,, 张煦怡, 王文敏, 杨延龙, 随龙龙, 张鹏鹏, 张亚黎, 张旺锋

,, 张煦怡, 王文敏, 杨延龙, 随龙龙, 张鹏鹏, 张亚黎, 张旺锋 ,*, 勾玲

,*, 勾玲 ,*石河子大学农学院 / 新疆生产建设兵团绿洲生态农业重点实验室, 新疆石河子 832000

,*石河子大学农学院 / 新疆生产建设兵团绿洲生态农业重点实验室, 新疆石河子 832000A method of defoliant application based on fiber damage and boll growth period of machine-harvested cotton

TIAN Jing-Shan ,, ZHANG Xu-Yi, WANG Wen-Min, YANG Yan-Long, SUI Long-Long, ZHANG Peng-Peng, ZHANG Ya-Li, ZHANG Wang-Feng

,, ZHANG Xu-Yi, WANG Wen-Min, YANG Yan-Long, SUI Long-Long, ZHANG Peng-Peng, ZHANG Ya-Li, ZHANG Wang-Feng ,*, GOU Ling

,*, GOU Ling ,*College of Agronomy, Shihezi University / Key Laboratory of Oasis Eco-Agriculture, the Xinjiang Production and Construction Corps, Shihezi 832003, Xinjiang, China

,*College of Agronomy, Shihezi University / Key Laboratory of Oasis Eco-Agriculture, the Xinjiang Production and Construction Corps, Shihezi 832003, Xinjiang, China通讯作者:

收稿日期:2019-12-13接受日期:2020-04-15网络出版日期:2020-09-12

| 基金资助: |

Received:2019-12-13Accepted:2020-04-15Online:2020-09-12

| Fund supported: |

作者简介 About authors

E-mail:

摘要

关键词:

Abstract

Keywords:

PDF (738KB)元数据多维度评价相关文章导出EndNote|Ris|Bibtex收藏本文

本文引用格式

田景山, 张煦怡, 王文敏, 杨延龙, 随龙龙, 张鹏鹏, 张亚黎, 张旺锋, 勾玲. 棉花脱叶催熟剂对纤维品质的影响及应用时间的确定[J]. 作物学报, 2020, 46(9): 1388-1397. doi:10.3724/SP.J.1006.2020.94196

TIAN Jing-Shan, ZHANG Xu-Yi, WANG Wen-Min, YANG Yan-Long, SUI Long-Long, ZHANG Peng-Peng, ZHANG Ya-Li, ZHANG Wang-Feng, GOU Ling.

棉花脱叶催熟技术是实现棉花机械采收的重要前提, 不仅能解决棉花成熟期集中吐絮的问题, 而且加快了收获前的叶片脱落, 能提高机采棉的采摘率和作业效率[1], 降低机采籽棉含杂率[2]。合理喷施脱叶催熟剂, 不仅会产生良好的脱叶催熟效果, 而且可以降低对产量和品质的负面影响[3,4,5]。棉铃吐絮率是判断脱叶催熟喷施时间较为常用的指标, 一般情况下推荐在60%的棉铃吐絮后进行脱叶催熟[3,6-7]。过早喷施脱叶催熟剂, 将会增加不成熟棉铃和纤维的比例[8,9], 推迟喷施脱叶催熟剂, 则会增加遭遇霜冻和恶劣天气的风险[10], 导致叶片枯而不落、增加籽棉含杂率[2]。然而, 脱叶催熟剂对环境温度比较敏感, 要求平均气温>16℃和最低温度>12℃[11]。

在新疆棉花生育后期, 一天内气温>20℃的时间逐渐减少、夜间温度急剧下降[12]。为确保机械采收, 部分棉田植株顶部棉铃尚未完全发育就喷施脱叶催熟剂, 这势必严重影响成铃和纤维发育[13,14]。因此, 脱叶催熟剂喷施时间不仅要考虑气温变化, 还应综合考虑棉花顶部棉铃铃期、吐絮率及喷施后的气温状况。因此, 适时喷施脱叶催熟剂非常关键, 但也较难确定[3], 需均衡考虑脱叶催熟效果和棉花产量、品质之间的平衡关系[15]。

棉铃是棉花产量和纤维品质的载体, 棉铃形态特征与纤维品质密切关联[16], 棉铃形态可以通过棉铃体积、棉铃长度、棉铃直径的大小来反映。棉铃体积、单铃重与纤维品质呈正相关, 大铃形成显著促进了产量提高和纤维品质改善[17]。棉铃铃期长、生长速度快, 则棉铃体积大、单铃重高; 棉铃长度对棉铃体积和单铃重的影响最大, 栽培管理应根据棉铃形态特征, 通过促进棉铃长度的增长提高铃重[18]。因此, 棉铃形态的改变影响到产量提高和纤维品质的改善[19], 机采棉品种的棉铃则应具备铃壳薄、铃大小适中等特点[20,21]。近年来, 随着机采棉的快速发展, 棉花品质下降问题突出, 特别是从源头上就存在品种过多导致棉铃铃期差异大、品质一致性差等问题[22]。目前, 新疆棉区推荐田间吐絮率30%~40%为脱叶催熟剂最佳喷施时间[11], 但该方法并未考虑棉花品种及棉铃形态特征。那么, 什么样的棉铃形态既能适应脱叶催熟又能确保提质增效?基于此, 本研究采用多品种试验和分阶段喷施脱叶催熟剂的方式, 开展了脱叶催熟剂对棉纤维品质影响的研究, 分析脱叶催熟剂喷施时期对纤维品质的损伤程度, 明确棉铃形态特征与纤维品质的定量关系, 探讨适宜脱叶催熟剂的使用时期和棉铃形态。

1 材料与方法

1.1 试验设计

1.1.1 脱叶催熟剂对纤维品质影响 于2016—2017年在石河子大学农学试验站(45°19′N, 86°03′E)和新疆乌兰乌苏农业气象试验站(44°17′N, 85°49′E)进行, 供试材料选择“‘新陆早’”系列棉花品种, 随机区组设计, 留苗密度为18~23万株 hm-2。待棉株开花后, 对上部果枝(第7果枝及以上)第1果节的当日所开白花挂牌标记。采用分阶段喷施脱叶催熟剂的方式, 分别在铃龄30、37、44 d喷施, 以不喷施脱叶催熟剂为对照(CK); 供试药剂为噻苯隆(80%可湿性粉剂)和乙烯利(40%水剂), 用量分别为450 g hm-2、1350 mL hm-2。具体种植的棉花品种、播种日期和挂花日期、脱叶催熟剂喷施时间见表1。Table 1

表1

表1脱叶催熟剂试验种植的棉花品种、播种日期、挂花日期和脱叶催熟剂喷施时间

Table 1

| 年份 Year | 试验地点 Experiment plot | ‘新陆早’系列品种序号 No. of ‘Xinluzao’ cotton cultivars | 播种日期 Sowing dates (month/day) | 挂花时期 Tagged dates (month/day) | 脱叶催熟剂 喷施时间 Defoliation times (d) |

|---|---|---|---|---|---|

| 2016 | 石河子大学农学试验站 Shihezi University Experiment Station | 1, 6, 7, 13, 33, 45 | 4/21 | 7/20 | 30, 37 |

| 46, 47, 58, 60, 62, 63, 64 | 4/21 | 7/20 | 37, 44 | ||

| 新疆乌兰乌苏农业气象试验站 Wulanwusu Agrometeorological Experiment Station | 33 | 4/15 | 7/15 | 30, 37, 44 | |

| 33 | 4/15 | 7/22 | 30, 37 | ||

| 59 | 4/8, 4/15, 4/22 | 7/15, 7/15, 7/22 | 30, 37, 44 | ||

| 2017 | 石河子大学农学试验站 Shihezi University Experiment Station | 45, 46, 47, 60, 61, 62, 63, 64 | 4/22 | 7/12 | 30, 37 |

| 33, 59 | 4/22 | 7/12 | 30, 37, 44 |

新窗口打开|下载CSV

1.1.2 适期脱叶催熟的棉铃形态 于2014—2017年在石河子大学农学试验站(45°19′N, 86°03′E)进行, 供试材料选择‘新陆早’系列棉花品种, 随机区组设计, 留苗密度为18~23万株 hm-2。待棉株开花后, 对中部果枝(第5~6果枝)第1果节的当日所开白花挂牌标记。在标记棉铃吐絮期(铃龄43~53 d), 取大小相同棉铃6个左右(上午8:00—9:00), 用装有冰袋的保鲜桶带回室内, 测定棉铃长度、直径和体积。具体种植的棉花品种、播种日期、挂花日期和取样时间见表2。

Table 2

表2

表2品种试验种植的棉花品种、播种日期、挂花日期和取样时间

Table 2

| 年份 Year | ‘新陆早’系列品种序号 No. of ‘Xinluzao’ cotton cultivars | 播种日期 Sowing dates (month/day) | 挂花时期 Tagged dates (month/day) | 取样时间 Sampling dates (d) |

|---|---|---|---|---|

| 2014 | 1, 2, 5, 7, 10, 13, 24, 36, 45, 52, 53 | 5/1 | 7/15 | 46 |

| 2015 | 1, 2, 5, 7, 10, 24, 36, 52, 53 | 4/20 | 7/9 | 53 |

| 2016 | 1, 6, 7, 13, 33, 45, 46, 47, 58, 60, 62, 63, 64 | 4/21 | 7/20 | 43 |

| 2017 | 45, 46, 47, 60, 61, 62, 63, 64 | 4/22 | 7/12 | 50 |

新窗口打开|下载CSV

1.2 测定项目与方法

棉铃长度是以游标卡尺测量从棉铃铃尖到铃基的垂直距离, 棉铃直径是以游标卡尺测量棉铃横径的最大值, 棉铃体积采用排水法测定。待挂牌标记棉铃裂铃吐絮时, 收取大小一致的棉铃, 统一风干轧花, 皮棉试样送至农业部棉花品质监督检验测试中心(新疆乌鲁木齐和河南安阳), 测定棉纤维上半部平均长度(长度)和断裂比强度(比强度)。棉铃铃期是从棉花开花之日至棉铃开裂(线裂或微裂)之日的天数, 棉纤维品质损伤量是喷施脱叶催熟剂处理试样的纤维品质与对照的差值, 其中差值为负值表示喷施脱叶催熟剂处理较对照降低, 正值则表示增加。Rd/b是脱叶催熟剂喷施时的棉铃铃龄(d)与铃期(b)的比值, 其中铃期为不喷施脱叶催熟剂处理(对照)的棉铃铃期。

1.3 数据统计与分析

采用Microsoft Excel 2016录入、整理和计算数据, 运用DPS数据处理系统进行分析, 数据间的多重比较采用LSD法, SigmaPlot 12.0作图。2 结果与分析

2.1 脱叶催熟剂对棉纤维品质的影响

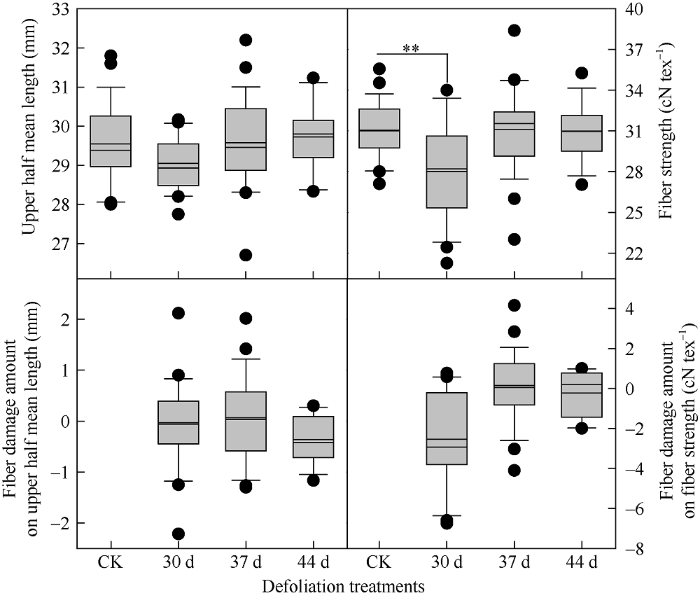

由图1可看出, 棉纤维长度受脱叶催熟剂施药时间的影响不显著, 较对照平均值降低了0.2%~ 1.2%。棉纤维比强度受脱叶催熟剂喷施时间的影响较大, 在铃龄37 d和44 d喷施与对照差异不显著, 平均降低了0.1%~0.6%; 在铃龄30 d喷施则显著降低了纤维比强度, 较对照平均降低了8.5%。图1

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图1脱叶催熟剂喷施时间对棉纤维长度和比强度的影响

脱叶催熟剂喷施时间在铃龄30、37、44 d处理的样本数分别是21、28、13。图中粗实线表示该组数据的平均值。**表示在P < 0.01差异显著。

Fig. 1Effects on fiber length and fiber strength of different defoliant application time

Samples number of defoliation times on the 30th, 37th, and 44th days post-anthesis were 21, 28, and 13, respectively. In the figure, the thick solid line represents the average value of the defoliant treatment. ** indicates statistically significant difference at P < 0.01.

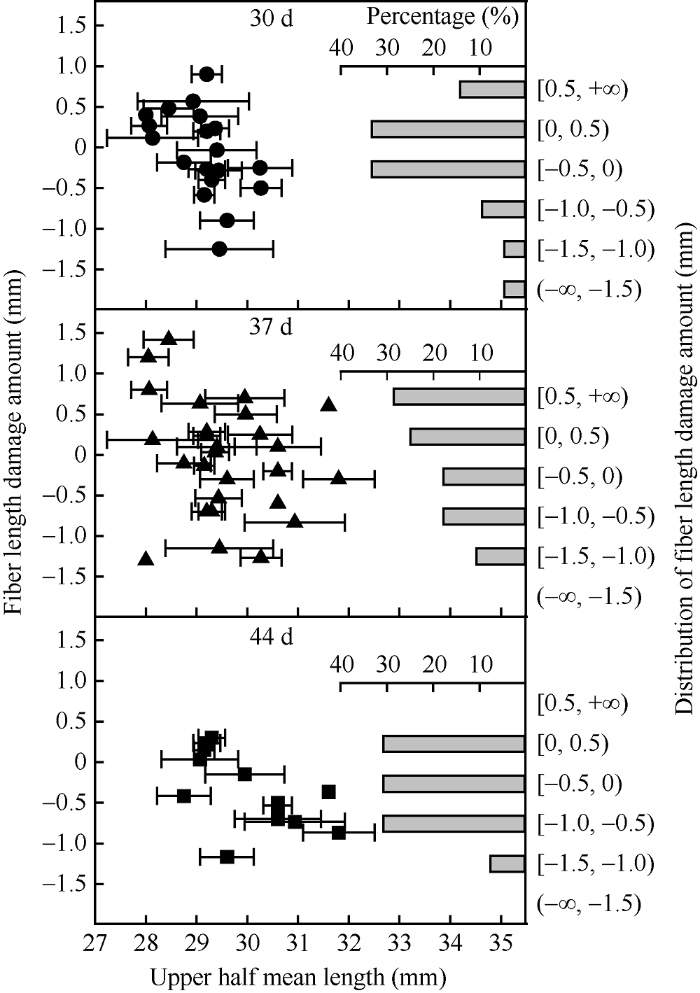

喷施脱叶催熟剂后不同品种的纤维长度较对照有增加、亦有降低, 即纤维长度的损伤量有正值、亦有负值; 对损伤量进行统计, 并以0.5 mm级距将其分为6个等级。由图2可看出, 脱叶催熟剂喷施时间对纤维长度损伤量的等级分布影响较小, 各损伤等级所占的比例以铃龄30 d喷施脱叶催熟剂的波动较大。损伤量<0 mm所占总品种数的比例在铃龄30 d和37 d喷施时分别为52%和46%, 且以损伤量-1.0~0 mm为主, 分别占总品种数的43%和36%; 铃龄44 d喷施时的损伤量则以-1.0~0.5 mm为主, 各占31%。在不同铃龄喷施脱叶催熟剂, 纤维长度损伤量>0 mm亦占很大比例, 约31%~54%。

图2

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图2脱叶催熟剂喷施时间对棉纤维长度损伤等级的影响

柱状图是不同等级的纤维长度损伤量在试点间的比例分布, 横坐标是不同等级纤维长度的损伤量占全部试点数的百分比(%), 纵坐标是纤维长度损伤量的等级。散点图中的误差线为该组数值的标准偏差。处理同

Fig. 2Effects on distribution of fiber length damage amount of different defoliant application times

The bar graphs represent the distribution of fiber length damage among all samples, the X-axis is the percentage of fiber length damage grades and the Y-axis is the grades of fiber length damage amount. In the scatter graphs, the values are means ± standard deviation. Treatments are the same as those given in

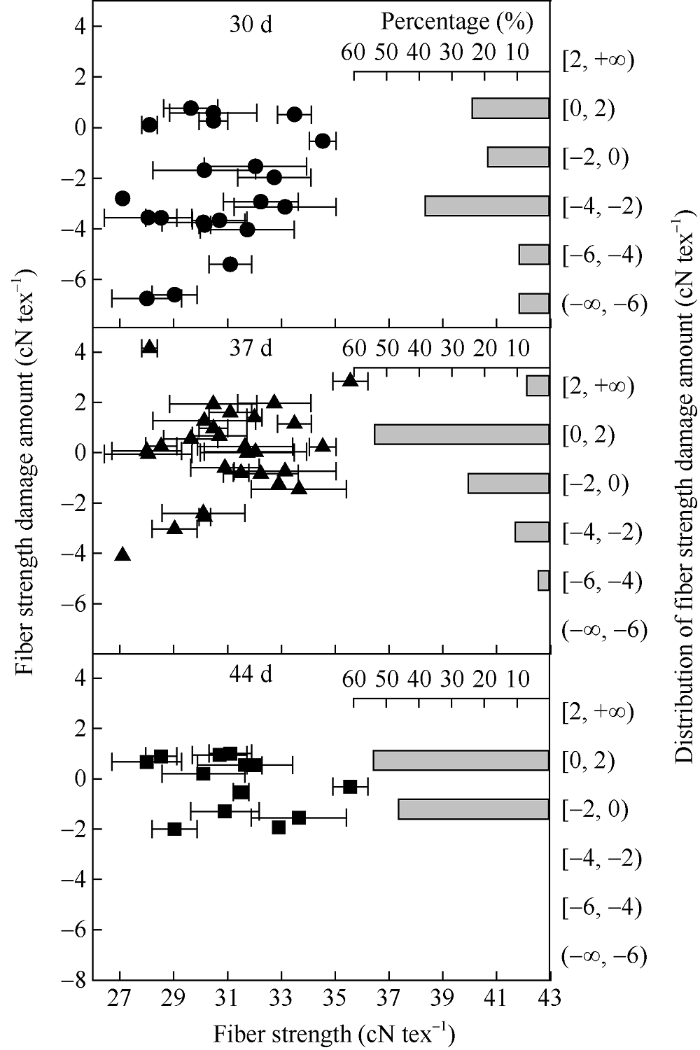

喷施脱叶催熟剂后不同品种的纤维比强度较对照有增加、亦有降低, 即纤维比强度的损伤量有正值、亦有负值; 对损伤量进行统计, 并以2 cN tex-1级距将其分为6个等级。由图3可看出, 脱叶催熟剂喷施时间对纤维比强度损伤量的等级分布影响较大, 铃龄30 d喷施时的损伤量<0 cN tex-1的比例高达76%, 且以[-4 cN tex-1, -2 cN tex-1]所占总品种数的比例最高, 占38%; 损伤量(-∞, -4 cN tex-1)所占比例高达20%。在铃龄37 d喷施脱叶催熟剂, 纤维比强度损伤量主要分布在-2~2 cN tex-1, 占总品种数的79%, 且以[0 cN tex-1, 2 cN tex-1]所占比例最高, 占总品种数的54%; 另有11%品种的损伤量在-4~2 cN tex-1。在铃龄44 d喷施脱叶催熟剂对纤维比强度的损伤量分布影响较小, 主要在[-2 cN tex-1, 0 cN tex-1]和[0 cN tex-1, 2 cN tex-1], 分别占总品种数的46%和54%。

图3

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图3脱叶催熟剂喷施时间对棉纤维比强度损伤等级的影响

柱状图是不同等级的纤维比强度损伤量在试点间的比例分布, 横坐标是不同等级纤维比强度的损伤量占全部试点数的百分比(%), 纵坐标是纤维比强度损伤量的等级。散点图中的误差线为该组数值的标准偏差。处理同

Fig. 3Effects on distribution of fiber strength damage amount of different defoliant application time

The bar graphs represent the distribution of fiber strength damage among all samples, the X-axis is the percentage of fiber strength damage grades and the Y-axis is the grades of fiber strength damage amount. In the scatter graphs, the values are means ± standard deviation. Treatments are the same as those given in

由图4可看出, 脱叶催熟剂对纤维长度和比强度的损伤量随棉铃铃期延长而加剧; 且脱叶催熟剂喷施时间越早、纤维品质损伤量越大, 其中纤维比强度的损伤量大于纤维长度的损伤量, 如在铃龄30 d喷施脱叶催熟剂, 纤维比强度和长度的损伤变幅分别为0.5266 cN tex-1 d-1和0.0868 mm d-1, 在铃龄44 d喷施时则仅为0.0065 cN tex-1 d-1和0.0428 mm d-1。

图4

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图4棉纤维长度和比强度的损伤量与对照处理棉铃铃期的关系

处理同

Fig. 4Relationships between fiber length and strength damage amounts and boll growth period of the control treatments on different defoliant application time

Treatments are the same as those given in

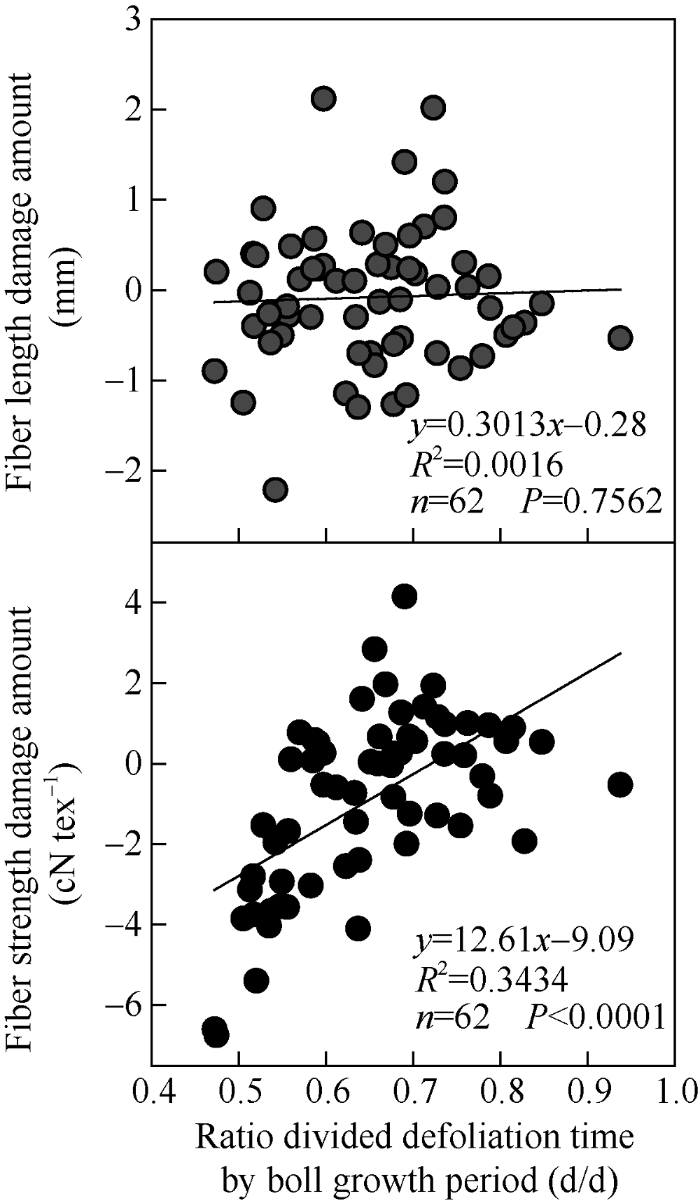

由图5可看出, Rd/b与纤维长度损伤量呈线性关系(R2=0.0016), 未达到显著性差异水平; Rd/b与纤维比强度呈显著正线性关系(R2=0.3434)。

图5

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图5棉纤维长度和比强度的损伤量与脱叶催熟剂喷施时的棉铃铃龄与铃期的比值(Rd/b)间的定量关系

Fig. 5Quantitative relationship between fiber length and strength damage amounts and the ratio of boll growth period with on defoliant application time (Rd/b)

2.2 棉铃形态与铃期的定量关系

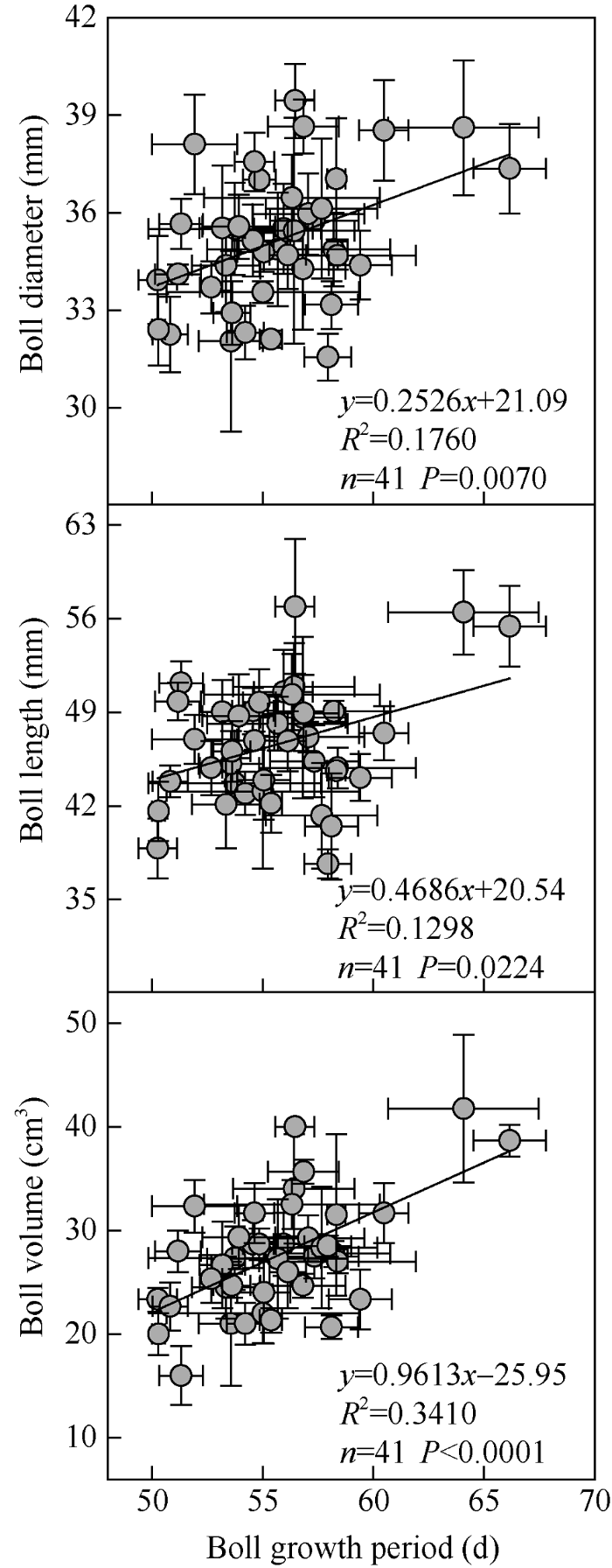

由图6可看出, 棉铃铃期与棉铃长度呈正线性相关(R2=0.1298), 达到显著性差异水平; 铃期则与铃直径和铃体积呈极显著线性相关(R2=0.1760和R2=0.3410)。图6

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图6棉铃铃期与棉铃直径、长度和体积间的定量关系

Fig. 6Quantitative relationship of boll growth period with boll characters including boll diameter, length, and volume

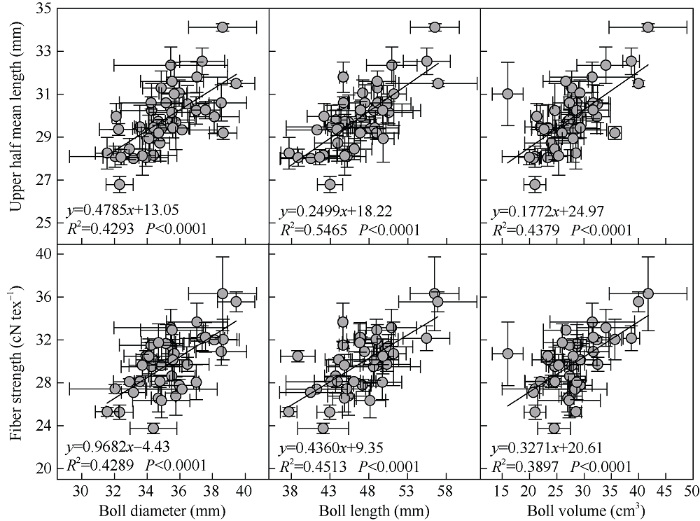

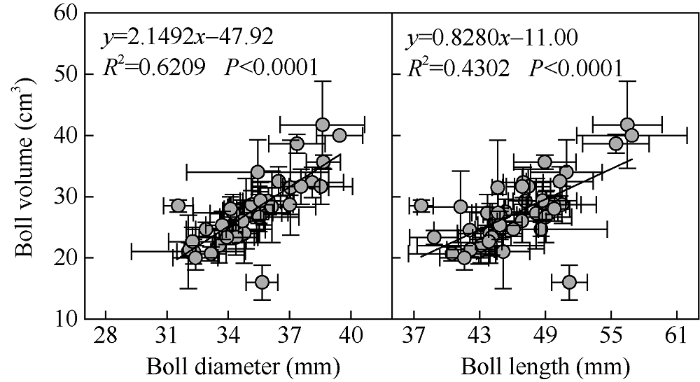

棉纤维长度和比强度与棉铃形态(直径、长度、体积)均呈显著正线性关系(图7), R2>0.3897。根据拟合方程可计算出, 生产>31 mm的纤维需要求棉铃体积>34.0 cm3、铃长度>51.1 mm、铃直径>37.5 mm, 生产>31 cN tex-1的纤维需要求棉铃体积>31.8 cm3、铃长度>49.7 mm、铃直径>36.6 mm。棉铃直径和铃长度与铃体积呈极显著正线性关系(R2=0.6209和R2=0.4302) (图8)。

图7

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图7棉纤维长度和比强度与棉铃直径、长度和体积间的定量关系

Fig. 7Quantitative relationship between boll characters (diameter, length, and volume) and fiber quality (fiber length and fiber strength)

图8

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图8棉铃体积与棉铃直径和铃长度的定量关系

Fig. 8Quantitative relationship between boll volume and boll diameter and length

3 讨论

3.1 脱叶催熟剂喷施时间对棉花纤维品质的损伤

棉花脱叶催熟剂喷施是否得当将直接影响着棉花脱叶效果, 并对机械采收质量和原棉品质有着极其重要的影响。一般而言, 合理的脱叶催熟剂喷施时间不仅会产生良好的脱叶催熟效果, 而且可以降低对产量和品质的负面影响[3,4,5]。本研究表明, 脱叶催熟剂对纤维长度的影响不显著, 在铃龄30 d和37 d时喷施脱叶催熟剂后, 纤维长度表现增加趋势的品种约占1/2。棉纤维细胞在开花当天就开始伸长[23], 铃龄30 d纤维伸长基本停止[24]。可见, 铃龄30 d时纤维发育已达到该品种的固有长度, 此时喷施脱叶催熟剂对纤维长度影响较小。棉花脱叶催熟在某种程度上影响了叶片的光合作用和叶片光合产物向棉铃的转运[14,25], 改变了棉花铃叶系统的源-库关系[26,27]。目前, 我国批准登记棉花脱叶剂有效成分仍以噻苯隆(thidiazuron)为主[28], 并复配乙烯利(ethephon)以获得更好、更为安全的脱叶效果和催熟效果[29]。噻苯隆和乙烯利同时具有催熟和脱叶功能[30], 一般情况下, 噻苯隆的脱叶效果优于催熟效果, 乙烯利的催熟效果优于脱叶效果[31]。本研究表明, 棉纤维比强度受脱叶催熟剂的影响较为明显, 其损伤量的变化幅度更大, 较不喷施脱叶催熟剂处理的最大降幅可达4 cN tex-1。前人研究表明, 喷施脱叶剂(噻苯隆复配乙烯利)后7 d内是实现良好脱叶效果的关键时间段, 脱叶率高达55%~ 79%[32]; 棉花叶片中脱落酸含量显著升高、生长素含量显著下降[33,34], 叶柄与茎枝间的断裂强度大幅降低[35,36], 引起叶片迅速脱落, 阻断了叶片光合产物的转运[14,37]。棉纤维比强度形成的本质就是纤维素大量沉积于次生壁内侧的过程, 铃龄5~15 d纤维素就已开始沉积[38,39], 至铃龄42 d次生壁加厚期基本结束[40]。可见, 脱叶催熟可能阻碍或减少了光合产物向纤维的分配与运输, 影响了纤维比强度的形成; 且脱叶催熟剂喷施时间越早, 纤维比强度的损伤变幅则会迅速扩大。

乙烯利作为催熟剂在棉花生产上广泛应用,棉铃在开裂和明显脱水之前,其释放的乙烯量显著提高[41,42]。喷施乙烯利后7 d内,棉花叶片光合能力变化不大,叶片贮藏的光合产物更多的向棉铃输送,特别是改变了棉花光合产物的运转分配比例,使更多光合产物累积在纤维中,运转至棉籽中的分配量有所减少[25]。本研究表明,铃龄30 d和37 d时喷施脱叶催熟剂后,仍有24%和61%品种的纤维比强度表现增加趋势。可见,当棉铃发育基本发育完全(次生壁加厚期基本结束)时,推迟喷施脱叶催熟剂则乙烯利的催熟效果要大于脱叶剂的脱叶影响,即纤维比强度主要受催熟剂的影响。棉花生产中可根据棉花品种早熟性及棉铃特性,最早可尝试在铃龄37 d时喷施脱叶催熟剂,发挥催熟剂的催熟作用。脱叶剂和催熟剂虽影响了棉花叶片光合产物转运与分配,但其作用机制有所差异。那么,针对不同熟制和棉铃特征的棉花品种,在有限的资源条件下如何协调脱叶效果与催熟效果以及脱叶剂与催熟剂是否复配使用,仍需通过脱叶与催熟影响棉纤维发育的生理机制予以探讨。

3.2 适宜脱叶催熟剂的使用时期和棉铃形态

棉铃是棉花产量和纤维品质形成的基本单位, 其发育过程包括棉铃体积的增大和内部物质的充实, 其中, 棉铃体积的增大主要表现为铃长度和铃直径的增长, 棉铃内部物质的充实主要体现为棉铃铃重的逐步增加。棉铃形态(铃体积、铃长度和铃直径)与纤维品质密切相关, 棉铃长度和直径与棉纤维长度和比强度呈显著正相关[43], 铃体积与纤维比强度呈显著正相关、与马克隆值呈显著负相关[44]。为此, 前人认为高品质棉促进大铃形成是棉花高产优质的关键[17], 应以棉铃长度为重要指标进行高品质类型棉花品种选育, 以棉铃体积提高为载体进行高产优质栽培调节[18]。本研究也证实, 棉纤维长度和比强度与棉铃形态(直径、长度、体积)均呈显著正线性关系, 棉铃体积随铃直径和铃长度的增长而显著增大, 生产纤维比强度>31 cN tex-1的纤维就要求棉铃体积> 31.8 cm3, 生产>30 cN tex-1的纤维就要求棉铃体积> 28.7 cm3 (表3)。Table 3

表3

表3生产30 cN tex-1和31 cN tex-1纤维比强度所需要的铃体积、铃直径、铃长度、铃期和脱叶催熟剂喷施时的棉铃铃龄与铃期的比值(Rd/b)及脱叶催熟剂的喷施时间

Table 3

| 性状 Trait | 生产纤维比强度>31 cN tex-1 要求的参数 Values for producing >30 cN tex-1 fiber strength | 生产纤维比强度>30 cN tex-1 要求的参数 Values for producing >30 cN tex-1 fiber strength | |

|---|---|---|---|

| 铃体积Boll volume (cm3) | 31.8 | 28.7 | |

| 铃长度Boll length (mm) | 49.7 | 47.4 | |

| 铃直径Boll diameter (mm) | 36.6 | 35.6 | |

| 铃期Boll growth period (d) | 60.0 | 56.8 | |

| 比强度损伤 Fiber strength damage amount < 0.5 cN tex-1 | 脱叶催熟剂喷施时的棉铃铃龄与铃期的比值(Rd/b) Ratio divided defoliation time by boll growth period (d/b) | 0.68 | 0.68 |

| 脱叶催熟剂喷施时间 Defoliant application time (d) | 40.9 | 38.7 | |

| 比强度损伤 Fiber strength damage amount < 0 cN tex-1 | 脱叶催熟剂喷施时的棉铃铃龄与铃期的比值(Rd/b) Ratio divided defoliation time by boll growth period (d/b) | 0.72 | 0.68 |

| 脱叶催熟剂喷施时间 Defoliant application time (d) | 43.3 | 41.0 | |

新窗口打开|下载CSV

棉铃吐絮快且集中是新疆机采棉品种选育的一项重要指标[45,46], 铃大小则作为选择早熟、吐絮快而集中性状的间接指标[45]。本研究表明, 脱叶催熟剂喷施时间对纤维长度的影响较小, 而对纤维比强度的影响较为明显。棉铃吐絮率、有效积温法、吐絮铃以上主茎节数、刀切法和马克隆值预测法是几种判断脱叶催熟剂喷施时间的有效方法[47], 其中, 棉铃吐絮率是一种较为常用的方法, 一般情况下, 在60%的棉铃吐絮后进行脱叶催熟[3,6-7]。前人研究指出, 对于生育期较短的棉花品种, 采用棉铃吐絮率确定脱叶催熟剂喷施时间的方法就不再适用, 应根据棉铃成熟度判断[48]。本研究表明, 棉纤维长度和比强度损伤随棉铃铃期延长而加剧, 脱叶催熟剂喷施时间越早则要求棉铃铃期就越短; 从脱叶催熟剂喷施时的棉铃铃龄与铃期的比值(Rd/b)与纤维长度和比强度损伤量的关系分析, 比强度损伤与之显著相关。因此, 脱叶催熟剂的喷施时间在综合考虑气温和棉铃发育的基础上, 也应关注Rd/b这一指标, 该指标的某一阈值也可作为确定脱叶催熟剂喷施时间的依据。据推算, 若确保纤维比强度损伤<0.5 cN tex-1时, Rd/b应大于0.68, 比强度损伤<0 cN tex-1, 则需Rd/b大于0.72 (表3)。

就棉花脱叶而言, 喷施脱叶催熟剂后的气温变化是影响脱叶效果的重要因素[31], 较高的温度增强了叶片对药剂的敏感性, 可实现快速脱叶[49]。由于新疆后期降温过快[12], 棉花生长季节有限, 棉花生长发育后期既要催熟又要脱叶, 脱叶催熟技术需要协调棉铃发育状况和气温变化之间的关系。脱叶催熟剂喷施时间过早, 虽能实现良好的脱叶效果, 但将会严重损害叶片的光合能力[14], 势必减少养料向棉铃的供应量, 使棉铃和纤维发育进程受阻, 增加了不成熟棉铃和纤维的比例[6,8], 导致产量下降和品质变劣[8,9]。在新疆棉区, 棉株顶部棉铃能否基本完全发育成熟将直接影响着原棉品质。为此, 棉株顶部棉铃铃期的长短至关重要, 也间接决定着脱叶催熟剂的喷施时间。本研究表明, 棉铃铃期与棉铃体积呈显著的正线性关系, 生产要求纤维比强度> 31 cN tex-1时, 就需要棉铃铃期>60.0 d, 生产>30 cN tex-1的纤维则要求棉铃铃期>56.8 d。根据脱叶催熟剂喷施时的棉铃铃龄与铃期的比值(Rd/b)可计算出, 控制比强度损伤<0.5 cN tex-1应在铃龄38.7~40.9 d喷施脱叶催熟剂; 当确保纤维比强度无损伤或增加时, 脱叶催熟剂喷施时间应适当延迟至铃龄41.0~43.3 d (表3)。新疆棉区脱叶催熟剂的使用需综合考虑棉田吐絮率和喷施后的气温状况, 正常年份情况下, 北疆棉区9月5日至10日, 南疆和东疆棉区9月15至20日。据此可推测出, 当控制比强度损伤<0.5 cN tex-1时, 棉株顶部棉铃的开花日期应在7月26日至8月2日(北疆)和8月5日至12日(南疆和东疆); 当确保纤维比强度无损伤或增加时, 棉株顶部棉铃的开花日期应在7月23日至31日(北疆)和8月2日至10日(南疆和东疆)。

4 结论

喷施脱叶催熟剂对棉花纤维长度的影响不显著, 较不喷施处理仅降低了0.2%~1.2%; 纤维比强度损伤受脱叶催熟剂影响的变化幅度较大, 主要集中在-4~0 cN tex-1。铃龄30 d和37 d喷施脱叶催熟剂, 约有1/2品种的纤维长度表现增加趋势, 纤维比强度表现增加趋势的比例分别为总品种的24%和61%。可见, 脱叶催熟剂对纤维比强度的影响更为明显, 且随喷施时间提前, 对比强度的损伤越大。纤维比强度与棉铃体积、棉铃体积与铃期均呈显著正线性关系, 若生产>31 cN tex-1的纤维就需要棉铃体积>31.8 cm3, 棉铃铃期>60.0 d。相对而言, 脱叶催熟剂喷施时间越早则要求棉铃铃期就越短, 可根据脱叶催熟剂喷施时的棉铃铃龄与铃期的比值(Rd/b)确定脱叶催熟剂的喷施时间。当控制纤维比强度损伤量<0.5 cN tex-1时, Rd/b应大于0.68, 在铃龄40.9 d可喷施脱叶催熟剂; 新疆北疆棉区棉花顶部棉铃的终花日期应早于8月2日, 南疆和东疆棉区的则在8月12日之前。

参考文献 原文顺序

文献年度倒序

文中引用次数倒序

被引期刊影响因子

[本文引用: 1]

[本文引用: 2]

[本文引用: 5]

[本文引用: 2]

[本文引用: 2]

[本文引用: 3]

[本文引用: 2]

[本文引用: 3]

[本文引用: 2]

[本文引用: 1]

[本文引用: 2]

[本文引用: 2]

URL [本文引用: 2]

本研究从1984年起,在石河子、莫索湾、博乐、库尔勒、库车、阿拉尔、喀什、麦盖提和吐鲁番进行。3年结果表明,上述各地6至9月上旬气温条件优越,适宜棉铃发育。从9月起,气温下降快,其变化特点是:白天气温保持相当高;一天内气温≥20℃的时间逐渐减少;夜间温度下降急剧。从9月中旬至10月中旬的某一时期起,夜温就成为各地棉铃正常

[本文引用: 2]

[本文引用: 1]

[本文引用: 4]

URL [本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 2]

[本文引用: 2]

[本文引用: 2]

[本文引用: 2]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 2]

[本文引用: 2]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 2]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

URLPMID:30715415 [本文引用: 1]

DOI:10.1016/j.sajb.2007.12.001URL [本文引用: 1]

URLPMID:17964177 [本文引用: 1]

DOI:10.11963/issn.1002-7807.201604005URL [本文引用: 1]

Fv/Fm)及PSⅡ反应中心开放部分的比例,使初始荧光(Minimal fluorescence, Fo)上升、光合电子传递速率(Electron transport rate, ETR)和PSⅡ总的光化学量子产量(Photosynthetic quantum yield, Yield)降低,提高了非光化学猝灭系数(Non-radiant energy, NPQ),说明脱叶剂胁迫下棉花叶片发生了光抑制,PSⅡ复合体受到损伤伴随着光合电子传递受阻。吐絮率10%时喷施脱叶剂使棉花铃重、衣分、皮棉产量显著低于对照。吐絮率50%时喷施脱吐隆300 g·hm–2 + 40%乙烯利1200 mL·hm–2,第25天棉花脱叶率为90.1%,吐絮率为99.87%,对棉花铃重、衣分及皮棉产量影响最小且更有利于促进叶片脱落和棉铃成熟。]]>

[本文引用: 1]

DOI:10.1104/pp.59.6.1088URLPMID:16660000 [本文引用: 1]

The composition of the cell wall of the cotton fiber (Gossypium hirsutum L. Acala SJ-1) has been studied from the early stages of elongation (5 days postanthesis) through the period of secondary wall formation, using cell walls derived both from fibers developing on the plant and from fibers obtained from excised, cultured ovules. The cell wall of the elongating cotton fiber was shown to be a dynamic structure. Expressed as a weight per cent of the total cell wall, cellulose, neutral sugars (rhamnose, fucose, arabinose, mannose, galactose, and noncellulosic glucose), uronic acids, and total protein undergo marked changes in content during the elongation period. As a way of analyzing absolute changes in the walls with time, data have also been expressed as grams component per millimeter of fiber length. Expressed in this way for plant-grown fibers, the data show that the thickness of the cell wall is relatively constant until about 12 days postanthesis; after this time it markedly increases until secondary wall cellulose deposition is completed. Between 12 and 16 days postanthesis increases in all components contribute to total wall increase per millimeter fiber length. The deposition of secondary wall cellulose begins at about 16 days postanthesis (at least 5 days prior to the cessation of elongation) and continues until about 32 days postanthesis. At the time of the onset of secondary wall cellulose deposition, a sharp decline in protein and uronic acid content occurs. The content of some of the individual neutral sugars changes during development, the most prominent change being a large increase in noncellulosic glucose which occurs just prior to the onset of secondary wall cellulose deposition. Methylation analyses indicate that this glucose, at least in part, is 3-linked. In contrast to the neutral sugars, no significant changes in cell wall amino acid composition are observed during fiber development.Compositional analyses of cell walls derived from culture-grown fibers indicate that these walls are remarkably similar to those derived from fibers grown on the plant, both in terms of composition and in terms of relative changes in composition during development.A comparison of our results on total cell wall composition and linkages of sugars as determined by a preliminary methylation analysis of unfractionated fiber walls indicates that the primary cell wall of cotton fibers is similar to that of primary cell walls of other dicotyledons and of gymnosperms as reported in the literature.

DOI:10.1093/pcp/pcf048URLPMID:11978869 [本文引用: 1]

Cotton (Gossypium herbaceum L.) fiber development consists of a fiber elongation stage (up to 20 d post-anthesis) and a subsequent cell wall thickening stage. Cell wall analysis revealed that the extractable matrix (pectic and hemicellulosic) polysaccharides accounted for 30-50% of total sugar content in the fiber elongation stage but less than 3% in the cell wall thickening stage. By contrast, cellulose increased dramatically after the fiber elongation ceased. The amounts of extractable xyloglucans and arabinose- and galactose-containing polymers per seed increased in the early fiber elongation stage and decreased thereafter. The amounts of extractable acidic polymers and non-cellulosic beta-glucans (mainly composed of beta-1,3-glucans) increased in parallel with fiber elongation and then decreased. The molecular masses of extractable non-cellulosic beta-glucans, and arabinose- and galactose-containing polymers decreased during both fiber elongation and cell wall thickening stages. The molecular mass of extractable xyloglucans also decreased during the fiber elongation stage, but this decrease ceased during the cell wall thickening stage. Conversely, the molecular size of acidic polymers in the extractable pectic fraction increased during both stages. Thus, not only the amounts but also the molecular size of the extractable matrix polysaccharides showed substantial changes during cotton fiber development.

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 2]

[本文引用: 2]

[本文引用: 1]

[本文引用: 1]

URL [本文引用: 1]

[本文引用: 1]

[本文引用: 1]