摘要/Abstract

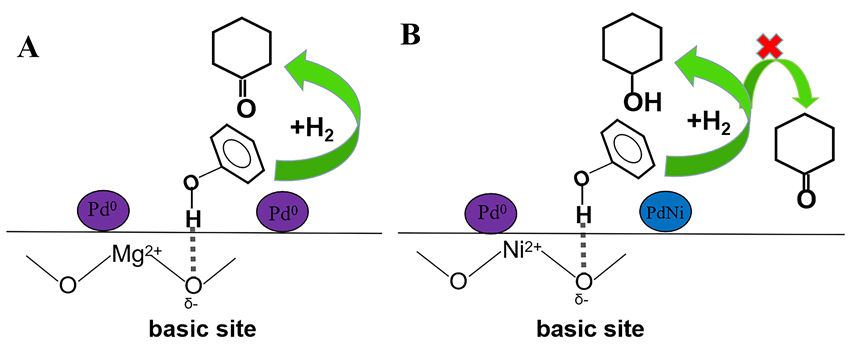

环己酮是合成尼龙等材料的重要中间体, 但苯酚直接加氢反应制备环己酮容易生成环己醇而降低收率. 采用原位生长策略制备Pd/MgAl-LDO@Al2O3催化剂, 并用于苯酚选择性加氢反应, 获得的催化剂在高底物比条件具有良好的催化性能, 相较于Pd/Al2O3催化剂, Pd/MgAl-LDO@Al2O3催化剂使苯酚转化率显著增加, 苯酚转化率在97%时环己酮选择性可达88%. 利用X射线衍射(XRD)、程序升温脱附(TPD)、高分辨透射电子显微镜(HRTEM)和X射线光电子能谱(XPS)等手段对催化剂结构进行表征发现在氧化铝上原位生长类水滑石结构能够优化催化剂孔结构并提高活性组分分散度, 且增加了载体表面碱位点的强度, 碱位点的存在影响了苯酚的吸附形式, 从而大幅增加环己酮的选择性. 此外, 当将Ni引入层状结构时, 通过NaBH4的还原可获得PdNi合金结构. 动力学研究表明, 由于PdNi合金的形成, Pd/NiAl-LDO@Al2O3催化剂苯酚加氢反应的能垒低于Pd/MgAl-LDO@Al2O3, 同时合金结构导致环己酮选择性的明显降低.

关键词: 苯酚选择性加氢, 环己酮, 高底物比, 原位生长, 碱位点

Cyclohexanone is an important intermediate for the synthesis of nylon, but the direct hydrogenation reaction of phenol to cyclohexanone can easily generate cyclohexanol. In this paper, the in situ synthesis strategy is used to grow the layered double hydrotalcites on alumina. Compared with the pristine alumina, the modified support has increased specific surface area, average pore size and abundant acid-base sites on the surface. Pd/MgAl-LDO@Al2O3 catalyst was then prepared by the calcination of precursor with layered structure, followed by the impregnation of Pd. The catalyst is used for the selective hydrogenation of phenol (reaction conditions: phenol/Pd=1000 mol/mol, 80 ℃, 0.4 MPa H2). The obtained Pd/MgAl-LDO@Al2O3 shows enhanced catalytic performance under a high substrate/Pd ratio. Detailly, when the phenol conversion is 97%, the cyclohexanone selectivity can reach 88%. High-resolution transmission electron microscopy (HRTEM) and X-ray photoelectron spectroscopy (XPS) analysis are performed to characterize the catalyst, and it is found that in situ growth of hydrotalcite-like structure on alumina can effectively decrease the average particle size of Pd and then increase the dispersion of active component. Moreover, when Ni is introduced into the layered structure, PdNi alloy structure could be obtained by the easy reduction process of using NaBH4. Kinetics study indicates the energy barrier of the phenol hydrogenation reaction over Pd/NiAl-LDO@Al2O3 is lower than that over Pd/MgAl-LDO@Al2O3 due to the formation of PdNi alloy. But the alloy structure leads to an obvious decrease of cyclohexanone selectivity. According to the product distribution and characterization results, a possible mechanism is proposed. Phenol is adsorbed on the surface of the basic sites on the Pd/MgAl-LDO@Al2O3 catalyst in a non-coplanar manner, which is conducive to the selective hydrogenation of phenol to produce cyclohexanone and inhibits the over-hydrogenation of cyclohexanone. After repeated use for 5 times, the Pd/MgAl-LDO@Al2O3 catalyst shows excellent stability. The phenol conversion could keep at ca. 90% and the cyclohexanone selectivity maintains ca. 90%.

Key words: selective hydrogenation of phenol, cyclohexanone, high substrate/Pd ratio, in situ growth, basic site

PDF全文下载地址:

点我下载PDF