

FGM细观尺度上的孔隙,包括了组份材料本身带有的材料孔隙和不同微粒之间无法充分接触而形成的界面结构孔隙.以往的多孔FGM模型,仅采用了整体孔隙表达式,而并未对不同类型的孔隙进行表征.因此,本文将从细观结构出发,建立各类孔隙与相应组份含量的关系,并考虑组份和孔隙填充物性质的湿热相关性,提出多孔FGM的材料模型,并将所建立的材料模型应用于旋转变厚度圆板结构,分析其在湿热环境下的力学响应.

1 材料模型和几何模型

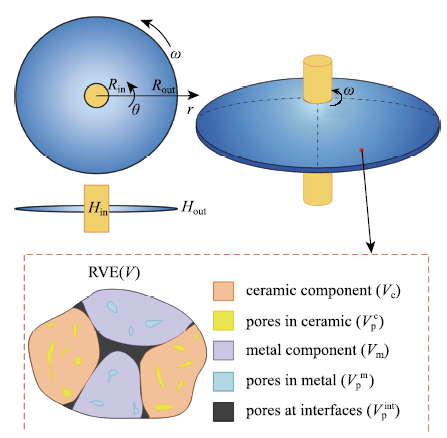

考虑绕中心轴旋转的空心变厚度圆板,其内外半径分别为$R_{{\rm in}}$和$R_{{\rm out}}$,内外边缘厚度分别为$H_{{\rm in}}$和$H_{{\rm out}}$.构成该圆板的FGM包含陶瓷和金属组份,并具有沿环向均匀分布的孔隙.圆板的材料性质参数$P$满足如下关系[30]且各组份材料的体积分数满足

其中,$P_{\rm c}$和$P_{\rm m}$分别表示陶瓷(ceramic)和金属(metal)组份的材料性质,$P_{\rm p}$表示孔隙(pore)或孔隙填充物的材料性质,$V_{\rm c}$,$V_{\rm m}$和$V_{\rm p}$分别表示三者的体积分数,并且$V_{\rm m}$随圆板半径呈如下幂函数变化[30]

式中,$\eta _{\rm m}$为金属组份的孔隙参数,$n(0 \le n \le \infty)$为FG指数. 当$n = 0$时,材料成分全部为金属;当$n \to + \infty$时,材料成分全部为陶瓷. 圆板几何形状、所用柱坐标系$(r,\theta,z)$及多孔FGM的代表性体积单元(RVE)示意图如图1所示

图1

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图1变厚度FG圆板材料和几何模型示意图

Fig.1Material and geometrical model of the FG circular plate with variable thickness

本文分别考虑FGM各组份本身带有的孔隙及不同组份结合时产生的界面和结构间隙,上述各类孔隙与各组份含量相关,故假设FG圆板的孔隙体积分数满足

其中,$V_{\rm p}$,$V_{\rm p}^{\rm c}$,$V_{\rm p}^{\rm m}$和$V_{\rm p}^{{\rm int}}$分别为FGM、陶瓷组份、金属组份和结合界面中孔隙所占体积分数;$\eta _{\rm c}$为陶瓷组份的孔隙参数;$\eta _{{\rm int}}$为界面孔隙参数. 显然,当$V_{\rm c} (r) = 0$或$V_{\rm m} (r) = 0$时,为单一材料,无界面孔隙,只有单一材料孔隙;当$V_{\rm c} (r) = V_{\rm m} (r)$时,界面孔隙率达到最大.将(4)式代入(2)式,可得$V_{\rm c} (r)$和$V_{\rm p} (r)$.

考虑到组份材料和孔隙的部分物性参数受温度的影响,本文采用如下与温度相关的材料参数表达式[23]

其中

式中,$T$表示温度,$P_{ij} (i = 0,1,2,3)$为常数.

湿度的变化是材料中水或水蒸气含量的变化,将对材料的质量和密度产生影响.由于陶瓷和金属组份吸湿能力弱,故仅考虑孔隙的吸湿.忽略孔隙内压强的变化,考虑吸湿孔隙中同时存在气相水和液相水,孔隙的物性参数满足如下关系

其中,$S(r)$表示液相水饱和度(或称填充率),在此处为孔隙吸湿后液相水占据孔隙的体积分数,即$S(r)= {V_{\rm w} (r)}/{V_{\rm p} (r)}$,显然有$0 \le S(r) \le 1$.

考虑FG圆板厚度沿径向变化,采用如下规律

其中$\lambda (\lambda \ge 0)$是控制厚度变化规律的几何参数.

2 控制方程及求解

2.1 湿热控制方程及其DQM求解

当FG圆板仅有沿径向变化的温度和湿度场时,不计湿热传导过程,采用无源一维稳态温度和湿度方程如下式中,$T = T(r)$,$C = C(r)$.仅考虑固体组份的传热,热传导系数$\kappa (r,T)$满足式(5),且$\kappa _{\rm p} (T) = 0$;仅考虑孔隙传湿,而忽略金属和陶瓷材料的吸湿性时,扩散系数$D(r,T,S) = D_{\rm p} (r,T,S)$满足式(7).

由于吸湿后材料的湿度$C = {(m_{\rm w} + m_{\rm v} )}/ {m_{{\rm dry}} }$,则液相水饱和度和材料湿度之间有如下线性关系

注意到,由于忽略了孔隙中的空气,即采用了$V_{\rm p} = V_{\rm w} + V_{\rm v}$,故仅当$V_{\rm p} = 0$(无孔隙)时有$C = 0$.总湿度中液相水分量$C_{\rm w}$和水蒸气分量$C_{\rm v}$分别为

当$S = 0$时,材料中无液相水;当$S = 1$时,材料达到吸水饱和.利用式(11),则湿度方程式(10)可用液相水填充率$S$表示为

其中

$$ S = S(r)\\ f_{{\rm S1}} = \frac{(\rho _{\rm w}-\rho _{\rm v} )V_{\rm p} (r)}{\rho _{\rm c} V_{\rm c} (r) + \rho _{\rm m} V_{\rm m} (r)}\\ f_{{\rm S2}} = \frac{\rho _{\rm v} V_{\rm p} (r)}{\rho _{\rm c} V_{\rm c} (r) + \rho _{\rm m} V_{\rm m} (r)} $$

不计材料表面与外界的温度和物质交换,给定FG圆板内外边界湿热条件如下

采用DQM对上述湿热传导方程进行求解.DQM中某个采样点上的微分是由所有采样点上的函数值求加权和所得,故取少量采样点就可以得到光滑曲线.$r = r_i$处$f(r)$的k阶导数表达式为[31-32]

式中,$q$为沿径向离散采样点总数,c为权系数,其表达式为

其中$\prod {(r_i )} = \prod\limits_{j = 1,j \ne i}^q {(r_i-r_j )}$.

为提高计算精度,采用如下非均匀的Chebyshev-Gauss-Lobatto采样网格点[31]沿径向离散

基于此,离散后的温度控制方程可写为

其中$i = 1,2,\cdots ,q$;$h_i = h(r_i )$,$\kappa _i = \kappa (r_i ,T_i )$,$T_i = T(r_i )$,$(\quad )'_{r_i } = \left. {\frac{{{\rm d}(}\quad )}{{\rm d}r}} \right|_{r = r_i }$.离散以后,式(14)表示的温度边界条件为

式(19)和式(20)构成一组高阶代数方程,利用牛顿迭代法可以求解,获得温度场的数值解.

用牛顿迭代法解非线性代数方程$f(x) = 0$,是将$f(x)$在$x_0$点的某领域内展开成泰勒级数,取其线性部分(即泰勒展开的前两项),并令其等于0,以此作为非线性方程的近似方程,即具有迭代关系式$x_{\rm n+1} =x_n-{f(x_n )} / {{f}'(x_n )}$.

将湿度控制方程式(13)进行离散,并将温度场数值结果代入,得到

其中,$f^{(i)} = f(r_i )$,$C_i = C(r_i )$,$D_i = D(r_i ,T_i ,S_i)$. 离散以后,液相水填充率边界条件为

式(21)和式(22)构成一组高阶代数方程,利用牛顿迭代法可以求解.将求得的液相水填充率数值结果代入式(11)和式(12),即可获得圆板的湿度场及所含液相水和水蒸气分量.

2.2 位移控制方程及其DQM求解

忽略自重,旋转FG圆板受径向体力$f_r (r) = \rho (r)\omega ^2r$.考虑到结构和载荷的对称性,FG圆板内位移和应力与$\theta$无关.于是,圆板的应力平衡方程可写为其中,$\sigma _r =\sigma _r (r)$和$\sigma _\theta =\sigma _\theta(r)$分别表示径向和环向应力,密度$\rho (r)$满足式(1).由于湿度扩散是传质过程,孔隙的质量密度将与湿度相关.

考虑到平面应力问题,且应变和位移分量只与径向相关,FG圆板中面的小变形几何方程为

其中,$\varepsilon _r =\varepsilon _r (r)$和$\varepsilon _\theta =\varepsilon _\theta (r)$分别表示径向和环向应变,$u\mbox{ = }u(r)$表示径向位移.

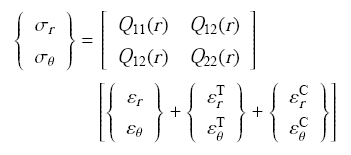

采用如下湿热弹性本构方程

其中

$E(r,T)$是弹性模量,满足式(5)且$E_{\rm p} = 0$;$\nu (r)$为泊松比,满足式(1)且$\nu _{\rm p} = 0$. 上式中湿热应力分量为

其中,$\Delta T(r) = T(r)-T_0$,$\Delta C(r) = C(r)-C_0$,$T_0$和$C_0$分别为圆板的初始温度和湿度;$\alpha (r) = \alpha (r,T)$是热膨胀系数,$\beta (r) = \beta (r,T)$是湿膨胀系数且$\beta _{\rm c} = \beta _{\rm m} = 0$,则圆板中的湿应变$\varepsilon _r^{\rm C} = \varepsilon _\theta ^{\rm C} = 0$.

将式(24)和式(25)代入式(23),获得旋转FG圆板的位移控制方程如下

其中

$$ f_1 = h(r)Q_{11} (r) \\ f_2 = Q_{11} (r)\left[ {\frac{h(r)}{r} + \frac{{\rm d}h(r)}{{\rm d}r}} \right] + h(r)\frac{{\rm d}Q_{{\rm 11}} (r)}{{\rm d}r} \\ f_3 = \frac{Q_{12} (r)}{r}\frac{{\rm d}h(r)}{{\rm d}r} + \frac{h(r)}{r}\frac{{\rm d}Q_{{12}} (r)}{{\rm d}r}-\frac{h(r)}{r^2}Q_{{11}} (r)\\ f_4 = rh(r)\rho (r)\omega ^2-\frac{{\rm d}\{[Q_{{11}} (r) + Q_{{12}} (r)]h(r)\alpha (r)\Delta T(r)\}}{{\rm d}r}$$

FG圆板内边与转轴连接,视为固定端,外边自由,则其边界条件可写为

将式(24)~式(26)代入式(29),可得到用位移描述的边界条件.

同样采用DQM对上述位移控制方程进行求解,离散后的位移控制方程为

其中,$i = 1,2,\cdots ,q$;$f^{(i)} = f(r_i )$,$u_i = u(r_i )$.用位移表达的离散边界条件为

将获得的位移场数值解代入式(24)和式(25)即可获得应力场的数值解.

3 算例和讨论

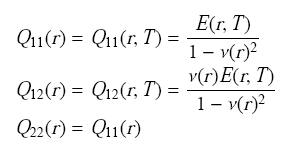

为验证本文数值计算过程的可靠性和正确性,首先考虑一忽略湿热效应的等厚度旋转均质圆板,令该均质圆板由金属材料组成,即取参数$E = 201.04~ {\rm GPa}$,$\nu = 0.326$,$\rho = 8166~{{\rm kg}}/{{\rm m}^3}$和$\omega = 1000~{\rm r}/{{\rm min}}$.事实上,该均质等厚度圆板力学模型是本文变厚度旋转FGM圆板的一种特殊简化形式,具体表现为,梯度指数$n = 0$表示FGM圆板仅含金属组份.该均质等厚度圆板的位移控制方程为$$ \frac{{\rm d}}{{\rm d}r}\left\{ {\frac{1}{r}\frac{{\rm d}[ru(r)]}{{\rm d}r}} \right\} =-\frac{(1-\nu ^2)\rho \omega ^2r}{E}$$

其中,$\rho$,$\omega$,E和$\nu$均为常数.通过两次求积分运算,可以得到上式的通解

$$ u(r) =-\frac{(1-\nu ^2)\rho \omega ^2}{8E}r^3 + \frac{Y_1 }{2}r + \frac{Y_2 }{r}$$

其中,$Y_1$和$Y_2$是待定常数,应用式(29)的边界条件可以求得,进而可获得该等厚度均质圆板的位移和应力场解析解.

然后,在本文的数值求解模型中,取FG指数$n = 0$,圆板厚度$h(r)\equiv 1$及厚度变化指数$\lambda = 0$,各组份孔隙参数$\eta _{\rm c} = \eta _{\rm m} = \eta _{{\rm int}} \to 0$,湿热场$T(r) = C(r) \equiv 0$,转速$\omega = 1000 ~{\rm r}/{{\rm min}}$,则本文模型退化为与上述均质等厚度圆板一致,将DQM计算结果与解析结果进行对比.

由图2可知,两种结果十分吻合,表明了本文数值计算过程的正确性.

图2

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图2验证算例

Fig.2Validation example

后续的算例中考虑湿热环境下的变厚度旋转FG圆板,其部分常量材料参为:$ \rho _{\rm c} = 2370~{\rm kg / m}^3, \nu _{\rm c} = 0.240$;$\rho _{\rm m} = 8166~{\rm kg / m}^3, \nu _{\rm m} = 0.326$;$ \rho _{\rm v} = 0.017~{\rm kg / m}^3, \rho _{\rm w} = 1000~{\rm kg / m}^3$ 温度相关材料参数见表1.

Table 1

表1

表1FGM温度相关材料参数[30,33]

Table 1

| P0 | P1 | P2 | P3 | |

|---|---|---|---|---|

| kc/(W ? (m ? K)-1) | 13.723 | -1.032 x 10-3 | 5.466 x 10-7 | -7.876 x 10-11 |

| ac/K-1 | 5.872 x 10-6 | 9.095 x 10-4 | 0 | 0 |

| Ec/GPa | 348.43 | -3.070 x 10-4 | 2.160 x 10-7 | -8.946 x 10-11 |

| Km/(W ? (m ? K)-1) | 15.379 | -1.264 x 10-3 | 2.092 x 10-6 | -7.223 x 10-10 |

| am /K-1 | 1.233 x 10-5 | 8.086 x 10-4 | 0 | 0 |

| Em/GPa | 201.04 | 3.079 x 10-4 | -6.534 x 10-7 | 0 |

| Dv/(m2 ? s-1) | 2.176 x 10-5 | 9.619 x 10-3 | -1.091 x 10-4 | 1.523 x 10-6 |

| Dw/(m2 ? s-1) | 1.819 x 10-9 | -1.401 x 10-2 | 1.290 x 10-3 | -7.874 x 10-6 |

新窗口打开|下载CSV

3.1 材料参数对FG圆板湿热力学行为的影响

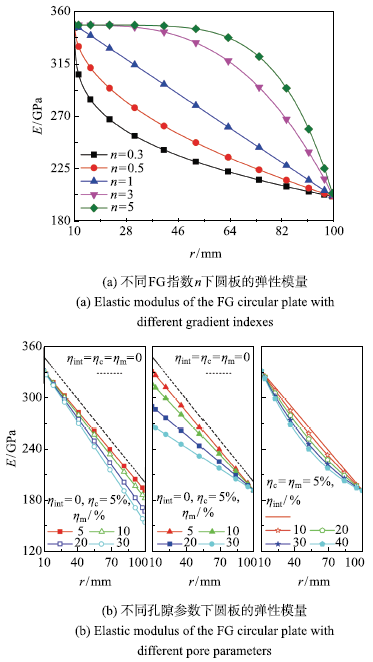

取旋转FG圆板的几何参数$R_{{\rm in}} = 10~\mbox{mm}$,$R_{{\rm out}} = 100~\mbox{mm}$,$H_{{\rm in}} = 1~\mbox{mm}$,$H_{{\rm out}} = 5~\mbox{mm}$,$\lambda = 1$;圆板转速$\omega = 1000~ {\rm r} /{\mbox{min}}$.常温干燥条件下,材料参数对圆板弹性模量的影响如图3所示.图3(a)给出了不同FG指数$n$下无孔隙($\eta _{\rm c} = \eta _{\rm m} = \eta _{{\rm int}} = 0)$圆板的弹性模量. 可知,当$n = 1$时,FG圆板材料属性沿径向线性变化;当$\mbox{0} < n < 1$时,$n$值越小,材料整体性质越向金属靠拢;当$n > 1$时,$n$值越大,材料整体性质越向陶瓷靠拢. 取FG指数$n = 1$,图3(b)给出了常温干燥条件下不同孔隙参数对圆板弹性模量的影响.易知,孔隙的存在使材料的弹性模量整体降低,且孔隙率越大,降低幅度越大.进一步分析发现,组份孔隙率$\eta _{\rm c}$和$\eta _{\rm m}$的变化并不影响弹性模量曲线的基本形状,其影响程度由各组份含量决定;而界面孔隙率$\eta _{{\rm int}}$使弹性模量曲线下凹,影响程度由$V_{\rm c} \cdot V_{\rm m}$决定,且影响幅度最大处发生在沿圆板径向的中部.

图3

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图3材料参数对弹性模量的影响

Fig.3Influences of material parameters to the elastic modulus

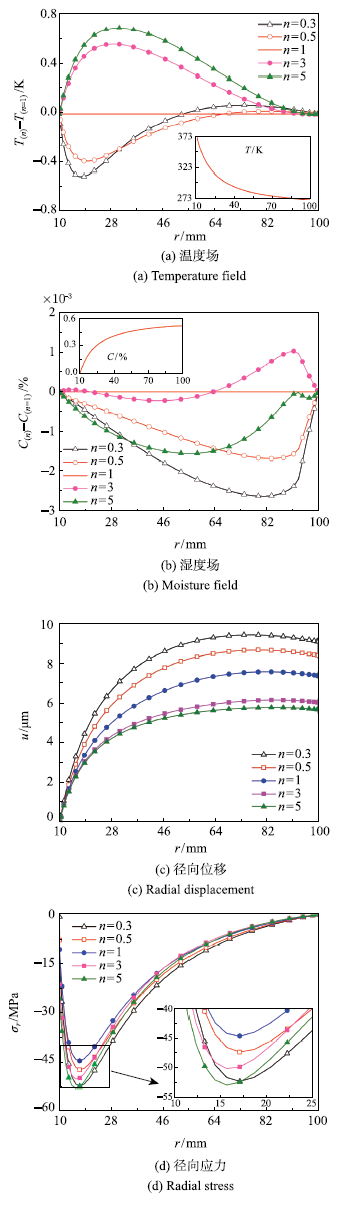

取孔隙参数$\eta _{\rm c} = \eta _{\rm m} = \eta _{{\rm int}} = 10\mbox{%}$,温度边界条件$T_{{\rm in}} = 373~\mbox{K}$和$T_{{\rm out}}=273~{\rm K}$,湿度边界条件$S_{{\rm in}} = 0$和$S_{\rm out}=0.5$,FG指数$n$对变厚度含孔隙FG圆板湿热力学响应的影响如图4所示.从式(9)可知,$n$对温度场的影响来源于其对热传导系数$\kappa$的影响,由表可知本文选取的两种组份材料$\kappa$值相近,故$n$对温度场整体影响较小. 因此图4(a)给出了$n = 1$时的温度场,及$n$取其他值时的温度与$n = 1$温度的差值,简记为$T_{(n)}-T_{(n = 1)}$,以清晰表达$n$对温度场的影响.由图可见,$n$对温度场的影响主要出现在靠近边界温度较高的一侧,并大致呈现随着$n$增大,同一半径处温度增大的趋势.同样地,由于$n$对湿度场整体影响较小,图4(b)给出了$n = 1$时的湿度场和湿度场差值$C_{(n)}-C_{(n = 1)}$.因本文不考虑组份材料的吸湿性,$n$对湿度的影响来源于其对孔隙体积分数$V_{\rm p}$的影响. 由图可知,影响较大处出现在靠近边界湿度较高的一侧,并且$n = 1\sim 3$时整体湿度值最大,$0 < n < 1$时整体湿度随$n$减小而降低,$n > 3$时整体湿度随$n$增大而降低.图4(c)和图4(d)给出了取不同$n$值时圆板的径向位移和径向应力,发现在同一半径处,径向位移随$n$值的增大而减小,结合图3(a)可知这是由于$n$值的增大使圆板整体刚度增加;$\left| {\sigma _r } \right|$的峰值在$0 < n < 1$时随$n$的增大而减小,在$n>1$时随$n$的增大而增大,结合图3(a)可知,组份均匀变化将有利于缓和FG圆板内的应力.

图4

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图4FG指数$n$对圆板湿热力学响应的影响

Fig.4Effect of gradient index$n$ to the hygrothermal mechanical responses of the FG circular plate

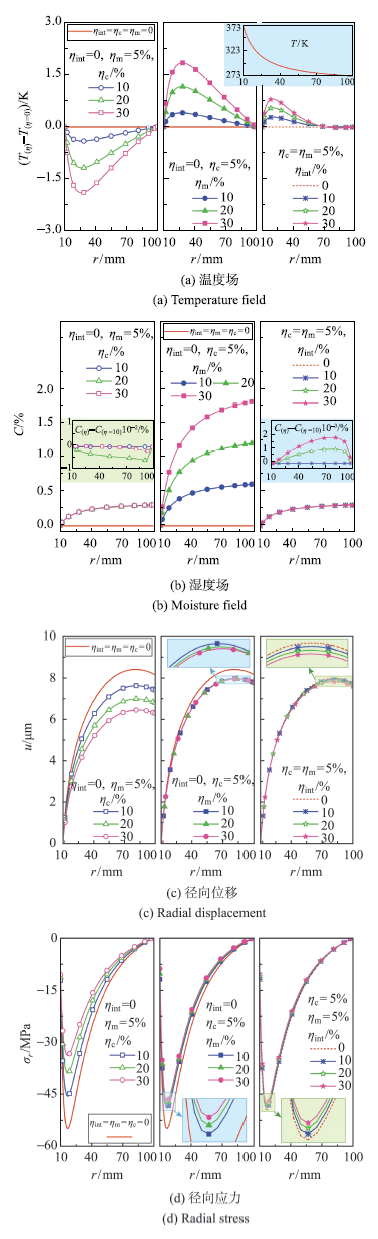

取FG指数$n = 1$,温度边界条件$T_{{\rm in}} = 373~\mbox{K}$和$T_{{\rm out}} = 273~\mbox{K}$,湿度边界条件$S_{{\rm in}} = 0$和$S_{{\rm out}} = 0.5$,孔隙参数对变厚度FG圆板湿热力学响应的影响如图5所示.由于孔隙参数对温度场整体影响较小, 图5(a)给出了$\eta _{\rm c} = \eta _{\rm m} = \eta _{{\rm int}} = 0$时的温度场及温度差$T_{(\eta )}-T_{(\eta = 0)}$,其中$T_{(\eta = 0)}$表示$\eta _{\rm c} = \eta _{\rm m} = \eta _{{\rm int}} = 0$时的温度场.由图易知,各孔隙参数对温度场影响最大处出现在靠近边界温度较高一侧;且在同一半径处,圆板温度随$\eta _{\rm c}$的增大而略微减小,随$\eta _{\rm m}$或$\eta _{{\rm int}}$的增大而略微增大,而$\eta _{\rm c}$和$\eta _{\rm m}$对温度的影响相比于$\eta _{{\rm int}}$稍大.图5(b)显示各孔隙参数对湿度场影响最大处出现在靠近边界湿度较高一侧,但由于本文考虑的热传导主要产生于陶瓷和金属组份材料,湿度扩散主要产生于孔隙,故孔隙参数对湿度场的影响规律与对温度的影响明显不同.由于设定了圆板内侧陶瓷组份占多,外侧金属组份占多,且$S_{{\rm in}}= 0$,$S_{\rm out}=0.5$,图中$\eta _{\rm m}$对湿度场的影响程度明显大于$\eta _{\rm c}$和$\eta _{{\rm int}}$,且在同一半径处湿度随$\eta _{\rm m}$增大而增大. 至于$\eta _{\rm c}$和$\eta _{{\rm int}}$对湿度的影响,图5(b)给出了湿度差$C_{(\eta )}-C_{(\eta = 10)}$,其中$C_{(\eta = 10)}$表示$(\eta _{\rm c} ,\eta _{\rm m} ,\eta _{{\rm int}} ) = (10\mbox{%} ,5\mbox{%} ,0)$或$(\eta _{\rm c} ,\eta _{\rm m} ,\eta _{{\rm int}} ) = (5\mbox{%} ,5\mbox{%} ,10\mbox{%} )$时的湿度场,发现在同一半径处,$\eta _{\rm c}$和$\eta _{{\rm int}}$的增大均会使湿度略微增大.图5(c)和图5(d)给出了取不同孔隙参数时圆板的径向位移和径向应力,孔隙参数对位移和应力的影响是其对刚度和对湿热场影响的综合结果.在同一半径处,径向位移和$\left| {\sigma _r } \right|$分别随$\eta _{\rm c}$,$\eta _{\rm m}$和$\eta _{{\rm int}}$的增大而减小,其中$\eta _{\rm c}$的影响最为明显,这是由于本文设定了FG圆板陶瓷组份占多的一侧为固定端.

图5

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图5孔隙参数对FG圆板湿热力学响应的影响

Fig.5Effect of pore parameters to the hygrothermal mechanical responses of the FG circular plate

3.2 FG圆板厚度参数的影响

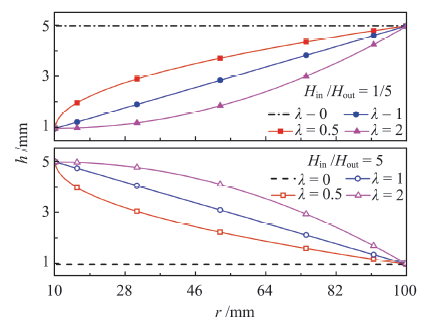

取圆板孔隙参数$\eta _{\rm c} = \eta _{\rm m} = \eta _{{\rm int}} = 10\mbox{%}$,FG指数$n = 1$,温度和湿度边界条件$T_{{\rm in}} = 373~\mbox{K}$,$T_{{\rm out}} = 273~\mbox{K}$,$S_{{\rm in}} = 0$,$S_{{\rm out}} = 0.5$,圆板转速$\omega = 1000~ {\rm r} /{\mbox{min}}$. 图6为不同厚度参数下圆板厚度沿径向的变化.图6

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图6FG圆板厚度沿径向的变化

Fig.6Thickness variation of the FG circular plate along its radius

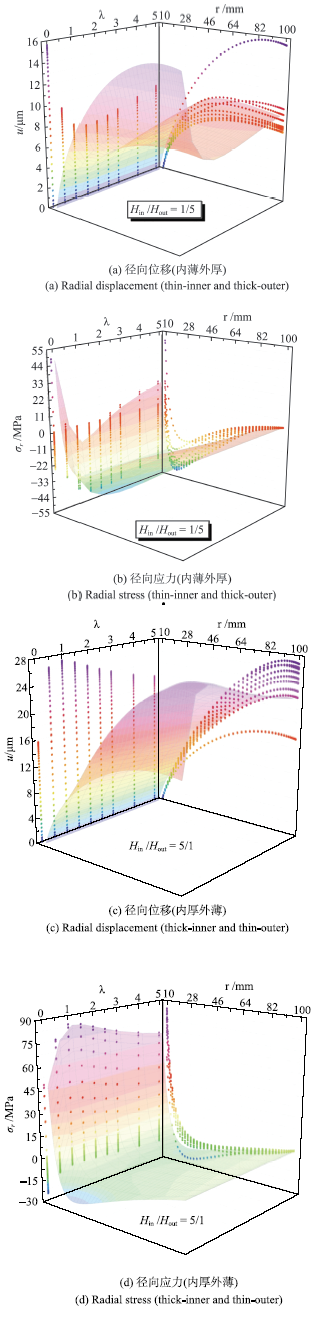

由于圆板厚度参数对材料组份和性质无影响,从而厚度参数的变化不改变其温度和湿度分布,故图7仅给出了不同厚度参数下圆板的径向位移和径向应力.$\lambda =0$(等厚度)时圆板厚度对位移和应力场无影响;$\lambda \ne 0$时,内薄外厚(${H_{{\rm in}} } / {H_{{\rm out}} } = 1/5)$圆板比内厚外薄(${H_{{\rm in}} } / {H_{{\rm out}} } = 5)$圆板的整体位移和应力更小;在同一半径处,内薄外厚圆板的位移和应力随$\lambda$的增大先减小后增大,而内厚外薄圆板的位移和应力随$\lambda$的增大先增大后减小,且上述$\lambda$影响的最大处均出现在$\lambda = 1$附近.结果表明,对于内边固定外边自由的FG旋转圆板,内薄外厚且厚度线性变化的几何结构将有利于缓和其形变和应力分布.

图7

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图7厚度参数对FG圆板湿热力学响应的影响

Fig.7Effect of thickness parameters to hygrothermal mechanical responses of the FG circular plate

4 结 论

本文提出了用组份本身孔隙及结合界面孔隙线性叠加得到的孔隙体积分数计算式,考虑组份材料和孔隙填充物(液相水和水蒸气)性质的温度相关性,及圆板整体湿度扩散系数和密度的湿度相关性,建立了湿热环境下旋转变厚度FG圆板的力学模型.采用DQM对控制方程进行求解,获得了圆板的湿热力学响应.通过具体算例,得到了如下结论.(1)FG指数的变化对圆板湿热场影响较小,而对径向位移和应力影响明显.孔隙参数对圆板湿热力学响应的影响主要来源于组份体积分数的变化,其对温度场影响较小,对湿度场的影响程度取决于组份孔隙参数和湿度边界条件的设定;孔隙参数对位移和应力的影响取决于对整体弹性模量的影响.

(2)在稳态湿热场下,内厚外薄的圆板比内薄外厚的圆板具有更大的整体位移和应力,厚度指数$\lambda$对位移和应力影响最大处出现在$\lambda = 1$附近.对于内边固定外边自由的FG旋转圆板,内薄外厚且厚度线性变化的几何结构有利于缓和形变和应力分布.

参考文献 原文顺序

文献年度倒序

文中引用次数倒序

被引期刊影响因子

DOIURL [本文引用: 1]

A numerical scheme for buckling analysis of functionally graded circular plate (FGCP) subjected to uniformly radial compression including shear deformation rested on Pasternak elastic foundation is presented. The linear and quadratic thickness variation patterns with various boundary conditions are considered. A modified Euler–Lagrange equation is achieved and then solved by converting differential equation to a nonlinear algebraic system of equations. Also, based on the traction–free surface without using shear correction factor, a new approach by considering shear deformation for buckling analysis of FGCP rested on elastic foundation is carried out. The stability equation based on shear stress-free surface is solved by the spectral Ritz method. The spectral Ritz method has good flexibility in the sense of satisfying the boundary conditions. The effects of both linear and quadratic thickness variation and Poisson’s ratio are investigated. By taking small numbers of the basis, the outcomes in literature are improved.

URL [本文引用: 1]

DOIURL [本文引用: 1]

Practical applications such as airplane wings are usually subjected to combined thermal and mechanical loads, and they hence are prone to buckling failure. Preceding works on the buckling of advanced materials, e.g., functionally graded materials, under combined thermal and mechanical loads are rather rare in literature. In this paper, we report new numerical results of thermal-mechanical buckling of functionally graded rectangular and skew plates (FGPs) under combined thermal and mechanical loads. The numerical responses of buckling are computed using isogeometric analysis (IGA) based on the first-order shear deformation plate theory (FSDT) without shear-locking effect. We present formulations and then provide validation of numerical results computed by the proposed formulation against reference existing solutions. Parametric study is also performed to explore insight into the effects of various numerical aspect ratios such as gradient index, plate aspect ratio, loading type, skew angle, and boundary condition, etc. on mechanical response of FGPs. The stability diagrams are also presented.

DOIURL [本文引用: 1]

This paper presents a novel formulation based on an improved moving Kriging (iMK) meshfree method and a refined plate theory (RPT) for geometrically nonlinear static and dynamic analyses of functionally graded material (FGM) plates. The nonlinearity of plates is formed in the total Lagrangian approach based on the von Karman strain assumptions. The present plate formulation has the following advantages: only four variables for each node, the tangential stress-zero boundary condition at the top and bottom surfaces of plates, and the stringent continuity requirement of the generalized displacements being simply treated without any additional variables. The novelty of the iMK meshfree method is to propose a quartic spline correlation function for establishment of basic shape functions. Thanks to this improvement, the solution of the iMK meshfree method is stable and no longer depends on an uncertain adjustment of correlation parameterIn addition, a simple rotation-free technique originated from isogeometric analysis (IGA) is successfully applied to the iMK meshfree method for enforcing the slopes of clamped boundary condition. Several numerical examples are provided to demonstrate high performance of the present method in comparison with other numerical methods.

DOIURL [本文引用: 1]

61Nonlinear thermoelectrical stability of perfect/imperfect circular FGP plates according to modified couple stress theory is first presented.61Snap-through phenomenon in the thermally preloaded plates due to concentrated/uniform lateral loads is then studied.61Two types of thermal loading including uniform temperature rise and heat conduction across the thickness are considered.61The influence of key parameters on stability and snap-through features of microstructure-dependent FGP plates are investigated.

DOIURL [本文引用: 1]

We present a rotation free isogeometric analysis formulation based on Kirchhoff-Love theory, which aims to address free vibration and buckling behaviors of functionally graded thin plates with in-plane material inhomogeneity. For Kirchhoff-Love thin plate analysis, construction of C 1 conforming finite element approximation is not straightforward, while isogeometric analysis with high-order continuity splines basis functions is ideally suited for Kirchhoff-Love elements. We first explain the formulations and then provide verification of the present method through numerical examples. Studies on convergence and comparison with reference solutions are demonstrated to show the effectiveness and accuracy of the proposed method. Effects on natural frequencies, critical buckling loads and mode shapes originated from the material inhomogeneity and boundary conditions are numerically investigated.

[本文引用: 1]

DOIURL [本文引用: 1]

基于von Kármán几何非线性板理论研究热冲击载荷作用下缺陷功能梯度圆板的动力屈曲及后屈曲。假设功能梯度材料的物理性能参数沿厚度方向按照幂函数形式连续变化。由Fourier热传导定律,采用Laplace变换法和微分方程幂级数解法求得热冲击载荷作用下功能梯度板内的动态温度场。利用幂级数展开圆板轴对称大变形的非线性动力学控制方程,并与Runge-Kutta法相结合进行数值求解,获得中心最大挠度的动力响应和屈曲临界温度。结果表明:随着材料参数和几何缺陷的增大,板发生屈曲的时间提前;临界升温载荷随径厚比和载荷参数的增大而降低。

DOIURL [本文引用: 1]

基于von Kármán几何非线性板理论研究热冲击载荷作用下缺陷功能梯度圆板的动力屈曲及后屈曲。假设功能梯度材料的物理性能参数沿厚度方向按照幂函数形式连续变化。由Fourier热传导定律,采用Laplace变换法和微分方程幂级数解法求得热冲击载荷作用下功能梯度板内的动态温度场。利用幂级数展开圆板轴对称大变形的非线性动力学控制方程,并与Runge-Kutta法相结合进行数值求解,获得中心最大挠度的动力响应和屈曲临界温度。结果表明:随着材料参数和几何缺陷的增大,板发生屈曲的时间提前;临界升温载荷随径厚比和载荷参数的增大而降低。

DOIURL

In the paper, nonlinear dynamic analysis of a circular plate composed of functionally graded material (FGM) is presented. Considering a transverse shear deformation and geometric nonlinearity, the von Karman geometric relation of the FGM circular plate is established. Based on the theory of the first-order shear deformation, a new set of equilibrium equations is developed by the principle of minimum total energy. Applying the finite difference method and Newmark scheme, the nonlinear transient problem is solved by the iterative method. To validate the presented method, the transient problem of the FGM circular plate is compared with those of the existed literature, and good agreement is observed. The effects of the volume fraction index, boundary conditions, mechanical load and the ratio of thickness to radius on the nonlinear transient problem of the FGM circular plate are investigated.

DOIURL

Based on the theory of the first-order shear deformation, a new set of equilibrium equations is developed by the principle of Hamilton. Using the Giannakopoulos' contact model, the expressions of the contact force and the central deflection for a functionally graded materials circular plate are obtained. By using the orthotropic collocation point method and Newmark method, the unknown variable functions are discreted in space domain and time domain, and the whole problem is solved by the iterative method synthetically. Numerical results show that the material compositions, geometrical parameters and the initial velocity of the striking ball have great effects on the nonlinear dynamic response of the functionally graded materials circular plate.

[本文引用: 1]

[本文引用: 1]

DOIURL [本文引用: 1]

In this article, free vibration of a rotating circular nanoplate made of two directional functionally graded piezo materials (two directional FGPM) is modeled based on the first shear deformation theory (FSDT). Based on the power-law model, electro-elastic properties of two directional FGP rotating circular nanoplates are supposed to change continuously along the thickness and radius. Employing the modified couple stress theory, the small size effect of the equations of the plate is considered. The governing equations of the first shear deformation theory (FSDT) for the studied plate are obtained based on Hamilton principle; these equations are solved using differential quadrature method (DQM). It is shown that the vibration behavior of the plate is significantly affected by angular velocity, external electric voltage, size dependency and power-law index (thickness and radial directions).

DOIURLMagsci [本文引用: 1]

<p>功能梯度材料的宏观物理性能随空间位置连续变化,能充分减少不同组份材料结合部位界面性能的不匹配因素.功能梯度壁板用作高速飞行器的热防护结构,能有效消除气动加热带来的壁板内部热应力集中.本文考虑热过屈曲变形引入的结构几何非线性,分析功能梯度壁板的气动弹性颤振边界.基于幂函数材料分布假设,采用混合定律计算功能梯度材料的等效力学性能.根据一阶剪切变形板理论、冯·卡门应变-位移关系和一阶活塞理论,基于虚功原理建立超声速气流中受热功能梯度壁板的非线性气动弹性有限元方程.采用牛顿-拉弗森迭代法数值求解壁板的热屈曲变形,分析超声速气流对热屈曲变形的影响机理.在壁板热过屈曲的静力平衡位置分析动态稳定性,确定了壁板的颤振边界.研究表明,当陶瓷-金属功能梯度壁板的组份材料沿厚度方向梯度分布时,会破坏结构的对称性导致壁板在面内热应力作用下发生指向金属侧的热屈曲变形.超声速气流中壁板热屈曲变形最大的位置随气流速压增大向下游推移,并伴随屈曲变形量的减小.热过屈曲壁板的几何非线性效应会提高壁板的颤振边界,这种影响在高温、低无量纲速压且壁板发生大挠度热屈曲变形时表现显著.较高无量纲气流速压下由于壁板的热屈曲变形被气动力限定在小挠度范围,几何非线性效应不明显.</p>

DOIURLMagsci [本文引用: 1]

<p>功能梯度材料的宏观物理性能随空间位置连续变化,能充分减少不同组份材料结合部位界面性能的不匹配因素.功能梯度壁板用作高速飞行器的热防护结构,能有效消除气动加热带来的壁板内部热应力集中.本文考虑热过屈曲变形引入的结构几何非线性,分析功能梯度壁板的气动弹性颤振边界.基于幂函数材料分布假设,采用混合定律计算功能梯度材料的等效力学性能.根据一阶剪切变形板理论、冯·卡门应变-位移关系和一阶活塞理论,基于虚功原理建立超声速气流中受热功能梯度壁板的非线性气动弹性有限元方程.采用牛顿-拉弗森迭代法数值求解壁板的热屈曲变形,分析超声速气流对热屈曲变形的影响机理.在壁板热过屈曲的静力平衡位置分析动态稳定性,确定了壁板的颤振边界.研究表明,当陶瓷-金属功能梯度壁板的组份材料沿厚度方向梯度分布时,会破坏结构的对称性导致壁板在面内热应力作用下发生指向金属侧的热屈曲变形.超声速气流中壁板热屈曲变形最大的位置随气流速压增大向下游推移,并伴随屈曲变形量的减小.热过屈曲壁板的几何非线性效应会提高壁板的颤振边界,这种影响在高温、低无量纲速压且壁板发生大挠度热屈曲变形时表现显著.较高无量纲气流速压下由于壁板的热屈曲变形被气动力限定在小挠度范围,几何非线性效应不明显.</p>

DOIURL [本文引用: 2]

基于Euler-Bernoulli梁理论和单向耦合的热传导理论,研究了功能梯度材料(functionally graded material,FGM)微梁的热弹性阻尼(thermoelastic damping,TED).假设矩形截面微梁的材料性质沿厚度方向按幂函数连续变化,忽略了温度梯度在轴向的变化,建立了单向耦合的变系数一维热传导方程.热力耦合的横向自由振动微分方程由经典梁理论获得.采用分层均匀化方法将变系数的热传导方程简化为一系列在各分层内定义的常系数微分方程,利用上下表面的绝热边界条件和界面处的连续性条件获得了微梁温度场的分层解析解.将温度场代入微梁的运动方程,获得了包含热弹性阻尼的复频率,进而求得了代表热弹性阻尼的逆品质因子.在给定金属-陶瓷功能梯度材料后,通过数值计算结果定量分析了材料梯度指数、频率阶数、几何尺寸以及边界条件对TED的影响.结果表明:(1)若梁长固定不变,梁厚度小于某个数值时,改变陶瓷材料体积分数可以使得TED取得最小值;(2)固有频率阶数对TED的最大值没有影响,但是频率阶数越高对应的临界厚度越小;(3)不同的边界条件对应的TED的最大值相同,但是随着支座约束刚度增大对应的临界厚度减小;(4)TED的最大值和对应的临界厚度随着金属组分的增大而增大.

DOIURL [本文引用: 2]

基于Euler-Bernoulli梁理论和单向耦合的热传导理论,研究了功能梯度材料(functionally graded material,FGM)微梁的热弹性阻尼(thermoelastic damping,TED).假设矩形截面微梁的材料性质沿厚度方向按幂函数连续变化,忽略了温度梯度在轴向的变化,建立了单向耦合的变系数一维热传导方程.热力耦合的横向自由振动微分方程由经典梁理论获得.采用分层均匀化方法将变系数的热传导方程简化为一系列在各分层内定义的常系数微分方程,利用上下表面的绝热边界条件和界面处的连续性条件获得了微梁温度场的分层解析解.将温度场代入微梁的运动方程,获得了包含热弹性阻尼的复频率,进而求得了代表热弹性阻尼的逆品质因子.在给定金属-陶瓷功能梯度材料后,通过数值计算结果定量分析了材料梯度指数、频率阶数、几何尺寸以及边界条件对TED的影响.结果表明:(1)若梁长固定不变,梁厚度小于某个数值时,改变陶瓷材料体积分数可以使得TED取得最小值;(2)固有频率阶数对TED的最大值没有影响,但是频率阶数越高对应的临界厚度越小;(3)不同的边界条件对应的TED的最大值相同,但是随着支座约束刚度增大对应的临界厚度减小;(4)TED的最大值和对应的临界厚度随着金属组分的增大而增大.

DOIURL [本文引用: 1]

本文对一类中心刚体-柔性梁系统在大范围转动下的刚柔耦合动力学问题进行了研究. 柔性梁为功能梯度材料(functionally graded materials, FGM)楔形变截面梁,材料体积分数在梁轴向呈幂律分布变化. 以弧长坐标来描述柔性FGM梁的几何位移关系,分别使用倾角和拉伸应变变量描述柔性梁的横向弯曲和纵向拉伸变形,并计及剪切效应. 采用假设模态法离散变形场,运用第二类拉格朗日方程进行方程推导,得到系统考虑剪切效应的刚柔耦合动力学模型. 基于全新的刚柔耦合动力学建模理论,研究不同轴向材料梯度分布的FGM楔形梁,通过数值仿真计算,分析讨论不同的转速、梯度分布规律以及变截面参数对系统动力学特性的影响. 结果表明,剪切效应对大高跨比的FGM楔形梁的变形影响较为明显,不容忽略;材料梯度分布规律和截面参数的选取均会对旋转FGM楔形梁的动力学响应和频率产生较大影响. 本文提出的考虑剪切效应的倾角刚柔耦合动力学模型是对以往非剪切模型的进一步完善,可应用于工程中的 Timoshenko梁结构的动力学问题求解.

DOIURL [本文引用: 1]

本文对一类中心刚体-柔性梁系统在大范围转动下的刚柔耦合动力学问题进行了研究. 柔性梁为功能梯度材料(functionally graded materials, FGM)楔形变截面梁,材料体积分数在梁轴向呈幂律分布变化. 以弧长坐标来描述柔性FGM梁的几何位移关系,分别使用倾角和拉伸应变变量描述柔性梁的横向弯曲和纵向拉伸变形,并计及剪切效应. 采用假设模态法离散变形场,运用第二类拉格朗日方程进行方程推导,得到系统考虑剪切效应的刚柔耦合动力学模型. 基于全新的刚柔耦合动力学建模理论,研究不同轴向材料梯度分布的FGM楔形梁,通过数值仿真计算,分析讨论不同的转速、梯度分布规律以及变截面参数对系统动力学特性的影响. 结果表明,剪切效应对大高跨比的FGM楔形梁的变形影响较为明显,不容忽略;材料梯度分布规律和截面参数的选取均会对旋转FGM楔形梁的动力学响应和频率产生较大影响. 本文提出的考虑剪切效应的倾角刚柔耦合动力学模型是对以往非剪切模型的进一步完善,可应用于工程中的 Timoshenko梁结构的动力学问题求解.

DOIURL [本文引用: 1]

通过对碳纤维环氧复合材料试样进行不同湿热环境下的拉伸和压缩实验,分析其吸湿特性、拉压力学性能、破坏后断口形貌以及动态力学性能,探讨湿热对该复合材料的拉伸和压缩性能的影响。结果表明:碳纤维环氧复合材料的吸湿过程满足Fick定律,饱和吸湿率约为0.86%。吸湿后材料表面变得光滑,有少量纤维拔出和树脂破坏发生,但吸湿后没有发生化学反应和新物质生成。吸湿后在130℃下,复合材料的拉伸性能保持率为96%,而压缩性能保持率仅为69%。吸湿后玻璃化转变温度比干态时下降了33℃。

DOIURL [本文引用: 1]

通过对碳纤维环氧复合材料试样进行不同湿热环境下的拉伸和压缩实验,分析其吸湿特性、拉压力学性能、破坏后断口形貌以及动态力学性能,探讨湿热对该复合材料的拉伸和压缩性能的影响。结果表明:碳纤维环氧复合材料的吸湿过程满足Fick定律,饱和吸湿率约为0.86%。吸湿后材料表面变得光滑,有少量纤维拔出和树脂破坏发生,但吸湿后没有发生化学反应和新物质生成。吸湿后在130℃下,复合材料的拉伸性能保持率为96%,而压缩性能保持率仅为69%。吸湿后玻璃化转变温度比干态时下降了33℃。

.

[本文引用: 1]

[本文引用: 1]

URL [本文引用: 1]

研究在湿热条件下复合材料的冲击损伤特征,是复合材料应用在舰船壳体的一个重要基础。现有的有限元方法在分析损伤及裂纹扩展问题中遇到了一定困难,需引入近场动力学(PD)理论,用于分析复合材料湿热冲击损伤。在复合材料近场动力学模型中,定义层内和层间共4种不同作用键;在本构方程中引入湿热伸长率项,改进键伸长率判定和键常数为湿热环境下的形式,建立了湿热环境下复合材料层合板PD模型。基于上述模型,模拟了不同湿热环境下复合材料层合板冲击损伤,并分析冲击速度对湿热处理复合材料层合板吸能性能的影响。结果表明:在冲击速度较低情况下,湿热因素对层合板冲击损伤影响较大;当温度与湿度共同作用时,层合板抵抗冲击能力更强。

URL [本文引用: 1]

研究在湿热条件下复合材料的冲击损伤特征,是复合材料应用在舰船壳体的一个重要基础。现有的有限元方法在分析损伤及裂纹扩展问题中遇到了一定困难,需引入近场动力学(PD)理论,用于分析复合材料湿热冲击损伤。在复合材料近场动力学模型中,定义层内和层间共4种不同作用键;在本构方程中引入湿热伸长率项,改进键伸长率判定和键常数为湿热环境下的形式,建立了湿热环境下复合材料层合板PD模型。基于上述模型,模拟了不同湿热环境下复合材料层合板冲击损伤,并分析冲击速度对湿热处理复合材料层合板吸能性能的影响。结果表明:在冲击速度较低情况下,湿热因素对层合板冲击损伤影响较大;当温度与湿度共同作用时,层合板抵抗冲击能力更强。

URL [本文引用: 1]

复合材料层合结构在制造和使用过程中经常暴露在湿热环境中,复合材料湿热行为准确分析已是复合材料结构设计不可回避问题。然而,至今复合材料湿热分析理论模型仍存在如下问题:已有分析复合材料湿热问题理论模型多忽略层间应力连续条件,不能准确计算层间应力;近期复合材料湿热研究甚至假设湿热膨胀系数不随铺设角变化,此假设将产生误导。该文发展预先满足层间应力连续并考虑横法向应变的高阶整体-局部理论,构造三角形单元分析在湿热力载荷作用下复合材料力学行为,并研究湿热膨胀系数对湿热行为影响。

URL [本文引用: 1]

复合材料层合结构在制造和使用过程中经常暴露在湿热环境中,复合材料湿热行为准确分析已是复合材料结构设计不可回避问题。然而,至今复合材料湿热分析理论模型仍存在如下问题:已有分析复合材料湿热问题理论模型多忽略层间应力连续条件,不能准确计算层间应力;近期复合材料湿热研究甚至假设湿热膨胀系数不随铺设角变化,此假设将产生误导。该文发展预先满足层间应力连续并考虑横法向应变的高阶整体-局部理论,构造三角形单元分析在湿热力载荷作用下复合材料力学行为,并研究湿热膨胀系数对湿热行为影响。

URL [本文引用: 1]

目的 研究湿热环境对聚甲基丙烯酸甲酯(PMMA)混杂纳米复合材料性能的影响。方法 利用制备的水包油型杂化乳液稳定剂EMI/GO/CNTs稳定以甲基丙烯酸甲酯(MMA)为油相的水包油型Pickering乳液,用偶氮二异丁氰(AIBN)为引发剂,引发Pickering乳液进行悬浮聚合,聚合产物为PMMA混杂纳米复合材料。将PMMA混杂纳米复合材料模压成型,分别在室温及50℃下进行水浸吸湿实验。采用光学显微镜对Pickering乳液液滴形貌进行分析,通过复合材料的质量变化、动态力学分析测试、导电性测试,对复合材料的吸湿率、玻璃化转变温度及导电性变化进行分析。结果 用EMI/GO/CNTs稳定的以MMA为油相的水包油型Pickering乳液具有良好的稳定性,乳液液滴的尺寸分布范围较窄,分布较均匀。复合材料的吸水量随时间增加逐渐增大,达到吸湿平衡状态后,吸湿率基本不变。不同温度下水浸复合材料的吸湿速度和平衡吸湿率不同,50℃水浸比25℃水浸的复合材料的吸湿速度快且平衡吸湿率大。湿热后复合材料的玻璃化转变温度基本不变。复合材料经湿热环境处理后电导率升高1~2个数量级。结论 利用制备的杂化乳液稳定剂制备出Pickering乳液并进行悬浮聚合、模压成型,制备出PMMA复合材料。经水浸湿热处理后的复合材料,其吸湿率和电导率均有一定变化,玻璃化转变温度基本不变。

URL [本文引用: 1]

目的 研究湿热环境对聚甲基丙烯酸甲酯(PMMA)混杂纳米复合材料性能的影响。方法 利用制备的水包油型杂化乳液稳定剂EMI/GO/CNTs稳定以甲基丙烯酸甲酯(MMA)为油相的水包油型Pickering乳液,用偶氮二异丁氰(AIBN)为引发剂,引发Pickering乳液进行悬浮聚合,聚合产物为PMMA混杂纳米复合材料。将PMMA混杂纳米复合材料模压成型,分别在室温及50℃下进行水浸吸湿实验。采用光学显微镜对Pickering乳液液滴形貌进行分析,通过复合材料的质量变化、动态力学分析测试、导电性测试,对复合材料的吸湿率、玻璃化转变温度及导电性变化进行分析。结果 用EMI/GO/CNTs稳定的以MMA为油相的水包油型Pickering乳液具有良好的稳定性,乳液液滴的尺寸分布范围较窄,分布较均匀。复合材料的吸水量随时间增加逐渐增大,达到吸湿平衡状态后,吸湿率基本不变。不同温度下水浸复合材料的吸湿速度和平衡吸湿率不同,50℃水浸比25℃水浸的复合材料的吸湿速度快且平衡吸湿率大。湿热后复合材料的玻璃化转变温度基本不变。复合材料经湿热环境处理后电导率升高1~2个数量级。结论 利用制备的杂化乳液稳定剂制备出Pickering乳液并进行悬浮聚合、模压成型,制备出PMMA复合材料。经水浸湿热处理后的复合材料,其吸湿率和电导率均有一定变化,玻璃化转变温度基本不变。

DOIMagsci [本文引用: 1]

<p>功能梯度材料具有复杂的细部结构, 其内部构造远比匀质材料复杂, 因此其构件动力分析很难求得其解析解。本文中提出了一种新颖的功能梯度构件动力分析的细观元法, 其目的在于建立材料的宏观性能与其组分材料性能及细观构造之间的定量关系, 以便揭示不同的材料组合及其变异所具有不同的宏观性能的内在机制。利用细观元法对含有空隙、 杂质及组分突变等情况下的功能梯度构件进行动力分析, 求得其三维固有频率及振型的三维分布。从而可知空隙、 杂质及组分突变均对功能梯度材料构件的宏观动力特性有很大的影响。</p>

DOIMagsci [本文引用: 1]

<p>功能梯度材料具有复杂的细部结构, 其内部构造远比匀质材料复杂, 因此其构件动力分析很难求得其解析解。本文中提出了一种新颖的功能梯度构件动力分析的细观元法, 其目的在于建立材料的宏观性能与其组分材料性能及细观构造之间的定量关系, 以便揭示不同的材料组合及其变异所具有不同的宏观性能的内在机制。利用细观元法对含有空隙、 杂质及组分突变等情况下的功能梯度构件进行动力分析, 求得其三维固有频率及振型的三维分布。从而可知空隙、 杂质及组分突变均对功能梯度材料构件的宏观动力特性有很大的影响。</p>

DOIURL [本文引用: 2]

The bending responses of porous functionally graded (FG) single-layered and sandwich thick rectangular plates are investigated according to a quasi-3D shear deformation theory. Both the effect of shear strain and normal deformation are included in the present theory and so it does not need any shear correction factor. The equilibrium equations according to the porous FG single-layered and sandwich plates are derived. The solution of the problem is derived by using Navier technique. Numerical results have been reported, and compared with those available in the open literature for non-porous single-layered and sandwich plates. Effects of the exponent graded and porosity factors are investigated.

DOIURL [本文引用: 1]

Some Functionally Graded Materials contain pores due to the result of processing; this influences their elastic and mechanical properties. Therefore, it may be very useful to examine the vibration behavior of thin Functionally Graded Annular Plates Clamped at both edges including porosities. In the present study, the rule of mixture is modified to take into account the effect of porosity and to approximate the material properties assumed to be graded in the thickness direction of the examined annular plate. A semi-analytical model based on Hamilton principle and spectral analysis is adopted using a homogenization procedure to reduce the problem under consideration to that of an equivalent isotropic homogeneous annular plate. The problem is solved by a numerical iterative method. The effects of porosity, material property, and elastic foundations characteristics on the CCFGAP axisymmetric large deflection response are presented and discussed in detail.

DOIURL [本文引用: 1]

In this paper, the free vibration characteristics and the static behaviour of porous functionally graded magneto-electro-elastic (FGMEE) plate is investigated using finite element method. The porosities arise due to the maladies in the fabrication processes and such porosities or micro-voids are accounted using modified power law. Influence of different porosity distributions on the behaviour of PFGMEE plate are considered in this study. The through thickness variation of material properties is achieved to obtain a functionally graded MEE plate. The coupled constitutive equations along with the principle of virtual work are used to develop a FE model for FGMEE plates. Influence of various porosity distributions on the structural behaviour of the plate is thoroughly investigated. The effect of porosity volume and material gradient index on the free vibration and static behaviour is explicitly studied. This study also includes the evaluation of the effect of geometrical parameters such as thickness ratio, aspect ratio, and boundary condition on the structural characteristics of porous FGMEE plate.

DOIURL [本文引用: 1]

In this paper, the free vibration analysis of rectangular plates composed of functionally graded materials with porosities is investigated based on a simple first-order shear deformation plate theory. The network of pores in assumed to be empty or filled by low pressure air and the material properties of the plate varies through the thickness. Using Hamilton's principle and utilizing the variational method, the governing equations of motion of FG plates with porosities are derived. Considering two boundary layer functions, the governing equations of the system are rewritten and decoupled. Finally, two decoupled equations are solved analytically for L vy-type boundary conditions so as to obtain the eigenfrequencies of the plate. The effects of porosity parameter, power law index, thickness-side ratio, aspect ratio, porosity distribution and boundary conditions on natural frequencies of the plate are investigated in detail.

DOIURL [本文引用: 1]

This article presents a finite element (FE) formulation to assess the influence of porosity on the static responses and free vibration of functionally graded skew magneto-electro-elastic (FGSMEE) plate. The porosity is accounted for local density using modified power law. The skew edges of the plate are achieved by implementing transformation matrix. The coupled constitutive relations establish the different couplings associated with MEE materials. The displacements, potentials, and stresses for the porous skew plate are established through static analysis. The influence of porosity on the natural frequency of the skew plate is investigated via free vibration analysis. The influence of different porosity distributions on various skew angles of the FGSMEE plate has been studied. The effect of porosity volume, skew angle, and geometrical parameters such as aspect ratio, thickness ratio, and boundary conditions on the porous FGSMEE plate is investigated.

DOIURL [本文引用: 1]

A first known study is conducted on the vibrations of functionally graded material (FGM) rectangular plates with porosities and moving in thermal environment. The FGM plates contain porosities owing to the technical issues during the preparation of FGMs. Two types of porosity distribution, namely, even and uneven distribution, are considered. The geometric nonlinearity is taken into account by using von K rm n nonlinear plate theory. The out-of-plane equation of motion of the system is derived based on the D'Alembert's principle with the consideration of the thermal effect and longitudinal speed. Then the Galerkin method is employed to discretize the partial differential equation of motion to a set of ordinary differential equations. These time-varying ordinary differential equations are solved analytically by means of the method of harmonic balance. The accuracy of approximately analytical solutions is verified by the adaptive step-size fourth-order Runge utta technique. Additionally, the stability of steady-state solutions is analyzed for the analytical solutions. Vibration characteristics such as natural frequency and nonlinear frequency response are shown. The present model is a hardening-spring system based on the nonlinear frequency response results. Effects of some key parameters are investigated on the vibration of rectangular FGM plates with porosities and moving in thermal environment.

DOIURL [本文引用: 1]

为了快速分析非均质材料结构在复杂载荷作用下的动态响应, 提出一种模型降阶方法, 只需计算结构在简单均质材料情况下的动力学问题, 进而用其计算结果对非均质材料结构进行分析. 首先, 采用结构内部任意一点处的材料参数值作为整个结构的材料参数, 利用有限元分析软件计算该均质材料结构在动态载荷作用下的位移场建立数据库, 该数据库包含计算模型各个节点(自由度为N)在某时间段内L个时刻的位移; 其次, 对数据库中的信息按照时间离散的特定方式组集成瞬像矩阵, 并利用特征正交分解方法对其进行分解, 得到该模型的L个特征正交基底, 选取其中能反应模型主要特征的H个(其中$H<L\ll N$)作为一组最优基底, 通过这组基底建立模型的低阶离散控制方程; 最后, 求解低阶离散微分方程组, 得到功能梯度材料结构在复杂载荷作用下的位移场. 文中分别给出二维和三维算例, 比较了降阶模型和全阶模型计算结果, 验证了该方法的有效性, 并且计算效率能提高1~2个数量级.

DOIURL [本文引用: 1]

为了快速分析非均质材料结构在复杂载荷作用下的动态响应, 提出一种模型降阶方法, 只需计算结构在简单均质材料情况下的动力学问题, 进而用其计算结果对非均质材料结构进行分析. 首先, 采用结构内部任意一点处的材料参数值作为整个结构的材料参数, 利用有限元分析软件计算该均质材料结构在动态载荷作用下的位移场建立数据库, 该数据库包含计算模型各个节点(自由度为N)在某时间段内L个时刻的位移; 其次, 对数据库中的信息按照时间离散的特定方式组集成瞬像矩阵, 并利用特征正交分解方法对其进行分解, 得到该模型的L个特征正交基底, 选取其中能反应模型主要特征的H个(其中$H<L\ll N$)作为一组最优基底, 通过这组基底建立模型的低阶离散控制方程; 最后, 求解低阶离散微分方程组, 得到功能梯度材料结构在复杂载荷作用下的位移场. 文中分别给出二维和三维算例, 比较了降阶模型和全阶模型计算结果, 验证了该方法的有效性, 并且计算效率能提高1~2个数量级.

DOIURL [本文引用: 3]

In the present paper, radial and hoop thermal and mechanical stress analysis of a rotating disk made of functionally graded material (FGM) with variable thickness is carried out by using finite element method (FEM). To model the disk by FEM, one-dimensional two-degree elements with three nodes are used. It is assumed that the material properties, such as elastic modulus, Poisson ratio and thermal expansion coefficient, are considered to vary using a power law function in the radial direction. The geometrical and boundary conditions are in the shape of two models including thermal stress (model-A) and mechanical stress (model-B). In model-A there exists no pressure in both external and internal layers, and there is a temperature distribution considered as a second order function in the radial direction of the rotating disk. In this case, the temperature dependency of the material properties is considered and a hyperbolic type is assumed for the geometry of the disk. In model-B, there is a constant pressure only on the internal layer and a pressure on the internal layer of the disk without temperature distribution but with different types of surface profiles. Furthermore, the displacements and stresses for various power law indices (N) and angular velocities are calculated and compared to other results in the literature. The effect of varying thicknesses and dependency of material properties on temperature distribution is investigated.

DOIURL [本文引用: 1]

URL

对于较厚的多层复合壳体,其振动位移沿厚度方向呈锯齿形变化且层间剪切和拉、压应力呈三维耦合状态,采用传统的等效单层理论分析已不能满足精度要求. 建立不受结构厚度、铺层材料性质和铺层方式限制的三维分析方法具有重要的研究价值. 本文以独立铺层为建模对象,结合广义谱方法与微分求积技术建立了一种适用一般边界条件和铺层方式的多层复合壳体三维分析新方法——谱--微分求积混合法. 该方法应用三维弹性理论对独立铺层进行精确建模,有效克服了二维简化理论对横向变形以及层间应力估计不确切的缺点;引入微分求积技术对铺层进行数值离散,将三维偏微分问题转化为二维偏微分问题,降低了求解维度和难度;应用广义谱方法近似地表述离散计算面上的场变量,将获取的二维偏微分方程转化为以场变量谱展开系数为未知量的线性代数方程组,避免了对超越方程的求解. 数值验证结果表明该方法收敛性好,计算精度高.

URL

对于较厚的多层复合壳体,其振动位移沿厚度方向呈锯齿形变化且层间剪切和拉、压应力呈三维耦合状态,采用传统的等效单层理论分析已不能满足精度要求. 建立不受结构厚度、铺层材料性质和铺层方式限制的三维分析方法具有重要的研究价值. 本文以独立铺层为建模对象,结合广义谱方法与微分求积技术建立了一种适用一般边界条件和铺层方式的多层复合壳体三维分析新方法——谱--微分求积混合法. 该方法应用三维弹性理论对独立铺层进行精确建模,有效克服了二维简化理论对横向变形以及层间应力估计不确切的缺点;引入微分求积技术对铺层进行数值离散,将三维偏微分问题转化为二维偏微分问题,降低了求解维度和难度;应用广义谱方法近似地表述离散计算面上的场变量,将获取的二维偏微分方程转化为以场变量谱展开系数为未知量的线性代数方程组,避免了对超越方程的求解. 数值验证结果表明该方法收敛性好,计算精度高.

DOIURL [本文引用: 2]

The dynamic thermoelastic response of functionally graded cylinders and plates is studied. Thermomechanical coupling is included in the formulation, and a finite element model of the formulation is developed. The heat conduction and the thermoelastic equations are solved for a functionally graded axisymmetric cylinder subjected to thermal loading. In addition, a thermoelastic boundary value problem using the first-order shear deformation plate theory (FSDT) that accounts for the transverse shear strains and the rotations, coupled with a three-dimensional heat conduction equation, is formulated for a functionally graded plate. Both problems are studied by varying the volume fraction of a ceramic and a metal using a power law distribution.