摘要/Abstract

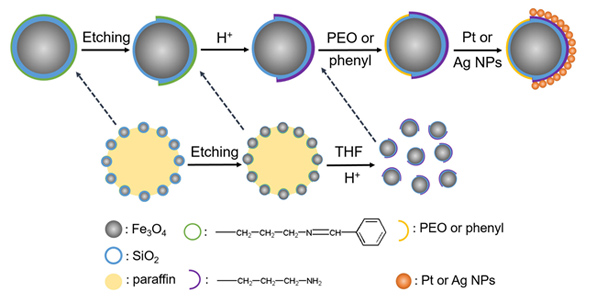

采用溶剂热法和溶胶-凝胶法制备了顺磁性Fe3O4@SiO2颗粒,以Pickering乳液界面保护法实现颗粒表面分区获得Fe3O4@SiO2 Janus颗粒,进一步选区复合生长Pt或Ag纳米颗粒制备Fe3O4@SiO2-Pt和Fe3O4@SiO2-Ag Janus颗粒.Fe3O4@SiO2-Pt Janus颗粒的Pt一侧进行催化过氧化氢的反应,具有自驱动功能.因其顺磁性和两亲性,Fe3O4@SiO2-Ag Janus颗粒能够作为磁响应颗粒乳化剂稳定油水乳液,并将Ag的催化功能引入界面.

关键词: Janus颗粒, 磁响应, 自驱动, 固体乳化剂, 催化

Fe3O4@SiO2 particles were synthesized by a solvothermal method and a classical stÖber method. Superparamagnetic Fe3O4 was the core, and a sol-gel coating of SiO2 was the shell. After the SiO2 surface was modified with amino groups, benzaldehyde was conjugated to the particles by a Schiff base reaction. The Fe3O4@SiO2 particles were emulsified in paraffin/water as a solid emulsifier to obtain an oil-in-water Pickering emulsion. After cooling the paraffin, the particles were fixed on the surface of the emulsion droplets. The particles were etched in ammonium fluoride aqueous solution, and Janus particles with different structures could be obtained by adjusting the etching time. Via the in situ growth of metal Pt or Ag nanoparticles, superparamagnetic Fe3O4@SiO2-Pt or Fe3O4@SiO2-Ag Janus particles were obtained. The movement of Fe3O4@SiO2-Pt Janus particles was observed due to the catalytic decomposition of hydrogen peroxide aqueous solution. It was found that in the short term, there was a linear motion, while in the long term, the motion direction and trajectory were random. Fe3O4@SiO2-Ag Janus particles were used as magnetic solid surfactants to stabilize the emulsions and catalyze the nitro reduction. About 60% of the surficial area of the Janus particles was modified by phenyl groups, while the remaining 40% was covered with Ag nanoparticles. Under the premise of maintaining the Janus balance, the whole particle became more hydrophobic, which was conducive to the formation of the water-in-oil emulsion. In addition, the Ag side of the Janus particles was towards the aqueous phase, and the opposite hydrophobic side was towards the oil phase. The Janus particles possessed a fixed orientation assembly at the oil-water interface. The assemble membrane possessed Janus characteristics, and it facilitated the stable dispersion of the emulsion and the catalysis. The method has the advantages of a simple principle, capability for mass production, universality and versatility. It is expected that Janus particles will be used to more precisely regulate the zoning with different functional substances.

Key words: Janus particle, magnetic response, self-driven, solid emulsifier, catalysis

PDF全文下载地址:

点我下载PDF