,1,2,4, N Riaz2, Dianchen Lu1, S Shafie31Department of Mathematics, Faculty of Science,

,1,2,4, N Riaz2, Dianchen Lu1, S Shafie31Department of Mathematics, Faculty of Science, 2Department of Mathematics,

3Department of Mathematical Sciences, Faculty of Science,

First author contact:

Received:2019-10-3Revised:2019-12-25Accepted:2019-12-25Online:2020-02-24

Abstract

Keywords:

PDF (1066KB)MetadataMetricsRelated articlesExportEndNote|Ris|BibtexFavorite

Cite this article

M Qasim, N Riaz, Dianchen Lu, S Shafie. Three-dimensional mixed convection flow with variable thermal conductivity and frictional heating. Communications in Theoretical Physics, 2020, 72(3): 035003- doi:10.1088/1572-9494/ab6908

1. Introduction

Flow induced by a continuously stretching sheet in a quiescent fluid have applications in manufacturing processes of plastic films, hot rolling, glass fiber, wire drawing, paper production, extrusion, spinning of laments, production of synthetic sheets, glass fiber and paper production, extrusion, continuous casting, spinning of laments, production of synthetic sheets etc [1–10]. In convection, there is a fluid flowing relative to surface and a temperature difference between fluid and surface. In these heat convection processes, energy is transferred from a surface to fluid flowing over it as a result of temperature difference between fluid and surface. The flow over a surface is also induced by thermal buoyancy and these thermal buoyancy effects are more prominent if the surface is vertical. When the sheet is being stretched vertically with a forced velocity then buoyance forces cannot be neglected and flow in this case is mixed convective flow [11–19].Boundary layer flow over an exponentially stretching surface is firstly investigated by Magyari and Keller [20]. Elbashbeshy [21] performed heat transfer analysis of the flow induced by a permeable exponentially stretching sheet. Sajid and Hayat [22] computed the series solution of the self-similar equations that governs the flow over an exponentially stretching sheet in the presence of linear thermal radiation by the homotopy analysis method. The effect of thermal radiation in the presence of viscous dissipation on the flow over an exponentially stretching sheet is examined by Bidin and Nazar [23]. Partha et al [24] provided the similarity solution of mixed convection flow over an exponentially stretching sheet in the presence of frictional heating. Bhattacharyya and Layek [25] investigated boundary layer flow over an exponentially stretching surface in an exponentially moving parallel free stream. Dual solutions of MHD boundary layer flow induced by an exponentially stretching sheet with non-uniform heat sink/source are analysed by Raju et al [26]. Sulochana and Sandeep [27] examined the stagnation point flow of nanofluid over an exponentially shrinking/stretching cylinder. Three-dimensional flow of viscous fluid over an exponentially stretching sheet is firstly studied by Liu et al [28]. Afridi and Qasim [29] inspected the entropy generation in three-dimensional boundary flow over an exponentially stretching surface in the presence of viscous dissipation.

All studies cited above related to flow induced by the exponentially stretching sheet with constant fluid properties. It is now well established that the physical properties of fluids may vary with temperature [30–34]. The magnitude of variation in properties varies from one fluid to another and depends on temperature limits of ambient fluid. It can be observed that the variable viscosity and thermal conductivity are quite significant for most of the fluids as compared to the variations in other properties. It is also believed that the difference between the theoretical and experimental results is because the properties of fluid are assumed to be constant and not temperature-dependent.

To best of our knowledge no one analysed the three-dimensional boundary layer flow over an exponentially stretching sheet with temperature-dependent thermal conductivity. Keeping this in mind, our aim is to analyse three-dimensional mixed convection flow induced by exponentially stretching sheet in the presence of frictional heating. The thermal conductivity of fluid is assumed to vary with temperature. Governing equations are modelled and simplified under boundary layer approximations. Modelled partial differential equations are then transformed into non-linear ordinary differential equations by utilizing similarity transformations. Special forms of stretching velocity and surface temperature varying exponentially are chosen for accurate similarity transformations. The novelty of the present study is the self-similar solution of three-dimensional boundary-layer flow in the presence of mixed convection, viscous dissipation and temperature-dependent thermal conductivity. To check the validation of our numerical code of the shooting method obtained results are also compared with Matlab boundary value solver bvp4c [35]. Effects of physical parameters of interest on velocity and temperature profile are analyzed.

2. Formulation

Three-dimensional mixed convection boundary layer flow over a sheet that is being stretched exponentially has been considered for investigation. The sheet is being stretched in both $x-$ and $y-$ directions with velocities ${u}_{w}={u}_{0}{{\rm{e}}}^{\left(\tfrac{x+y}{L}\right)}$ and ${v}_{w}={v}_{0}{{\rm{e}}}^{\left(\tfrac{x+y}{L}\right)}$ respectively. The temperature of the sheet is ${T}_{s}={T}_{a}+A{{\rm{e}}}^{2\left(\tfrac{x+y}{L}\right)}$ (A is the constant characteristic temperature) and the temperature of the ambient fluid is ${T}_{a}.$ In the presence of frictional heating the boundary layer equations for the flow and heat transfer are [28, 29]:Introducing similarity transformations

3. Solution methodologies

3.1. Shooting method

In order to solve self-similar non-linear equations (3.2. Bvp4c

The numerical solutions are also computed by using Matlab built-in boundary value solver bvp4c. Matlab code bvp4c for the two-point boundary value problem is a finite difference code based on three-stage collocation at Lobatto points. These collocation polynomials provide a ${C}^{1}$-continuous solution, which is fourth order uniformly accurate in the interval of integration. Mesh selection and error control are based on the residual of the continuous solution. The collocation method routines a mesh of points to divide the interval of integration into subintervals. The solver computed a numerical solution by solving a global system of algebraic equations resulting from the boundary conditions and the collocation conditions imposed on all the subintervals. The solver then estimates the error of obtained numerical solution on each subinterval. The solver adapts the mesh and repeats the process, until the solution satisfies the tolerance criteria [35].3.3. Code validation

The comparison between the shooting method and bvp4c is presented in table 1 for the validation of our numerical codes. Moreover, table 2 shows the comparison of present results with the existing study. The attained results are found to be in excellent agreement.Table 1.

Table 1.Effects of different physical parameters on ${F}^{{\prime\prime} }\left(0\right),-{G}^{{\prime\prime} }\left(0\right),$ ${{\rm{\Theta }}}^{{\prime\prime} }\left(0\right)$ and comparison between shooting method and built-in routine bvp4c in Matlab.

| $-{F}^{{\prime\prime} }\left(0\right)$ | $-{G}^{{\prime\prime} }\left(0\right)$ | $-{{\rm{\Theta }}}^{{\prime} }\left(0\right)$ | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| λ | ${\Pr }$ | Ec | δ | ϵ | Shooting | bvp4c | Shooting | bvp4c | Shooting | bvp4c |

| 0.0 | 1.2 | 0.6 | 0.2 | 0.5 | 1.569 89 | 1.569 62 | 0.784 94 | 0.784 75 | 1.823 65 | 1.823 55 |

| 0.5 | 1.2 | 0.6 | 0.2 | 0.5 | 1.271 68 | 1.271 24 | 0.806 53 | 0.806 12 | 1.932 93 | 1.932 77 |

| 1.0 | 1.2 | 0.6 | 0.2 | 0.5 | 0.996 57 | 0.996 18 | 0.823 76 | 0.823 45 | 2.015 22 | 2.015 09 |

| 1.5 | 1.2 | 0.6 | 0.2 | 0.5 | 0.735 65 | 0.735 44 | 0.838 61 | 0.838 36 | 2.080 27 | 2.080 11 |

| 1.2 | 0.3 | 0.6 | 0.2 | 0.5 | 0.591 71 | 0.591 49 | 0.865 19 | 0.864 87 | 1.007 37 | 1.007 23 |

| 1.2 | 0.7 | 0.6 | 0.2 | 0.5 | 0.773 96 | 0.773 64 | 0.843 76 | 0.843 42 | 1.556 59 | 1.556 41 |

| 1.2 | 1.2 | 0.6 | 0.2 | 0.5 | 0.890 79 | 0.890 47 | 0.829 93 | 0.829 78 | 2.042 99 | 2.042 81 |

| 1.2 | 6.7 | 0.6 | 0.2 | 0.5 | 1.171 19 | 1.170 98 | 0.803 08 | 0.802 73 | 4.752 33 | 4.752 02 |

| 1.2 | 1.0 | 0.0 | 0.2 | 0.5 | 0.892 27 | 0.892 06 | 0.829 71 | 0.829 65 | 2.033 36 | 2.033 22 |

| 1.2 | 1.0 | 1.0 | 0.2 | 0.5 | 0.827 28 | 0.826 95 | 0.837 35 | 0.837 19 | 1.760 31 | 1.760 17 |

| 1.2 | 1.0 | 2.0 | 0.2 | 0.5 | 0.771 27 | 0.771 13 | 0.843 79 | 0.843 52 | 1.524 76 | 1.524 61 |

| 1.2 | 1.0 | 3.0 | 0.2 | 0.5 | 0.722 07 | 0.721 95 | 0.849 35 | 0.849 14 | 1.316 99 | 1.316 71 |

| 1.2 | 1.0 | 0.5 | 0.0 | 0.5 | 0.887 74 | 0.887 55 | 0.830 98 | 0.830 65 | 2.129 88 | 2.129 69 |

| 1.2 | 1.0 | 0.5 | 1.0 | 0.5 | 0.765 63 | 0.765 48 | 0.843 08 | 0.842 88 | 1.375 84 | 1.375 77 |

| 1.2 | 1.0 | 0.5 | 2.0 | 0.5 | 0.683 16 | 0.683 03 | 0.852 15 | 0.851 94 | 1.081 84 | 1.081 69 |

| 1.2 | 1.0 | 0.5 | 3.0 | 0.5 | 0.622 25 | 0.622 11 | 0.859 14 | 0.858 92 | 0.916 69 | 0.916 52 |

New window|CSV

Table 2.

Table 2.Comparison between our numerical results and the results of Liu et al [28] for ${F}^{{\prime\prime} }\left(0\right)\,$ and ${G}^{{\prime\prime} }\left(0\right)$ in the case where $\lambda =0,\delta =0,{Ec}=0.$

| $-{F}^{{\prime\prime} }\left(0\right)$ | $-{G}^{{\prime\prime} }\left(0\right)$ | |||

|---|---|---|---|---|

| ϵ | [28] | Present | [28] | Present |

| 0.0 | 1.281 808 56 | 1.281 808 56 | 0.784 944 23 | 0.784 944 23 |

| 0.5 | 1.569 888 46 | 1.569 888 47 | 0.000 000 0 | 0.000 000 0 |

| 1.0 | 1.812 751 05 | 1.812 751 05 | 1.812 751 05 | 1.812 751 05 |

New window|CSV

4. Results and discussion

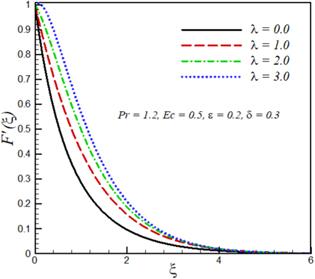

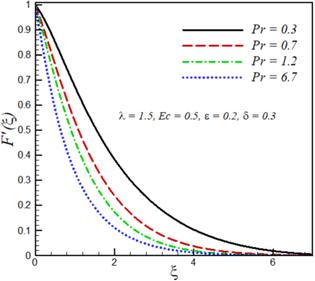

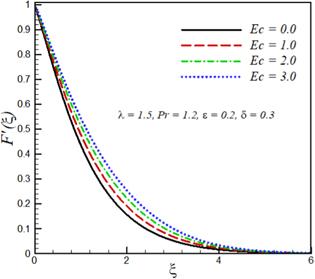

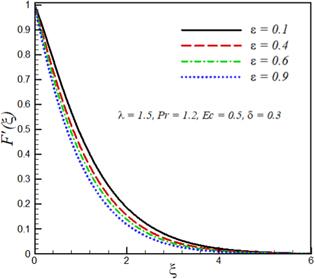

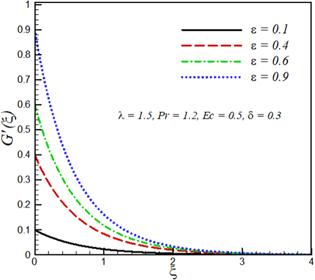

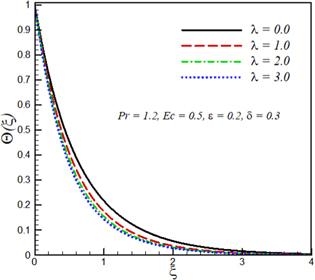

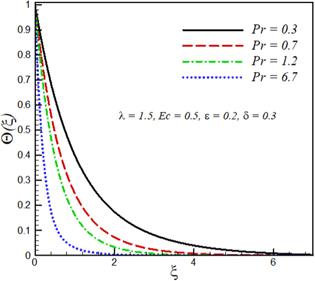

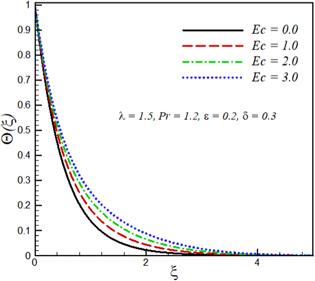

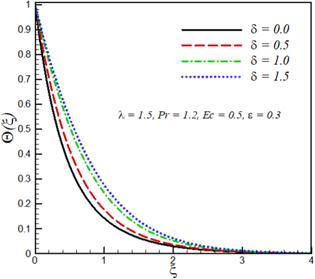

The effects of mixed convection parameter λ, Prandtl number $\Pr $ Eckert number Ec, velocity ratio parameter ϵ and variable thermal conductivity parameter δ on velocity components ${F}^{{\prime} }\left(\xi \right),$ ${G}^{{\prime} }\left(\xi \right)$ and temperature ${\rm{\Theta }}\left(\xi \right)$ are investigated. This purpose is achieved by plotting figures 1–9. The effect of the mixed convection parameter on velocity ${F}^{{\prime} }\left(\xi \right)$ is seen in figure 1. Velocity ${F}^{{\prime} }\left(\xi \right)$ increases by increasing $\lambda .$ For large λ, there is a stronger buoyancy force due to which momentum boundary layer increases. The influence of Prandtl number $\Pr $ on velocity ${F}^{{\prime} }\left(\xi \right)$ is displayed in figure 2. The large values of Prandtl number $\Pr $ correspond to stronger momentum and weaker thermal diffusivity, which therefore reduces the thermal boundary layer thickness. Figure 3 explicates the effect of Eckert number Ec on the velocity As expected velocity increases by increasing ${Ec}.$ Figure 4 illustrates that velocity ${F}^{{\prime} }\left(\xi \right)$ decreases by increasing velocity ratio parameter ϵ whereas velocity ${G}^{{\prime} }\left(\xi \right)$ increases by increasing velocity ratio parameter ϵ (see figure 5). Temperature and thermal boundary layer decreases upon increasing mixed convection parameter λ (see figure 6). Increasing the buoyancy parameter specifies the higher temperature from the surface relative to ambient, therefore thermal boundary layer decreases. The influence of Prandtl number $\Pr $ on the temperature field is illustrated in figure 7. The increase in the Prandtl number $Pr$ indicates a reduction in the thermal conductivity of the fluid and because of this reduction, the penetration depth of the thermal energy decreases, therefore temperature of the fluid decreases. Figure 8 shows that temperature distribution and thermal boundary layer thickness increases with an increase in Eckert number ${Ec}.$ Physically, by increasing friction between the adjacent layers of fluid increases and the kinetic energy of fluid is converted into thermal energy, which in turn rises the fluid temperature. The influence of the thermal conductivity parameter $\delta \ $ on the temperature profile is portrayed in figure 9. It is observed that the temperature of the fluid in the boundary layer increases by increasing the value of the variable thermal conductivity parameter δ. Physically, as the thermal conductivity parameter increases, the thermal conductivity of the fluid increases and, as a result, the thermal energy of fluid increases, resulting in an increase in temperature. Table 1 shows that skin friction coefficients along $-{F}^{{\prime\prime} }\left(0\right)$ transverse direction decreases by increasing mixed convection parameter λ, whereas $-{G}^{{\prime\prime} }\left(0\right)$ and local Nusselt number $-{{\rm{\Theta }}}^{{\prime} }\left(0\right)$ increases with increasing mixed convection parameter $\lambda .$ Skin friction coefficients and local Nusselt number decreases by increasing the variable thermal conductivity parameter. $-{F}^{{\prime\prime} }\left(0\right)$ and $-{{\rm{\Theta }}}^{{\prime} }\left(0\right)$ are decreasing functions of Eckert number Ec whereas increasing functions of Prandtl number ${\Pr }.$Figure 1.

New window|Download| PPT slide

New window|Download| PPT slideFigure 1.Effects of mixed convection parameter λ on velocity ${F}^{{\prime} }\left(\xi \right).$

Figure 2.

New window|Download| PPT slide

New window|Download| PPT slideFigure 2.Effect of Prandtl number $\Pr $ on velocity ${F}^{{\prime} }\left(\xi \right).$

Figure 3.

New window|Download| PPT slide

New window|Download| PPT slideFigure 3.Effect of Eckert number Ec on velocity ${F}^{{\prime} }\left(\xi \right).$

Figure 4.

New window|Download| PPT slide

New window|Download| PPT slideFigure 4.Effect of velocity ratio parameter ϵ on velocity ${F}^{{\prime} }\left(\xi \right).$

Figure 5.

New window|Download| PPT slide

New window|Download| PPT slideFigure 5.Effect of velocity ratio parameter ϵ on velocity ${G}^{{\prime} }\left(\xi \right).$

Figure 6.

New window|Download| PPT slide

New window|Download| PPT slideFigure 6.Effect of mixed convection parameter λ on temperature profile ${\rm{\Theta }}\left(\xi \right).$

Figure 7.

New window|Download| PPT slide

New window|Download| PPT slideFigure 7.Effect of Prandtl number $\Pr $ on temperature profile ${\rm{\Theta }}\left(\xi \right).$

Figure 8.

New window|Download| PPT slide

New window|Download| PPT slideFigure 8.Effect of Eckert number Ec on temperature profile ${\rm{\Theta }}\left(\xi \right).$

Figure 9.

New window|Download| PPT slide

New window|Download| PPT slideFigure 9.Effect of variable thermal conductivity parameter δ on temperature profile ${\rm{\Theta }}\left(\xi \right).$

5. Closing remarks

From the current analysis, the following specific conclusions are deduced:The problem is self-similar in the presence mixed convection as well as viscous dissipation for a special type of surface temperature.The mixed convection parameter increases the velocity profile, but it decreases the temperature profile in the boundary layer region.

Velocity component ${F}^{{\prime} }$ in the transverse direction and dimensionless temperature Θ decreases by increasing the Prandtl number, whereas both are decreasing functions of the Eckert number.

Velocity decreases ${F}^{{\prime} }$ whereas ${G}^{{\prime} }$ increases by increasing the velocity ratio parameter.

Temperature profile increases by increasing the variable thermal conductivity parameter.

Reference By original order

By published year

By cited within times

By Impact factor

DOI:10.1016/j.jtice.2010.01.013 [Cited within: 1]

DOI:10.1016/j.ijmecsci.2011.07.012

DOI:10.1016/j.ijthermalsci.2011.02.019

DOI:10.1016/j.ijheatmasstransfer.2012.10.006

DOI:10.1016/j.ijthermalsci.2014.03.009

DOI:10.1186/s40712-016-0054-2

DOI:10.1016/j.ijheatmasstransfer.2017.05.042

DOI:10.3390/e19080414

DOI:10.1063/1.4965926 [Cited within: 1]

DOI:10.1016/S0735-1933(99)00058-5 [Cited within: 1]

DOI:10.1017/S1727719100002343

DOI:10.1016/j.ijnonlinmec.2009.12.003

DOI:10.1016/j.ijmecsci.2013.10.011

DOI:10.1002/apj.1954

DOI:10.1016/j.partic.2016.01.001

DOI:10.1080/15376494.2016.1232454

DOI:10.3390/e19010010

DOI:10.1016/j.cnsns.2018.04.002 [Cited within: 1]

DOI:10.1088/0022-3727/32/5/012 [Cited within: 1]

[Cited within: 1]

DOI:10.1016/j.icheatmasstransfer.2007.08.006 [Cited within: 1]

[Cited within: 1]

DOI:10.1007/s00231-004-0552-2 [Cited within: 1]

DOI:10.1155/2014/785049 [Cited within: 1]

DOI:10.18869/acadpub.jafm.68.225.24784 [Cited within: 1]

[Cited within: 1]

DOI:10.1080/00986445.2012.703148 [Cited within: 3]

DOI:10.1115/1.4038703 [Cited within: 3]

DOI:10.1007/BF01379650 [Cited within: 2]

DOI:10.1016/0735-1933(96)00009-7

DOI:10.1016/j.ijnonlinmec.2009.12.003

DOI:10.1590/S0104-66322014000100011

DOI:10.1007/s10483-015-1926-9 [Cited within: 2]

DOI:10.1145/502800.502801 [Cited within: 2]