, 苏帆2,3, 孙境求2,3, 田家宇1, 胡承志2,3

, 苏帆2,3, 孙境求2,3, 田家宇1, 胡承志2,3

1. 河北工业大学土木与交通学院, 天津 300401;

2. 中国科学院生态环境研究中心, 环境水质学国家重点实验室, 北京 100085;

3. 中国科学院大学, 北京 100049

收稿日期: 2020-07-13; 修回日期: 2020-08-15; 录用日期: 2020-08-15

基金项目: 国家自然科学基金资助项目(No.51978646);中国科学院前沿科学重点研究项目(No.QYZDY-SSW-DQC004)

作者简介: 于伯洋(1995-), 男, E-mail:ybyand@163.com

通讯作者(责任作者): 胡承志, E-mail:czhu@rcees.ac.cn

摘要:电控膜生物反应器(Electrical membrane bioreactor,eMBR)在膜生物反应器中引入电极反应、电场效应,将膜分离技术、微生物降解以及电化学水处理技术有机结合,提升出水水质、减缓膜污染、强化产生物气,对构建"碳中和"型污水处理技术模式具有重要科学意义和应用价值.近年来,膜材料科学和反应器设计不断发展,推动eMBR技术进步,在强化污染物去除、电化学控制膜污染和微生物电化学响应原理方面取得重要进展;对eMBR的研究出现新态势:注重导电膜/膜电极材料研制与应用、回收污水中资源与能源、短流程-无药剂的反应器构造和工艺设计.本文总结回顾了国内外相关研究,分析了eMBR的基本特征和优势功能,重点关注膜污染电控原理以及微生物的电场响应机制,并展望了eMBR的发展趋势,以期推动电驱动膜分离技术的研究与应用.

关键词:膜生物反应器膜污染电化学膜电极超滤

Review and prospect of electrical membrane bioreactor technology

YU Boyang1,2

, SU Fan2,3, SUN Jingqiu2,3, TIAN Jiayu1, HU Chengzhi2,3

, SU Fan2,3, SUN Jingqiu2,3, TIAN Jiayu1, HU Chengzhi2,3

1. School of Civil and Transportation, Hebei University of Technology, Tianjin 300401;

2. Key Laboratory of Drinking Water Science and Technology, Research Center for Eco-Environmental Sciences, Chinese Academy of Sciences, Beijing 100085;

3. University of Chinese Academy of Sciences, Beijing 100049

Received 13 July 2020; received in revised from 15 August 2020; accepted 15 August 2020

Abstract: Electrical membrane bioreactor (eMBR) introduces electrode reaction and electric field into membrane bioreactor,which combines membrane separation technology,microbiol degradation and electrochemical technology,leading to the improvement of effluent water quality,reduction of membrane fouling,and the enhancement of the gas production. It has exhibited important scientific significance and application value for constructing "carbon neutral" sewage treatment technology. In recent years,the continuous improvements in membrane material science and reactor design have facilitated the development of eMBR technology,and made important progress in strengthening the removal of pollutants,electrochemical control of membrane fouling and microbial electrochemical response mechanism. New trends have emerged in the eMBR research that the investigations are now focusing on the development and application of conductive membrane/membrane electrode materials,the recovery of resources and energy in sewage,and the design and construction of short-process-no-dosage reactor. This article reviews the relevant research,analyzes the basic characteristics and advantages of eMBR,focuses on the electrical control mechanism of membrane fouling and the response of microorganisms to electric field. The prospect of eMBR has been discussed as well,for the sake of promoting the development and application of electrically driven membrane separation technology.

Keywords: membrane bioreactormembrane foulingelectrochemistrymembrane electrodeultrafiltration

1 引言(Introduction)污水处理与回用是影响水的社会良性循环与否的重要因素, 无论是市政污水还是工业废水, 都具有高效处理, 循环利用的实际需求.膜生物反应器(MBR)在废水处理领域中占有相当大的份额, 可以在高效处理污水的同时, 减少占地面积, 提升处理负荷(Huang et al., 2015; Krzeminski et al., 2017).1969年, 美国Smith等将活性污泥法与超滤膜分离结合研究城市污水处理工艺, 首次提出MBR概念.进入到21世纪以来, 材料科学的进步与制膜工艺的提高推动了MBR技术发展, 2006年我国首次运行万吨级MBR项目, MBR在我国市政与工业废水处理中得到广泛应用(Xiao et al., 2014).但膜污染造成的通量下降、能耗药耗上升成为限制MBR技术应用的主要因素(Drews, 2010; Wang et al., 2014;Meng et al., 2017).

控制MBR膜污染主要方法有絮凝、氧化、曝气反冲洗、加强水力扰动等方法.这些预处理或膜污染控制方法均可在电化学反应器中同时实现, 因此, 将电化学和膜分离结合形成电控MBR, 可有效减缓膜污染, 提升反应器效率, 具有重要科学意义和应用价值, 已经成为膜分离领域的重要研究方向.电控膜生物反应器(eMBR)可有效发挥电化学定向转移电子、强化生物化学反应的优势, 改善膜分离出水水质、减缓膜污染, 电化学和膜分离过程具有良好的协同效应.2007年, Chen等(2007a; 2007b)首次将直流电场引入MBR, 稳定膜通量、减缓膜污染, 开启和引发了eMBR的研究与应用热潮.

检索显示, 从2005—2019年, 全世界范围内以eMBR为主题的论文发表数量和被引频次均逐年上升(图 1).eMBR技术与MBR技术相比, 可以更有效地去除污染物、减缓膜污染, 甚至可以调控微生物群落结构、调控生物能回收, eMBR在市政和工业废水处理领域具有广阔的应用前景.此外, 电化学和膜分离技术易于设备化和自动化, 节省占地且处理过程不需要外加药剂, 因此可以形成无药剂-短流程水处理工艺, 非常适用于分散型饮用水或污水处理工程.本文综合近年来国内外的研究进展, 归纳了eMBR的结构特点, 分析了电化学控制膜污染的机理、微生物的电响应机制, 并总结了反应器中膜材料的研究趋势, 最后对eMBR的研究和工程应用进行了展望.

图 1(Fig. 1)

|

| 图 1 根据Web of Science检索电控膜生物反应器领域的科学计量研究(2010—2019) Fig. 1Bibliometric study about the field of electric/electro membrane bioreactor(2010—2019) |

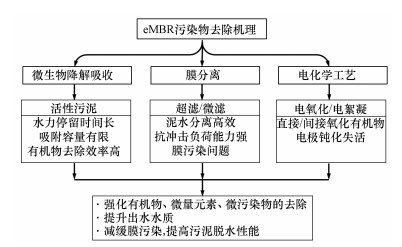

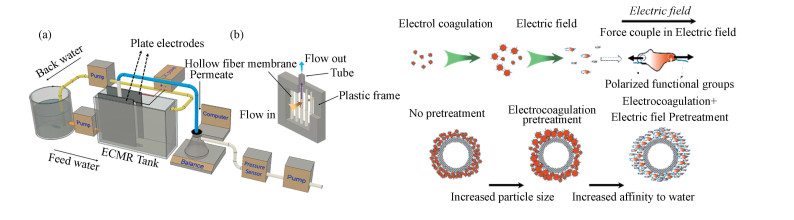

2 电控膜生物反应器的工作原理及结构特征(Working principle and structure feature of eMBR)eMBR是在传统MBR基础上, 引入电极反应、电场效应, 将膜分离、生化和电化学三者优势结合的新型水处理技术(图 2).反应器生化系统降解有机污染物, 膜组件进行高效泥水分离, 电极电场促进污染物降解、减缓膜污染.由于这3部分操作单元自身的多样性, eMBR存在多种类型, 如图 3所示, 根据反应器中生化反应的微生物分类, 可分为好氧eMBR(图 3a)和厌氧eMBR(图 3b), 好氧eMBR在反应器中设置曝气装置为微生物提供溶解氧(Borea et al., 2019; Al-Qodah et al., 2019), 厌氧eMBR要严格封闭, 杜绝空气渗入.用铁或铝做阳极时, 如图 3c所示, 构成电絮凝膜生物反应器(Bani-Melhem et al., 2012; Sun et al., 2018), 牺牲阳极电解氧化释放的铁或铝离子发生絮凝反应, 将小分子/小尺寸污染物转化为大颗粒物(Hakizimana et al., 2016;Sardari et al., 2018).当膜材料本身导电, 将膜与电极一体化, 构成膜电极生物反应器(Zheng et al., 2018), 如图 3d、3e所示, 可以分为膜阴极生物反应器和膜阳极生物反应器.此外, 向反应器内投加颗粒填料, 构成流化床电控膜生物反应器, 如图 3f所示, 导电颗粒填料在承载微生物的同时也促进了电子传递(Chen et al., 2019a).电化学工艺与MBR集成构造短流程-无药剂反应器, 内部配置紧凑, 可有效去除有机物、营养盐和微量污染物, 可大规模应用.

图 2(Fig. 2)

|

| 图 2 电化学与MBR结合的特征和优势 Fig. 2Features and benefits of coupling electrochemical processes with MBR |

图 3(Fig. 3)

|

| 图 3 电控膜生物反应器装置示意图 Fig. 3Schematic diagram of electrical membrane bioreactor |

3 电控膜生物反应器的功能优势(Functional advantage of eMBR)3.1 增强污染物去除外加电压/电流有效增强了MBR对污染物的去除效能.在eMBR中, 负电性有机污染物在电场力驱动下向阳极移动, 阳极表面发生氧化反应将大分子有机物转化为小分子有机物或者直接矿化.阴极表面发生氧化还原反应, 生成活性氧, 有助于去除有机污染物(Modin et al., 2012;Wang et al., 2013).全燮课题组(Yang et al., 2019a; 2019b; 2019d)合成碳纳米管中空纤维导电膜(CNTs-HFMs), 当在好氧膜生物反应器中使用CNTs-HFMs做膜阳极, 同时发生阳极氧化和膜过滤的作用, 与MBR相比, eMBR具有更好的COD和NH4+-N去除效率;而在厌氧膜生物反应器中采用CNTs-HFMs阴极膜, COD去除率可达到95%以上.胡承志课题组研究(Su et al., 2020)证明电絮凝膜生物反应器的COD、NH4+-N、TP去除率分别比传统MBR增加了15.4%、6.7%、39.7%.eMBR也可以强化去除难降解有毒污染物, Chen等(2019a)搭建MBR以石墨板做反应器阳极、复合导电PVDF膜做膜阴极, 施加2 V·cm-1的电场、连续运行42 d, 对磺胺甲恶唑(SMX)去除率由11.3%提升至80.3%, 出水毒性减弱(图 4).Belli等以铝做阳极, 不锈钢做阴极, 在10和15 A·m-2的电流密度条件下, 色度去除率分别为50%和70%, COD去除率均在75%~77%, NH4+去除率也均超过90%(Belli et al., 2019, Battistelli et al., 2018).获得高去除率的同时, Al和Fe的沉淀物保留在反应器内, 随着时间积累对eMBR微生物群落产生毒性(Elabbas et al., 2016).因此需要确定合适的操作条件, 有效提升出水水质的同时降低对eMBR中生化过程的影响.

图 4(Fig. 4)

|

| 图 4 电场和电极增强MBR对污染物的去除(Chen et al., 2019a) Fig. 4Electric fields and electrode enhance the removal of pollutants by MBR(Chen et al., 2019a) |

3.2 强化膜污染控制膜污染是MBR应用发展的主要限制因素(Zhang et al., 2019;Chen et al., 2019b).膜污染可分为有机污染、无机污染和生物污染(Du et al., 2020), 造成膜通量下降、跨膜压差(TMP)上升.研究发现施加直流电场可以明显减轻膜污染(Sepehri et al., 2018), Ronen等(2015)采用碳纳米管改性的聚乙烯醇(PVA)膜做阴极, -1.5 V电压下膜表面微生物存活率降低27%.Dudchenko等(2014)采用PVA-CNT-COOH改性导电膜, 建立膜阴极MBR反应器, 发现在-5 V条件下运行100 min时, TMP降低了51.1%, 有效降低海藻酸钠在膜表面的附着沉积.eMBR中膜污染减缓也体现在降低清洗频率、增强清洗效果方面.Ensano等(2019)证实电絮凝使MBR的膜污染降低44%, 化学清洗频率降低了18%, 减少化学物质对膜的损伤、延长膜的寿命.Bani-Melhem等(2011)建立铁阳极eMBR, 电场强度1 V·cm-1, 间歇直流电供电模式下(开关比1:3), 运行5 d后膜渗透性相较于无电场条件提高了16%, 膜经过物理清洗后通量恢复率也优于无电场条件.Hua等(2015)建立PTEE膜过滤-铝阳极eMBR, 在20 A·m-2条件下运行15 d, eMBR膜组件从未达到清洗条件(TMP≥70 kPa), 平均结垢率4.1 kPa·d-1, 比对照MBR平均结垢率(32.0 kPa·d-1)低7.8倍.

3.3 优化反应器产能厌氧反应过程中产生甲烷以及许多中间体, 例如乙醇、挥发性脂肪酸(VFA)和氢气, 这些产物都具有应用价值.通过控制电极氧化还原电位, 可改变厌氧反应途径, 调整产物回收率.2004年, Mustacchi等(2005)首次将电场引入厌氧膜生物反应器, 回收浓缩苯甲酸, 苯甲酸产率提升42%.Jiang等(2018b)建立了电发酵反应器, 用阳离子交换膜将阴阳两极分隔开, 在不同的工作电位下测量了各个产物的生成量, 在中性pH值条件下, 降低电极电位会促进甲烷和氢气的产生.电极电位从0.2 V增加到1.0 V(相对于Ag/AgCl), 甲烷产量增加68%, 乙酸产量增加33%, 丙酸和丁酸的产量变化较小.Liu等(2019b)在厌氧反应器中引入电极, 迅速将VFA的平均浓度从6617 mg·L-1降低至174 mg·L-1, 同时甲烷产量提高13.5%.微生物燃料电池(MFC)和膜生物反应器在结构上有一定的相似性, 集成后可实现废水净化同步产电, MBR增加有机负荷、提升MFC产能效率, 在当前MFC-MBR研究产电功率密度最大可达到6.8 W·m-3 (Malaeb et al., 2013).

4 电化学减缓膜污染机理(Mechanism of electrochemistry reducing membrane fouling)4.1 调控滤饼层结构研究表明, 电化学调控滤饼层形貌结构, 在膜表面形成疏松多孔的滤饼层, 有助于控制膜污染.在eMBR中采用Fe或Al作牺牲阳极, 电絮凝作用调节絮体疏松程度, 形成透水性更强的滤饼层结构, 从而减缓膜污染.胡承志课题组(Sun et al., 2017; Sun et al., 2018; Zhao et al., 2019)构建电控膜分离反应器(图 6a), 探究电絮凝、电氧化以及电场的耦合作用(图 6b), 电场诱导絮凝物发生偶极化作用, 增强滤饼层亲水性、抑制有机污染, 同时减小水渗透阻力、提高水通量.同时, 电絮凝过程耦合电氧化作用, 调节有机污染物官能团结构, 提高有机污染物极性, 形成更加疏松亲水的滤饼层, 更好地实现膜污染控制.此外, 铝电极产生的絮体呈现出更高的极化度, 易聚集, 相较于铁极板具有更好的抑制膜污染的效果.除絮体结构改变以外, 滤饼层物质组成也会受到电场影响发生改变, Liu等(2019a)证明电絮凝降低溶解性微生物代谢产物(SMP)和紧密结合型胞外聚合物(TB-EPS)中的蛋白质和多糖含量, 对过滤比阻(SRF)的测试也显示下降的趋势.

图 5(Fig. 5)

|

| 图 5 eMBR和常规MBR的TMP变化(Yang et al., 2019c) Fig. 5TMP evolution of eMBR and conventional MBR(Yang et al., 2019c) |

图 6(Fig. 6)

|

| 图 6 电场联合电絮凝缓解膜污染机理示意图(Sun et al., 2017) Fig. 6Schematic diagram of electric field coupled electro flocculation to alleviate membrane fouling(Sun et al., 2017) |

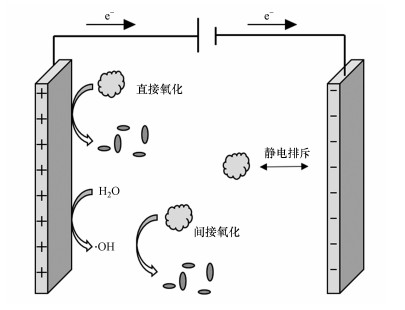

4.2 电氧化降解污染物电氧化是指阳极发生电化学反应直接或间接氧化降解有机污染物的方法.如图 7所示, 在电化学阳极氧化过程中, 直接氧化发生在低电势条件下(低于析氧电势), 通常反应速率较低.工作电位高于析氧电位时发生间接氧化, 在阳极表面形成活性氧簇(例如·OH), 进一步提高有机污染物的降解效果(Mandal et al., 2017; Pa?dzior et al., 2019).Fan等(2016)自制CNT/陶瓷导电膜、搭建反应器, 证实导电膜同时作为阳极时, 吸附在膜表面的细菌细胞内的胞内辅酶A被不可逆的直接氧化(Rahaman et al., 2012), 细胞膜降解、细菌失活, 从而抑制膜的生物污染, 膜通量上升2.9倍.当阳极电位超过1.6 V时, 会产生活性氯, Elimelech课题组(Wang et al., 2020)制备导电复合陶瓷膜, 施加3 V生成RCS(主要是HClO和ClO)氧化膜表面有机污染物, 通电1 min几乎实现膜通量的完全恢复.

图 7(Fig. 7)

|

| 图 7 膜电极电氧化和静电排斥污染物机理图 Fig. 7Mechanism diagram of electrooxidation and electrostatic repulsion of pollutants in membrane electrode |

4.3 电排斥污染物膜组件做阴极时会减缓污泥在膜表面附着沉积.通常情况下, 污泥表面呈负电性, 污泥颗粒和阴极相互排斥, 不易在膜表面沉积, 滤饼层形成速度减慢, 从而减缓膜污染(图 7).膜组件为阴极时, 增大电压, 膜组件附近和膜表面的污泥Zeta电位升高, 污泥表面负电荷数量增多, 污泥颗粒之间、污泥和阴极膜之间的静电排斥力增大, 膜表面污泥稳定性也随之降低, 难以形成致密的滤饼层(Ding et al., 2018; Shi et al., 2019).也有研究表明(Yang et al., 2019b), 电场导致EPS中蛋白质含量降低, 导致带正电荷的胺基减少, 多糖、羧基、磷酸基等所带的负电荷难以被中和, 由此污泥显现出更强的负电性, 静电排斥力增强.

5 微生物的电化学响应与应用(Microbial electrochemical response and application)5.1 微生物代谢的路径变化施加直流电加速电子转移, 提高微生物的代谢速率, 影响微生物群落的进化, 进而使微生物适应电场环境、发展特定功能(Liu et al., 2015; Ailijiang et al., 2016;Jiang et al., 2018a).在此过程中, 电场增强了微生物的丰富度和多样性.ElNaker等(2019)研究了不同电流密度对微生物的影响, 在3 A·m-2的电流密度下细菌总数增加, 但是电流密度分别增加到5和7 A·m-2时, 细菌总数分别减少10%和18%;还发现5~7 A·m-2的外加电流有助于微生物群落进化, 电场促进了多种功能菌种群数量增加, 可以更有效地去除废水中的有害污染物.Chen等(2019a)研究证实, 在反应器中施加电场, 放线菌和芽孢杆菌等功能菌丰度增加, 加快了对抗生素的去除.电絮凝过程中产生的铁离子, 同样会促进微生物的生长, Zhang等(2020)证实亚铁离子增加反硝化除磷相关细菌(Saprospiraceae等)以及硝酸盐依赖性厌氧亚铁化相关细菌(Azospira等)的丰度, 由此引起的微生物演替导致氮磷去除性能增强.

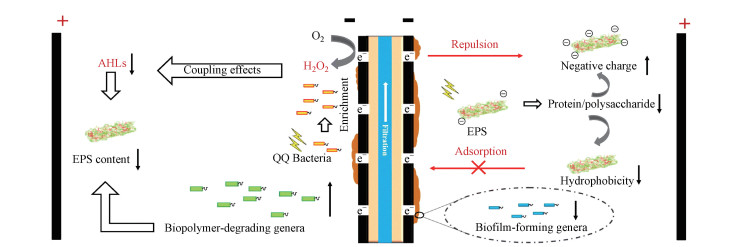

5.2 EPS组成与浓度改变电场不仅影响了微生物的生长增值, 同时也会改变胞外聚合物(EPS)的浓度以及组成成分.EPS主要由蛋白质和多糖组成, 是造成膜污染的主要原因(Lin et al., 2014).Shi等(2019)研究表明, 电压从0升高至0.8 V·cm-1, 细胞代谢加速, EPS含量降低;而电压由0.8 V·cm-1升至1.75 V·cm-1, 三磷酸腺苷(ATP)含量降低, 影响EPS合成, 同样会降低EPS含量.同时, 蛋白质和多糖的含量伴随着EPS含量降低而降低.也有研究(Liu et al., 2019a)认为, EPS的减少可能是由于丝状菌被电场抑制, 而丝状菌的过度生长会导致过多的EPS产生(Meng et al., 2006).

电场还可以通过降解信号分子, 进一步降低EPS.细胞间信号, 例如N-酰基-高丝氨酸内酯(AHLs), 与EPS的产生和生物膜的形成密切相关(Ren et al., 2013).Jiang等(2020a)证明随着电压升高, 阴极产生的H2O2浓度升高, AHLs被降解、含量降低, 微生物难以富集, 从而降低了EPS含量并减缓膜污染, 如图 8所示.EPS和微生物之间关系十分紧密, 电场也会通过增大群体猝灭细菌的丰度, 促进AHLs降解, 进而降低EPS含量(Jiang et al., 2020b).

图 8(Fig. 8)

|

| 图 8 电场通过降解AHLs来降低EPS含量 Fig. 8The electric field reduced the content of EPS by degrading AHLs |

6 结论(Conclusions)随着材料科学与表征技术的不断发展, 电控膜生物反应器技术研究日趋深入, 从膜分离与电极电场的简单结合发展到导电膜组件的研究、从膜污染缓解机理到微生物电响应机制、从关注提升水处理效率到优化能源的回收利用, eMBR技术原理与应用研究取得了长足的进步.eMBR技术发展至今, 显现出污染物高效去除、膜污染强化控制、废水净化同步产能等优势.

7 展望(Future prospect)eMBR技术发展也遇到不少瓶颈:Al/Fe阳极溶解以及污染物在阳极表面沉积会缩短电极寿命(Hasan et al., 2014), 电极材料析出的金属离子可能会阻碍少数细菌的生长(Wang et al., 2011)、导致污泥中重金属积累(Mollah et al., 2004), 反应器运行过程中产生如氯胺等有毒副产物(Bagastyo et al., 2012).此外, 市场上没有廉价高效的导电膜组件, 实验室制备膜组件尚难以大规模应用, 反应器中电场或电极反应强化微生物电子转移、激活微生物活性机理还未能突破.

eMBR相比于MBR增加了电化学过程, 能源需求增加.Hasan等(2014)研究中试规模的eMBR能耗估计为1.1~1.6 kWh·m-3, 大大高于常规MBR能耗(0.4~0.8 kWh·m-3).与传统MBR相比, eMBR能耗增加约10%(Zhang et al., 2015).尽管能耗升高, 但出水水质提升, 同时设备维护简化、膜更换频率和人工成本降低, 目前没有文献对eMBR运行期间成本做详细估算.eMBR要面对实际的工程应用, 需要优化电流密度、SRT、HRT以及曝气流速等运行参数, 延长电极使用寿命, 深入研究新型污染物的去除机制.

综合国内外相关研究与应用的态势, 笔者认为在未来一段时间内电控膜生物反应器主要研究方向有:

① 膜电极组件研制.高电导率高稳定性的导电膜材料是膜电极反应器的核心, 一是研制抗污染、抗腐蚀的导电膜材料, 可长期稳定使用;二是优化膜组件与电极的空间组合, 实现协同效应.

② 反应器结构优化.反应器结构优化可强化水处理、膜污染控制、产能产电效率, 如何充分发挥膜分离、微生物降解以及电化学的组合优势, 设计和优化反应器构型是将来的研究重点之一.

③ 资源能源的回收.强化污水处理效果的同时, 实现资源能源回收是电控厌氧膜生物反应器的研究重点之一, 控制电极反应和电极电位, 定向回收污水中的C、N、P, 充分发挥电控膜生物反应器优势.

参考文献

| Ailijiang N, Chang J, Liang P, et al. 2016. Electrical stimulation on biodegradation of phenol and responses of microbial communities in conductive carriers supported biofilms of the bioelectrochemical reactor[J]. Bioresour Technology, 201: 1-7. DOI:10.1016/j.biortech.2015.11.026 |

| Al-qodah Z, Al-qudah Y, Omar W. 2019. On the performance of electrocoagulation-assisted biological treatment processes:A review on the state of the art[J]. Environmental Science Pollution Research International, 26: 28689-28713. DOI:10.1007/s11356-019-06053-6 |

| Bagastyo A Y, Batstone D J, Kristiana I, et al. 2012. Electrochemical oxidation of reverse osmosis concentrate on boron-doped diamond anodes at circumneutral and acidic pH[J]. Water Research, 46: 6104-6112. DOI:10.1016/j.watres.2012.08.038 |

| Bani-melhem K, Elektorowicz M. 2011. Performance of the submerged membrane electro-bioreactor (SMEBR) with iron electrodes for wastewater treatment and fouling reduction[J]. Journal of Membrane Science, 379: 434-439. DOI:10.1016/j.memsci.2011.06.017 |

| Bani-melhem K, Smith E. 2012. Grey water treatment by a continuous process of an electrocoagulation unit and a submerged membrane bioreactor system[J]. Chemical Engineering Journal, 198-199: 201-210. DOI:10.1016/j.cej.2012.05.065 |

| Battistelli A A, Belli T J, Costa R E, et al. 2018. Application of low-density electric current to performance improvement of membrane bioreactor treating raw municipal wastewater[J]. International Journal of Environmental Science and Technology, 16: 3949-3960. |

| Belli T J, Battistelli A A, Costa R E, et al. 2019. Evaluating the performance and membrane fouling of an electro-membrane bioreactor treating textile industrial wastewater[J]. International Journal of Environmental Science and Technology, 16: 6817-6826. DOI:10.1007/s13762-019-02245-2 |

| Borea L, Ensano B M B, Hasan S W, et al. 2019. Are pharmaceuticals removal and membrane fouling in electromembrane bioreactor affected by current density?[J]. Science of the Total Environmental, 692: 732-740. DOI:10.1016/j.scitotenv.2019.07.149 |

| Chen J P, Yang C Z, Zhou J H, et al. 2007a. Study of the influence of the electric field on membrane flux of a new type of membrane bioreactor[J]. Chemical Engineering Journal, 128: 177-180. DOI:10.1016/j.cej.2006.10.010 |

| Chen J P, Yang C Z, Zhou J H. 2007b. The effect of pulsed direct current field on the membrane flux of a new style of membrane bioreactor[J]. Chemical Engineering & Technology, 30: 1262-1265. |

| Chen M, Xu J, Dai R, et al. 2019a. Development of a moving-bed electrochemical membrane bioreactor to enhance removal of low-concentration antibiotic from wastewater[J]. Bioresource Technology, 293: 122022. DOI:10.1016/j.biortech.2019.122022 |

| Chen Y, Teng J, Shen L, et al. 2019b. Novel insights into membrane fouling caused by gel layer in a membrane bioreactor:Effects of hydrogen bonding[J]. Bioresour Technology, 276: 219-225. DOI:10.1016/j.biortech.2019.01.010 |

| Ding A, Fan Q, Cheng R, et al. 2018. Impacts of applied voltage on microbial electrolysis cell-anaerobic membrane bioreactor (MEC-AnMBR) and its membrane fouling mitigation mechanism[J]. Chemical Engineering Journal, 333: 630-635. DOI:10.1016/j.cej.2017.09.190 |

| Drews A. 2010. Membrane fouling in membrane bioreactors-Characterisation, contradictions, cause and cures[J]. Journal of Membrane Science, 363: 1-28. DOI:10.1016/j.memsci.2010.06.046 |

| Du X, Shi Y, Jegatheesan V, et al. 2020. A Review on the Mechanism, Impacts and Control Methods of Membrane Fouling in MBR System[J]. Membranes (Basel), 10(2): 1-33. |

| Dudchenko A V, Rolf J, Russell K, et al. 2014. Organic fouling inhibition on electrically conducting carbon nanotube-polyvinyl alcohol composite ultrafiltration membranes[J]. Journal of Membrane Science, 468: 1-10. DOI:10.1016/j.memsci.2014.05.041 |

| Elabbas S, Ouazzani N, Mandi L, et al. 2016. Treatment of highly concentrated tannery wastewater using electrocoagulation:Influence of the quality of aluminium used for the electrode[J]. Journal of Hazardous Materials, 319: 69-77. DOI:10.1016/j.jhazmat.2015.12.067 |

| Elnaker N A, Hasan S W, Yousef A F. 2019. Impact of current density on the function and microbial community structure in electro-bioreactors[J]. Journal of Hazardous Materials, 368: 877-884. DOI:10.1016/j.jhazmat.2018.09.016 |

| Ensano B M B, Borea L, Naddeo V, et al. 2019. Control of emerging contaminants by the combination of electrochemical processes and membrane bioreactors[J]. Environmental Science Pollution Research International, 26: 1103-1112. DOI:10.1007/s11356-017-9097-z |

| Fan X, Zhao H, Quan X, et al. 2016. Nanocarbon-based membrane filtration integrated with electric field driving for effective membrane fouling mitigation[J]. Water Research, 88: 285-292. DOI:10.1016/j.watres.2015.10.043 |

| Hakizimana J N, Gourich B, Vial C, et al. 2016. Assessment of hardness, microorganism and organic matter removal from seawater by electrocoagulation as a pretreatment of desalination by reverse osmosis[J]. Desalination, 393: 90-101. DOI:10.1016/j.desal.2015.12.025 |

| Hasan S W, Elektorowicz M, Oleszkiewicz J A. 2014. Start-up period investigation of pilot-scale submerged membrane electro-bioreactor (SMEBR) treating raw municipal wastewater[J]. Chemosphere, 97: 71-77. DOI:10.1016/j.chemosphere.2013.11.009 |

| Hua L C, Huang C P, Su Y C, et al. 2015. Effects of electro-coagulation on fouling mitigation and sludge characteristics in a coagulation-assisted membrane bioreactor[J]. Journal of Membrane Science, 495: 29-36. DOI:10.1016/j.memsci.2015.07.062 |

| Huang L, Lee D J. 2015. Membrane bioreactor:A mini review on recent R&D works[J]. Bioresour Technology, 194: 383-388. DOI:10.1016/j.biortech.2015.07.013 |

| Hasan S W, Elektorowicz M, Oleszkiewicz J A. 2014. Start-up period investigation of pilot-scale submerged membrane electro-bioreactor (SMEBR) treating raw municipal wastewater[J]. Chemosphere, 97: 71-77. DOI:10.1016/j.chemosphere.2013.11.009 |

| Jiang B, Zeng Q, Hou Y, et al. 2020a. Impacts of long-term electric field applied on the membrane fouling mitigation and shifts of microbial communities in EMBR for treating phenol wastewater[J]. Science of the Total Environmental, 716: 137139. DOI:10.1016/j.scitotenv.2020.137139 |

| Jiang B, Zeng Q, Hou Y, et al. 2020b. Quorum quenching bacteria bioaugmented GO/PPy modified membrane in EMBR for membrane antifouling[J]. Science of the Total Environmental, 718: 137412. DOI:10.1016/j.scitotenv.2020.137412 |

| Jiang X, Shen J, Xu K, et al. 2018a. Substantial enhancement of anaerobic pyridine bio-mineralization by electrical stimulation[J]. Water Research, 130: 291-299. DOI:10.1016/j.watres.2017.12.005 |

| Jiang Y, Lu L, Wang H, et al. 2018b. Electrochemical control of redox potential arrests methanogenesis and regulates products in mixed culture electro-fermentation[J]. ACS Sustainable Chemistry & Engineering, 6: 8650-8658. |

| Krzeminski P, Leverette L, MALAMIS S, et al. 2017. Membrane bioreactors:A review on recent developments in energy reduction, fouling control, novel configurations, LCA and market prospects[J]. Journal of Membrane Science, 527: 207-227. DOI:10.1016/j.memsci.2016.12.010 |

| Lin H, Zhang M, Wang F, et al. 2014. A critical review of extracellular polymeric substances (EPSs) in membrane bioreactors:Characteristics, roles in membrane fouling and control strategies[J]. Journal of Membrane Science, 460: 110-125. DOI:10.1016/j.memsci.2014.02.034 |

| Liu J, Ju X, Gao B, et al. 2019a. Effect of electrocoagulation on MBR under different power supply conditions[J]. Biochemical Engineering Journal, 152: 107371. DOI:10.1016/j.bej.2019.107371 |

| Liu S, Deng Z, Li H, et al. 2019b. Contribution of electrodes and electric current to process stability and methane production during the electro-fermentation of food waste[J]. Bioresour Technol, 288: 121536. DOI:10.1016/j.biortech.2019.121536 |

| Liu S, Song H, Wei S, et al. 2015. Effect of direct electrical stimulation on decolorization and degradation of azo dye reactive brilliant red X-3B in biofilm-electrode reactors[J]. Biochemical Engineering Journal, 93: 294-302. DOI:10.1016/j.bej.2014.11.002 |

| Malaeb L, Katuri K P, Logan B E, et al. 2013. A hybrid microbial fuel cell membrane bioreactor with a conductive ultrafiltration membrane biocathode for wastewater treatment[J]. Environmental Science Technology, 47: 11821-11828. DOI:10.1021/es4030113 |

| Mandal P, Dubey B K, Gupta A K. 2017. Review on landfill leachate treatment by electrochemical oxidation:Drawbacks, challenges and future scope[J]. Waste Management, 69: 250-273. DOI:10.1016/j.wasman.2017.08.034 |

| Meng F, Zhang H, Yang F, et al. 2006. Effect of filamentous bacteria on membrane fouling in submerged membrane bioreactor[J]. Journal of Membrane Science, 272: 161-168. DOI:10.1016/j.memsci.2005.07.041 |

| Meng F, Zhang S, Oh Y, et al. 2017. Fouling in membrane bioreactors:An updated review[J]. Water Research, 114: 151-180. DOI:10.1016/j.watres.2017.02.006 |

| Modin O, Fukushi K. 2012. Development and testing of bioelectrochemical reactors converting wastewater organics into hydrogen peroxide[J]. Water Science and Technology, 66: 831-836. DOI:10.2166/wst.2012.255 |

| Mollah M Y, Morkovsky P, Gomes J A, et al. 2004. Fundamentals, present and future perspectives of electrocoagulation[J]. Journal of Hazardous Materials, 114: 199-210. DOI:10.1016/j.jhazmat.2004.08.009 |

| Mustacchi R, Knowles C J, Li H, et al. 2005. Enhanced biotransformations and product recovery in a membrane bioreactor through application of a direct electric current[J]. Biotechnol Bioeng, 89: 18-23. DOI:10.1002/bit.20299 |

| Pa?dzior K, Bilińska L, Ledakowicz S. 2019. A review of the existing and emerging technologies in the combination of AOPs and biological processes in industrial textile wastewater treatment[J]. Chemical Engineering Journal, 376: 120597. DOI:10.1016/j.cej.2018.12.057 |

| Rahaman M S, Vecitis C D, Elimelech M. 2012. Electrochemical carbon-nanotube filter performance toward virus removal and inactivation in the presence of natural organic matter[J]. Environmental Science Technology, 46: 1556-1564. DOI:10.1021/es203607d |

| Ren T T, Li X Y, Yu H Q. 2013. Effect of N-acy-l-homoserine lactones-like molecules from aerobic granules on biofilm formation by Escherichia coli K12[J]. Bioresour Technology, 129: 655-658. DOI:10.1016/j.biortech.2012.12.043 |

| Ronen A, Duan W, Wheeldon I, et al. 2015. Microbial attachment inhibition through low-voltage electrochemical reactions on electrically conducting membranes[J]. Environmental Science Technology, 49: 12741-12750. DOI:10.1021/acs.est.5b01281 |

| Sardari K, Fyfe P, Lincicome D, et al. 2018. Aluminum electrocoagulation followed by forward osmosis for treating hydraulic fracturing produced waters[J]. Desalination, 428: 172-181. DOI:10.1016/j.desal.2017.11.030 |

| Sepehri A, Sarrafzadeh M H. 2018. Effect of nitrifiers community on fouling mitigation and nitrification efficiency in a membrane bioreactor[J]. Chemical Engineering and Processing-Process Intensification, 128: 10-18. DOI:10.1016/j.cep.2018.04.006 |

| Shi S, Xu J, Zeng Q, et al. 2019. Impacts of applied voltage on EMBR treating phenol wastewater:Performance and membrane antifouling mechanism[J]. Bioresour Technology, 282: 56-62. DOI:10.1016/j.biortech.2019.02.113 |

| Su F, Liang Y, Liu G, et al. 2020. Enhancement of anti-fouling and contaminant removal in an electro-membrane bioreactor:Significance of electrocoagulation and electric field[J]. Separation and Purification Technology, 248: 117077. DOI:10.1016/j.seppur.2020.117077 |

| Sun J, Hu C, Tong T, et al. 2017. Performance and mechanisms of ultrafiltration membrane fouling mitigation by coupling coagulation and applied electric field in a novel electrocoagulation membrane reactor[J]. Environ Sci Technol, 51: 8544-8551. DOI:10.1021/acs.est.7b01189 |

| Sun J, Hu C, Zhao K, et al. 2018. Enhanced membrane fouling mitigation by modulating cake layer porosity and hydrophilicity in an electro-coagulation/oxidation membrane reactor (ECOMR)[J]. Journal of Membrane Science, 550: 72-79. DOI:10.1016/j.memsci.2017.12.073 |

| Wang X, Sun M, Zhao Y, et al. 2020. In Situ Electrochemical Generation of Reactive Chlorine Species for Efficient Ultrafiltration Membrane Self-Cleaning[J]. Environmental Science Technology, 54: 6997-7007. |

| Wang Y K, Li W W, Sheng G P, et al. 2013. In-situ utilization of generated electricity in an electrochemical membrane bioreactor to mitigate membrane fouling[J]. Water Research, 47: 5794-5800. DOI:10.1016/j.watres.2013.06.058 |

| Wang Y K, Sheng G P, Li W W, et al. 2011. Development of a novel bioelectrochemical membrane reactor for wastewater treatment[J]. Environmental Science Technology, 45: 9256-9261. DOI:10.1021/es2019803 |

| Wang Z, Ma J, Tang C Y, et al. 2014. Membrane cleaning in membrane bioreactors:A review[J]. Journal of Membrane Science, 468: 276-307. DOI:10.1016/j.memsci.2014.05.060 |

| Xiao K, Xu Y, Liang S, et al. 2014. Engineering application of membrane bioreactor for wastewater treatment in China:Current state and future prospect[J]. Frontiers of Environmental Science & Engineering, 8: 805-819. |

| Yang Y, Qiao S, Jin R, et al. 2019a. A novel aerobic electrochemical membrane bioreactor with CNTs hollow fiber membrane by electrochemical oxidation to improve water quality and mitigate membrane fouling[J]. Water Research, 151: 54-63. DOI:10.1016/j.watres.2018.12.012 |

| Yang Y, Qiao S, Jin R, et al. 2019b. Novel anaerobic electrochemical membrane bioreactor with a CNTs hollow fiber membrane cathode to mitigate membrane fouling and enhance energy recovery[J]. Environmental Science Technology, 53: 1014-1021. DOI:10.1021/acs.est.8b05186 |

| Yang Y, Qiao S, Jin R F, et al. 2019c. A novel aerobic electrochemical membrane bioreactor with CNTs hollow fiber membrane by electrochemical oxidation to improve water quality and mitigate membrane fouling[J]. Water Research, 151: 54-63. DOI:10.1016/j.watres.2018.12.012 |

| Yang Y, Qiao S, Zheng M, et al. 2019d. Enhanced permeability, contaminants removal and antifouling ability of CNTs-based hollow fiber membranes under electrochemical assistance[J]. Journal of Membrane Science, 582: 335-341. DOI:10.1016/j.memsci.2019.04.026 |

| Zhang C, Xu X, Yuan L, et al. 2020. Performance enhancement by adding ferrous to a combined modified University of Cape Town and post-anoxic/aerobic-membrane bioreactor[J]. Chemosphere, 243: 125300. DOI:10.1016/j.chemosphere.2019.125300 |

| Zhang J, Satti A, Chen X, et al. 2015. Low-voltage electric field applied into MBR for fouling suppression:Performance and mechanisms[J]. Chemical Engineering Journal, 273: 223-230. DOI:10.1016/j.cej.2015.03.044 |

| Zhang W, Jiang F. 2019. Membrane fouling in aerobic granular sludge (AGS)-membrane bioreactor (MBR):Effect of AGS size[J]. Water Research, 157: 445-453. DOI:10.1016/j.watres.2018.07.069 |

| Zhao K, Sun J, Hu C, et al. 2019. Membrane fouling reduction through electrochemically regulating flocs aggregation in an electro-coagulation membrane reactor[J]. Journal of Environmental Science, 83: 144-151. DOI:10.1016/j.jes.2019.04.001 |

| Zheng J, Wang Z, Ma J, et al. 2018. Development of an electrochemical ceramic membrane filtration system for efficient contaminant removal from waters[J]. Environmental Science Technology, 52: 4117-4126. DOI:10.1021/acs.est.7b06407 |