摘要/Abstract

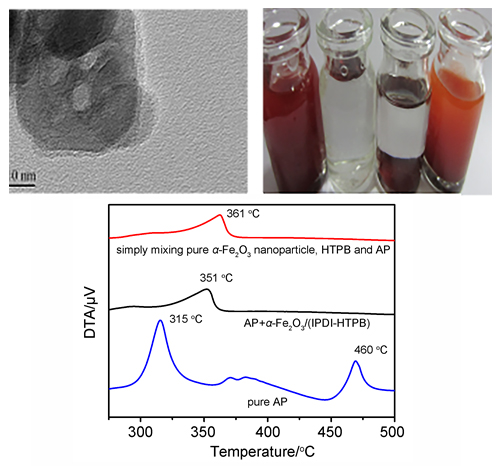

为改善纳米α-Fe2O3在复合推进剂中的分散性,提高其催化性能,选择推进剂的配方组分固化剂异氟尔酮二异氰酸酯(IPDI)为嫁接桥梁,将端羟基聚丁二烯(HTPB)接枝在纳米α-Fe2O3粒子的表面,制得纳米α-Fe2O3/(IPDI-HTPB)复合粒子.首先研究了IPDI与HTPB反应动力学,优化制备条件;然后采用X射线衍射仪(XRD)、透射电子显微镜(TEM)、傅里叶变换红外光谱仪(FTIR)和热重分析(TGA)等手段对复合粒子的结构进行表征,采用DTA对比了复合前后纳米α-Fe2O3粒子对高氯酸铵(AP)热分解的催化性能的影响.结果表明,依靠IPDI的偶联作用,可将HTPB接枝在纳米α-Fe2O3的表面,包覆层厚度约为5 nm,改性后的纳米α-Fe2O3/(IPDI-HTPB)复合粒子的分散性大幅提高,纳米α-Fe2O3/(IPDI-HTPB)复合粒子对AP的热分解的催化性能也明显优于纯纳米α-Fe2O3粒子.

关键词: α-Fe2O3, 端羟基聚丁二烯(HTPB), 纳米复合粒子, 催化性能

In ammonium perchlorate (AP) based composite propellants, α-Fe2O3 nanoparticles and hydroxyl terminated polybutadiene (HTPB) are commonly used as catalyst and binder respectively. Their properties and dispersion significantly affect the combustion performance of the composite propellants. However, α-Fe2O3 nanoparticles are hard to disperse uniformly in the binder HTPB owing to the high viscosity, which will decrease their catalytic activity. Directly composite processing of α-Fe2O3 nanoparticles with other main components of composite propellants may be an effective strategy to prevent from aggregation without introducing other components to the solid propellant at the same time. In this paper, the α-Fe2O3/ (IPDI-HTPB) composite nanoparticles were prepared by choosing curing agent isophorone diisocyanate (IPDI) as grafting bridge. The typical procedure was as follows: (1) The first step was to synthesize IPDI-HTPB. In order to adjudged the reaction terminal point of IPDI and HTPB, the reaction kinetics of HTPB and IPDI were first researched and the proper reaction conditions were chosen as follows:molar ratio of HTPB and IPDI is 1:1, reaction temperature is under 80℃ and reaction time is 2 h. (2) The second step was to synthesize α-Fe2O3/(IPDI-HTPB) composite nanoparticles. Firstly, the stoichiometric α-Fe2O3 nanoparticles were dispersed in toluene under ultrasound for 10 min. Secondly, the mixture were added in the above IPDI-HTPB solution and the reaction kept for 4 h. Thirdly, the α-Fe2O3/(IPDI-HTPB) composite nanoparticles were centrifuged and washed with toluene and ether for several times. Finally, α-Fe2O3/(IPDI-HTPB) composite nanoparticles were dried in the oven at 80℃ for 12 h. (3) The structure of α-Fe2O3/(IPDI-HTPB) composite nanoparticles were characterized by X-ray diffractometer (XRD), transmittance electron microscopy (TEM), Fourier transform infrared spectrometer (FTIR) and thermogravimetric analysis (TGA). It was observed that HTPB could be chemically coated on the surface of the α-Fe2O3 nanoparticles by the grafting activity of IPDI. The depth of the IPDI-HTPB was nearly 5 nm. The α-Fe2O3/(IPDI-HTPB) composite nanoparticles showed hydrophobicity after the composite process. Compare with the pure α-Fe2O3 nanoparticles, α-Fe2O3 nanoparticles in α-Fe2O3/IPDI-HTPB composite nanoparticles showed better catalytic activity on the thermal decomposition of AP.

Key words: α-Fe2O3 nanoparticles, hydroxyl terminated polybutadiene (HTPB), composite nanoparticles, catalytic activity

PDF全文下载地址:

点我下载PDF