全文HTML

--> --> --> 重金属污染问题是当今世界面临的主要环境问题之一。近年来,随着我国工业化的逐步发展,矿山开采、电镀工业和金属加工等行业每年产生大量酸性废水,每升废水中铜浓度高达几十至几百毫克,如不加处理排放到水体会造成严重的污染问题。水体中的Cu2+被普遍认为是铜对水生生物致毒的主要离子形式[1],水生生物受水体中Cu2+污染毒害并在体内富集,通过生物放大过程进入食物链,最终威胁到人体健康。为控制天然水体不被铜离子污染,污水综合排放标准(GB 8978-1996)规定,工业废水中铜及其化合物最高容许排放浓度为1 mg·L?1(按铜计),因此,采取合理有效的方式处理重金属废水是当务之急。目前,常见的重金属废水处理方法包括化学沉淀法、膜分离、电渗析、离子交换、吸附法等,其中吸附法以其操作简单、效率高、成本低和无二次污染等优点已被广泛采用[2]。生物炭由于孔隙结构发达、比表面积大及表面官能团丰富等特点,对水体中污染物有较好的去除效果[3],且其原料成本低、来源广,被认为是一种新型环保吸附剂。以秸秆及畜禽粪便等农牧业废弃物为原料制备生物炭,不仅将废弃物资源化利用,而且所制备的生物炭能有效地修复污染水体,是一种“双赢”处理模式。生物炭对水体中重金属的去除效果与其比表面积、孔径分布、表面官能团及分子组成等性质有关,采用不同生物炭制备工艺的热解过程参数不同,得到生物炭的性质也存在较大差异[4]。应用在水处理中的生物炭大多采用慢速热解这一制备方法,产生的生物炭比表面积较大,孔隙发育较好,有利于对污染物的吸附。然而,慢速热解等主流热解工艺主要依靠电力加热提供生物质热解所需能量,热解过程存在高能耗和高污染等问题,增加了生物炭生产成本,不利于生物炭吸附材料的工业化应用[5]。太阳能热解技术以生物质材料为反应物,利用太阳能提供高温热解反应过程所需能量[6]。与传统热解技术相比,其可减少能源消耗,间接降低了温室气体排放,是一种节能环保的新技术。目前,利用太阳能热解制备生物炭的研究集中于太阳能直接辐射生物质原料,在快速热解条件下产生更多生物油及合成气,研究产物在生物燃料方面的应用[7]。生物炭作为太阳能热解生物质的一种副产物,因其具有产量低和性能差的缺点,故较少在水污染领域的研究应用。

本研究使用新型太阳能装置,以真空集热管为反应器,采用槽式聚光器聚焦太阳辐射,利用太阳能为热源将玉米秸秆和牛粪2种原料热解制备成生物炭,对其进行分析表征和吸附Cu2+静态实验,对比其与传统热解方式制备的生物炭在理化性质和吸附性能上的差异,从而验证太阳能热解制备生物炭在水处理领域的可行性,探究了玉米秸秆及牛粪生物炭对水中Cu2+的吸附特性和机制,以期为生物炭在重金属废水处理中的应用提供参考。

1.1. 实验材料

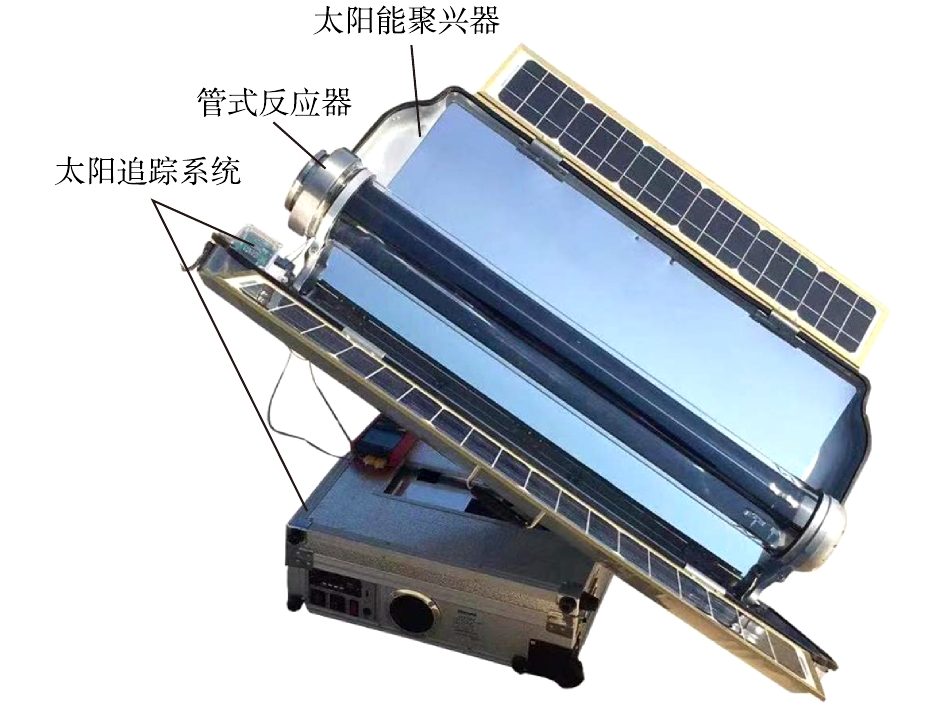

如图1所示,太阳能热解装置(HGC-0.8/6.5Kz,皇明)主要包括太阳能聚光器、管式反应器和太阳追踪系统3个部分。聚光器为槽式聚光器,其将太阳辐射线状聚焦,是加热管状反应器的理想选择;管式反应器为真空吸热管,吸热管内层为铜管,外层为透明石英玻璃管,2层之间为真空结构,铜管外侧涂有太阳能吸收涂层,能吸收太阳辐射并转化为热量使反应器升温;太阳追踪系统包括光敏电阻及动力装置,通过光敏电阻,调动动力装置在水平和竖直方位上移动,使聚光器在1 d内垂直接收太阳辐射,确保热解反应稳定进行;太阳能功率计(SM206-SOLAR,欣宝科技)用以测量地面实时直接辐射强度,热电偶温度计(UNI-T325,优利德)测量热解过程反应器内的温度。传统热解使用真空管式炉(SLG1200-60,上海升利)制备生物炭材料,选择原料包括玉米秸秆和牛粪2种。玉米秸秆(J)采自山东省菏泽市周边农田,牛粪(N)取自河南周口某养殖场。1.2. 生物炭的制备

将2种原料用蒸馏水冲洗3次后,用电热鼓风干燥箱(DHG-9023A,上海精宏)105 ℃下烘干至恒重,粉碎过35目筛,储存在干燥器中备用。太阳能热解生物质步骤如下:在晴朗天气,选择可接收太阳照射的开阔地带放置太阳能热解设备;用坩埚盛放2种生物质原料,并将其放于热解反应器中,打开聚光器接收太阳辐射;反应器接收辐射热量开始升温,热解过程持续2 h后,关闭聚光器;待反应器内温度降至室温后,将生物炭取出,记录实验过程中太阳辐射强度和装置温度变化,其中玉米秸秆生物炭标记为TJ,牛粪生物炭为TN。传统方式制备的生物炭采用慢速热解法[8],利用真空管式炉,按照太阳能热解过程中温度变化条件设定最高温度为430 ℃、升温速率为8 ℃·min?1。热解制备出的玉米秸秆及牛粪生物炭分别标记为CJ和CN,将制备出的所有生物炭储存在干燥器中备用。1.3. 生物炭的表征

采用热重分析仪(TG209F3,Tarsus)对原料进行热重分析,在升温速率10 ℃·min?1、氮气流速300 mL·min?1、温度为30~1 000 ℃条件下,观察热重曲线,并利用差热分析法得出DTG曲线。利用场发射扫描电子显微镜(SU8200,HITACHI)放大1 000倍,在比例尺为50 μm下观察生物炭表面形貌结构,额定扫描电压为8.0 kV。生物炭的比表面积、孔体积及孔径采用BET法(GB/T 19587-2004)测定,使用比表面与孔隙度分析仪(ASAP 2460,Micromeritics)测定孔隙,吸附介质为液氮。使用KBr压片法在傅里叶变换红外光谱仪(TENSOR27,Bruker)上测试生物炭的透射红外光谱,干燥样品与KBr以质量比1∶200混合,研磨均匀进行压片测试,波数为4 000~400 cm?1,分辨率为2 cm?1,扫描16次。1.4. 静态吸附实验

生物炭对铜离子的吸附实验采用批量平衡法。利用Cu(NO3)2·3H2O(AR)配置1 000 mg·L?1 的Cu2+溶液作为储备液,分别称取(0.100±0.005) g玉米秸秆生物炭和牛粪生物炭,投入到盛有Cu2+溶液的锥形瓶中,向溶液中加入0.01 mol·L?1的NaNO3作为背景电解质。实验用水均为蒸馏水,吸附实验在室温25 ℃下进行,每组吸附实验设3个平行和空白处理(生物炭+H2O),溶液中Cu2+浓度采用ICP-MS(Nexlon 350X,PerkinElmer)测定。在考察pH对吸附的影响时,称取0.1 g生物炭于100 mL锥形瓶中,加入50 mL 100 mg·L?1的Cu2+溶液,使用0.1 mol·L?1的NaOH和HNO3溶液调节pH为1、2、3、4、5、6,以150 r·min?1振荡24 h后离心、过滤,测定溶液中Cu2+的浓度,再通过式(1)计算生物炭对Cu2+的吸附量。

式中:qe为吸附量,mg·g?1;c0和ce分别为Cu2+的初始浓度和吸附平衡浓度,mg·L?1;V为溶液体积,L;m为生物炭质量,g。

在进行吸附等温实验时,称取0.1 g生物炭于100 mL锥形瓶中,向锥形瓶中加入50 mL质量浓度分别为20、40、80、120、150、200 mg·L?1的Cu2+溶液,在25 ℃下以转速150 r·min?1振荡24 h,离心、过滤,测定溶液中的Cu2+浓度。分别用Langmuir(式(2))和Freundlich(式(3))吸附等温模型拟合4种生物炭在25 ℃下对Cu2+的吸附等温线。

式中:ce为吸附平衡是溶液浓度,mg·L?1;qe为平衡时生物炭的吸附量,mg·g?1;k为材料对重金属亲和力的常数,L·mg?1;qm为最大吸附量,mg·g?1;kf为吸附容量,mg·g?1;n为吸附强度,g·L?1。

在进行吸附动力学实验时,取100 mL初始质量浓度为50 mg·L?1的Cu2+于锥形瓶中,称取0.1 g生物炭加入到锥形瓶,吸附时间设置为15、30、60、120、240、480、960、1 440、2 880 min。于25 ℃以150 r·min?1振荡,离心、过滤,测定溶液中Cu2+浓度。采用准一级动力学(式(4))、准二级动力学(式(5))和颗粒内扩散模型[9](式(6))对吸附动力学数据进行拟合分析,进而比较2种生物炭吸附速率的差异及其对应的吸附机制。

式中:t为反应时间,h;qt代表t时的吸附量,mg·g?1;qe代表平衡吸附量,mg·g?1;k1为准一级吸附速率常数,min?1;k2为准二级吸附速率常数,g·(mg·min)?1;kip为颗粒内扩散速率常数,mg·(g·min0.5)?1;C为常数。

2.1. 原料的热重分析

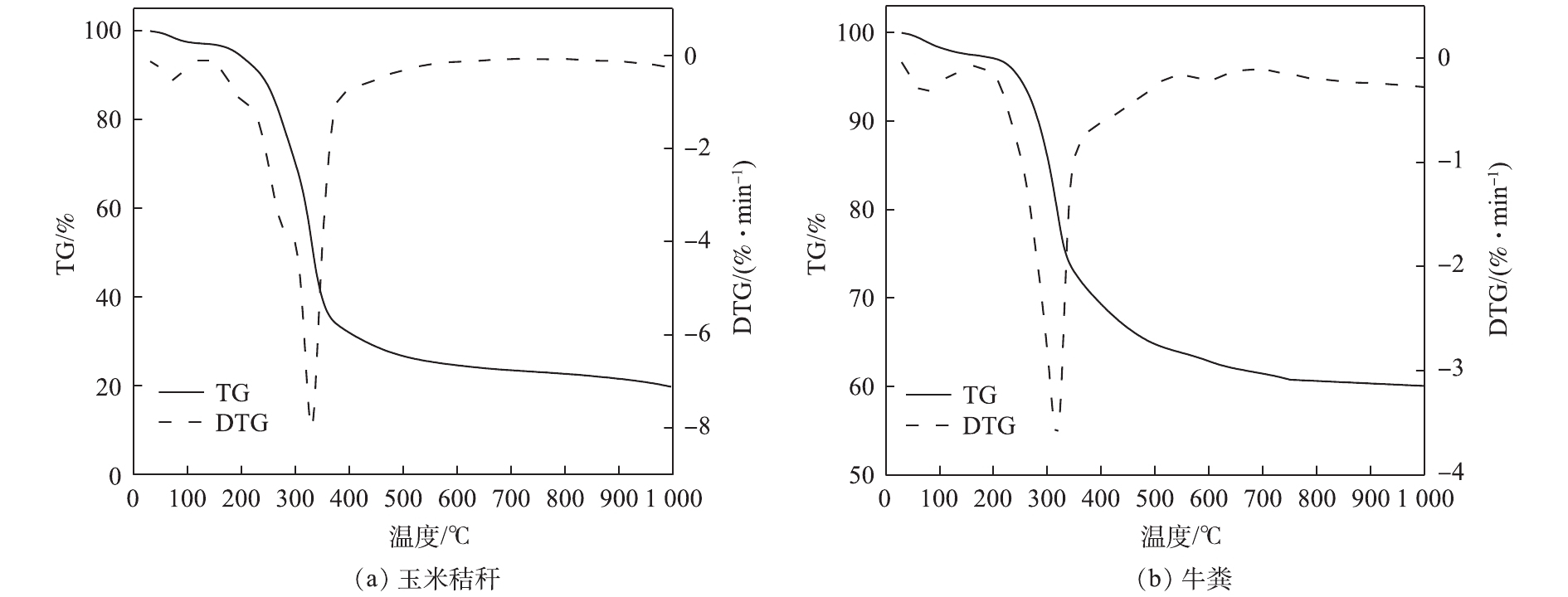

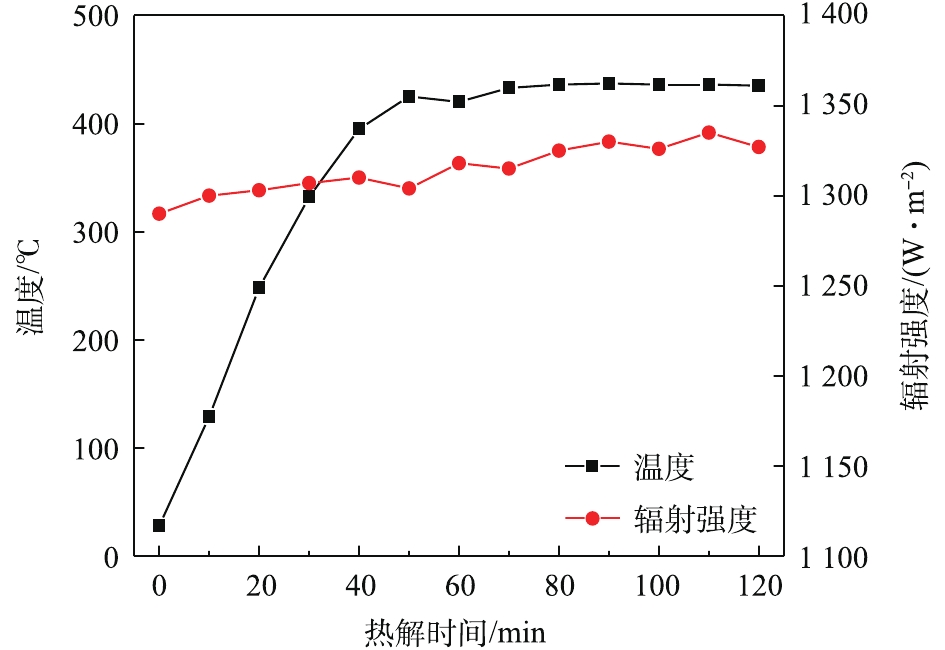

为研究原料中各组分的热解特性,分别对2种原料进行了热重分析。玉米秸秆和牛粪中含有相同的木质素、纤维素等有机成分,其热解过程表现出一定的相似性[10]。由图2可知,2种原料的热解过程大体可分为3个阶段。第1阶段为脱水干燥阶段(30~130 ℃),水分和少量挥发性物质的蒸发散失;第2阶段为主要热解阶段(210~410 ℃),生物质中含有的纤维素、半纤维素等有机物发生分解,分解产物以挥发性物质为主,其中包括H2、CH4、CO2、CO等不可凝结气体和产物冷凝形成的生物油(复杂含氧有机化合物与水的混合物)[11],该阶段生物质的失重速率迅速升高,玉米秸秆在330 ℃失重速率达到峰值,牛粪在310 ℃时失重速率最大,在该阶段玉米秸秆失重率达70%,牛粪重量损失35%左右[12]。第3阶段为炭化阶段(410 ℃以后),原料进一步热解炭化,热损失速率逐渐降低,生物质炭化程度进一步加深。牛粪中含有较多灰分,大部分灰分物质在温度升高过程中不断矿化积累,导致剩余固体质量占比较高[13]。结合2种原料热解特性和太阳能热解装置能实现的温度条件,选择在炭化阶段以430 ℃对生物质进行热解。为确保太阳能热解过程中温度保持稳定,选择天气状况好,云层相对较少的晴朗天气进行热解实验。青岛地区晴朗天气地面太阳辐射强度为800~1 400 W·m?2[14]。图3为太阳能热解制备生物炭过程中太阳辐射强度和装置温度的变化。可以看出,制备过程中的最高温度为430 ℃,升温速率约为8 ℃·min?1,热解过程持续时间为2 h。

2.2. 扫描电镜分析

为探究生物质热解前后表面形貌的变化,对比不同热解方式下生物炭表面形貌的差异,本研究对2种材料热解前后的样品进行扫描电镜表征。由图4可见:玉米秸秆和牛粪经热解后表面形貌发生了明显的变化。玉米秸秆炭化后表面变得光滑,炭架结构更加明显,生物炭孔隙结构发达,大小孔隙相间分布,其表面的大孔一般为植物组织固有的细胞结构,而小孔径的孔洞是由纤维素、半纤维素等有机物质热解散失所形成的[15];牛粪经热解后表面粗糙度增加,生物炭表层相对不规整,同时形成一些管状孔结构。牛粪中包含粗纤维、蛋白质和无机矿物等组分,物质组成相对较为复杂,植物成分热解产生的部分多孔结构中孔隙相对不完整,无机矿物成分的炭化积累增加了生物炭表面粗糙度[16]。采用不同的热解方式对生物炭表面结构的影响较小,生物质本身结构性质对生物炭表面形貌有较大影响,尽管通过扫描电镜可以对生物炭的表面形貌进行了直观观察,但生物炭的比表面积、孔径分布和孔体积等特征须采用BET方法进行表征和分析。2.3. 比表面积分析

为进一步比较生物炭之间的孔隙结构差异,分析不同原料和热解方式对生物炭孔隙结构的影响,本研究对4种生物炭进行了比表面积和孔径分析测试,结果如图5所示。根据IUPAC(1985)分类,4种材料的氮气等温吸附-脱附曲线符合Ⅱ型,其属于多孔介质表面发生多层吸附的情况。表1为在2种热解方式下所制备出生物炭的孔隙特征(比表面积、总孔体积及平均孔径)数据。太阳能热解所制备的生物炭的比表面积(TJ=30.72 m2·g?1、TN=10.72 m2·g?1)和孔容略高于传统热解方式下制备的生物炭材料(CJ=29.45 m2·g?1、CN=8.35 m2·g?1),生物炭的平均孔径后者较大。相比于热解方式,原料种类对生物炭孔隙结构起着更为重要的作用,玉米秸秆生物炭的比表面积和孔容均明显高于牛粪生物炭。玉米秸秆自身维管束结构加上热解过程挥发分物质大量分解逸出是导致生物炭孔隙结构发达的原因;然而,牛粪中含有较多的无机矿物成分,根据已有研究[17]结果,无机矿物会在高温下熔融并填充生物炭中的孔隙,导致其比表面积的下降,生物炭的比表面积与无机矿物组分含量成负相关关系。

2.4. 红外光谱分析

为评价不同热解方式和制备原料对生物炭表面官能团的影响,本研究采用FT-IR对热解前后的样品进行了表征,结果如图6所示。相同原料经不同热解方式所制备的生物炭的特征吸收峰的位置和数量基本相同,即生物炭表面官能团的种类和丰富程度较为接近。在热解前后部分特征吸附峰的强度变化较大,原因在于热解过程中物质组分的变化引起相应表面官能团数量的相对减少或增加。玉米秸秆和牛粪在3 400 cm?1左右处较宽的吸收峰是由酚式羟基O—H伸缩振动产生的,其对应的峰强度在热解后大幅度减小。在2 918~2 925 cm?1的吸收峰是由纤维素等高分子聚合物中脂肪碳链的C—H伸缩振动产生的。由于热解过程中脂肪族化合物不断降解,生物炭中该吸收峰强度减弱甚至消失。在1 580~1 650 cm?1处为木质素结构中的芳香族C=C的特征吸收峰[18],玉米秸秆经热解后,该特征峰发生偏移,峰值变大,即芳香化程度加剧,牛粪经热解后,该峰强度明显减小。玉米秸秆在1 350~1 420 cm?1处为羧基对应的C=O及C—O伸缩振动峰[19],右侧C—O振动峰在热解后消失,左侧C=O振动峰在热解后位置发生偏移,峰强度没有明显的变化。据已有研究[20]证明:羧基中C=O键一般经500 ℃以上高温热解后会显著减少;牛粪中位于1 421 cm?1的振动峰可能与

2.5. 初始pH对铜离子吸附的影响

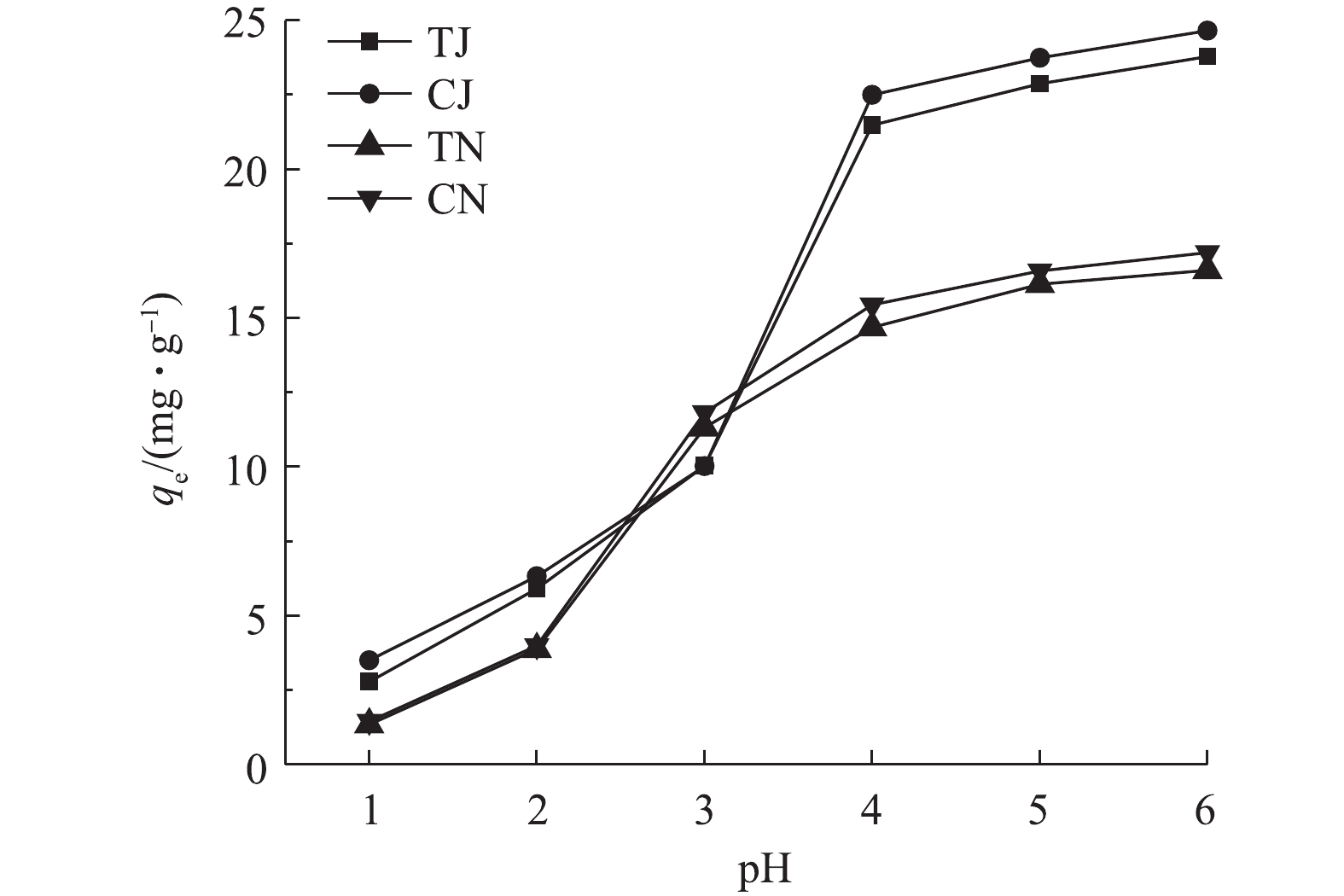

为探究溶液初始pH对生物炭吸附Cu2+的影响,将Cu2+溶液的初始pH设置为1.0~6.0,进行吸附实验,结果如图7所示。采用2种热解方式制备的生物炭在不同pH条件下对Cu2+吸附效果差别不大。4种生物炭对Cu2+的吸附能力随pH的增加而不断升高,在pH为1~4时,随着pH的升高,生物炭对Cu2+吸附量迅速增加;当pH>4时,吸附量逐渐趋于平稳。玉米秸秆生物炭对Cu2+的吸附能力优于牛粪生物炭。pH越低,溶液中H+浓度越高,大量的H+会与Cu2+竞争生物炭表面有限的吸附位点[24],导致pH较低时生物炭对Cu2+吸附能力不强。随pH的升高,生物炭表面官能团如—COOH、—OH等的解离增加,与Cu2+反应生成表面络合物的能力增强[25]。2.6. 吸附等温线

生物炭对Cu2+的吸附等温过程如图8所示。可以看出,生物炭对Cu2+的吸附量随着Cu2+平衡浓度的增加,呈现先增大后逐渐稳定的趋势,4种生物炭对Cu2+的吸附能力大小顺序为CJ>TJ>TN>CN,玉米秸秆生物炭(TJ、CJ)对Cu2+的吸附能力大于牛粪生物炭(TN、CN)。为进一步研究生物炭对Cu2+的等温吸附特性,采用Langmuir和Freundlich模型对等温吸附数据进行拟合(图8),拟合参数如表2所示。对于玉米秸秆生物炭对Cu2+的吸附,Langmuir方程的拟合相关度更高,R2分别为0.998 5和0.995 4,Langmuir模型更适合描述玉米秸秆生物炭对Cu2+的吸附过程,表明生物炭对Cu2+为单分子层吸附[26],TJ和CJ的理论最大吸附量分别为25.81 mg·g?1和25.92 mg·g?1;牛粪生物炭对铜离子的吸附更适用Freundlich模型(R2为0.979 9~0.985 4),说明生物炭对Cu2+主要为多层异相吸附[27]。另外,采用太阳能热解方式不仅减少了传统电力热解中的能耗,从而间接减少了温室气体的排放,而且太阳能热解制备出生物炭材料吸附性能与传统管式炉所制备出生物炭的表面形貌、比表面积、官能团种类等理化性质相似,对Cu2+的吸附性能较为接近,这种节能环保型工艺符合未来热解炭化技术发展的方向。

2.7. 吸附动力学

本研究通过吸附动力学实验找出了生物炭对Cu2+的吸附量与吸附时间之间的关系,掌握生物炭对Cu2+的吸附效率,为实际水处理工艺设计和操作提供参考。如图9(a)所示,2种热解方式下所制备的生物炭对Cu2+吸附动力学数据的变化趋势一致。在吸附过程中,4种生物炭对Cu2+的吸附速率均为前期较快,前8 h的吸附量占总吸附量的85%左右,之后吸附速率有所下降,24 h内吸附基本达到了平衡。在吸附过程的初期,生物炭表面具有丰富的孔道和官能团结构可提供较多的吸附结合位点[28],有利于对Cu2+的快速吸附,随着反应的不断进行,活性位点逐渐减少、离子间静电斥力[29]增强使得吸附反应难以继续进行,故吸附逐渐达到平衡。为研究吸附机制,本研究采用一级动力学、二级动力学及颗粒内扩散模型对4种生物炭吸附动力学数据进行拟合,拟合结果如图9所示。由表3的拟合数据结果可知:在4种生物炭对Cu2+的吸附数据的拟合结果中,二级动力学拟合的可决系数高于一级动力学和颗粒内扩散的对应数值。这表明二级动力学模型更适合描述4种生物炭对Cu2+的吸附动力学过程,4种生物炭对Cu2+的吸附过程主要受化学吸附的控制[30],其中速率常数k2反映了生物炭吸附Cu2+的速率,TJ和CJ均具有较大的k2值,能较早达到吸附平衡。由颗粒内扩散模型的拟合数据可知,其拟合结果并非为一条过原点的直线,这说明颗粒内扩散为生物炭吸附Cu2+速率控制的步骤之一,此外还存在表面吸附等共同控制吸附反应速率[31]。

2.8. 吸附机制

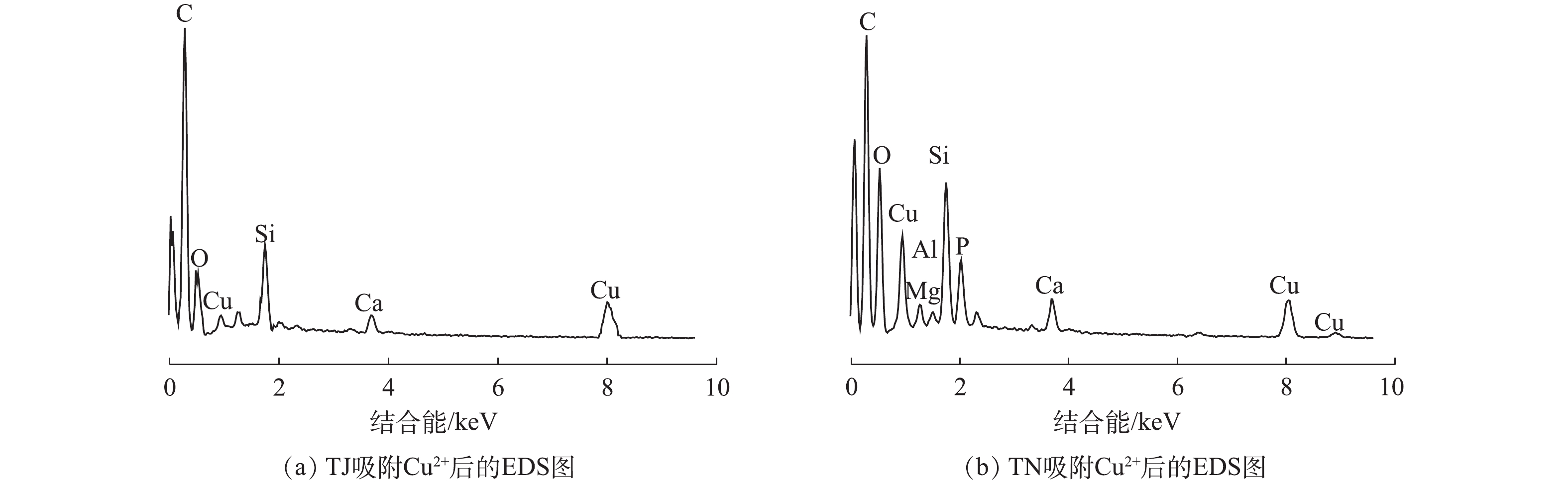

生物炭吸附重金属的主要机制包括静电吸引、表面络合、物理吸附和沉淀作用等,这些不同的吸附行为与生物炭自身的结构组成和理化性质相关[32]。本研究采用2种不同的热解方式制备的生物炭在表征结果和对Cu2+的吸附特性上没有明显的差异。然而,2种不同的原料所制备出的生物炭在理化性质和对Cu2+的吸附效果上存在较大的区别。因此,以太阳能热解2种原料所制备的TJ和TN生物炭为例,对其吸附Cu2+后的样品进行EDS分析,结果如图10所示。玉米秸秆生物炭(TJ)表面主要富含碳、氧、硅等元素,牛粪生物炭(TN)表面除含有碳、氧、硅、磷元素之外,钙、镁和铝等无机金属元素的含量相对丰富,表明其含有大量磷酸盐、碳酸盐、硅酸盐等无机矿物成分[33],此外,吸附后的生物炭表面均有明显的铜元素存在。对比生物炭吸附Cu2+前后的FT-IR图谱(图11)可知,玉米秸秆生物炭在吸附前位于3 363 cm?1处的—OH特征峰和1 409 cm?1处的—COOH吸收峰在吸附后分别偏移至3 323 cm?1和1 427 cm?1处。这表明羧基、酚羟基参与了Cu2+的吸附反应过程,其主要通过表面络合反应吸附Cu2+,络合反应的发生改变了官能团的结构,从而致使光谱中对应吸收峰的位置发生偏移[34]。位于1 578 cm?1处的C=C吸附后偏移至1 583 cm?1处,说明在吸附过程中可能存在阳离子-π作用[35]。此外,Si—Cu表面沉淀作用使得红外光谱中位于460 cm?1处的Si—O振动峰偏移至468 cm?1处。对比牛粪生物炭吸附前后红外谱图可知,除3 363 cm?1处的—OH吸收峰和460 cm?1处的Si—O吸收峰发生偏移外,在1 425 cm?1处,与

2)玉米秸秆生物炭和牛粪生物炭在对Cu2+的吸附特性上存在差异。在最佳pH=6的条件下,玉米秸秆生物炭对Cu2+的吸附等温线符合Langmuir模型,牛粪生物炭符合Freundlich模型,前者对Cu2+的吸附性能优于后者;两者对Cu2+的吸附动力学数据均符合二级动力学模型,表明其对Cu2+的吸附速率主要受化学吸附控制;表面官能团的络合、阳离子-π作用和沉淀反应是玉米秸秆生物炭吸附Cu2+过程的主要机制,而牛粪生物炭吸附Cu2+过程的主导机制可能是沉淀作用。

3)采用太阳能热解与传统热解方式所制备出的生物炭在表面形貌、比表面积、孔隙结构和官能团种类等方面的性质相似,对水中的Cu2+的去除效果接近。这表明采用的太阳能热解方式与传统电热解方式在制备生物炭吸附材料方面的效用相同,为节能环保型生物炭材料的制备提供了一种全新的工艺。

参考文献

下载:

下载:

点击查看大图

点击查看大图