2.北控水务集团有限公司北控水务研究院,北京 100102

1.School of Chemical Engineering, Beijing University of Chemical Technology, Beijing 100029, China

2.Institute of Beijing Enterprises Water Group Limited, Beijing Enterprises Water Group Limited, Beijing 100102, China

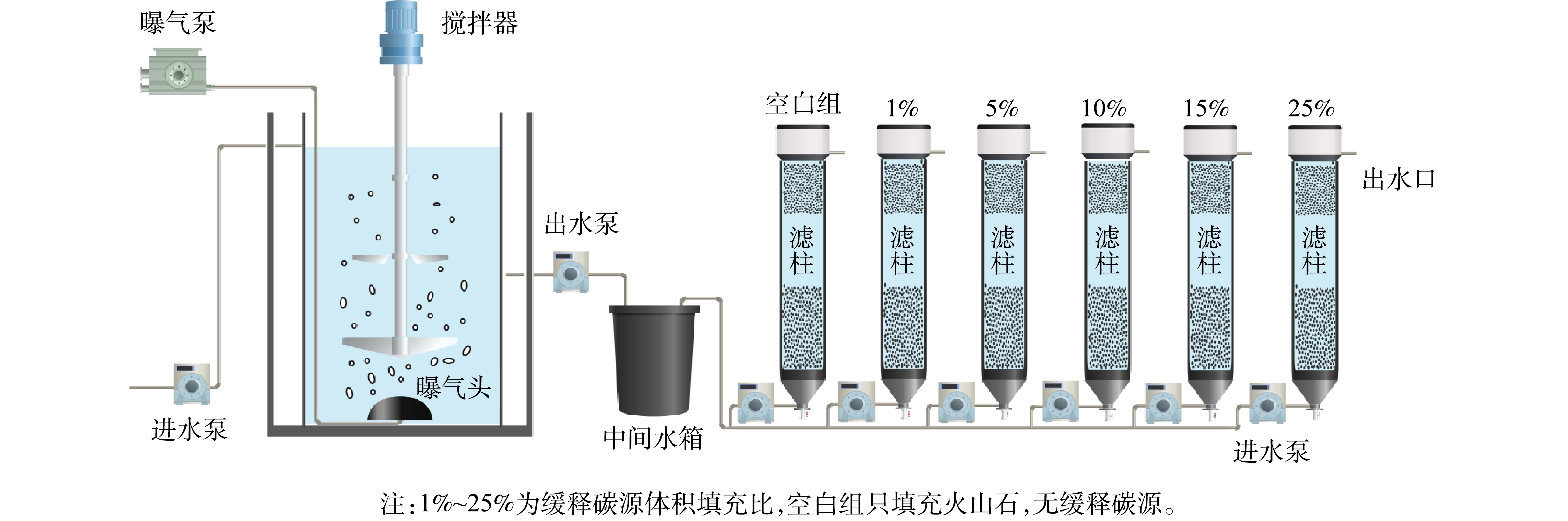

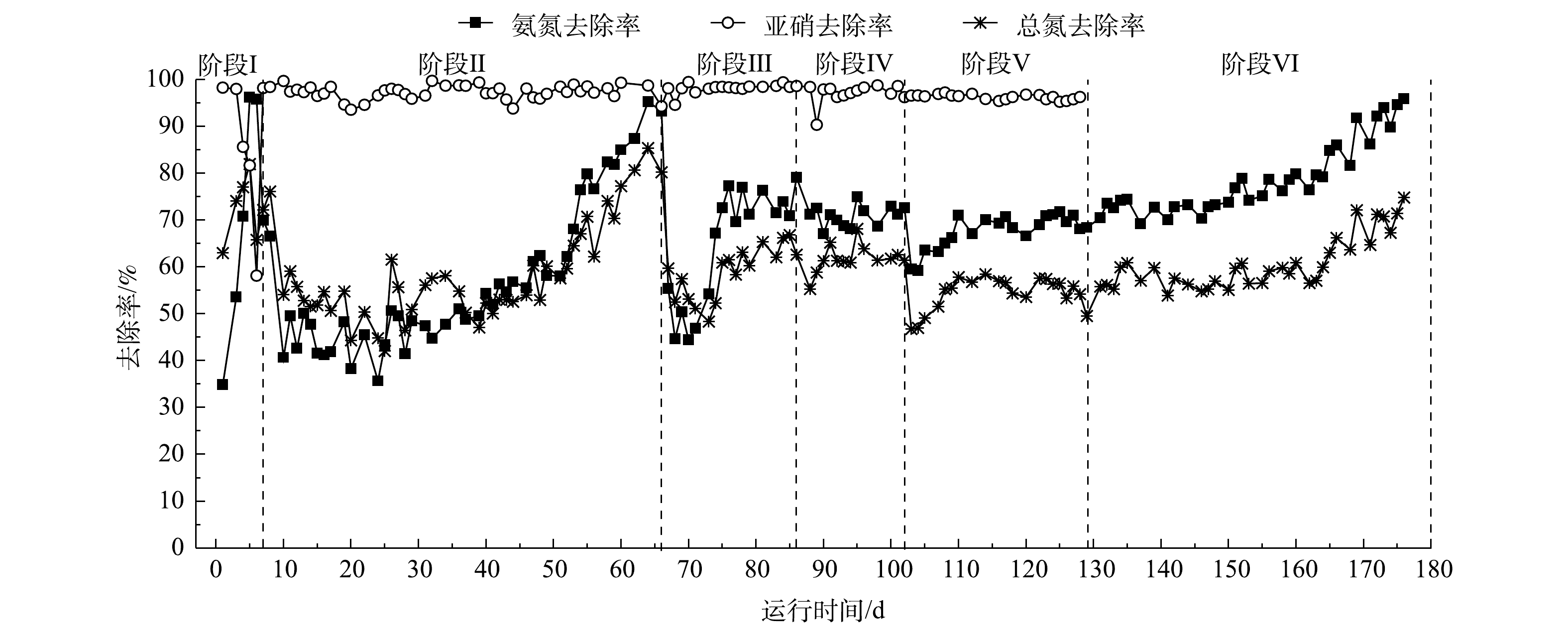

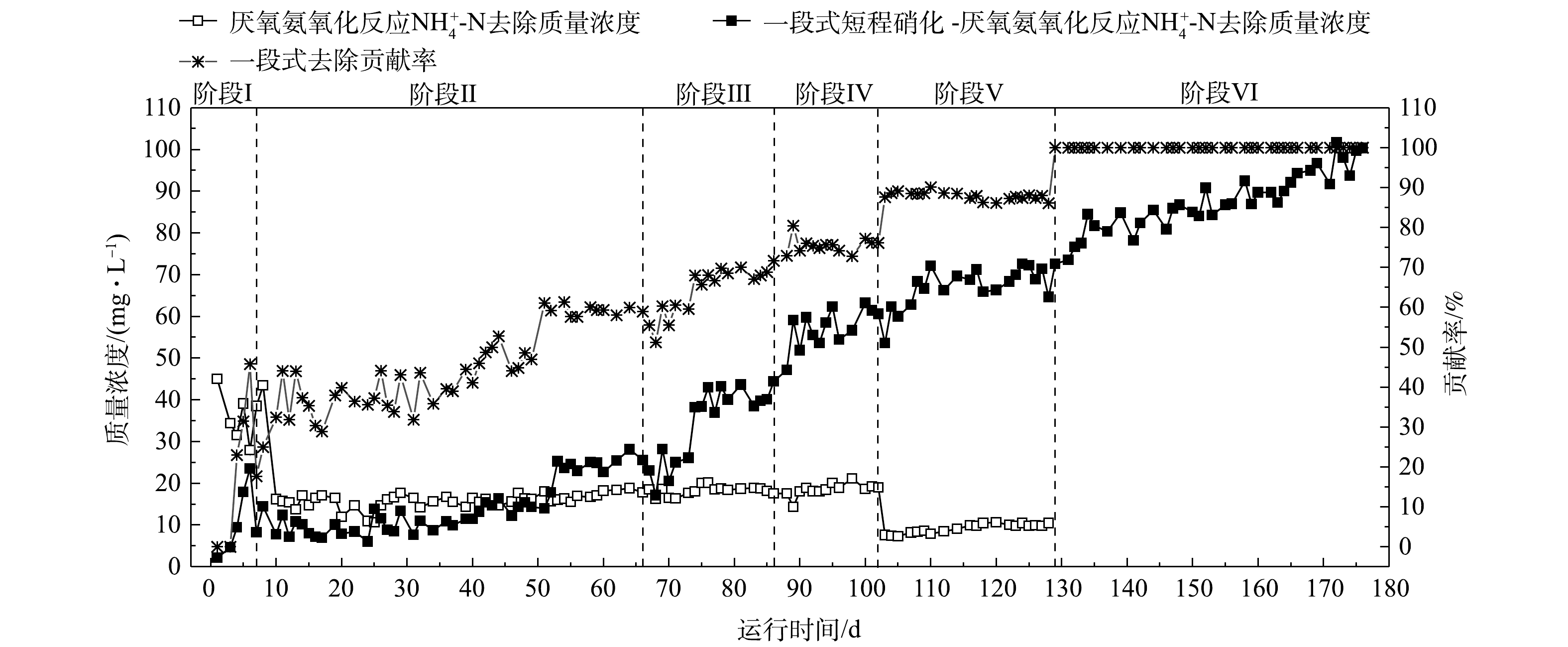

在SBR中进行一段式短程硝化-厌氧氨氧化工艺的启动驯化,并在达到稳定运行时,让SBR出水进入不同缓释碳源体积填充比的滤柱中,进行深度脱氮研究。结果表明,在SBR中经过176 d的启动驯化,成功实现一段式短程硝化-厌氧氨氧化工艺的稳定运行,进水

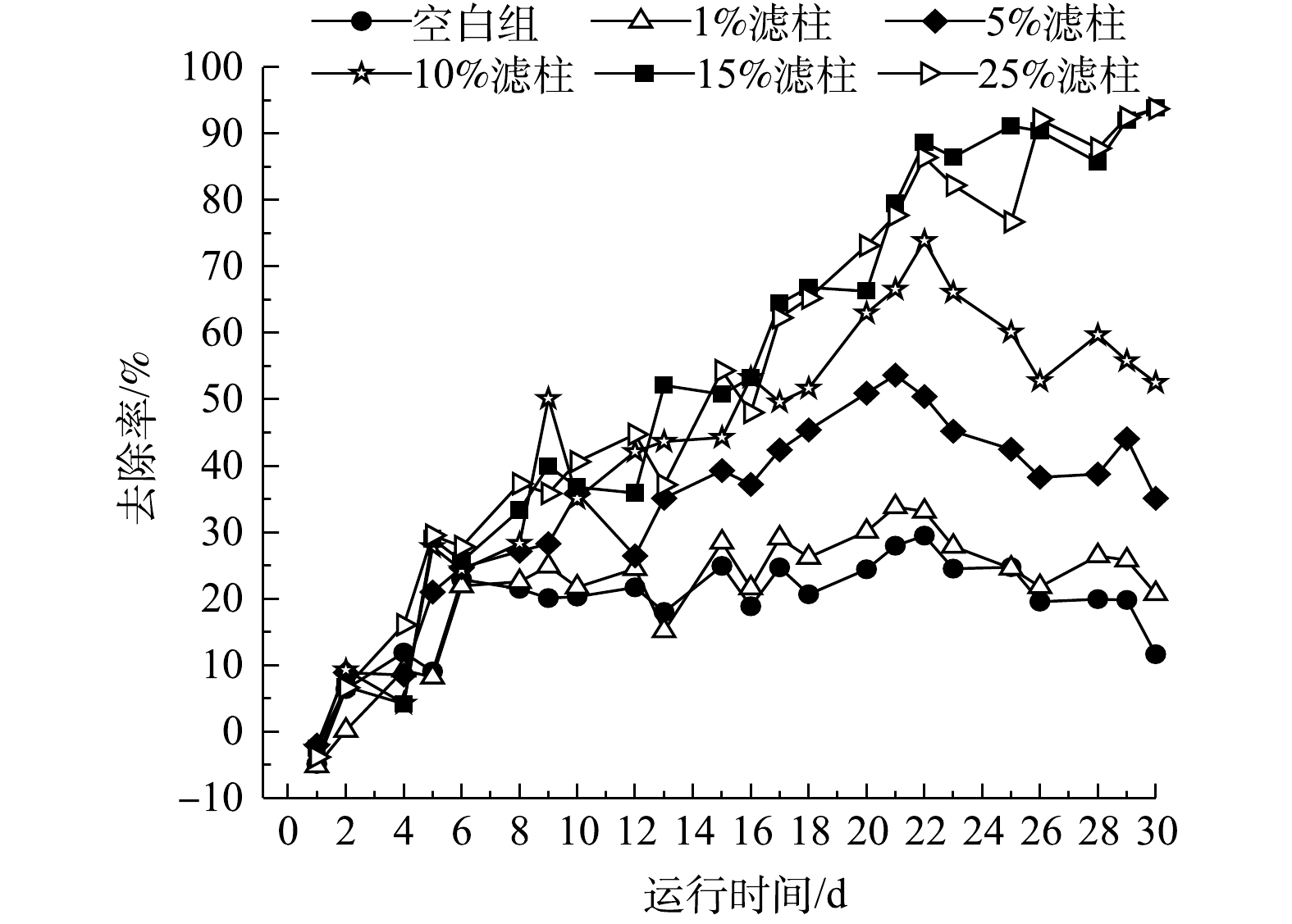

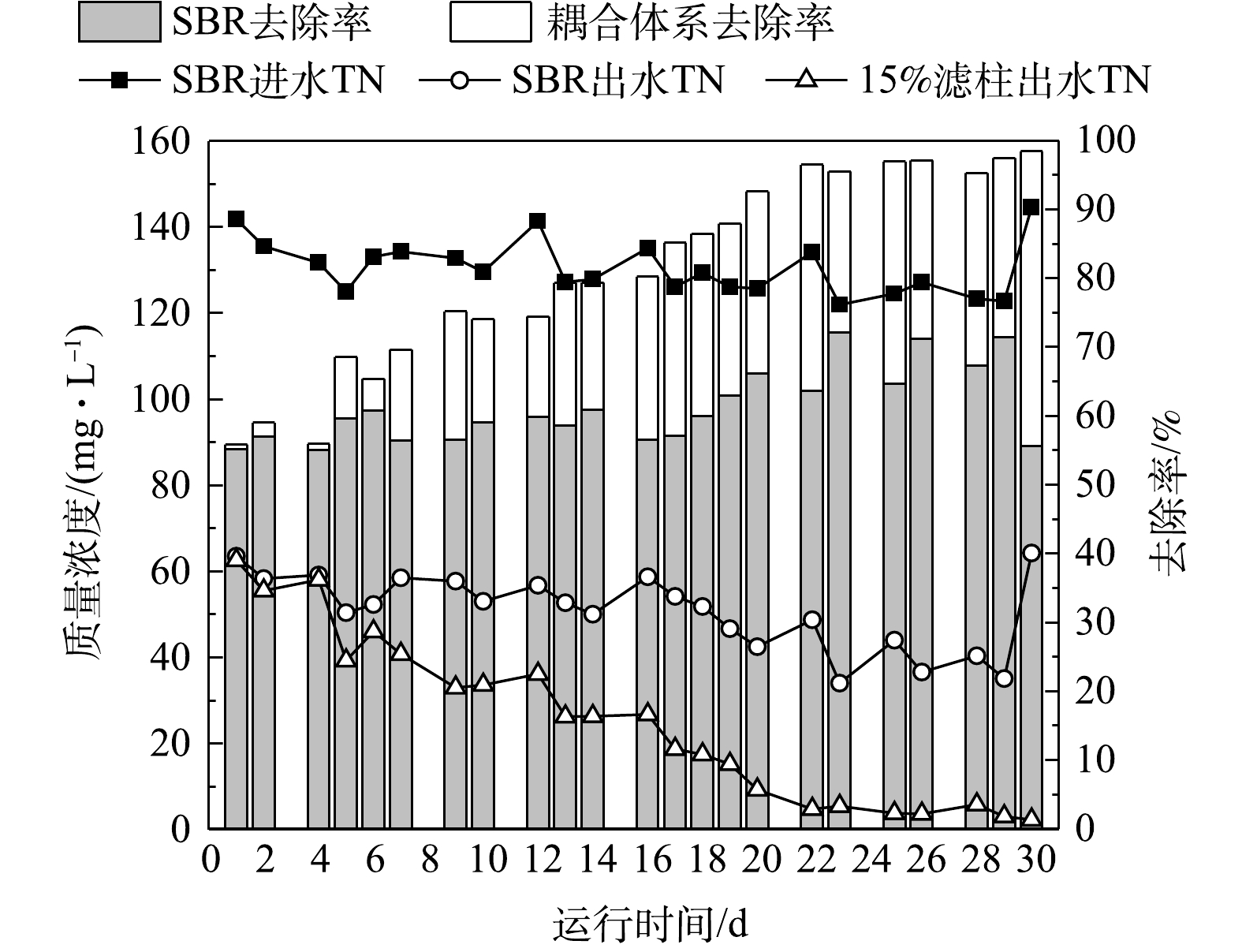

,该滤柱中通过一段式短程硝化-厌氧氨氧化反应和反硝化反应的共同作用完成深度脱氮。SBR与缓释碳源体积填充比为15%的滤柱组成的耦合系统平均TN去除率达96.7%,较SBR提升了28.9%。

Sequencing batch reactor (SBR) was used to domesticate the one-stage partial nitrification-anammox process. When its stable operation happened, the SBR effluent entered the filter column with different volume fill ratios of slow-release carbon source for advanced nitrogen removal. The results showed that the stable operation of the one-stage partial nitrification-anammox process was successfully realized after 176 days of domestication in SBR. When the influent concentration of

-N and TN reached 98% and 73%, respectively. The activities of AOB and anammox bacteria increased to 8.6 mg·(h·g)

. In the study of advanced nitrogen removal at low temperature of 15 ℃, the filter column with 15% volume fill ratio of slow-release carbon source had the best advanced nitrogen removal effect, TN in the effluent was less than 5 mg·L

, and advanced nitrogen removal was realized by the combination of partial nitrification-anammox and denitrification in the filter column. The average TN removal rate was 96.7% for the coupled system of SBR and the filter column with 15% volume fill ratio of slow-release carbon source, which was 28.9% higher than that of SBR.

.

Schematic diagram of reactor

Nitrogen removal performance of SBR

Nitrogen removal efficiency of SBR

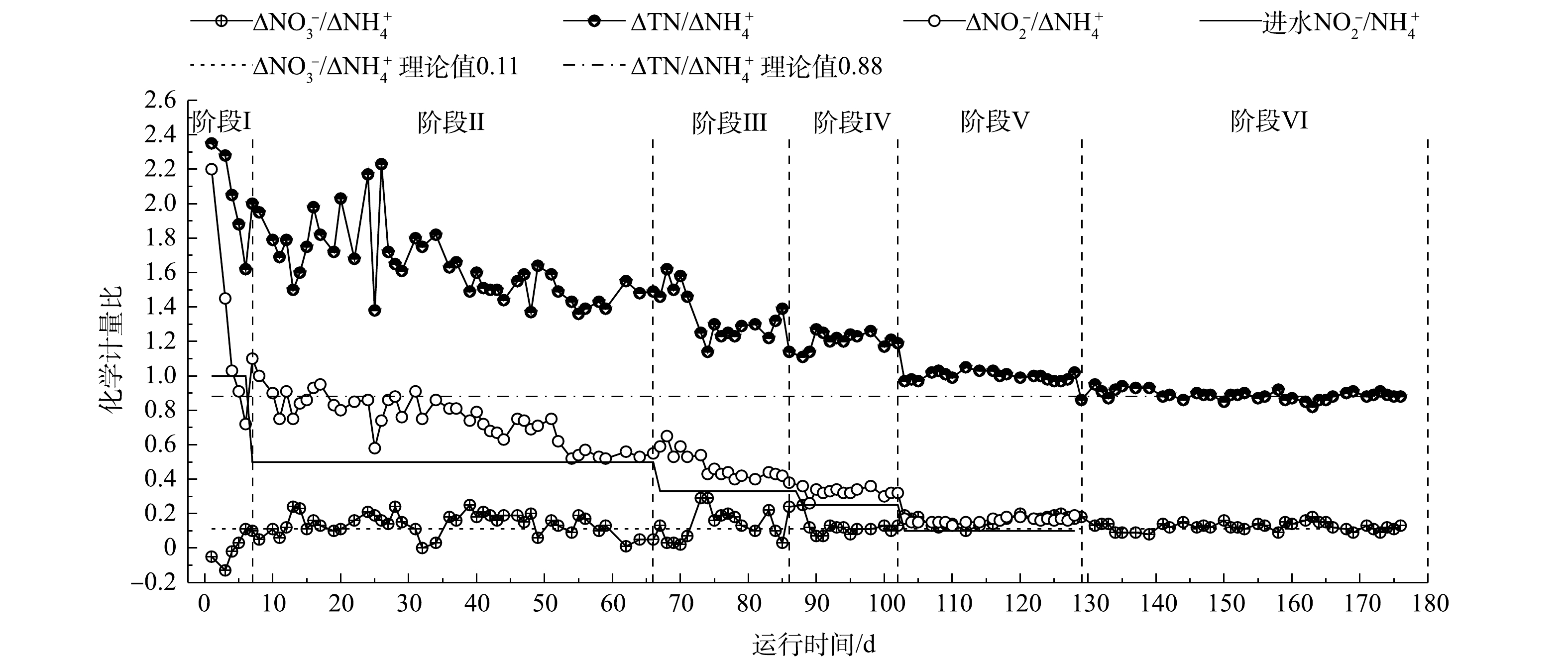

Variation of transformation path of ammonium

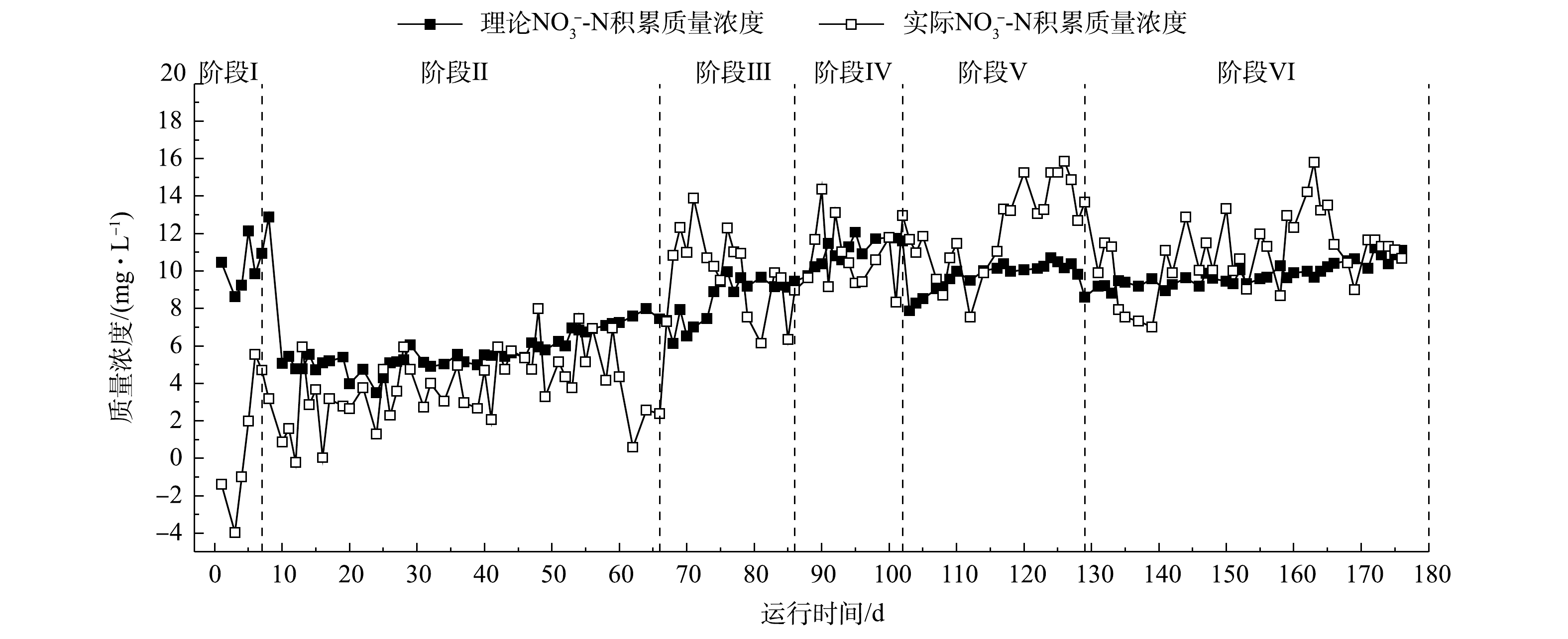

Variation of nitrate concentrations

Variation of nitrate accumulate

Variation of stoichiometric characteristics

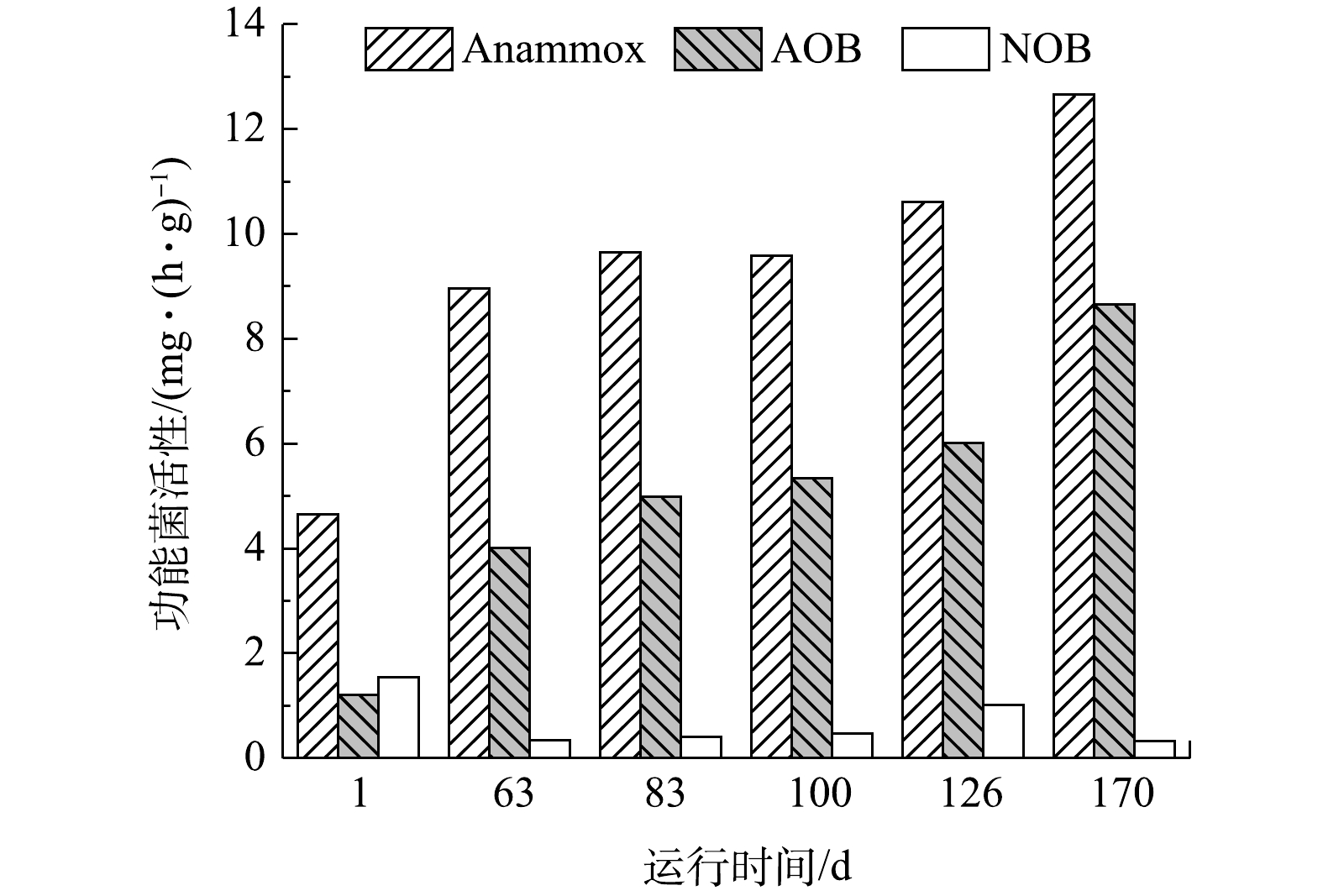

Variation of functional bacteria activities at the end of each stage

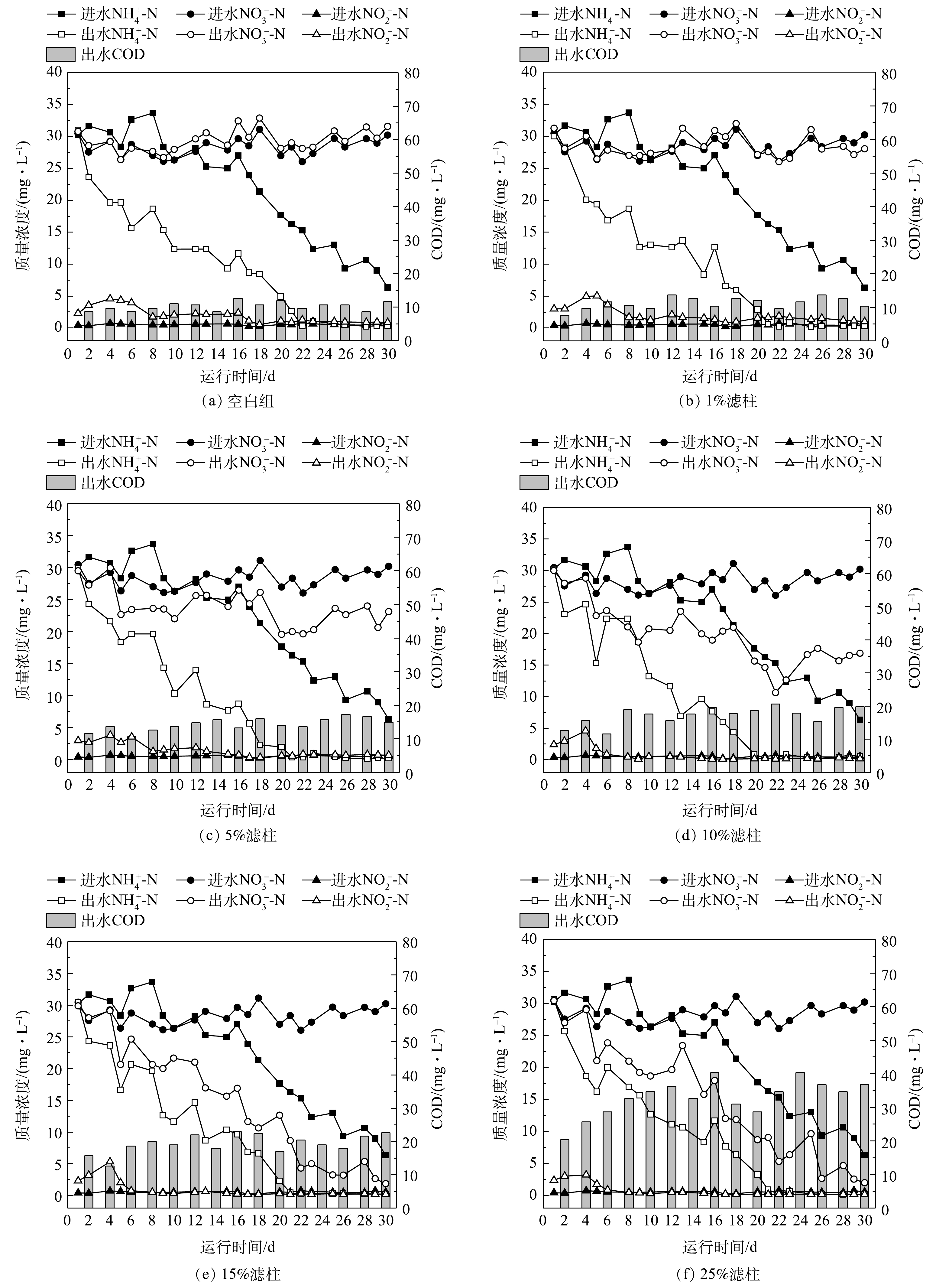

各缓释碳源体积填充比滤柱的进出水COD及氮素质量浓度变化

Variation of COD and nitrogen concentrations at different fill ratios of slow-release carbon source

Variation of TN remove rate at different fill ratios of slow-release carbon source

TN removal effect of the coulped process

| [1] | VAN DE GRAAF A A, MULDER A, DE BRUIJN P, et al. Anaerobic oxidation of ammonium is a biologically mediated process[J]. Applied and Environmental Microbiology, 1995, 61(4): 1246-1251. doi: 10.1128/aem.61.4.1246-1251.1995 |

| [2] | KARTAL B, KUENEN J G, VAN LOOSDRECHT M C M. Sewage treatment with anammox science[J]. Science, 2010, 328(5979): 702-703. doi: 10.1126/science.1185941 |

| [3] | YANG W, HE S, HAN M, et al. Nitrogen removal performance and microbial community structure in the start-up and substrate inhibition stages of an anammox reactor[J]. Journal of Bioscience and Bioengineering, 2018, 126(1): 88-95. doi: 10.1016/j.jbiosc.2018.02.004 |

| [4] | WANG G, XU X, ZHOU L, et al. A pilot-scale study on the start-up of partial nitrification-anammox process for anaerobic sludge digester liquor treatment[J]. Bioresource Technology, 2017, 241: 181-189. doi: 10.1016/j.biortech.2017.02.125 |

| [5] | ARRIAGADA C, GUZMáN-FIERRO V, GIUSTINIANOVICH E, et al. NOB suppression and adaptation strategies in the partial nitrification-Anammox process for a poultry manure anaerobic digester[J]. Process Biochemistry, 2017, 58: 258-265. doi: 10.1016/j.procbio.2017.03.028 |

| [6] | KELUSKAR R, NERURKAR A, DESAI A. Development of a simultaneous partial nitrification, anaerobic ammonia oxidation and denitrification (SNAD) bench scale process for removal of ammonia from effluent of a fertilizer industry[J]. Bioresource Technology, 2013, 130: 390-397. doi: 10.1016/j.biortech.2012.12.066 |

| [7] | STROUS M, PELLETIER E, MANGENOT S, et al. Deciphering the evolution and metabolism of an anammox bacterium from a community genome[J]. Nature, 2006, 440(7085): 790-794. doi: 10.1038/nature04647 |

| [8] | DE CLIPPELEIR H, YAN X, VERSTRAETE W, et al. OLAND is feasible to treat sewage-like nitrogen concentrations at low hydraulic residence times[J]. Applied Microbiology and Biotechnology, 2011, 90(4): 1537-1545. doi: 10.1007/s00253-011-3222-6 |

| [9] | CHEN H, LIU S, YANG F, et al. The development of simultaneous partial nitrification, ANAMMOX and denitrification (SNAD) process in a single reactor for nitrogen removal[J]. Bioresource Technology, 2009, 100(4): 1548-1554. doi: 10.1016/j.biortech.2008.09.003 |

| [10] | 葛勇涛, 焦阳, 李军, 等. 乙酸钠碳源强化生物滤池对二沉池出水的脱氮效果[J]. 中国给水排水, 2011, 27(7): 98-100. |

| [11] | 杨巧林, 奚小英, 陈娜, 等. 外加碳源对污水厂异常进水时的强化脱氮效果[J]. 中国给水排水, 2011, 27(3): 106-108. |

| [12] | WAN D, LIU H, QU J, et al. Using the combined bioelectrochemical and sulfur autotrophic denitrification system for groundwater denitrification[J]. Bioresource Technology, 2009, 100(1): 142-148. doi: 10.1016/j.biortech.2008.05.042 |

| [13] | XIA S, ZHANG Y, ZHONG F. A continuous stirred hydrogen-based polyvinyl chloride membrane biofilm reactor for the treatment of nitrate contaminated drinking water[J]. Bioresource Technology, 2009, 100(24): 6223-6228. doi: 10.1016/j.biortech.2009.07.002 |

| [14] | 邵留, 徐祖信, 金伟, 等. 农业废物反硝化固体碳源的优选[J]. 中国环境科学, 2011, 31(5): 748-754. |

| [15] | 刘江霞, 罗泽娇, 靳孟贵, 等. 以麦秆作为好氧反硝化碳源的研究[J]. 环境工程, 2008, 26(2): 94-96. |

| [16] | ZHOU X X, WANG Z L, LIU L H, et al. Experimental study on solid phase carbon source denitrification and denitrification using polyvinyl alcohol as framework material[J]. Environmental Pollution Control, 2019, 41(10): 1198-1238. |

| [17] | 王旭明, 从二丁, 罗文龙, 等. 固体碳源用于异养反硝化去除地下水中的硝酸盐[J]. 中国科学, 2008, 38(9): 824-828. |

| [18] | 程璐璐. 多碳源复合载体的释碳及其强化微生物脱氮过程研究[D]. 郑州: 郑州大学, 2019. |

| [19] | 吴大付, 陈红卫. 粮食作物不同种植模式对地下水硝酸盐含量的影响[J]. 农业现代化研究, 2007(1): 107-109. doi: 10.3969/j.issn.1000-0275.2007.01.028 |

| [20] | 苏彤, 范铮. 以聚羟基脂肪酸酯为固体碳源去除地下水中的硝酸盐[J]. 北方环境, 2011, 23(6): 138-141. |

| [21] | 张兰河, 孙立娇, 仇天雷, 等. 固体碳源填充床反应器脱除污水硝态氮效能的预测模型[J]. 农业工程学报, 2013, 29(6): 209-213. |

| [22] | 杨飞飞, 吴为中. 以PHBV为碳源和生物膜载体的生物反硝化研究[J]. 中国环境科学, 2014, 34(7): 1703-1708. |

| [23] | VAN DER GRAAF A A, DE BRUIJN P, ROBERTSON L A, et al. Autotrophic growth of anaerobic ammonium oxidizing microorganisms in a fluidized bed reactor[J]. Microbiology, 1996, 142(8), 2187-2196. |

| [24] | 国家环境保护总局. 水和废水监测分析方法[M]. 4版. 北京: 中国环境科学出版社, 2002. |

| [25] | 张凯, 张志华, 王朝朝, 等. ANAMMOX富集与优化停曝比对MBR-SNAD工艺的影响[J]. 中国环境科学, 2019, 39(6): 2370-2377. |

| [26] | POOT V, HOEKSTRA M, GELEIJNSE M A A, et al. Effects of the residual ammonium concentration on NOB repression during partial nitritation with granular sludge[J]. Water Research, 2016, 106(1): 518-530. |

| [27] | ZHANG Y, HE S, NIU Q, et al. Characterization of three types of inhibition and their recovery processes in an anammox UASB reactor[J]. Biochemical Engineering Journal, 2016, 109: 212-221. doi: 10.1016/j.bej.2016.01.022 |

| [28] | SOLIMAN M, ELDYASTI A. Development of partial nitrification as a first step of nitrite shunt process in a sequential batch reactor (SBR) using ammonium oxidizing bacteria (AOB) controlled by mixing regime[J]. Bioresource Technology, 2016, 221: 85-95. doi: 10.1016/j.biortech.2016.09.023 |

| [29] | LI J, ZHANG Q, LI X, et al. Rapid start-up and stable maintenance of domestic wastewater nitritation through short-term hydroxylamine addition[J]. Bioresource Technology, 2019, 278: 468-472. doi: 10.1016/j.biortech.2019.01.056 |

| [30] | KINDAICHI T, OKABE S, SATOH H, et al. Effects of hydroxylamine on microbial community structure and function of autotrophic nitrifying biofilms determined by in situ hybridization and the use of microelectrodes[J]. Water Science Technology, 2004, 49(11/12): 61-68. |

| [31] | 李佳, 李夕耀, 张琼, 等. 投加羟胺原位恢复城市污水短程硝化-厌氧氨氧化工艺[J]. 中国环境科学, 2019, 39(7): 2789-2795. |

| [32] | 王小龙. 基于颗粒污泥的单级自养脱氮系统构建及其脱氮效能研究[D]. 哈尔滨: 哈尔滨工业大学, 2018. |

| [33] | MAGRí A, VANOTTI M B, SZ?GI A A. Anammox sludge immobilized in polyvinyl alcohol (PVA) cryogel carriers[J]. Bioresource Technology, 2012, 114(1): 231-240. |

| [34] | MIAO Y, ZHANG L, YANG Y, et al. Start-up of single-stage partial nitrification-anammox process treating low-strength swage and its restoration from nitrate accumulation[J]. Bioresource Technology, 2016, 218: 771-779. doi: 10.1016/j.biortech.2016.06.125 |

| [35] | 李军, 杜佳, 郑照明, 等. 间歇曝气实现厌氧氨氧化快速启动的研究[J]. 中国给水排水, 2018, 34(11): 20-26. |

| [36] | 卞伟, 李军, 王盟, 等. SBR短程硝化工艺的启动及稳定运行适宜DO探究[J]. 北京工业大学学报, 2016, 42(2): 269-276. |

| [37] | 吕振, 李燕. pH和C∶N对厌氧氨氧化耦合短程反硝化脱氮性能的影响[J]. 环境污染与防治, 2018, 40(10): 1106-1111. |

| [38] | KUMAR M, LIN J. Co-existence of anammox and denitrification for simultaneous nitrogen and carbon removal: Strategies and issues[J]. Journal of Hazardous Materials, 2010, 178(1): 1-9. |

| [39] | 李昂, 刘锋, 陈天羽, 等. 基于固态碳源的自养-异养耦合生物脱氮工艺研究[J]. 化工环保, 2020, 40(5): 494-500. |

| [40] | LI P, ZUO J, WANG Y, et al. Tertiary nitrogen removal for municipal wastewater using a solid-phase denitrifying biofilter with polycaprolactone as the carbon source and filtration medium[J]. Water Research, 2016, 93(15): 74-83. |

| [41] | SHEN Z, ZHOU Y, WANG J. Comparison of denitrification performance and microbial diversity using starch/polylactic acid blends and ethanol as electron donor for nitrate removal[J]. Bioresource Technology, 2013, 131: 33-39. doi: 10.1016/j.biortech.2012.12.169 |

| [42] | 彭荷衢, 刁兴兴, 张伟军, 等. 两级自养反硝化实现垃圾渗滤液的深度脱氮[J]. 环境工程学报, 2019, 13(9): 2113-2120. |

| [43] | 李津青, 韩晓宇, 黄京, 等. 耦合反硝化的CANON工艺实时控制策略研究[J]. 中国给水排水, 2017, 33(23): 10-15. |

下载:

下载:

点击查看大图

点击查看大图