全文HTML

--> --> --> 高盐含油废水是一种典型的工业废水,主要是指油气田开采过程中产生的废水。油气田开采是通过向储油/气的地层中注液以采出石油和伴生天然气的过程。页岩气作为一种油气田开采的非常规天然气资源,具有清洁、高效、资源总量丰富等优势,近年来开采量逐渐增加[1-3]。目前,页岩气的开采使用水力压裂技术。该过程耗水量高,同时产生大量的压裂液返排至地面[4]。页岩气压裂返排液是水力压裂完成初期从页岩气井中返排的混合液。根据压裂液以及页岩层的特点,返排液含有大量溶解性盐类、有机物和各种化学添加剂,并携带一些油类、表面活性剂和悬浮物等污染物,呈现出污染物种类繁多、成分复杂、高COD、高矿化度、高稳定性等特点[5-8]。若页岩气压裂返排液直接外排,不仅会造成严重的水资源浪费,还会带来严重的环境污染和生态破坏等问题,如导致土壤板结盐碱化,地表水系污染等,进而威胁到人类生存和人体健康[9-10]。因此,这类高盐含油废水的有效处理是油气田开采,特别是页岩气开采过程中亟需解决的问题。膜蒸馏(membrane distillation,MD)是一种新兴的膜技术,采用热驱动实现分离的过程。在温度差产生的蒸汽压差的作用下,蒸汽跨越多孔疏水膜到达冷侧并冷凝,从而实现水与污染物的分离[11-14]。与其他膜技术相比,MD具有理论截盐率可达100%、对盐度不敏感、低品位废热再利用、操作条件温和、设备简单等优势[15-19],因此,MD在页岩气压裂返排液处理领域具有较好的应用前景[20]。然而,MD技术的应用仍受到传统疏水膜长期运行易润湿这一特性的限制[21-22]。由于页岩气压裂返排液中含有大量表面活性剂和油类物质,而表面活性剂可能对膜材料产生润湿作用,油类物质会通过疏水-疏水作用黏附疏水膜造成膜污染[23],所以要解决MD技术在页岩气压裂返排液处理中的应用问题,还应开发适宜的膜材料。

双疏膜的制备是基于荷叶效应提出的。这类膜对表面活性剂表现出良好的耐润湿性,但在水下易被油类物质污染。本课题组基于双疏膜的优势,制备了可同时抗润湿和抗膜污染作用的新型Janus膜。Janus膜的亲水表面可以防止油污黏附;底膜采用双疏膜,可以抵抗表面活性剂的润湿作用。本研究将Janus膜应用在MD系统中以处理高盐含油废水,研究其对低表面能污染物(如乳化油)的抗润湿和抗污染性能,为MD工艺处理页岩气压裂返排液的工业化应用提供有益参考。

1.1. 实验材料

1)基本材料。本实验采用平均孔径为0.45 μm的PVDF商品膜作为改性基膜;十六烷基三甲氧基硅烷(≥85%,HTDMS),γ-A12O3纳米颗粒(20 nm)、十二烷基硫酸钠、十二烷基三甲基氯化铵、十七氟癸基三甲氧基硅烷(FAS-17)、3-氨丙基-三甲氧基硅烷、聚乙烯醇(PVA)、十二烷基硫酸钠(SDS)等表面活性剂和膜制备材料由阿拉丁生化科技股份有限公司提供;无水乙醇、N,N-二甲基甲酰胺(DMF)、氯化钠(NaCl)、戊二醛和乙酸等溶剂和盐由国药集团化学试剂有限公司提供;去离子水为实验室自制;实验使用的原油采自大庆油田。2)膜抗润湿性能测试的进料液。为35 g·L?1 NaCl溶液和不同浓度(0.1、0.2和0.3 mmol·L?1)SDS 的NaCl(35 g·L?1)混合溶液。

3)膜抗污染性能测试的进料液。由于表面活性剂的存在,页岩气压裂返排液中的油类污染物呈现出乳化油和分散油2种状态,针对于不同油污存在状态的废水,配制了2种高盐含油废水进行膜蒸馏实验。膜抗污染性能测试的进料液分别为1 000 g·L?1原油与NaCl(35 g·L?1)混合溶液、1 000 g·L?1原油与0.2 mmol·L?1 SDS 的NaCl(35 g·L?1)乳化油混合溶液[24]。高盐含油废水需要用剪切乳化机以5×104 r·min?1的转速持续搅拌30 min,使油滴均匀分散在盐溶液中。

1.2. Janus膜的制备

疏水性Al2O3纳米颗粒的制备:1)首先将5 g HTDMS溶于100 mL乙醇中,在室温下搅拌10 min,制得改性溶液,再将5 g Al2O3纳米颗粒分散在改性溶液中,在35 ℃下搅拌10 h;2)然后将混合溶液离心分离,得到疏水性Al2O3纳米颗粒;3)疏水改性后,将疏水的纳米颗粒加入到由2 mL FAS-17和98 mL无水乙醇组成的混合溶液中,在35 ℃下搅拌12 h进行纳米颗粒氟化;4)最后将疏水的Al2O3纳米颗粒离心分离,并在60 ℃下干燥后备用。Al2O3纳米颗粒亲水改性:1)将Al2O3纳米颗粒分散在含1.5 g·L?1 3-氨丙基-三甲氧基硅烷的乙醇溶液中,并用乙酸将pH调整至4.0;2)制备的Al2O3纳米颗粒混合溶液在60 ℃下搅拌3 h;3)反应完成后,将混合溶液离心分离,纳米颗粒在60 ℃下烘干备用。

铸膜液的配制:1)称取10 g聚乙烯醇粉末和5 g亲水性Al2O3纳米颗粒置于90 mL超纯水中,将混合溶液在90 ℃下连续搅拌3 h,直到聚乙烯醇粉末完全溶解和Al2O3纳米颗粒分散均匀,制得铸膜液;2)待铸膜液冷却至室温后,加入6 mL戊二醛,在60 ℃下加热搅拌1 h使聚乙烯醇完全交联。

Janus膜的制备:1)先配制2 g·L?1的疏水性Al2O3-乙醇分散液,将分散液超声分散30 min后装入容量为50 mL的接有喷丝头的注射器中,并置于进样器里,将进样速度调为5 mL·h?1,喷丝头与高压电源相接作为正极;2)以PVDF商品膜为基膜,贴于静电纺丝机的滚轮上用于接收喷出的颗粒,滚轮与负极相接;3)设置两极参数分别为正电压+18 kV、负电压?2 kV,喷丝头移动速度为3.5 mm·s?1,室内温度25 ℃,湿度40%;4)设置好参数之后进行PVDF表面蚀刻,用电动喷枪将DMF喷涂在PVDF表面,使膜表面具有黏性;5)运用电喷雾过程将疏水纳米颗粒均匀地喷在被蚀刻的PVDF上,制得双疏膜,并置于室温中12 h,自然晾干备用;6)采用雾化器将无水乙醇喷涂在双疏膜表面,使其表面润湿,然后用电动喷枪在温度和湿度分别为25 ℃和30%时将铸膜液喷涂在双疏膜上,室温下干燥12 h后,即可制得Janus膜。

1.3. 实验方法

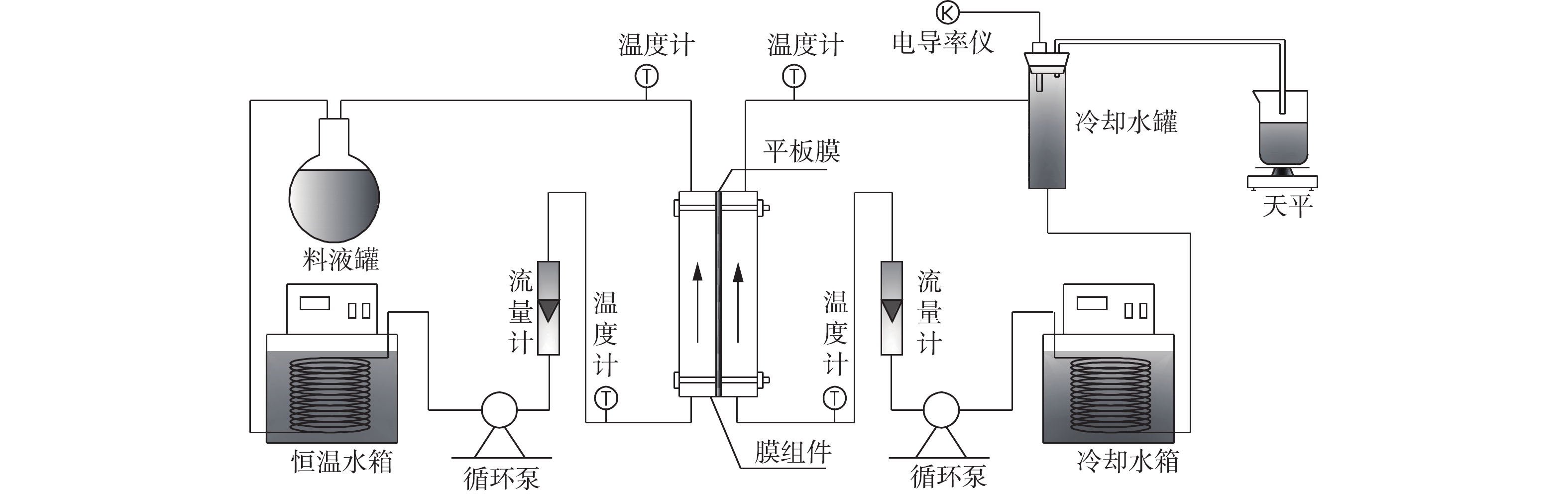

实验采用直接接触式膜蒸馏(direct contact membrane distillation, DCMD)工艺,装置如图1所示。本实验用于测试的膜样品分别为商业PVDF膜、自制的双疏膜和Janus膜。实验用膜的有效膜面积为7.47×10?3 m2。膜样品将膜组件分为热侧和冷侧。热侧为配制的模拟废水,冷侧为超纯水。两侧溶液通过磁力循环泵在膜组件中循环。热侧和冷侧的温度分别控制在53 ℃和20 ℃。两侧料液的流量均控制在1.75 L·h?1。膜通量通过冷侧的产水重量来计算,产水重量通过连接电脑的电子天平每隔2 min记录1次。1.4. 分析方法

采用场发射扫描电子显微镜(FE-SEM,SU-8020, Hitachi,日本)对膜表面及断面的形貌进行观察与分析。将干燥后的样品用导电胶贴至样品台上,真空喷金40 s后放入仪器中进行观测。膜表面官能团及化学元素是通过傅里叶红外光谱仪(ATR-FTIR,Nieolet8700,Thermo Fisher Scientific,美国)和X射线光电子能谱分析仪(XPS,PHI Quantera SXM,ULVAC-PHI,日本)进行分析。其中,XPS分析的主要元素有C、O、F、Al和Si。采用毛细流孔径仪(Porolux 1000,普罗美特有限公司,德国)测试膜的平均孔径和孔径分布。膜样品的孔隙率通过重量法测量,膜样品厚度通过测厚仪(Exploit, 中国)直接测量,测试5个不同的位置的厚度取平均值即为膜样品的厚度。通过接触角测量仪(OCA15EC,Data Physics,德国)测量膜样品的表面的接触角,从而判断膜样品的亲/疏水性。本研究测量了膜样品的空气中水接触角(water contact angle, WCA)和水下油接触角(oil contact angle, OCA)。每个样品测定5个平行点,计算平均值作为膜表面接触角值。

采用表面张力仪(DCAT 21,Data Physics, 德国)来测量油滴与膜表面的相互作用力。首先,将膜样品固定在特定测试容器底部,将附着膜样品的容器放在可升降的测试台上并在容器中注入一定量的超纯水。然后在水相中制备由铂-铱环和1滴原油(约10 μL)组成的油滴探针。测试过程分为4个主要事件,分别为接接触事件、预压事件、收缩事件和撤离事件。平台以0.01 mm·s?1的速度向上移动去接触固定的油滴探针,膜样品与油液滴接触后,继续向上移动1.5 mm以挤压油滴,然后平台以相同的速度向下移动到原始位置。利用微电子机械传感器记录原油与膜表面在不同位移下的相互作用力。

2.1. Janus膜的性能表征

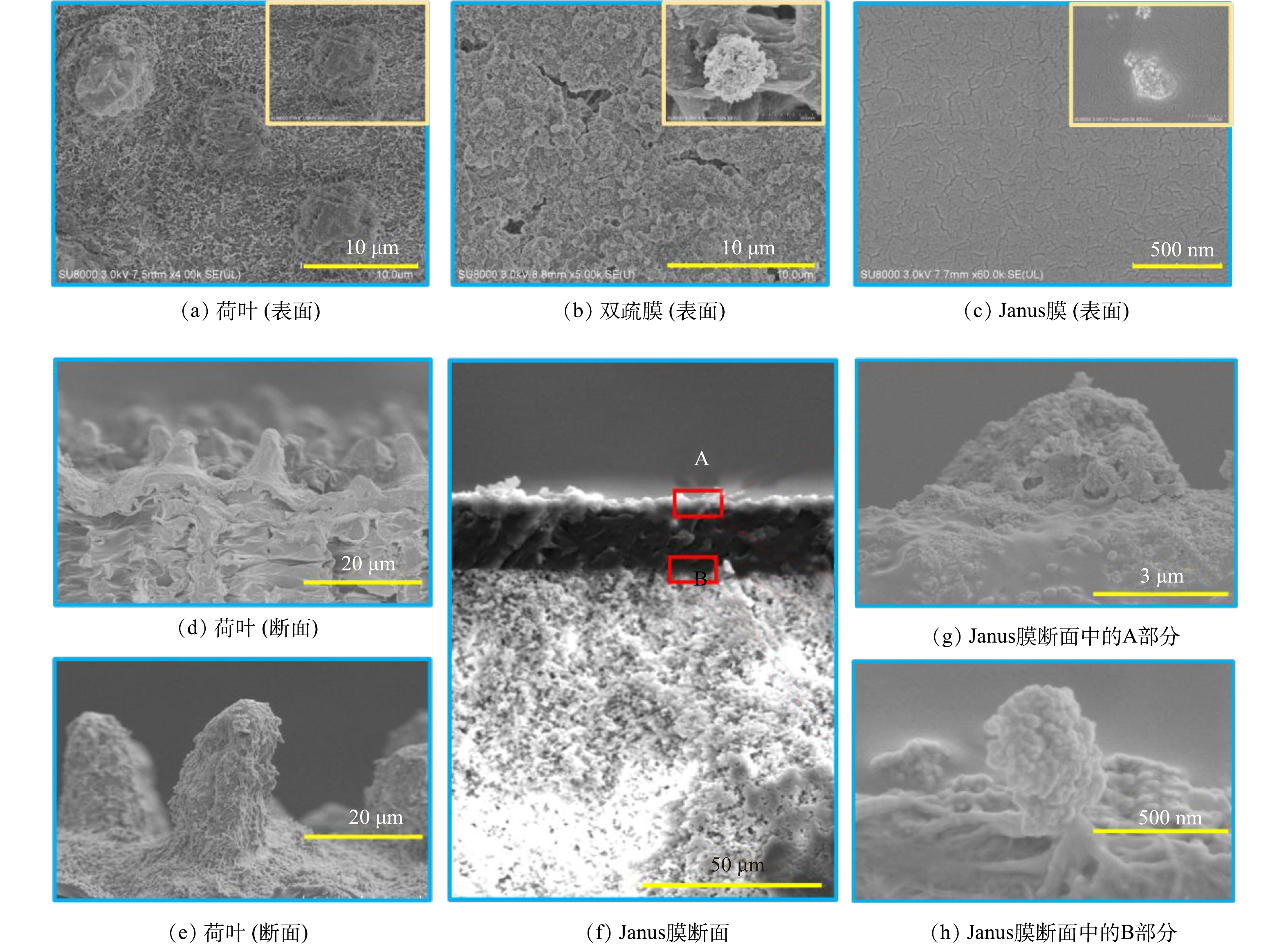

通过FE-SEM对膜表面形貌进行了观察,结果如图2所示。双疏基膜的构筑是启发于“荷叶出淤泥而不染”的性质。荷叶的表面具有“岛屿状”的凸起结构,每一个凸起上面还有小的凸起,形成了微-纳凹槽结构。双疏膜的表面上也具有类似于荷叶的微-纳凹槽结构。这是由于在电喷雾的过程中,疏水性Al2O3纳米颗粒通过静电作用发生团聚,形成了被纳米小凸起包裹的微米球,在与蚀刻后的PVDF膜表面结合后便形成了微-纳凹槽结构。Janus膜表面与传统的膜表面不一样,没有呈现出均匀的圆状孔,而是曲折的细缝。与传统的微孔滤膜相比,细缝可以有效地阻挡污染物进入膜孔而避免基膜污染,同时细缝会使进料液更快到达蒸发界面。Janus膜表面的粗糙结构,将增强膜表面的亲水性。图2(d)~图2(h)展示了荷叶与Janus膜的断面形貌。可以看出,荷叶的凹槽结构明显,每个凸起结构之间有一定的间隔,这样有利于气穴的形成。当液体与凸起表面接触时,液面与凸起表面会形成气穴,防止液体进入而增强表面的抗润湿能力[25-26]。在Janus膜的中间层有明显的凸起结构(见图2(f)),说明双疏基膜的表面凹槽结构未因亲水层的构建而被破坏,因此,其抗润湿能力不会受到影响。Janus膜的膜层之间结合紧密,在亲水层表面也具有明显的凸起结构。

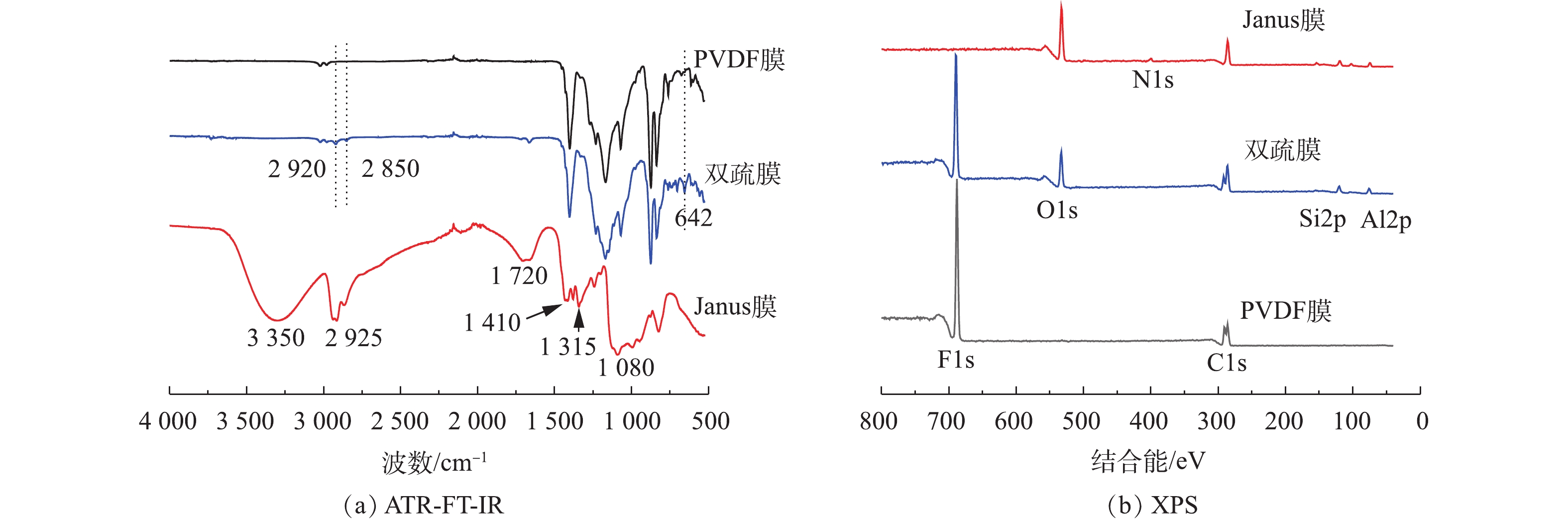

膜表面的化学成分分析结果见图3。PVDF膜在1 183 cm?1和3 025 cm?1处有2个明显的特征峰,分别代表C—F键的伸缩振动和弯曲振动。与PVDF商品膜相比,双疏膜在642 cm?1处出现1个新的振动峰,即Al—O—Si的振动峰。Al—O—Si键是通过Al2O3纳米颗粒上的—OH基团与—O—Si—基团通过醇解反应形成的[27]。Al—O—Si键的形成既表明Al2O3纳米颗粒被疏水性改性,也说明了疏水性改性的Al2O3纳米颗粒成功地构筑在PVDF膜表面,从而形成了双疏膜。由于PVA层的构建,Janus膜的光谱图在3 300和2 925 cm?1分别出现2个较宽的峰,分别是—OH和—CH2的振动峰,这是构成PVA的2个典型基团。此外,在1 720、1 640和1 080 cm?1处有3个新峰。这些新峰分别对应于羰基、—C=N—和C—O—C键的伸缩振动,来源于PVA、戊二醛和亲水性Al2O3纳米颗粒之间发生的交联反应[28]。结果表明,交联后的PVA在双疏膜上成功构建。

XPS的表征(见图3(b))进一步说明了Janus膜的完整性。PVDF膜在结合能为286.4 eV和689.1 eV处有2个明显的峰,分别是C1s和F1s的信号峰。相比于PVDF膜,双疏膜在532.7、103.05和75.1 eV处有3个新的峰产生,分别是O1s、Si2p和Al2p的信号峰。3个新峰的出现说明疏水性的Al2O3纳米颗粒稳固地锚定在PVDF膜表面。而在Janus膜上除了O1s、Si2p和Al2p 3个信号峰之外,还出现了一个结合能为400.05 eV的峰,对应的是N1s的信号峰。这是由于羟基、醛基和氨基之间的交联反应。XPS光谱图的结果与红外光谱的结果一致,说明双疏膜表面的凹槽结构成功构筑,并且Janus膜表各功能层结构完整。

2.2. 膜性能测试结果分析

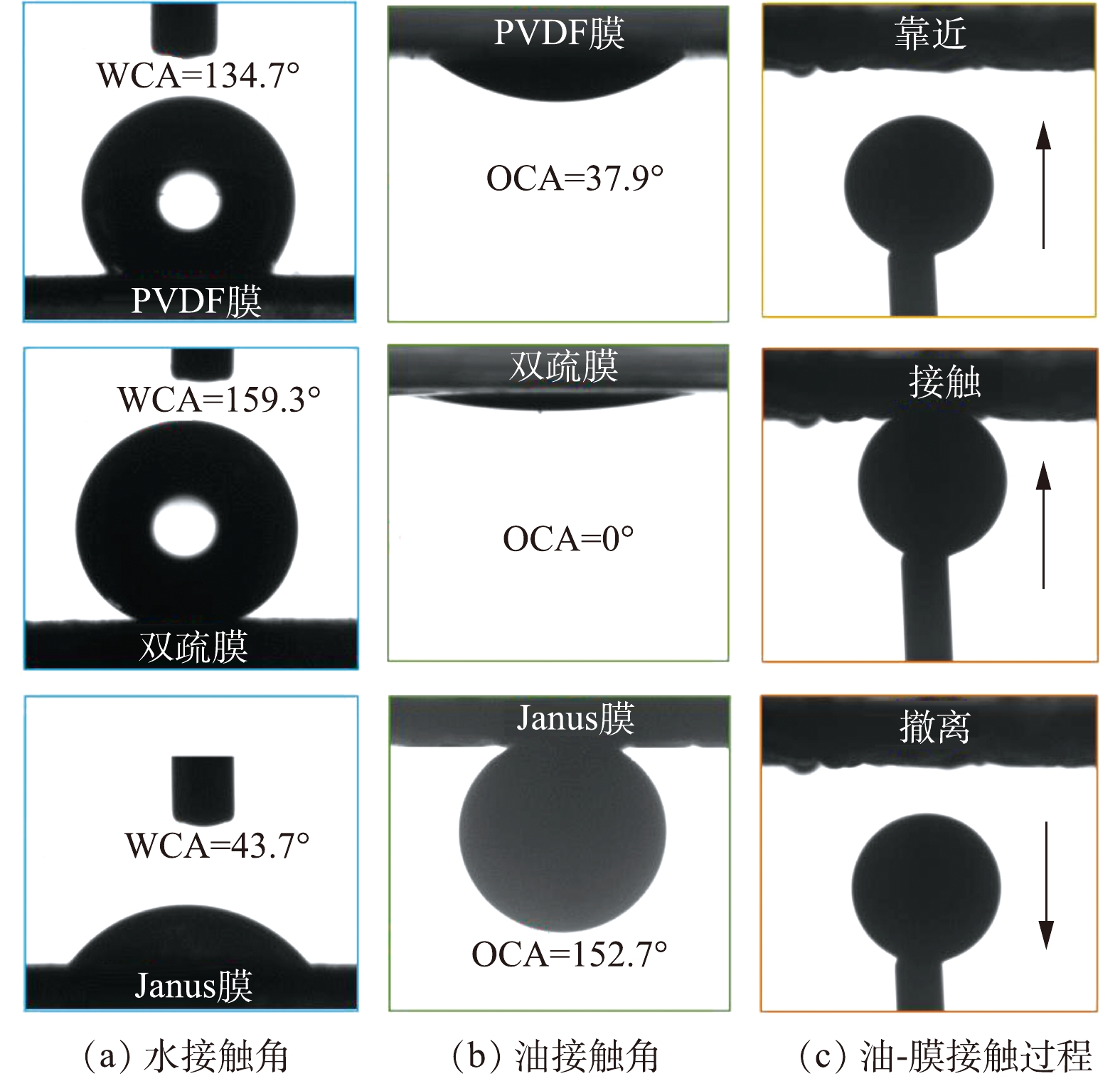

膜表面润湿性可以通过接触角的大小来判定结果见图4和图5。图4(a)为空气中的水接触角(WCA)测试结果。PVDF膜的WCA为134.7°。具有微-纳凹槽结构的双疏膜WCA从134.7°明显地增加到159.3°,表现出超疏水性。Janus膜表面为亲水性表面,其WCA为43.7°。Janus膜是以双疏膜为基膜进行改性而制备的,且双疏结构未被破坏,所以Janus膜的中间层也具有超疏水性。水下油接触角(OCAs)测试结果如图4(b)所示。Janus膜的OCA高达152.7°,而PVDF膜和双疏水膜的OCAs分别为37.9°和0°。这是由于油滴和疏水膜之间具有极强的疏水-疏水作用力,使油滴在膜表面黏附并铺展开,表明Janus膜具有水下超疏油能力。本研究同时模拟了油滴与Janus膜在膜组件中相互作用的过程:首先油滴与Janus膜接触,在液体撞击冲力的作用下,油滴会向下挤压而发生变形;然后在水力冲刷作用下[29],油滴从Janus膜上被带走。图4(c)显示了油滴与Janus膜之间反复进行接触-撤离的过程。操作该过程10次之后,Janus膜的OCA仍大于150°,表明Janus膜具有持久的超疏油性能。继续测量了除原油以外的其他3种不同油类物质在Janus膜上的水下OCAs(见图5)发现,Janus膜对正己烷、甲苯和汽油的水下OCAs分别为150.1°、146.7°和151.1°,说明Janus膜可以抵抗多种油类物质的污染。

图6为实验中3种膜的孔径分布图。与PVDF膜相比,双疏膜的孔径分布未发生明显变化,平均孔径为0.71 μm。而Janus膜的孔径分布明显变窄,这是由于亲水层的构筑使一些大孔被覆盖,使孔径分布更为集中。Janus的平均孔径为0.64 μm。3种膜的孔隙率及厚度测试结果如表1所示。与PVDF膜相比,双疏膜的孔隙率和膜厚度的变化并不明显;而Janus膜的孔隙率有所减小,其大小为61.9%,膜厚度为151 μm。尽管如此,膜孔径及孔隙率测试结果表明Janus膜符合DCMD用膜要求[11]。

2.3. Janus膜的脱盐性能测试

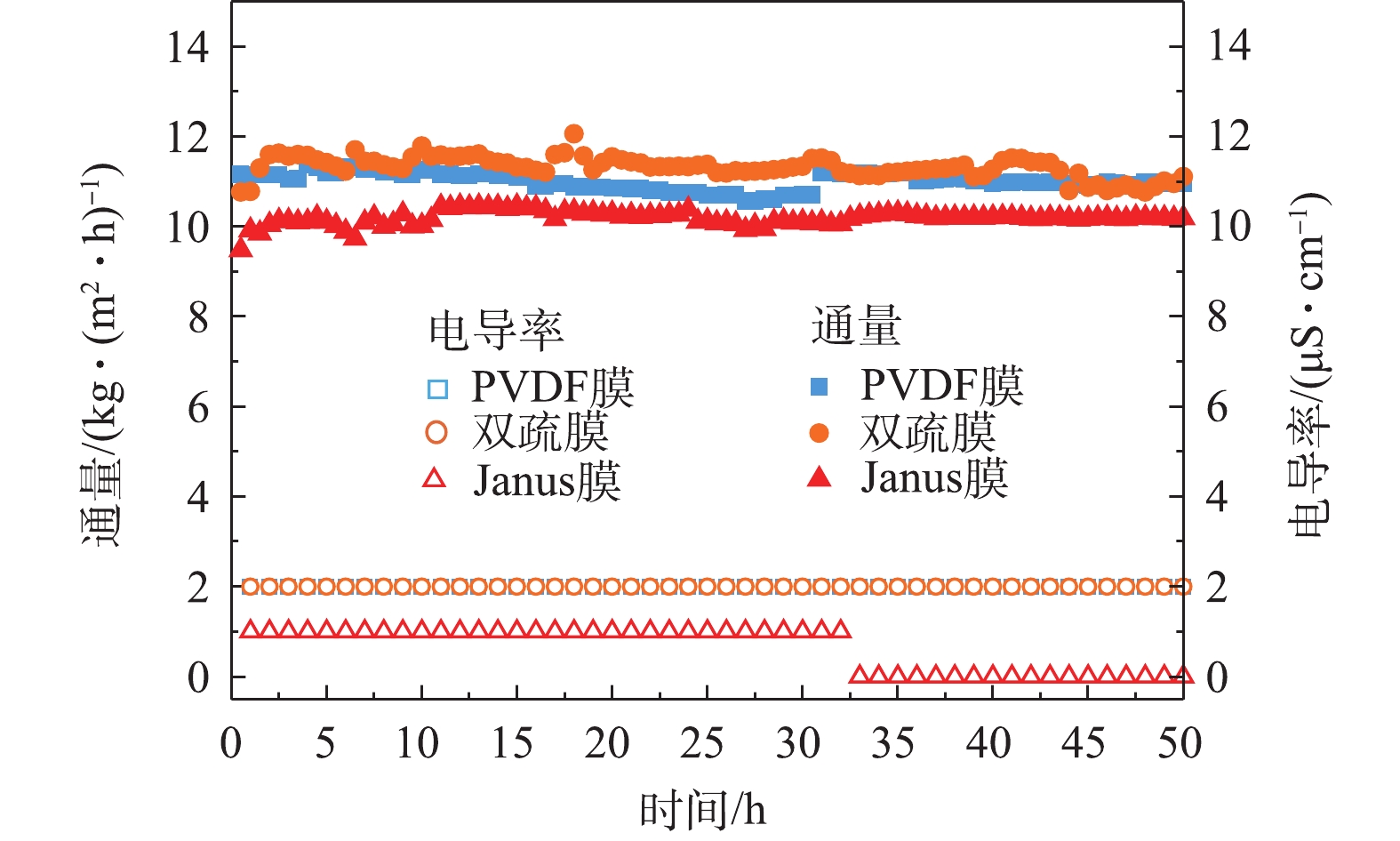

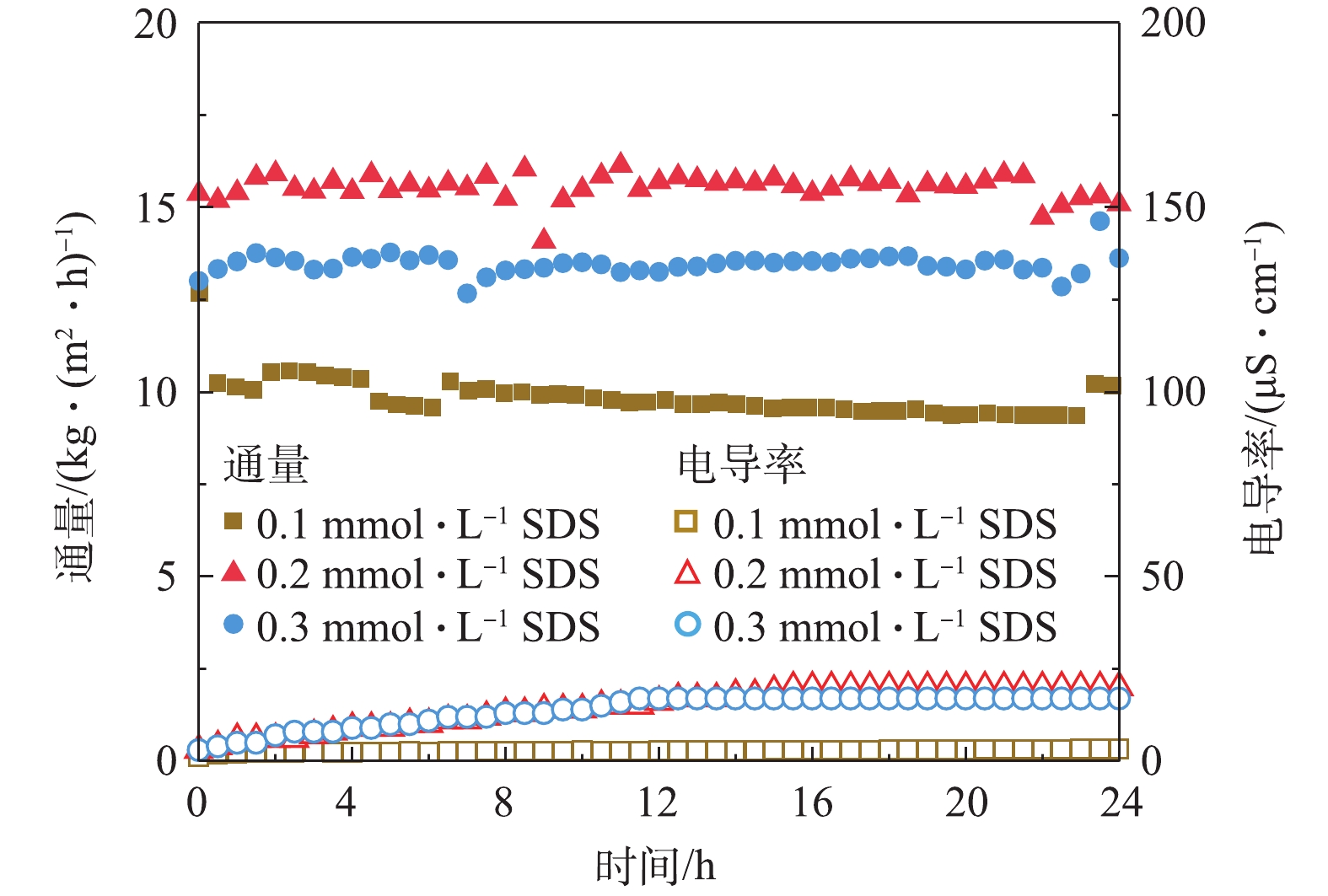

以35 g·L?1 NaCl溶液为进料液,对所制备的Janus膜进行脱盐性能测试,结果如图7所示。在长达50 h的DCMD运行过程中,3种膜的通量均保持稳定。PVDF膜、双疏膜和Janus膜的通量分别为11.06、10.94 和10.18 kg·(m2·h)?1。Janus膜通量略有降低,这主要是由于Janus膜孔径减小。在DCMD过程中,3种膜的电导率保持稳定,说明进料侧的盐类离子未通过膜孔进入渗透侧,由此可判断3种膜的截盐率可达100%。为测试Janus膜的抗润湿性能,采用具有低表面张力的含0.1、0.2和0.3 mmol·L?1 SDS的NaCl(35 g·L?1)溶液作为进料液进行DCMD实验。通量和电导率随时间的变化如图8所示。当进料液中SDS的浓度为0.1 mmol·L?1 时,Janus膜的通量稳定地维持在10.36 kg·(m2·h)?1左右,其电导率也未发生明显的变化,可保持100%的截盐率。当进料液中SDS的浓度为0.2 mmol·L?1时,Janus膜的通量为15.24 kg·(m2·h)?1,截盐率维持在99.99%;当进料液中SDS的浓度为0.3 mmol·L?1时,Janus膜的通量为13.13 kg·(m2·h)?1,截盐率也维持在99.99%;当进料液中SDS的浓度为0.3 mmol·L?1时,Janus膜的通量有所降低。这主要是由于此时的SDS浓度超过临界胶束浓度(0.2 mmol·L?1),进料液中有大量的SDS胶束团簇和SDS单体,大量胶束团簇的存在会在膜表面堆积,不利于进料液在Janus膜中的传质,使得Janus膜的通量有所降低。以上结果表明,在以含不同浓度的SDS盐溶液为进料液的DCMD实验中,Janus膜在24 h运行后仍未被润湿,说明Janus膜对表面活性剂具有良好的抗润湿效果。

2.4. 高盐含油废水膜蒸馏处理效能及膜抗污染性能定量分析

DCMD通量及电导率随时间的变化结果见图9。采用1 000 mg·L?1原油和35 g·L?1 NaCl混合溶液作为进料液测试Janus膜的抗污染能力,结果如图9(a)所示。PVDF膜和双疏膜的通量急剧下降,在30 min后降至0。这是因为油-膜之间存在极强的疏水-疏水作用[23, 30],使油滴黏附在疏水膜表面而造成膜孔堵塞;同时电导率出现急剧地上升,说明PVDF膜和双疏膜失去了截盐能力。在Janus膜运行45 h后,其通量和电导率均未发生明显变化,通量稳定地维持在9.75 kg·(m2·h)?1左右,截盐率为100%。对废水中油滴的粒径分布进行了测量,油滴直径为(4.8±0.8)μm,其粒径远远大于Janus膜上层膜表面的缝隙大小,故油滴不会进入亲水层而到达双疏基膜的表面。Janus膜表面的亲水层与水结合形成水化层,对油滴具有排斥作用,因此,Janus膜对高盐含油废水表现出良好的抵抗效果。当以SDS的临界胶束浓度(0.2 mmol·L?1)为投加量配制含乳化油高盐废水作为进水时,DCMD实验结果如图9(b)所示。PVDF膜通量在30 min左右快速降为0,说明PVDF膜已经被乳化油污染,并且膜孔被完全堵塞。而双疏膜的通量在2.5 h后才衰减至0,说明双疏膜对乳化油的抵抗能力比PVDF膜强。这是因为在阴离子稳定的乳化油高盐废水中,油滴被SDS单体包裹而形成了乳化油滴,此时的SDS单体疏水端与油滴结合,亲水端朝外,所以,双疏膜对乳化油滴具有一定的抵抗作用。废水中还有一些油滴未完全被SDS包裹,这些油滴很容易黏附在双疏膜上导致膜通量减少。与之相反,Janus的膜通量在25 h运行过程中仍稳定地维持在9.89 kg·(m2·h)?1左右,说明Janus膜未出现膜污染和膜润湿的现象。由于Janus膜的亲水层可以防止油滴进入双疏基膜表面,同时双疏基膜对被SDS完全包裹的乳化油也有良好的抵抗效果[31],这两重作用使得Janus对阴离子表面活性剂稳定的乳化油高盐废水具有优异的耐润湿和抗油污能力。

通过测量水下动态油-膜相互作用力来进一步定量解析Janus膜的抗油污性能,结果见图10。由图10(a)的油膜作用力曲线可知,当油滴与PVDF膜和双疏膜接触时,力曲线呈现向上陡升的趋势,说明PVDF膜和双疏膜对油滴表现出吸引力;且双疏膜的吸引力大于PVDF膜,说明双疏膜具有更强的疏水性。然而,当油滴接近Janus膜时,曲线出现向下趋势,说明Janus膜对油滴表现出排斥力,因此,Janus膜在处理含油废水时不会被油类物质污染。当油滴从膜表面剥离时,PVDF膜和疏水膜的力曲线逐渐上升,最终达到一个最大的作用力值,油-膜彻底分开时出现一个急剧下降的趋势。这是由于油滴在分裂成2个部分时需要很大的作用力,所以PVDF膜和双疏膜的力曲线出现一个峰值;当油滴从Janus膜表面撤离时,Janus膜对油滴没有产生吸引力,因此,力曲线没有出现一个大的峰值。

油-滴力学探针实验得到的油-膜作用力值能定量说明膜样品抗污染能力的大小。如图10(b)所示,3种膜中双疏膜对油滴的最大吸引力值最大,约为409 μN;而Janus膜对油滴的最大吸引力仅为131 μN,说明油滴不易黏附在Janus膜上。基线转移值代表了探针离开膜表面之后,探针上油滴的残留量。Janus膜的基线转移值明显比另外2种膜的要小,双疏膜的基线转移值最大。因此,油-滴力学探针实验结果亦表明Janus膜对油类物质具有优异的抗污染能力。

2) Janus膜的脱盐性能良好。在50 h的DCMD运行过程中,Janus膜对高盐废水的截盐率可维持在100%,膜通量保持在10.18 kg·(m2·h)?1。

3) Janus膜对低表面能液体具有良好的抗润湿性能。以含不同浓度SDS的NaCl(35 g·L?1)为进料液的DCMD过程中,Janus膜通量保持稳定,截盐率可达99.99%。

4) Janus膜对高盐含油废水表现出良好的抗污染能力。经过持续24 h 的DCMD运行后,Janus膜的渗透通量均保持稳定,截盐率保持在99.99%以上,表明Janus膜兼具抗润湿和抗污染的能力。油滴力学探针测试表明Janus膜对油滴的最大吸引力仅为131 μN,且其基线转移值远小于PVDF膜和双疏膜。此结果定量证实了Janus膜具有优异的抗油污性能。

参考文献

下载:

下载:

点击查看大图

点击查看大图