,2)北京理工大学机械与车辆学院,北京 100081

,2)北京理工大学机械与车辆学院,北京 100081STUDY ON INSTABILITY OF THE WIDE VANELESS DIFFUSER WITH DIFFERENT TREATMENTS OF VISCOSITY 1)

Hu Chenxing, Yang Ce ,2)School of Mechanical Engineering,Beijing Institute of Technology,Beijing 100081, China

,2)School of Mechanical Engineering,Beijing Institute of Technology,Beijing 100081, China通讯作者: 2) 杨策,教授,主要研究方向:内流流体力学与压缩系统稳定性问题. E-mail:yangce@bit.edu.cn

收稿日期:2019-07-29接受日期:2019-09-18网络出版日期:2019-09-18

| 基金资助: |

Received:2019-07-29Accepted:2019-09-18Online:2019-09-18

作者简介 About authors

摘要

径向无叶扩压器的全局稳定性可能受到核心主流失稳,出口回流与壁面边界层分离等因素影响,对于宽无叶扩压器,无黏核心主流与壁面边界层流动对不稳定扰动诱发的作用机理是当前研究的重点.本文首先通过数值计算获得了大宽度比孤立无叶扩压器平均流动,然后基于小扰动理论和周向均质假设,分别对欧拉方程与 Navier-Stokes 方程进行线性化,建立了基于无黏核心流动的稳定性分析方法,以及基于涡黏性与分子黏性的混合稳定性分析方法;通过与实验结果的对比,验证了混合稳定性分析方法预测所得流动失稳频率和全局直接模态的准确性;最后基于伴随方法获得了特征值的结构敏感性,揭示了不同黏性处理条件下宽无叶扩压器内全局不失稳扰动的源发区域.在只考虑核心主流的无黏条件下,宽无叶扩压器内流动不稳定扰动来源于流场中部,为二维的离心失稳;在同时考虑核心主流与边界层的作用时,宽无叶扩压器不稳定扰动不仅来源于扩压器流场中部的核心主流,壁面回流对于不稳定扰动的产生了重要影响.

关键词:

Abstract

The global stability of vaneless diffuser in the centrifugal compressor is often influenced by the main flow stability, backflow at exit and the boundary layer separation. For the vaneless diffuser with large axial width ratio, the effect of the main flow and boundary layer on the instability perturbations is the main subject. In this paper, the mean flow of the wide vaneless diffuser is firstly obtained with numerical simulations. The Eulers' and Navier-Stokes equations are linearized respectively based on the small perturbations assumption. Then the inviscid stability approach considering the inviscid main flow and the mixed stability approach considering the effect of both eddy viscosity and molecular viscosity are established. The prediction results are validated against the experimental results. At last, the structural sensitivity based on the adjoint method is adopted. And the wave-maker region is revealed under different treatments of viscosity. The instability perturbations are located at the middle of the flow field when inviscid main flow is only considered. And a centrifugal instability maybe the main cause of the vaneless diffuser stall. When the inviscid main flow and boundary layer are both considered, the wave-maker region not only lies at the main flow near the middle of the vaneless diffuser, but also lies at the reverse flow region of the boundary layer.

Keywords:

PDF (12942KB)元数据多维度评价相关文章导出EndNote|Ris|Bibtex收藏本文

本文引用格式

胡晨星, 杨策. 采用不同黏性处理方法的宽无叶扩压器不稳定流动研究 1). 力学学报[J], 2019, 51(6): 1775-1784 DOI:10.6052/0459-1879-19-207

Hu Chenxing, Yang Ce.

引言

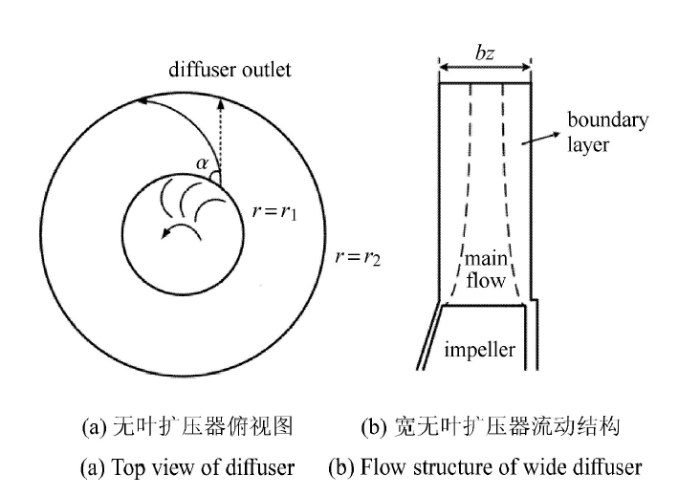

在日益增长的能源与国防工业需求推动下,离心压气机的整体性能呈现出高压比、高效率、宽安全裕度的发展趋势,这对离心压气机的设计与研发都提出了更高的要求.与此同时,离心压气机内的三维、黏性、非定常流动也更加复杂,由此引起的气动特性变化有可能导致流动失稳现象的发生,甚至在过渡态或非设计工况中导致严重的事故[1-2].因此,保障安全可靠性是进一步提升离心压气机气动性能的首要条件,也是航空发动机、涡轮增压等关键领域发展的核心技术问题.针对离心压气机的稳定性问题,国内外的****在过去几十年间展开了大量的理论、实验与数值研究[3-7].而作为离心压气机关键的``减速扩压''部件,无叶扩压器内流动特性往往关系到全场流动稳定性.典型的平行壁面无叶扩压器如图1(a)所示,无叶扩压器出口半径$r_2$与入口半径$r_1$的比值定义为径向半径比$Rf$,轴向宽度$b$与入口半径比$r_1$定义为宽度比$bz$.叶轮出口的高扰流气体以一定的周向入流角度$\alpha$进入无叶扩压器.对于具有较大宽度比的无叶扩压器,其内部流动结构如图1(b)所示,主要由壁面附近的湍流边界层流动,以及占据流道大部分区域的核心主流构成.

图1

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图1宽无叶扩压器流动示意图

Fig.1Sketch of the flow in the vaneless diffuser

三维发展的边界层流动可能因逆向压力梯度的影响发生分离,甚至回流[8-10];在远离壁面的主流区域,由于黏性力作用较小,可以视为近似无黏流动,呈螺旋线发展的规律.因此,尽管无叶扩压器结构简单,但是由于受限空间内三维非常流动的复杂性,目前对于大宽度比下无叶扩压器不稳定流动产生的深层物理机理,仍未有明确的定论.

基于诸多研究者对于无叶扩压器失速的主要诱因的探索,两种较为认可的理论研究路线被广泛采用,即无黏核心流不稳定性理论与壁面边界层不稳定性理论.其中无黏核心流理论主要针对了宽无叶扩压器,Moore[11],Shen 等[12],Tsujimoto 等[13]与 Abdelhamid[14] ****认为宽无叶扩压器内失稳的主要原因是核心主流的失稳,是一种二维离心失稳.这些****往往采用基于无黏流动的线性稳定性分析方法,并采用实验或数值模拟的方法对理论预测结果进行验证.Moore 与 Shen 等的无黏稳定性分析方法均是建立于旋转坐标系,以速度扰动激发的压力扰动为判断失稳标准,并预测得到了无叶扩压器的失速关键角以及失稳扰动转速[11-12].Lejvar[15]通过对孤立的无叶扩压器进行二维数值计算,验证了核心主流对无叶扩压器流动失稳的关键影响作用.计及壁面黏性的影响,Moore定性的认为由于边界层厚度的存在,会对主流产生排挤而促使主流加速.他用该理论解释实验中观察到的宽度减小时,失稳关键角度减小的现象.但该理论对于黏性的忽略有可能与实际流动存在较大差异,并且无法充分揭示壁面回流对失稳的影响机制.

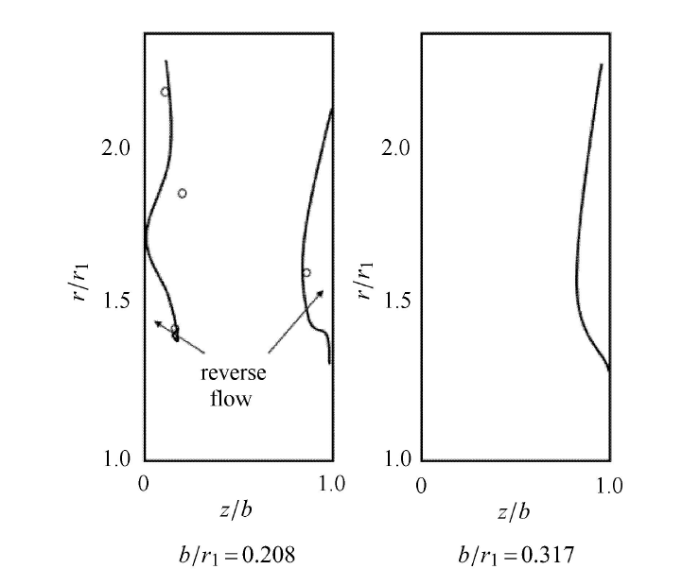

Jansen[16]、Senoo 等[17-18]、Frigne 等[19]认为无叶扩压器内的不稳定性主要是由壁面边界层分离现象诱发的.Senoo 与 Kinoshita[17]通过对三维边界层进行计算,考虑了两侧壁面边界层混合和入口的轴向非对称性影响,建立了经验公式,确定了回流与失速产生时的入口流动角度的关系.对于宽无叶扩压器内三维湍流边界层的作用,Tsurusaki 与 Munakata[20]通过建立边界层厚度预测模型,结合实验测量的方法,在宽扩压器失稳发生前捕捉到壁面回流区的局部速度扰动,如图2 所示.他们认为该现象证明了边界层回流对于无叶扩压器失稳的关键作用.

图2

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图2Tsurusaki与Munakata[20]模型与实验所得壁面回流区

Fig.2The reverse flow regions by prediction and experiment in Tsurusaki and Munakata's work[20]

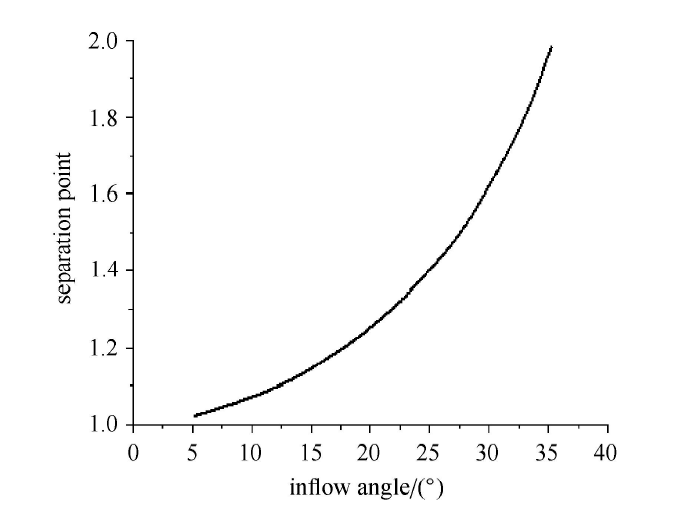

Dou 与 Mizuki [21]基于 Johnson[22]的边界层三角模型[20],提出了一种计算宽无叶扩压器内三维湍流边界层的方法.该方法假设扩压器流道内径向速度的分布为二阶梯形,并将动量方程与主流关系式联立,并预测得到了不同入流关键角度下边界层分离点的径向位置,如图3 所示.他们将理论预测结果与实验测量进行对比分析,认为当壁面径向回流发展至无叶扩压器入口,并与射流-尾流区域相互作用时,才会产生无叶扩压器内的旋转失速.但是应该注意到,在孤立的无叶扩压器的实验或数值计算中,也会有失稳的产生 [23]. 窦华书 [24] 针对不同宽度比 的无叶扩压器失稳机理进行了解释,他认为对于较宽的无叶扩压器,扩压器不会容易导致级的喘振,叶轮大概率会优先于扩压器发生失速;对于较小宽度扩压器,失速既可能先发生于叶轮,又可能先发生于无叶扩压器,此时限制扩压器稳定性的是流动损失.

图3

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图3Dou[21] 模型预测所得边界层分离点

Fig.3The separation point position predicted by Dou[21]

可以看到,基于边界层失稳理论分析方法的建立依赖于对边界层速度分布的构造模型,以及分离点的准确预测.计及主流在失稳产生过程中的作用,Frigne 和 Braembussche [19] 通过引入边界层厚度方程间接考虑了核心主流与边界层的相互作用,壁面边界层可以看作一种黏性激励的来源,而主流则可视为一个反馈系统,由边界层产生的局部扰动传播至主流区域,并实现放大.但应该注意到核心主流的作用并没有直接被考虑.

因此,如何同时考虑边界层与无黏主流的影响,是宽无叶扩压器失稳研究的关键所在.而基于 mean-flow 的混合稳定性方法,为综合考虑无叶扩压器内复杂流动稳定性打开了新思路.该方法通过引入涡黏性系数,使得拟序扰动方程封闭,而其平均流动往往来自于实验或者数值计算的时间平均结果.这一方法近年来成功应用于射流[25]、圆柱扰流[26]与受限空间流动[27].

在获得稳定性预测模型的基础上,宽无叶扩压器失稳研究的关键在于确定失稳的源发区域,而流动敏感性这一概念能够较为直接地确定扰动的源发区域. Giannetti 与 Luchini [28] 最早在二维圆柱绕流的敏感性研究中,确定了结构敏感性的概念,其代表线性化 N-S 方程算子发生结构改变的情况下,特征值的变化规律.他们将引起特征值变化最明显的区域定义为扰动的源发区域. Fani 等[29] 将结构敏感性应用到突然扩张的槽道流动中,确定了流动不稳定来源于壁面分离区域.在包括射流[30-32]、燃烧室[33-34]、机翼[35] 等复杂湍流中的成功应用,为研究无叶扩压器流动稳定性问题提供了新的思路.

综上所述,针对宽无叶扩压器稳定性研究中存在的关键问题,本文的主要研究内容主要分为三部分:首先通过对 Navier-Stokes 方程进行线性化,构建了基于湍流流动的混合稳定性分析方法,同时作为对比,构建了基于无黏流动的稳定性分析方法;然后结合拉格朗日恒等式构建了线性化的伴随方程,获得了特征值的结构敏感性;最后针对不同的黏性处理方法,获得了宽无叶扩压器失稳扰动的源发区域,揭示了核心主流与壁面边界层在失稳中的作用机制.

1 理论方法

1.1 数学模型的建立

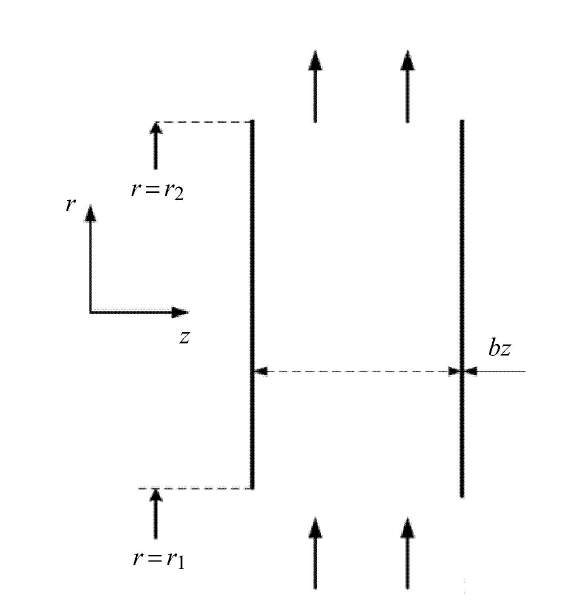

本文的研究对象是具有平行壁面的无叶扩压器. 假设周向方流动是轴对称,流动只沿径向与轴向发生变化. 此时无叶扩压器可简化为如图4所示.

图4

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图4无叶扩压器稳定性分析数学模型示意图

Fig.4The sketch of the vaneless diffuser model

1.2 方程的线性化

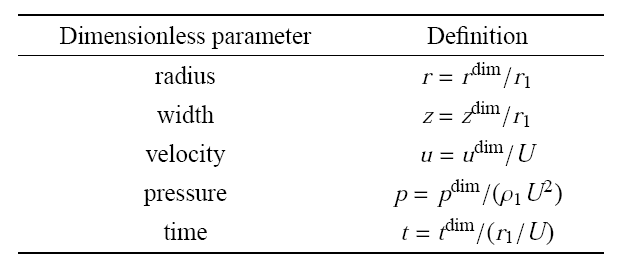

假设工质为不可压缩流体,无叶扩压器流动参数由状态向量 ${\pmb q} = ({\pmb u},p)^{\rm T}$ 来表示. 则无量纲化的三维 Navier-Stokes 方程为其中,流动参数均采用如表1所示的定义进行无量纲化.

Table 1

表1

表1流动与结构参数无量纲化

Table 1

|

新窗口打开|下载CSV

根据速度三分假设,无叶扩压器中的流动速度可分解为时间平均项、拟序结构项和随机湍流扰动项 3 个部分

在稳定性问题中,拟序结构波动是决定流动在大时间尺度内是否稳定的关键变量,因此针对平均项与拟序扰动项做如下假设:(1) 背景流动随时间不发生变化,即 $\frac{\partial^{-}}{\partial t} = 0$; (2) 由于平均流动沿周向均匀,有 $\frac{\partial^{-} }{\partial \theta } =0$,且方程 (1) 和方程 (2) 同样适用于时间平均项. 将式 (3) 代入控制方程可得平均流方程为

其中,$\tau ^{\rm R}$表示由于湍流随机扰动产生的雷诺应力,$\tau^C$代表由于拟序扰动产生的应力.将相平均后的控制方程 (1) 和 (2) 减去平均流方程 (4) 和 (5),即可得拟序扰动的控制方程

忽略任意二阶或更高阶的拟序扰动项 $\tau ^N = \overline {\tilde{\pmb u}\tilde {\pmb u}} - \tilde {\pmb u}\tilde {\pmb u}$,剩下的 $\tau$ 代表由于拟序扰动的通过引起的湍流随机扰动的波动. 由于 $\tau$的存在导致方程组 (4)$\sim$(6) 无法闭合.此时可以引入 Boussinesq 的湍流黏性假设,$\tau$ 可表达为以下形式

由于涡黏性系数的引入,定义等效雷诺数为 $Re_{\rm eff} = \rho _1U_1 d_1 / (\mu + \mu _t )$,其中下标1代表扩压器入口参数,$d_1$ 定义为无叶扩压器入口直径.将式 (7) 代入式 (6) 可得混合稳定性方法的控制方程

流动的边界条件为:

(1) 扩压器入口与壁面

(2) 扩压器出口

通常如果参数在某一个方向上是均质或对称的,那么应用 Laplace 变换可以将该方向上的变量的时间与空间参数分离出来.在不考虑蜗壳对无叶扩压器流动结构影响的前提下,无叶扩压器内流动在周向方向上往往具有对称性,并且周向方向同时是不稳定扰动的主要传播方向.此时利用 Laplace 变换,流动速度与压力的拟序扰动项均可以写成如下的形式

其中,$\hat {u}$ 和 $\hat{p}$ 代表扰动的幅值,$m$ 代表扰动的周向波数,特征值 $\omega =\omega _r + {\rm i}\omega _i $ 代表扰动的复频率.将式 (12) 和式 (13) 代入线性化方程 (8) 和式 (9),可得正则化的扰动方程

式 (8) 和式 (9) 等同于一个广义的特征值问题,将其表达为特征值问题的形式为

通过求解特征值问题 (17),可以获得用于判断流动稳定性的特征值与相应的全局模态.

1.3 伴随方程与结构敏感性

伴随的定义基于内积的概念,假设在有限空间 $\varOmega$ 存在向量 $l$ 和 $n$,两个向量的内积定义为其中 ${\pmb O}$ 是正定矩阵,即 ${\pmb O}^{\rm T} = {\pmb O}$.则对于线性算子矩阵有 $A$

即可得到

其中${\pmb A}^\dagger = {\pmb O}^{ - 1}{\pmb A}^{\rm T}{\pmb O}$定义为线性算子$A$的伴随算子,而$l$则为$n$的伴随向量. 将 式(14) $\sim$式(16)应用于式(20),即可推导得到线性化Navier-Stokes方程的伴随方程

其中,$\hat {\pmb u}^\dagger $ 和 $\hat {p}^\dagger$ 代表伴随扰动的幅值,特征值 $\omega ^\dagger$ 代表伴随扰动的复频率,其与特征值 $\omega$ 的关系为虚部相同,实部相反.线性化的伴随方程同样可以表示为广义特征值问题

通过求解式 (23) 代表的特征值问题,即可获得伴随特征值与伴随模态.

在获得了全局模态与伴随模态的基础上,参考 Gainnetti 与 Luchini[28] 的推导方法,本文引入了特征值的结构敏感性这一变量,表示如下式

结构敏感性的幅值大小不仅取决于当地扰动幅值的大小,还取决于扰动感受性,即梯度量的大小.其物理意义在于当某处流场内扰动幅值与扰动感受性同时处于较高水平时,结构敏感性则处于较高值,代表着扰动容易产生的区域.

2 平均流动

2.1 无黏平均流动

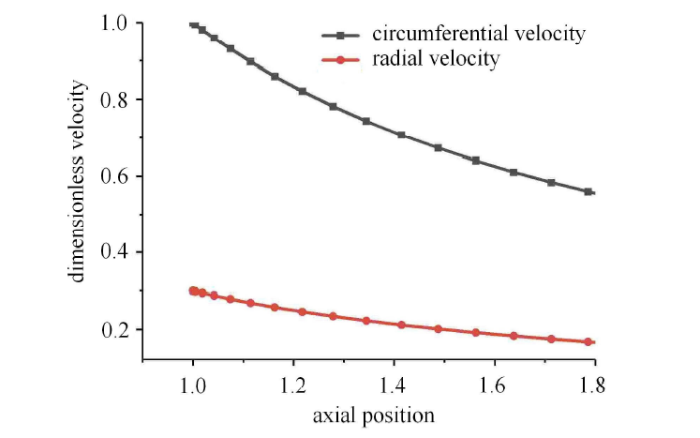

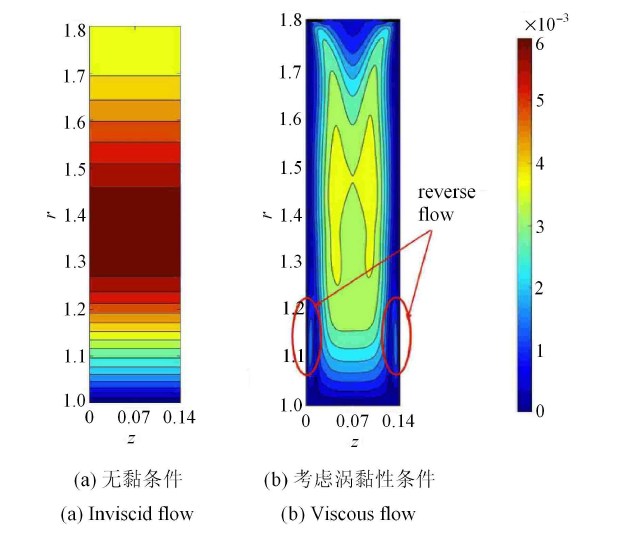

本文用于计算为孤立的宽无叶扩压器,径向半径比 $Rf$ 为 1.8,宽度半径比 $bz$ 为 0.14.为了验证核心主流的作用机制,首先求 取了无黏条件下的平均流动.考虑到平均流动随时间变化缓慢与周向均匀的假设,可建立无黏条件下简化的平均流动方程结合边界条件求解式 (26)$\sim$式 (29),可得无黏条件下径向速度与周向速度的分布.图5 所示为入流角度 14.2$^\circ$ 时无黏流动速度分布,可以看到径向速度与周向速度均沿着径向方向逐渐减小.

图5

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图5无黏条件下宽无叶扩压器平均流动

Fig.5The inviscid mean flow of the vaneless diffuser

2.2 考虑涡黏性的平均流动

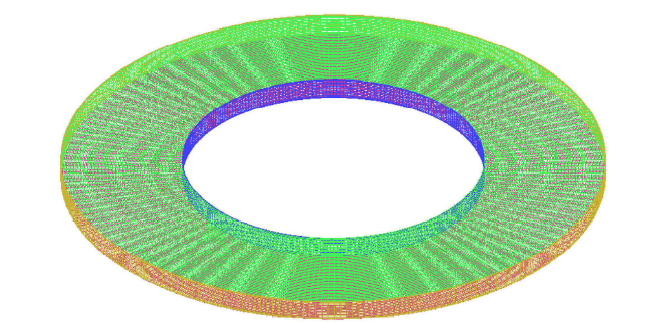

对于考虑黏性的平均流动,无法通过解析求解直接获得,而是采用数值模拟求解的方法.数值模拟采用的结构化网格如图6 所示,为了同时保证计算效率与准确度,通过网格无关性验证,确定了网格总数为 120 万.图6

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图6孤立宽无叶扩压器网格示意图

Fig.6Mesh of the isolated vaneless diffuser

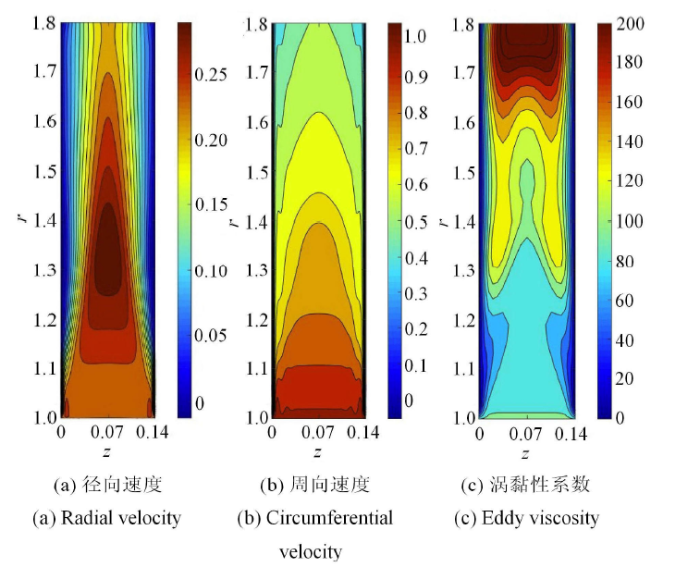

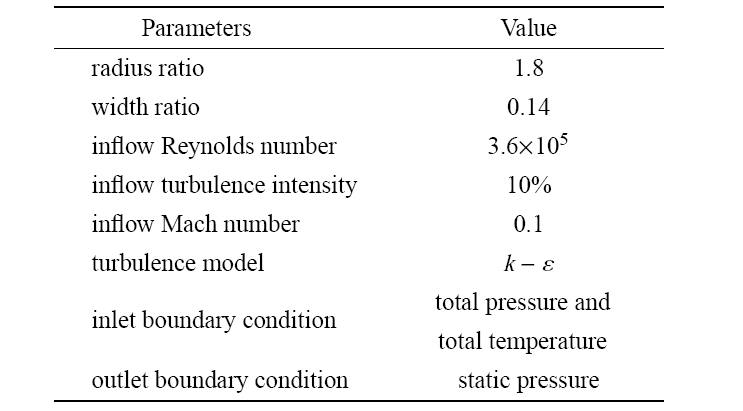

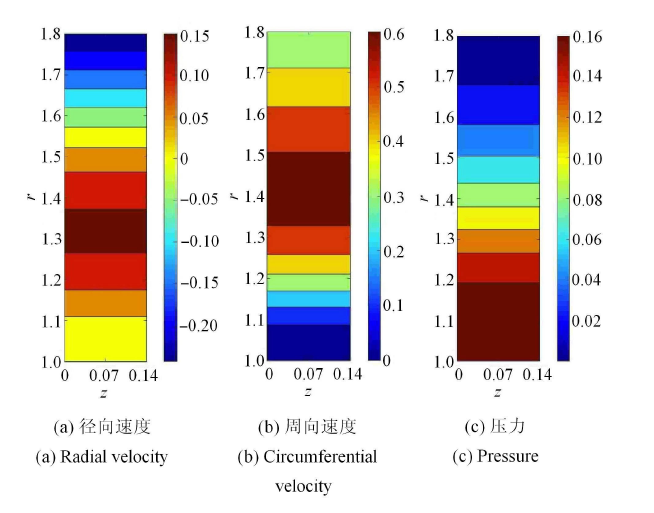

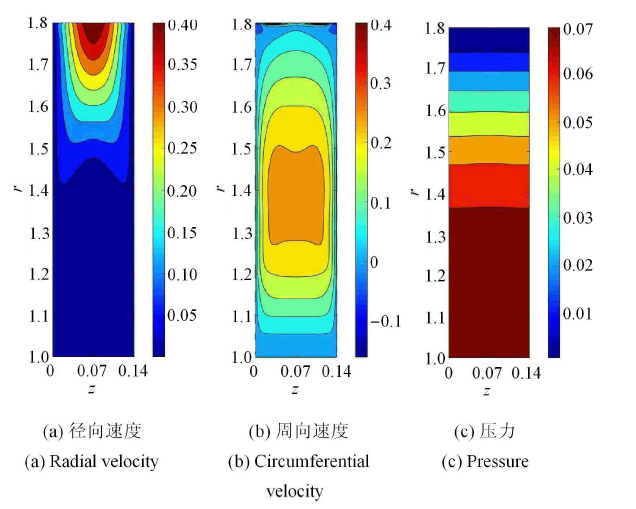

采用定常的雷诺时均 N-S 方程求解数值计算(RANS),湍流模型为$k$-$\varepsilon$模型,边界条件入口给定总温总压,出口给定静压,入口雷诺数给定 3.6$\times$10$^{5}$.通过不断减小入口流动角,当定常求解无法获得收敛时,认定此时对应的入口流动角为数值计算得到的关键入口流动角.图7 所示为在关键入流角 14.2$^\circ$ 下,宽无叶扩压器的径向速度、周向速度与涡黏性系数分布云图.由图可知,在宽无叶扩压器之中,壁面边界层厚度沿径向方向逐渐增大,但直至扩压器出口都未汇合为完全发展流动,而且对主流流动产生了挤压效应,导致径向速度在径向位置 $r=1.3 \sim 1.4$ 附近有所加速.考虑黏性下的周向速度分布与无黏条件下近似,沿径向方向逐渐减小,遵循角动量守恒定律.涡黏性系数的分布与边界层的发展规律关联性较高,其中高涡黏性区域主要集中于靠近扩压器出口的流道,以及径向位置 $r=1.3 \sim 1.6$ 的壁面附近.

图7

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图7数值计算所得宽无叶扩压器平均流动

Fig.7The turbulent mean flow of the vaneless diffuser

Table 2

表2

表2无叶扩压器平均流动数值计算参数

Table 2

|

新窗口打开|下载CSV

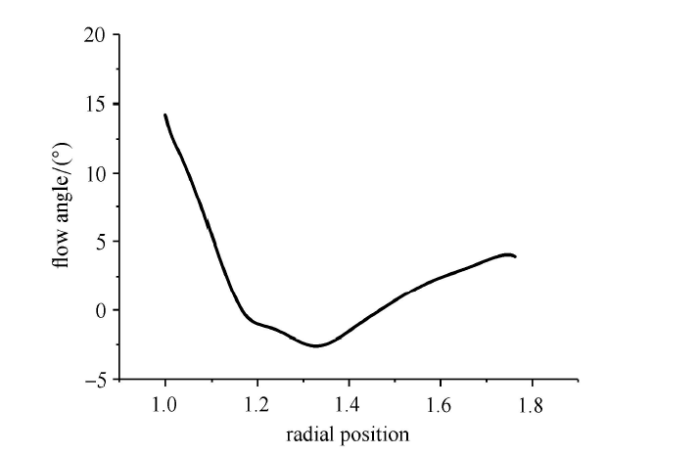

壁面边界层流动的分离与回流是近失速工况下宽扩压器流动的典型特征之一,图8所示为扩压器99%高度流动角度沿径向位置的分布.由图可知,在径向位置约 $r=1.1 \sim 1.4$ 附近存在着流动角度为负的流动,即在该区域内壁面附近产生了径向回流,并在径向位置 $r=1.4$ 边界层流动再次附着.

图8

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图8扩压器 99 % 宽度流动角度分布

Fig.8The flow angle at 99 % width of the vaneless diffuser

3 稳定性分析

3.1 特征谱相与模型验证

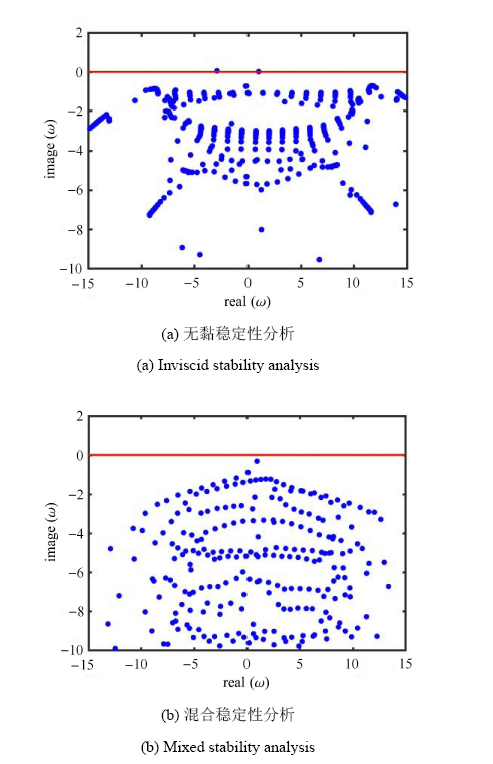

在本文中,广义特征值问题采用软件 MATLAB 中基于 QZ 算法的 $eig$ 函数进行求解.基于平均流动,通过求解特征值问题,可得获得无叶扩压器流动的特征值谱相.图9 所示分别为无黏稳定性分析和混合稳定性分析所得特征谱相分布.特征谱相中带有最大特征值虚部的特征值,定义为最不稳定特征值,并决定了流动的稳定性.此时对应的平均流动入流角度为 14.2$^\circ$,周向扰动波数为4,即两种稳定性分析均在周向波数为 4 时得到的最不稳定特征值虚部最大.图9

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图9无黏稳定性分析与混合稳定性分析所得特征谱相

Fig.9The eigenvalue spectrum calculated with inviscid and mixed stability

表3 所示为混合稳定性分析与无黏稳定性分析方法预测得到的特征谱相与实验结果[18] 进行对比.由表可知,采用混合稳定性分析方法能够较为准确的预测失速扰动的旋转速度,且相比无黏稳定性分析方法的预测结果更为准确.

Table 3

表3

表3混合稳定性预测与实验结果对比[18]

Table 3

|

新窗口打开|下载CSV

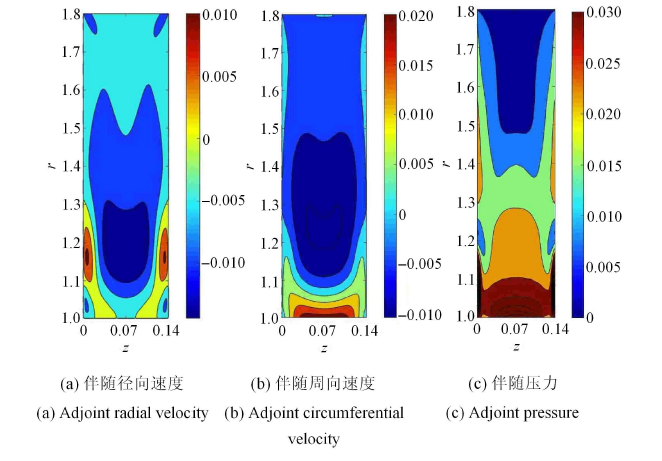

3.2 全局模态分析

采用线性稳定性分析方法,还可以得到对应最不稳定性特征值的全局模态.图10 所示为无黏条件下对应最不稳定特征值的速度与压力全局模态.由图可知,无黏条件下在扩压器出口附近存在较强的径向速度回流扰动,而在径向位置 $r=1.3\sim 1.5$ 附近,径向速度与周向速度均有较高幅值的扰动,压力扰动则主要集中于扩压器入口附近.图10

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图10无黏稳定性分析所得无叶扩压器特征模态

Fig.10The eigenmodes of the inviscid stability analysis

图1 所示为考虑黏性的混合稳定性分析所得全局模态.在考虑黏性影响下,径向速度扰动高幅值区域更加集中于出口. 对比无黏稳定性分析结果,除受黏性影响导致的轴向分布不均匀以外,周向速度与压力扰动的高幅值区域分布与无黏稳定性分析 结果保持基本一致.

图11

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图11混合稳定性分析所得无叶扩压器特征模态

Fig.11The eigenmodes of the mixed stability analysis

4 伴随模态与结构敏感性

4.1 伴随模态

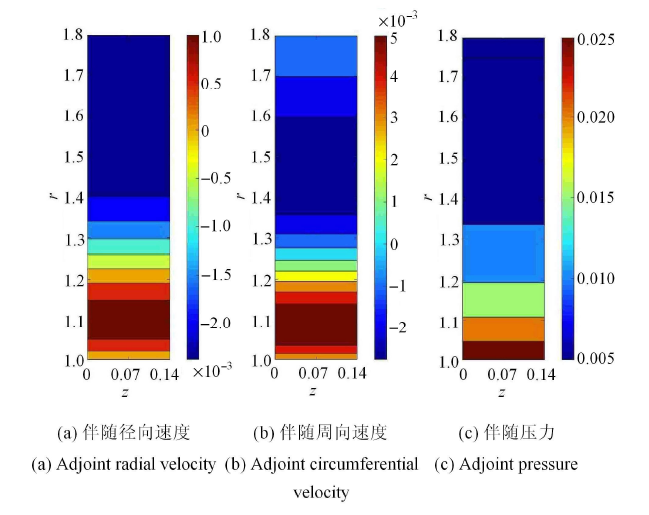

全局模态代表了流动扰动的强度,而伴随模态则可以揭示扰动的感受性.感受性的物理意义是当系统的初始条件、边界条件、动量力与质量力等条件发生变化时,系统稳定性相应引起的变化.本文推导了线性化的伴随方程,采用与稳定性分析一致的广义特征值求解方法,获得了无黏条件下的伴随模态,如图 12 所示.由图可知,伴随速度的模态与全局模态存在着明显的差异,并且基本呈现反向发展的规律. 伴随径向速度扰动和伴随周向速度扰动的高幅值区域主要集中于扩压器入口区域.而伴随压力沿着径向方向伴随扰动逐渐减弱.图12

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图12无黏稳定性分析所得伴随模态

Fig.12The adjoint eigenmodes of the inviscid analysis

在考虑黏性影响下,可得伴随速度与压力的模态分布云图如图 13 所示.由伴随径向速度模态分布可知,在靠近扩压器入口的主流和边界层区域分别存在反向的伴随扰动.其中径向位置 $r=1.1 \sim1.3$ 附近的高伴随模态区域,与壁面边界层回流相对应.这表明尽管入口附近区域扰动的幅值较小,但感受性较强,是易于将扰动放大的区域.伴随周向速度与压力的高幅值区域均集中于 $r=1.0 \sim1.3$ 径向位置.

图13

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图13混合稳定性分析所得伴随模态

Fig.13The adjoint eigenmodes of the mixed stability analysis

4.2 结构敏感性

通过结合全局模态与伴随模态,可以获得特征值的结构敏感性,其物理意义为扰动强度和感受性的综合,往往代表不稳定扰动的源发区域,即 wavemaker 结构.图 14 所示为无黏与考虑黏性条件下特征值的结构敏感性云图.由图 14(a) 可知,在无黏条件下不稳定扰动的主要来源均位于$r=1.3\sim1.5$径向位置,即靠近流场中部,而在扩压器出口附近的径向速度扰动并未产生决定性的诱发作用.根据 Lejevar 等的研究[13],核心主流的失稳可视为一种二维的离心不稳定.由图 14(b) 可知,在考虑黏性的影响以后,除在核心流动区域存在高结构敏感性区域外,在径向位置 $r=1.1\sim 1.2$ 的壁面附近区域同样存在高敏感性区域,对应了径向回流区域. 对比全局模态与伴随模态可知,扰动的诱发与放大, 不仅与当地扰动的幅值或强度有关,而且与该位置流动对扰动的感受性相关. 综上所述,在考虑黏性作用时,宽无叶扩 压器的全局不稳定扰动在核心主流与壁面径向回流共同作用下诱发.图14

新窗口打开|下载原图ZIP|生成PPT

新窗口打开|下载原图ZIP|生成PPT图14无叶扩压器流动特征值的结构敏感性云图

Fig.14The structural sensitivity of the vaneless diffuser flow

5 结论与总结

本文针对宽无叶扩压器中不稳定扰动的诱发源发区域为研究重点,基于不同的黏性处理方法,分别建立了无黏条件和考虑黏性条件下的扩压器稳定性分析方法,结合数值模拟获得的平均流动,成功预测了宽无叶扩压器的失稳特性. 结合无叶扩压器的全局模态与伴随模态,获得了特征值的结构敏感性,从而揭示了不同黏性条件下不稳定扰动的源发区域,为宽无叶扩压器稳定性机理研究提供了新思路. 本文的主要结论包括:(1)本文在考虑涡黏性条件下建立的混合稳定性分析方法,相比无黏稳定性分析方法,可以更为为准确的预测得到宽无叶扩压器失稳扰动的旋转速度,而采用两种方法预测所得的失速团个数一致.

(2)在无黏条件下,径向半径比 1.8,宽度比 0.14 的宽扩压器失稳来源于径向位置 $r=1.3\sim 1.5$ 的流动区域,为一种二维离心失稳;在考虑黏性作用时,宽无叶扩压器的全局不稳定扰动在核心主流与径向位置 $r=1.1 \sim 1.2$ 处壁面径向回流的共同作用下诱发.

(3)不稳定扰动的诱发与放大,不仅与当地扰动的强弱有关,而且与该空间位置流动对扰动的感受性相关.

参考文献 原文顺序

文献年度倒序

文中引用次数倒序

被引期刊影响因子

[本文引用: 1]

[本文引用: 1]

[博士论文].

[本文引用: 1]

[本文引用: 1]

DOIURLPMID [本文引用: 1]

To reveal the effect of high-temperature creep on the blade-tip radial running clearance of aeroengine high-pressure turbines, a distributed collaborative generalized regression extremum neural network is proposed by absorbing the heuristic thoughts of distributed collaborative response surface method and the generalized extremum neural network, in order to improve the reliability analysis of blade-tip clearance with creep behavior in terms of modeling precision and simulation efficiency. In this method, the generalized extremum neural network was used to handle the transients by simplifying the response process as one extremum and to address the strong nonlinearity by means of its nonlinear mapping ability. The distributed collaborative response surface method was applied to handle multi-object multi-discipline analysis, by decomposing one "big" model with hyperparameters and high nonlinearity into a series of "small" sub-models with few parameters and low nonlinearity. Based on the developed method, the blade-tip clearance reliability analysis of an aeroengine high-pressure turbine was performed subject to the creep behaviors of structural materials, by considering the randomness of influencing parameters such as gas temperature, rotational speed, material parameters, convective heat transfer coefficient, and so forth. It was found that the reliability degree of the clearance is 0.9909 when the allowable value is 2.2 mm, and the creep deformation of the clearance presents a normal distribution with a mean of 1.9829 mm and a standard deviation of 0.07539 mm. Based on a comparison of the methods, it is demonstrated that the proposed method requires a computing time of 1.201 s and has a computational accuracy of 99.929% over 104 simulations, which are improvements of 70.5% and 1.23%, respectively, relative to the distributed collaborative response surface method. Meanwhile, the high efficiency and high precision of the presented approach become more obvious with the increasing simulations. The efforts of this study provide a promising approach to improve the dynamic reliability analysis of complex structures.

DOIURLPMID

To reveal the effect of high-temperature creep on the blade-tip radial running clearance of aeroengine high-pressure turbines, a distributed collaborative generalized regression extremum neural network is proposed by absorbing the heuristic thoughts of distributed collaborative response surface method and the generalized extremum neural network, in order to improve the reliability analysis of blade-tip clearance with creep behavior in terms of modeling precision and simulation efficiency. In this method, the generalized extremum neural network was used to handle the transients by simplifying the response process as one extremum and to address the strong nonlinearity by means of its nonlinear mapping ability. The distributed collaborative response surface method was applied to handle multi-object multi-discipline analysis, by decomposing one "big" model with hyperparameters and high nonlinearity into a series of "small" sub-models with few parameters and low nonlinearity. Based on the developed method, the blade-tip clearance reliability analysis of an aeroengine high-pressure turbine was performed subject to the creep behaviors of structural materials, by considering the randomness of influencing parameters such as gas temperature, rotational speed, material parameters, convective heat transfer coefficient, and so forth. It was found that the reliability degree of the clearance is 0.9909 when the allowable value is 2.2 mm, and the creep deformation of the clearance presents a normal distribution with a mean of 1.9829 mm and a standard deviation of 0.07539 mm. Based on a comparison of the methods, it is demonstrated that the proposed method requires a computing time of 1.201 s and has a computational accuracy of 99.929% over 104 simulations, which are improvements of 70.5% and 1.23%, respectively, relative to the distributed collaborative response surface method. Meanwhile, the high efficiency and high precision of the presented approach become more obvious with the increasing simulations. The efforts of this study provide a promising approach to improve the dynamic reliability analysis of complex structures.

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

[本文引用: 1]

DOIURL [本文引用: 2]

URL [本文引用: 2]

A three-dimensional compressible flow model was presented to study the occurrence of rotating waves in vaneless diffusers of centrifugal compressors. Solutions to the discrete 3D Euler equations for compressible flow were obtained via singular value decomposition (SVD) method. Critical inlet mass flow rate of vaneless diffuser stall and relative rotating speed of stall cell were calculated. The effects of inlet Mach number were studied and the results show that both critical inlet mass flow rate and rotating wave speed vary with inlet Mach number especially when the diffuser is long. In addition, critical inlet mass flow rate and rotating wave speed are also influenced by diffuser outlet/inlet radius ratio, departure from axial uniform distribution of the undisturbed radial velocity at the diffuser inlet, and impeller back swept angle. Finally, a comparison with experimental results in open literature was made, and the results of 3D model show better agreement than those of 2D model.

DOIURL [本文引用: 2]

[本文引用: 1]

[Master Thesis].

[本文引用: 1]

DOIURL [本文引用: 1]

DOIURL [本文引用: 2]

[本文引用: 4]

DOIURLPMID [本文引用: 2]

To reveal the effect of high-temperature creep on the blade-tip radial running clearance of aeroengine high-pressure turbines, a distributed collaborative generalized regression extremum neural network is proposed by absorbing the heuristic thoughts of distributed collaborative response surface method and the generalized extremum neural network, in order to improve the reliability analysis of blade-tip clearance with creep behavior in terms of modeling precision and simulation efficiency. In this method, the generalized extremum neural network was used to handle the transients by simplifying the response process as one extremum and to address the strong nonlinearity by means of its nonlinear mapping ability. The distributed collaborative response surface method was applied to handle multi-object multi-discipline analysis, by decomposing one "big" model with hyperparameters and high nonlinearity into a series of "small" sub-models with few parameters and low nonlinearity. Based on the developed method, the blade-tip clearance reliability analysis of an aeroengine high-pressure turbine was performed subject to the creep behaviors of structural materials, by considering the randomness of influencing parameters such as gas temperature, rotational speed, material parameters, convective heat transfer coefficient, and so forth. It was found that the reliability degree of the clearance is 0.9909 when the allowable value is 2.2 mm, and the creep deformation of the clearance presents a normal distribution with a mean of 1.9829 mm and a standard deviation of 0.07539 mm. Based on a comparison of the methods, it is demonstrated that the proposed method requires a computing time of 1.201 s and has a computational accuracy of 99.929% over 104 simulations, which are improvements of 70.5% and 1.23%, respectively, relative to the distributed collaborative response surface method. Meanwhile, the high efficiency and high precision of the presented approach become more obvious with the increasing simulations. The efforts of this study provide a promising approach to improve the dynamic reliability analysis of complex structures.

[本文引用: 4]

DOIURL [本文引用: 3]

[本文引用: 1]

URL [本文引用: 1]

提出了一种离心压缩机系统内无叶扩压器失速的三维理论模型.该模型采用线性化的三维欧拉方程分析扩压器内的流体不可压缩流动,采用有限差分法和奇异值分裂(SVD)法进行求解,以预测无叶扩压器失速的临界来流角和失速团相对转速.结果表明,在三维情况下,无叶扩压器失速的临界来流角和失速团相对转速除了受到扩压器几何尺寸的影响以外,还受到扩压器入口流体平均径向速度的轴向分布的影响.与二维模型相比,三维模型所得到的预测结果与实验结果更相符.

URL [本文引用: 1]

提出了一种离心压缩机系统内无叶扩压器失速的三维理论模型.该模型采用线性化的三维欧拉方程分析扩压器内的流体不可压缩流动,采用有限差分法和奇异值分裂(SVD)法进行求解,以预测无叶扩压器失速的临界来流角和失速团相对转速.结果表明,在三维情况下,无叶扩压器失速的临界来流角和失速团相对转速除了受到扩压器几何尺寸的影响以外,还受到扩压器入口流体平均径向速度的轴向分布的影响.与二维模型相比,三维模型所得到的预测结果与实验结果更相符.

URL [本文引用: 1]

URL [本文引用: 1]

DOIURL [本文引用: 1]

[本文引用: 1]

DOIURLPMID [本文引用: 1]

We study a dynamical system consisting of two mutually coupled molecular lasers, each of which shows mixed-mode oscillations and chaos when uncoupled. The type of coupling, incoherent laser interaction via saturable absorbers is an example of inhibitory nonlinear coupling, which is also found in Hodgkin-Huxley models that describe action potentials in neurons. We have carried out extensive numerical bifurcation analysis and numerical simulations to show that for small-enough coupling, well below the chaotic synchronization threshold, the presence of distinctive resonances in a symmetric mirror configuration of the system generates a type of rare events characterized by very small amplitudes. When this symmetry is broken by introducing a relatively small difference between the lasers pump parameters near an in-phase Hopf bifurcation, we observe extreme rare events (rogue waves) in one of the lasers. In this case the outliers deviate from power-law distributions and are reminiscent of those known as dragon kings. We consider the conditions for both types of rare events to occur, their origin, as well as relevant statistical features.

DOIURL [本文引用: 2]

DOIURL [本文引用: 1]

DOIURL [本文引用: 1]

DOIURL

DOIURL [本文引用: 1]

DOIURLPMID [本文引用: 1]

We study a dynamical system consisting of two mutually coupled molecular lasers, each of which shows mixed-mode oscillations and chaos when uncoupled. The type of coupling, incoherent laser interaction via saturable absorbers is an example of inhibitory nonlinear coupling, which is also found in Hodgkin-Huxley models that describe action potentials in neurons. We have carried out extensive numerical bifurcation analysis and numerical simulations to show that for small-enough coupling, well below the chaotic synchronization threshold, the presence of distinctive resonances in a symmetric mirror configuration of the system generates a type of rare events characterized by very small amplitudes. When this symmetry is broken by introducing a relatively small difference between the lasers pump parameters near an in-phase Hopf bifurcation, we observe extreme rare events (rogue waves) in one of the lasers. In this case the outliers deviate from power-law distributions and are reminiscent of those known as dragon kings. We consider the conditions for both types of rare events to occur, their origin, as well as relevant statistical features.

URLPMID [本文引用: 1]

DOIURL [本文引用: 1]