,2,31Department of Physics, Beijing Institute of Technology, Beijing 100081,

,2,31Department of Physics, Beijing Institute of Technology, Beijing 100081, 2Beijing Key Laboratory for Nanomaterials and Nanodevices, Institute of Physics, Chinese Academy of Sciences, Beijing 100190,

3School of Physical Sciences,

Received:2020-02-21Revised:2020-04-2Accepted:2020-04-16Online:2020-06-18

Abstract

Keywords:

PDF (941KB)MetadataMetricsRelated articlesExportEndNote|Ris|BibtexFavorite

Cite this article

Yao-Dong Feng, Can-Can Liu, Qing-Fan Shi, Gang Sun. Dynamic properties of the two-dimensional density-driven segregation. Communications in Theoretical Physics, 2020, 72(7): 075601- doi:10.1088/1572-9494/ab8a27

1. Introduction

Granular materials are ubiquitous, and their special mechanical properties are critical to many industrial processes. One of the important characteristics of granular materials is the segregation phenomenon [1–3], which refers to the unique mixing or separation behavior that occurs in granular materials when they are vibrated [4–9] or flow [10–13]. The most typical segregation effect is mainly due to the difference in particle size, which is called the Brazil nut effect. But in addition to particle size, other factors also cause segregation behaviors, such as: difference in density [14, 15], angle of repose [16], temperature gradient [17], total particle size [18], and even air in containers [19, 20]. All these factors make the phenomenon of segregation a wide variety.The segregation states caused by different factors can be different. Some segregation states are completely separated. For example, in size-induced segregation, the segregation state is that the larger particles are above the smaller particles. In this state, the two kinds of particles are completely separated, which is easy to describe. However, in some environments the separation may be incomplete or partial [18, 21, 22]. This state is clearly different from the completely separated state or the completely mixed state, so it is difficult to describe. In simulation or theoretical research, this partial separation state can be described by the distribution profile of each kind of particle [15, 23]. However, the distribution profile is a function rather than a quantity, and it cannot be directly related to the degree of particle separation. To associate the distribution profile with the degree of separation, we must take advantage of some specific properties of the distribution profile.

In granular mixtures made of two kinds of different materials (different densities) but of the same size (no air in the container), we found a special state of partial segregation [21, 22]. Our theoretical and experimental studies have shown that the segregation state produced by such systems under vertical vibration is a partial segregation state that we call the lighter and mixed state (LMS) [24]. This state is that the lighter particles tend to rise and form a pure layer on the top of the system while the heavier particles and some of the lighter ones stay at the bottom and form a mixed layer. According to the characteristics of this state, we can define the ratio of the twice thickness of the pure top layer to that of the whole system as an order parameter to describe the degree of the particle separation. It is zero when the particles are completely mixed, and it is one when the particles are completely separated. It is a number between zero and one when the particles are partially separated. It can be said that this number quantitatively describes the degree of particle separation.

We know that the establishment of an order parameter plays a pivotal role in statistical physics. The establishment of an order parameter in granular system will also bring great benefits to the comprehensive study of granular materials. For example, in the study of segregation phenomenon, the final segregation state is only one aspect of the research, and the evolution process of this state is also an important subject of the research. But how to quantitatively describe the degree of the particle separation at different times is a decisive factor. With the order parameter we defined, the degree of particle separation at different times can be successfully described, which allow us to study the entire evolution of granular state in detail. Of course, although we can easily observe the order parameter of the final granular state (after the vibration stops) in the experimental research, it is difficult to observe the order parameter during the vibration. This is not only because the granular system is in motion (this can be solved by reading high-speed video), but because its state is inconsistent with the standard LMS state, it is difficult to give accurate values with an intuitive observation. However, in the simulation calculation, since we know the exact position of each particle, we can accurately calculate the order parameter through these positions, so that it is possible to study the evolution process of the granular state.

In this paper, we use molecular dynamics (MD) simulations to study the dynamics of a two-dimensional (2D) granular mixtures made of different densities but of the same size under vertical vibration. In the next section, we will first describe the models and simulation methods used, and show that LMS can also be observed in 2D simulations. In section

2. The scheme of the LMS

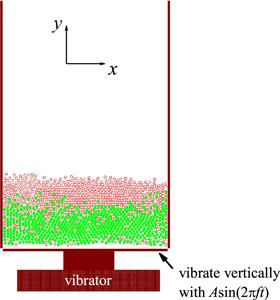

The MD simulations are carried out in a 2D system. Totally one thousand and two hundred spheres (circles), six hundred for each kind of material in general, are placed in a container with gravity field as shown in figure 1. The width of the container is 50 times the size of the sphere diameter d0=2.0 mm, which results in the spheres piling up about 24 layers. The height of the container is set to be so high that almost no spheres can reach the top of the container except at the beginning of the vibration. The bottom of the container moves vertically with a harmonic displacement functionFigure 1.

New window|Download| PPT slide

New window|Download| PPT slideFigure 1.The model used in simulation. Two kinds of particles, represented by the open and closed circles for the lighter and heavier particles, respectively, are placed in a container with gravity field. The container is shaked by a harmonic vibrator.

In order to treat multiple particle interactions, which seem to be the most important factor for this system, we use a soft sphere approach in our MD simulations. The Kuwabara–Kono model is used as normal interactions between particles or between particle and side wall [25, 26]

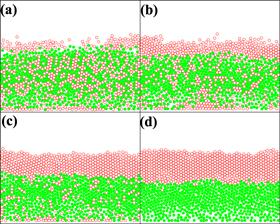

The simulation is carried out under vibration for 40 000 or 60 000 vibration periods from either a completely mixed initial state or a completely separated state. The generation of these initial states will be mentioned below. Figure 2 shows the time evolution of the segregation state during the simulation from a completely mixed initial state, where the acceleration amplitude is set to a relatively high value Γ=24.0 (the amplitude of the vibration A=0.8 mm, about one third of size of the diameter of the particles), and the frequency is set to f=85 Hz. Because the density different is very large, the final segregated state is almost a completely separated state (see figure 2(d)). However, in figures 2(b) and (c), we can see partial segregated states, which have characteristic that the lighter particles tend to go up and form a pure layer on top of the system, while the heavier ones and some of the lighter ones stay at bottom and form a mixed layer. We have called the state as the LMS in the previous work [24]. Figure 2 also shows that the thickness of the pure top layer increases gradually during the simulation, and gives a clear view about how the segregation state changes from a completely mixed state through the LMS state to a completely separated state during the simulation.

Figure 2.

New window|Download| PPT slide

New window|Download| PPT slideFigure 2.Typical segregated state of a binary granular mixture of the lighter particles with density

These illustrate that the time evolution of the segregation state can be indicated by the thickness of top layer (if the thickness of whole layer is fixed). In MD simulation, since every particle’s position can be traced during simulations, the average height for each type of particles at certain simulation time can be calculated trivially. The thicknesses of the top layer and the whole layer is calculated by

For equally mixed cases. we have suggested to use twice the ratio of the thickness of the top layer to that of the whole system as an order parameter [24], i.e.

3. Dynamic properties of the segregation

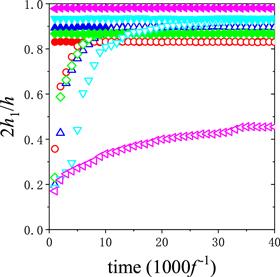

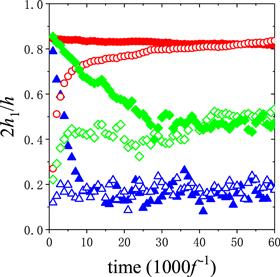

The time evolution of the order parameterFigure 3.

New window|Download| PPT slide

New window|Download| PPT slideFigure 3.Time evolution of the order parameter for larger density difference between the lighter (

The completely mixed initial state is generated by restoring the final state of a simulation for the system without density difference (both ρl and

From figure 3, we can see that the results from two different initial states tend to a same value and keep in that value steadily afterward if the vibration amplitude is not too small. Figure 3 also shows that the speed of the convergence depends seriously on the vibration amplitude. The smaller the vibration amplitude, the slower the convergence will be. When the vibration amplitude is too small (for example Γ=4.8), the simulation from two different initial states does not tend to a same state even at the end of the simulation (40 000 vibration periods).

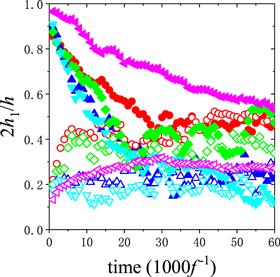

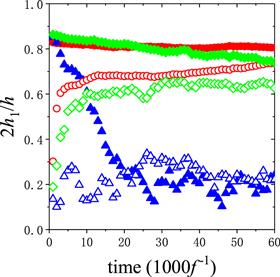

The convergence of the simulation also depends on the density difference between the lighter and heavier particles. Figure 4 depicts the time evolution of the order parameter for a system with smaller density difference at a series of vibration amplitude. Comparing with figure 3, we find that the convergence to the steady state becomes slower in figure 4 for the corresponding vibration amplitude. Another characteristic of the order parameter for the system with smaller density difference is that it fluctuates strongly even after the steady state is reached.

Figure 4.

New window|Download| PPT slide

New window|Download| PPT slideFigure 4.Time evolution of the order parameter for smaller density difference between the lighter (

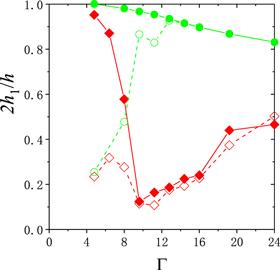

Figure 5 depicts the steady state order parameter as a function of vibration amplitude. The data in this figure is obtained by averaging the order parameters over time for the final 20 000 vibration periods. The total simulation time for

Figure 5.

New window|Download| PPT slide

New window|Download| PPT slideFigure 5.The steady state order parameter as a function of vibration amplitude. The circles are for

To show the convergent properties of the order parameter for more density combinations, we plot the time evolution of the order parameter for three typical cases at Γ=24.0 in figure 6, in which the simulation has reached its steady state for the final 20 000 vibration periods in all the cases. The figure shows that the steady value of the order parameter becomes smaller and the fluctuation of the order parameter becomes larger when the density difference between lighter and heavier particles decreases.

Figure 6.

New window|Download| PPT slide

New window|Download| PPT slideFigure 6.Time evolution of the order parameter for the density of the heavier particles being

We also found that the convergence to the steady state is slowed down when the total mass in the system increases. Figure 7 presents the time evolution of the order parameter for the heavier combinations of particles, where the density of the lighter particles is fixed at

Figure 7.

New window|Download| PPT slide

New window|Download| PPT slideFigure 7.Time evolution of the order parameter for the density of the heavier particles being

4. Summary and conclusion

In this paper, we have used MD simulations to study a 2D granular mixture made of different densities but of the same size under vertical vibration. We have presented a method that can accurately calculate the order parameter in the simulation. By use of the time evolution of the order parameter, we have discussed some dynamic properties of the segregation, which is almost impossible in the experimental research. We have found that the convergence to the steady state depends at least on the vibration amplitude, the total mass of the particles, and also the density difference between the lighter and heavier particles. The convergence is quicker for larger vibration amplitude, lighter total mass of the particles, and more density difference between the lighter and heavier particles. We have also found that the fluctuation of the order parameter is larger even after the steady state is reached for lighter total mass of the particles and less density difference between the lighter and heavier particles.Our work has shown that establishing an order parameter is very helpful in the investigation of partial segregation. There are many types of partial segregation. For example, in another experimental study, similar to the system we studied here but where air pressure played an important role, we found another partially segregated state, and its degree of separation can also be described by an order parameter [29]. Our work here can be extended to study the dynamic characteristics of these systems.

Acknowledgments

Project supported by the National Natural Science Foundation of China (Grant Nos. 10875166 and 11274355).Reference By original order

By published year

By cited within times

By Impact factor

DOI:10.1103/RevModPhys.68.1259 [Cited within: 1]

DOI:10.1088/0034-4885/67/3/R01 [Cited within: 1]

DOI:10.1016/0032-5910(76)80053-8 [Cited within: 1]

DOI:10.1016/0032-5910(90)80092-D

DOI:10.1016/0032-5910(76)80051-4

DOI:10.1016/j.powtec.2017.07.010

DOI:10.1103/PhysRevLett.58.1038

DOI:10.1126/science.255.5051.1523 [Cited within: 1]

DOI:10.1103/PhysRevLett.62.40 [Cited within: 1]

DOI:10.1103/PhysRevLett.65.2221

DOI:10.1103/PhysRevLett.69.2431

DOI:10.1088/0034-4885/68/2/R01 [Cited within: 1]

DOI:10.1103/PhysRevLett.86.3423 [Cited within: 1]

DOI:10.1103/PhysRevLett.88.124301 [Cited within: 2]

DOI:10.1016/0009-8981(78)90238-3 [Cited within: 1]

DOI:10.1007/BF01170399 [Cited within: 1]

DOI:10.1016/S0032-5910(97)03263-4 [Cited within: 2]

DOI:10.1038/35104697 [Cited within: 1]

DOI:10.1103/PhysRevLett.91.014302 [Cited within: 1]

DOI:10.1126/science.1066850 [Cited within: 2]

DOI:10.1103/PhysRevE.68.050301 [Cited within: 2]

DOI:10.1103/PhysRevLett.89.189603 [Cited within: 1]

DOI:10.1103/PhysRevE.75.061302 [Cited within: 3]

DOI:10.1143/JJAP.26.1230 [Cited within: 1]

DOI:10.1051/jp1:1996129 [Cited within: 1]

DOI:10.1051/jp2:1992255 [Cited within: 1]

DOI:10.1103/PhysRevE.49.2353 [Cited within: 1]

DOI:10.1088/0256-307X/25/7/058 [Cited within: 1]