摘要/Abstract

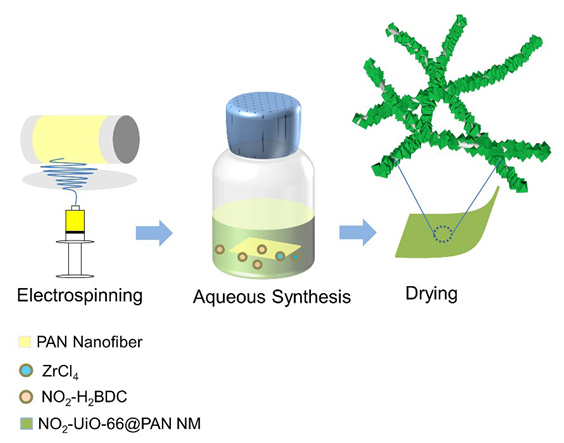

柔性高吸附性材料在废水废气处理、防护服制造、有毒有害物质监测等诸多领域中发挥着关键的作用. 本工作采用水相合成的方法, 以三氟乙酸(trifluoroacetic acid, TFA)为结构导向剂, 以水为溶剂, 在静电纺纳米纤维上原位生长了金属有机框架材料NO2-UiO-66, 制备了NO2-UiO-66@PAN(聚丙烯腈)柔性纳米纤维膜材料. 并研究了不同配比的三氟乙酸/去离子水、不同的金属盐与有机配体比例以及水热生长时间对NO2-UiO-66形貌和负载效果的影响. 最佳TFA添加含量为φTFA=30%, 金属盐与配体物质的量比为1∶1.5, 水热生长时间为4 h. 采用扫描电子显微镜(scanning electron microscope, SEM)、X射线衍射(X-ray diffraction, XRD)、傅里叶红外光谱(Fourier transform infrared spectroscopy, FT-IR)、热重(thermogravimetry, TG)分析及氮气吸附-脱附测试对NO2-UiO-66@PAN纳米纤维膜结构进行了表征. 结果表明, NO2-UiO-66均匀地负载在了纳米纤维上, 负载量可达33.28%, 比表面积为504.16 m2/g、孔体积为0.241 cm3/g. 并且在经过高温(320 ℃)、弯折和水、酸、碱洗涤后仍能保持结构的稳定性. 通过以上表征分析, 发现将NO2-UiO-66负载在纳米纤维上能够得到物理和化学稳定性质优异的膜材料, 在有毒有害等恶劣条件下有很大的应用潜力.

关键词: 静电纺丝, 纳米纤维, 金属有机框架, NO2-UiO-66, 水相合成

Flexible high adsorption materials play a key role in many fields such as wastewater and exhaust gas treatment, protective clothing manufacturing, toxic and harmful substance monitoring. In situ growth of NO2-UiO-66 on electrostatic spun nanofiber was obtained by aqueous synthesis using trifluoroacetic acid as regulator, and water as solvent. The effects of different ratio of trifluoroacetic acid (TFA)/deionized water, different metal salt and ligand proportions and hydrothermal growth time on NO2-UiO-66 morphology and load effects were studied. The add content of TFA was φTFA=30%, the molar ratio of metal salt and the ligand was 1∶1.5, and the hydrothermal growth time was maintained at 4 h, which proved to be the optimal synthetic conditions. The specific synthesis procedure of the NO2-UiO-66@polyacrylonitrile composite nanofiber membrane (NO2-UiO-66@PAN NM) was as follows: First, 10% (w) of PAN spinning liquid was woven into nanofiber membrane using the electrospinning method. Second, a solvent having a TFA content of 30% was prepared in a sealed glass bottle, followed by addition of metal salt (ZrCl4) and organic ligand (2-nitroterephthalic acid, NO2-H2BDC). Finally, the PAN nanofiber was immersed in the precursor mixture, and after 30 min of ultrasonic treatment, it was placed in an oven at 100 ℃ for 4 h to obtain the NO2-UiO-66@PAN NM. The structure of NO2-UiO-66@PAN NM was characterized by scanning electron microscope (SEM), X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FT-IR), thermogravimetry (TG) and nitrogen adsorption-desorption test. The characterization results showed that the NO2-UiO-66 were uniformly loaded on nanofibers. The load could reach 33.28%, the Brunner-Emmet-Teller measurements (BET) surface area was 504.16 m2/g, and the pore volume was 0.241 cm3/g. Further, the NO2-UiO-66@PAN nanofiber membrane still remained in the stability of the structure after being treated with high temperature (320 ℃), bending and washing with water, acid and alkali. Through the above characterization analysis, it was found that the NO2-UiO-66 loaded on the nanofibers, which enabled the membrane material excellent in physical and chemical stable properties, and has a large application potential under harsh conditions such as toxic and harmful.

Key words: electrospinning, nanofiber, metal-organic framework, NO2-UiO-66, aqueous synthesis

PDF全文下载地址:

点我下载PDF