西安交通大学动力工程多相流国家重点实验室, 西安 710049

2016年04月25日 收稿; 2016年05月20日 收修改稿

基金项目: 国家自然科学基金(51276140)资助

通信作者: 白博峰, E-mail:bfbai@mail.xjtu.edu.cn

摘要: 为揭示气液螺旋环状流界面波失稳机理,基于经典的Kelvin-Helmholtz不稳定性理论,利用双流体模型,建立螺旋涡流作用下界面波的动力学模型。通过求解界面波色散方程,给出界面失稳的准则并进行理论验证。研究表明,界面波的增长特性决定于气动力、离心力和表面张力的相互作用。其中,不同气液动压相对大小条件下,离心力对界面波稳定性存在三重影响。基于此准则条件,系统分析气流速度、旋流强度及管径对界面波增长特性的影响规律。

关键词: 螺旋环状流界面波K-H不稳定性稳定准则

Instability mechanism of interfacial waves in swirling annular gas-liquid flow

LIU Li, BAI Bofeng

State Key Laboratory of Multiphase Flow in Power Engineering, Xi'an Jiaotong University, Xi'an 710049, China

Abstract: To reveal the mechanism of interfacial wave instability in swirling annular gas-liquid flow, a theoretical model for interfacial waves is established based on the Kelvin-Helmholtz instability theory and the two-fluid model. The dispersion equation is derived, and the interfacial stability criterion is obtained and verified analytically. Results indicate that the interplay of aerodynamic, centrifugal, and surface tension forces gives rise to interfacial instability. Specially, the centrifugal force acting on the interface has triple effects on the stability, depending on the relative magnitudes of gas/liquid dynamic pressures. Effects of gas velocity, swirl intensity, and cylinder curvature on the growth characteristics of the interfacial waves are examined in detail.

Key words: swirling annular flowinterfacial waveK-H instabilitystability criterion

螺旋环状流是垂直管内的一种重要流型,广泛存在于石油、化工与核能等工业领域。例如,传统的气液分离系统[1-4]、气液强化换热系统[5-9]以及非常规油气田的开发利用[10]等。螺旋环状流中,中心高速螺旋气流与管壁螺旋液膜存在相对运动,由于不稳定性扰动的影响,引起气液各相流动结构和状态改变,导致液膜表面出现波动并发展成波动的液膜流动。深入了解液膜流动的水动力特性及其稳定性,研究其失稳过程、机理和控制条件是两相旋流技术应用推广的关键。

螺旋涡流作用下环状流的稳定性,其核心问题是管壁螺旋液膜与高速螺旋气流之间界面波的稳定性。与传统环状流不同,螺旋环状流中,两相螺旋流场诱导附加离心力作用于相界面,改变界面力平衡条件及相间作用机理,其特殊性将对界面波的动力学特性产生重要影响。

本文基于Kelvin-Helmholtz不稳定性理论,利用双流体模型,考虑旋流的影响,通过分析气液各相作用于相界面的受力平衡,建立螺旋涡流作用下环状流中界面波的动力学模型;采用特征根分析方法,获得界面失稳的临界条件,提出稳定性判断准则;基于此准则条件,系统分析气流速度、旋流强度及管径对液膜流动稳定性的影响规律。

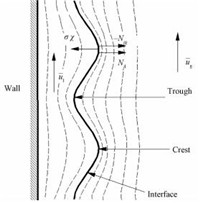

1 数理模型如图 1所示,管壁液膜在中心高速螺旋气流作用下沿竖直管道向上螺旋流动。圆管半径为Ro,液膜厚度平均值为δ。θ为螺旋流动方向与轴向的夹角,反映旋流强度的影响。理论分析时,作以下基本假设:

Fig. 1

| Download: JPG larger image |

图 1 螺旋环状流结构示意图 Fig. 1 Geometric configuration of the swirling annular two-phase flow | |

1)?液膜厚度与管径相比足够小,

2)?流体为稳态、无黏、不可压缩流动;

3)?气液流场充分发展,忽略速度耗散。

1.1 界面的扰动根据图 2所示界面波结构示意图,假设气液两相为均匀无黏流动,界面波斜率足够小,相界面存在一个小扰动?,则界面波方程[11]可表示为

Fig. 2

| Download: JPG larger image |

图 2 界面结构示意图 Fig. 2 Structure of the wavy interface | |

| $y = \hat y\cos k\left( {s - ct} \right),$ | (1) |

通常,波速c可以表示成复数的形式,即c=cR+icI,因此,界面方程又可表示为

| $y = \hat y\cos k\left( {s - {c_{\text{R}}}t} \right){{\text{e}}^{k{c_{\text{I}}}t}}.$ | (2) |

βI>0时,界面波波幅随时间呈指数增大,扰动增加,流动处于不稳定状态;

βI < 0时,界面波波幅随时间呈指数减小,扰动衰减,流动为稳定状态;

βI=0时,界面波波幅保持不变,扰动稳定不变,为中性稳定条件。

因此,界面波的稳定性问题决定于流体的流动参数及物性参数,对于给定的波数k,通过计算波速虚部正负以判断流动的稳定性。

1.2 不稳定性分析1.2.1 气相场对于螺旋环状流中的气相场,首先,将三维螺旋运动分解为2个分运动:柱坐标系下的环状流叠加极坐标系下的圆周运动。在环状流分析基础上,得到气相场作用于相界面的正应力;然后,将圆周运动诱导产生的离心力作为附加正应力叠加到环状流分析结果上;最终得到螺旋环状流中气相场作用于相界面的总正应力大小。

1)?环状流

假设气相场为轴对称不可压缩流动,忽略气流黏性的影响及在管内的速度耗散,圆柱坐标系下的气相控制方程[11]可以简化为

| $\begin{array}{*{20}{c}} {\frac{1}{r}\frac{\partial }{{\partial r}}\left( {r{u_r}} \right) + \frac{{\partial {u_z}}}{{\partial z}} = 0,} \\ {{u_r}\frac{{\partial {u_r}}}{{\partial r}} + {u_z}\frac{{\partial {u_r}}}{{\partial z}} = - \frac{1}{{{\rho _{\rm{g}}}}}\frac{{\partial p}}{{\partial r}},} \\ {{u_r}\frac{{\partial {u_z}}}{{\partial r}} + {u_z}\frac{{\partial {u_z}}}{{\partial z}} = - \frac{1}{{{\rho _{\rm{g}}}}}\frac{{\partial p}}{{\partial z}}.} \end{array}$ | (3) |

| $\begin{gathered} \psi = \bar \psi \left( r \right) + \hat \psi \left( r \right){{\text{e}}^{{\text{i}}kz}}, \hfill \\ p = \bar p\left( z \right) + \hat p\left( r \right){{\text{e}}^{{\text{i}}kz}}. \hfill \\ \end{gathered} $ | (4) |

因此,轴向速度uz和径向速度ur可分别表示为

| ${u_z} = \frac{1}{r}\frac{{\partial \psi }}{{\partial r}},{u_r} = - \frac{1}{r}\frac{{\partial \psi }}{{\partial z}}.$ | (5) |

| ${{\bar u}_z}\frac{{D\hat \psi }}{r} - D{{\bar u}_z}\frac{{\hat \psi }}{r} = - \frac{{\hat p}}{{{\rho _{\text{g}}}}},$ | (6) |

| ${k^2}{{\bar u}_z}\frac{{\hat \psi }}{r} = - \frac{{D\hat p}}{{{\rho _{\text{g}}}}}.$ | (7) |

对式 (6) 求偏导后联立式 (7) 消去压力扰动项,得到柱坐标系下的Orr-Sommerfeld方程

| $\begin{array}{*{20}{c}} {\left( {{{\bar u}_z} - {c_z}} \right)\left( {{D^2}\hat \psi - \frac{{D\hat \psi }}{r} - {k^2}\hat \psi } \right) + } \\ {\left( {\frac{{\partial {u_z}}}{{\partial r}} - {D^2}{u_z}} \right)\hat \psi = 0.} \end{array}$ | (8) |

当气相轴向平均速度uz趋近于界面波速cz时,上述方程中的第2项决定了临界层的影响[11-12]。在K-H不稳定分析中,认为气相场平均轴向速度uz在运动过程中基本保持不变,因此可以得到关于流函数ψ的微分方程

| ${D^2}\hat \psi - \frac{{D\hat \psi }}{r} - {k^2}\hat \psi = 0.$ | (9) |

| $\hat \psi = Ar{I_1}\left( {kr} \right) + Br{{\text{K}}_1}\left( {kr} \right),$ | (10) |

根据式 (5)、式 (10),径向速度分量可表示为

| ${u_r} = - {\text{i}}k\left[ {A{{\text{I}}_1}\left( {kr} \right) + B{{\text{K}}_1}\left( {kr} \right)} \right]{{\text{e}}^{{\text{i}}kz}}.$ | (11) |

| ${u_r} = - {\text{i}}kA{{\text{I}}_1}\left( {kr} \right){{\text{e}}^{{\text{i}}kz}}.$ | (12) |

| ${u_r} = \left( {{{\bar u}_z} - {c_z}} \right)\frac{{\partial {r_i}}}{{\partial z}} = {\text{i}}k\hat \delta \left( {{{\bar u}_z} - {c_z}} \right){{\text{e}}^{{\text{i}}kz}},$ | (13) |

| ${r_i} = \left( {{R_{\text{o}}} - \bar \delta } \right) + \hat \delta {{\text{e}}^{{\text{i}}kz}},$ | (14) |

由式 (12)、式 (13) 得到常数

| $\hat \psi \left( r \right) = - \hat \delta \left( {{{\bar u}_z} - {c_z}} \right)\frac{{r{{\text{I}}_1}\left( {kr} \right)}}{{{{\text{I}}_1}\left( {k{{\bar r}_i}} \right)}}.$ | (15) |

| ${\left( {{{\hat N}_{ig}}} \right)_1} = - k\hat \delta {\rho _{\text{g}}}{\left( {{{\bar u}_z} - {c_z}} \right)^2}.$ | (16) |

忽略气相黏性的影响及在管内的速度耗散,极坐标系下气相圆周运动的控制方程[13]可以表示为:

| $\begin{gathered} \frac{1}{r}\frac{\partial }{{\partial r}}\left( {r{u_r}} \right) + \frac{1}{r}\frac{{\partial {u_\theta }}}{{\partial \theta }} = 0, \hfill \\ {u_r}\frac{{\partial {u_r}}}{{\partial r}} + \frac{{{u_\theta }}}{r}\frac{{\partial {u_r}}}{{\partial \theta }} - \frac{{u_\theta ^2}}{r} = - \frac{1}{{{\rho _{\text{g}}}}}\frac{{\partial p}}{{\partial r}}, \hfill \\ {u_r}\frac{{\partial {u_\theta }}}{{\partial r}} + \frac{{{u_\theta }}}{r}\frac{{\partial {u_\theta }}}{{\partial \theta }} + \frac{{{u_r}{u_\theta }}}{r} = - \frac{1}{{{\rho _{\text{g}}}}}\frac{{\partial p}}{{r\partial \theta }}. \hfill \\ \end{gathered} $ | (17) |

| $\begin{gathered} \psi = \bar \psi \left( r \right) + \hat \psi \left( r \right){{\text{e}}^{{\text{i}}m\theta }}, \hfill \\ p = \bar p\left( \theta \right) + \hat p\left( r \right){{\text{e}}^{{\text{i}}m\theta }}. \hfill \\ \end{gathered} $ | (18) |

周向速度uθ及径向速度ur可分别表示为

| ${u_r} = \frac{1}{r}\frac{{\partial \psi }}{{\partial \theta }},{u_\theta } = - \frac{{\partial \psi }}{{\partial r}}.$ | (19) |

| ${\left( {{{\hat N}_{ig}}} \right)_2} = - \left[ {{\rho _{\text{g}}}\hat \delta m\frac{{{{\left( {{{\bar u}_\theta } - {c_\theta }} \right)}^2}}}{{{{\bar r}_i}}} + {\rho _{\text{g}}}\hat \delta \frac{{\bar u_\theta ^2}}{{{{\bar r}_i}}}} \right].$ | (20) |

| ${\left( {{{\hat N}_{ig}}} \right)_2} = - \left[ {{\rho _{\text{g}}}\hat \delta k{{\left( {{{\bar u}_\theta } - {c_\theta }} \right)}^2} + {\rho _{\text{g}}}\hat \delta \frac{{\bar u_\theta ^2}}{{{{\bar r}_i}}}} \right].$ | (21) |

| $\begin{gathered} {{\hat N}_{ig}} = {\left( {{{\hat N}_{ig}}} \right)_1} + {\left( {{{\hat N}_{ig}}} \right)_2} \hfill \\ \;\;\;\;\;\; = - {\rho _{\text{g}}}k\hat \delta {\left( {{{\bar u}_\theta } - {c_\theta }} \right)^2} - \frac{{{\rho _{\text{g}}}\hat \delta {{\left( {\sin \theta } \right)}^2}\bar u_{\text{g}}^2}}{{{{\bar r}_i}}}, \hfill \\ \end{gathered} $ | (22) |

| $\begin{gathered} {{\bar u}_z} = \bar u\cos \theta ,{c_z} = c\cos \theta , \hfill \\ {{\bar u}_\theta } = \bar u\sin \theta ,{c_\theta } = c\sin \theta . \hfill \\ \end{gathered} $ | (23) |

| $\begin{gathered} \frac{{\partial {u_y}}}{{\partial y}} + \frac{{\partial {u_s}}}{{\partial s}} = 0, \hfill \\ {u_y}\frac{{\partial {u_y}}}{{\partial y}} + {u_z}\frac{{\partial {u_y}}}{{\partial z}} + \frac{{u_\theta ^2}}{{{{\bar r}_i}}} = - \frac{1}{{{\rho _1}}}\frac{{\partial p}}{{\partial y}}, \hfill \\ {u_y}\frac{{\partial {u_z}}}{{\partial y}} + {u_z}\frac{{\partial {u_z}}}{{\partial z}} = - \frac{1}{{{\rho _l}}}\frac{{\partial p}}{{\partial z}}. \hfill \\ \end{gathered} $ | (24) |

与气相场类似的分析方法,得到液膜作用于相界面y=δ的正应力扰动量

| ${{\hat N}_{i{\text{l}}}} = \frac{{{\rho _1}{k^2}\hat \delta \bar \delta {{\left( {{{\bar u}_1} - c} \right)}^2}}}{2} - \frac{{{\rho _1}\hat \delta {{\left( {\sin \theta } \right)}^2}\bar u_1^2}}{{{{\bar r}_i}}}.$ | (25) |

| ${N_{ig}} = {{\bar N}_{ig}} + \left[ { - {\rho _{\text{g}}}k\hat \delta {{\left( {{{\bar u}_g} - c} \right)}^2} - \frac{{{\rho _g}\hat \delta {{\left( {\sin \theta } \right)}^2}\bar u_g^2}}{{{{\bar r}_i}}}} \right]{{\text{e}}^{{\text{i}}kz}},$ | (26) |

| ${N_{i{\text{l}}}} = {{\bar N}_{i{\text{l}}}} + \left[ {\frac{{{\rho _1}{k^2}\hat \delta \bar \delta {{\left( {{{\bar u}_1} - c} \right)}^2}}}{2} - \frac{{{\rho _1}\hat \delta {{\left( {\sin \theta } \right)}^2}\bar u_1^2}}{{{{\bar r}_i}}}} \right]{{\text{e}}^{{\text{i}}kz}}.$ | (27) |

1.3 界面稳定性条件根据界面波波峰处两相正应力与表面张力平衡条件 (图 2),进行界面稳定性分析。

| ${N_{i{\text{l}}}} - {N_{ig}} = \sigma \chi ,$ | (28) |

| $\chi = {k^2}\hat m{{\text{e}}^{{\text{i}}kz}}.$ | (29) |

| $\begin{array}{*{20}{c}} {{\rho _1}{{\left( {{{\bar u}_1} - c} \right)}^2}\frac{1}{2}k\bar \delta + {\rho _{\text{g}}}{{\left( {{{\bar u}_g} - c} \right)}^2} = k\sigma + } \\ {\frac{{{{\left( {\sin \theta } \right)}^2}\left( {{\rho _1}\bar u_1^2 - {\rho _{\text{g}}}\bar u_{\text{g}}^2} \right)}}{{{{\bar r}_i}k}}.} \end{array}$ | (30) |

| ${c_{\text{R}}} = \frac{{\frac{1}{2}k\bar \delta {\rho _1}{{\bar u}_1} + {\rho _{\text{g}}}{{\bar u}_{\text{g}}}}}{{\frac{1}{2}k\bar \delta {\rho _1} + {\rho _{\text{g}}}}},$ | (31) |

| $\begin{array}{*{20}{c}} {{c_1} = \frac{1}{{\frac{1}{2}k\bar \delta {\rho _1} + {\rho _{\text{g}}}}}\left\{ {\frac{1}{2}{\rho _1}{\rho _{\text{g}}}k\bar \delta {{\left( {{{\bar u}_g} - {{\bar u}_1}} \right)}^2} - } \right.} \\ {{{\left. {\left[ {k\sigma + \frac{{{{\left( {\sin \theta } \right)}^2}\left( {{\rho _1}\bar u_1^2 - {\rho _{\text{g}}}\bar u_{\text{g}}^2} \right)}}{{{{\bar r}_i}k}}} \right]\left( {\frac{1}{2}{\rho _1}k\bar \delta + {\rho _{\text{g}}}} \right)} \right\}}^{\frac{1}{2}}}} \end{array}$ | (32) |

| $k\sigma + \frac{{{{\left( {\sin \theta } \right)}^2}\left( {{\rho _1}\bar u_1^2 - {\rho _{\text{g}}}\bar u_{\text{g}}^2} \right)}}{{{{\bar r}_i}k}} > \frac{{\frac{1}{2}{\rho _1}{\rho _{\text{g}}}k\bar \delta {{\left( {{{\bar u}_g} - {{\bar u}_1}} \right)}^2}}}{{\frac{1}{2}{\rho _1}k\bar \delta + {\rho _{\text{g}}}}}.$ | (33) |

当旋流强度θ=0时,准则式同Hewitt和Hall-Taylor[11]给出的传统环状流中液膜流动稳定性准则相同。当式 (33) 中离心力项

2 结果分析2.1 扰动增长特性曲线为深入分析螺旋环状流中界面波的动力学特性,计算结果给出工质为空气-水的流动稳定性特征曲线,包括扰动增长率特性曲线、中性稳定性曲线和最快速波特性曲线,并系统分析气速、旋流强度及管径对界面波稳定性的影响规律。

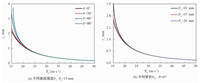

图 3给出一定液膜流速ul=1.72 m/s和波长λ=10 mm,不同旋流强度θ和管径Ro条件下,扰动增长率βI随气速ug的变化曲线。由图可知,存在临界气速ugc=49.5 m/s将液膜的流动分为2个特征区域:当ug < ugc时,离心力对液膜流动为稳定因素,这时离心力越大,即旋流强度θ越大、管径Ro越小,扰动增长率βI越小,液膜流动稳定性增强;相反,当ug>ugc时,离心力转变为不稳定作用力,不稳定离心力与气液相对运动的气动力共同作用加剧了液膜流动的不稳定性。此外,由图可知,当气速较小时,θ越大、Ro越小,对应起稳定作用的离心力越大,此时,离心力与表面张力的稳定作用足以克服不稳定气动力,βI小于0,界面扰动衰减,液膜流动趋于稳定。

Fig. 3

| Download: JPG larger image |

图 3 界面波扰动增长率特性曲线 Fig. 3 Characteristic curves of the wave growth rate | |

2.2 中性稳定性曲线当扰动增长率βI=0时,对应的波长称为临界波长λc。而λc-ug曲线称为中性稳定曲线。在中性稳定曲线上,扰动稳定不变,液膜流动处于临界稳定状态;一旦有扰动触发,流动状态随时可能改变,进入稳定区域或不稳定区域。中性稳定曲线下方,界面波波长小于临界值,扰动增长率βI小于0,扰动衰减,为稳定流动区;在中性稳定曲线上方,βI始终大于0,扰动增大,为不稳定流动区。图 4给出不同旋流强度θ和管径Ro条件下的中性稳定曲线。由图可知,一定液速下,λc随着ug的增大而急剧减小。当气速较小时,起稳定作用的离心力对中性稳定波有重要影响,θ越大、Ro越小,波长临界值λc越大,中性稳定曲线上移,稳定区域变大,液膜流动稳定性增强;随着气速的增大,离心力对界面波稳定作用逐渐减弱直至消失并转变为不稳定影响,此时,界面波主要受不稳定气动力控制,因此,旋流强度θ和管径Ro对中性稳定波的影响可忽略。

Fig. 4

| Download: JPG larger image |

图 4 中性稳定性曲线 Fig. 4 Neutral stability curves | |

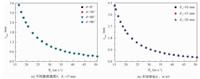

2.3 最快速波特性曲线当扰动增长率达到最大值 (βI)max时,界面波处于最不稳定状态,气液相界面极易失稳破碎。此时,界面波称为最快速波或最危险波。图 5给出不同旋流强度θ和管径Ro条件下,最快速波波长λmax的特性曲线。与中性稳定曲线相同 (图 5),λmax随气速的增大而急剧减小。然而,当气速较小时,旋流强度θ和管径Ro对最不稳定状态的界面波波长没有影响,即离心力不改变界面波失稳破裂时对应的波长大小,气液相对运动的气动力是控制界面波失稳的主导作用力。

Fig. 5

| Download: JPG larger image |

图 5 最快速波波长特性曲线 Fig. 5 Characteristic curves for the wavelengths of the most unstable waves | |

3 结论螺旋环状流中,两相螺旋涡流通过不同旋流强度下离心力的作用重新分配相界面处力平衡关系,对液膜流动的水动力特性及其稳定性产生重要影响。本文利用Kelvin-Helmholtz不稳定性理论及双流体模型,考虑旋流的影响,通过分析气液两相作用于相界面的力平衡条件,建立螺旋涡流作用下界面波的动力学模型,获得界面失稳的临界条件和稳定性判断准则,并与现有的理论模型进行对比验证。基于本文提出的准则条件,系统分析气速、旋流强度及管径的影响规律,得到螺旋涡流对界面波稳定性的影响取决于气液两相动压相对大小这一重要认识。主要结论如下:

1)?对一定的液膜流速,当气速小于临界值时,离心力为稳定作用力,旋流强度越大、管径越小,界面波越稳定;当气速大于临界值时,离心力为不稳定作用力;旋流强度越大、管径越小,界面波越不稳定;当气速等于临界值时,离心力对界面波的稳定性不产生影响。

2)?临界波长随着气速的增大而急剧减小,当气速较小时,旋流强度越大、管径越小,波长临界值越大,中性稳定曲线上移,稳定区域变大,液膜流动稳定性增强;随着气速的持续增大,旋流强度和管径对中性稳定波的影响逐渐减弱至可忽略。

3)?最快速波波长随气速的增大而急剧减小,在不同气速条件下,旋流强度和管径对最不稳定状态的界面波波长不产生影响。

参考文献

| [1] | Kataoka H, Tomiyama A, Hosokawa S, et al. Two-phase swirling flow in a gas-liquid separator[J].Journal of Power and Energy Systems, 2008, 2(4):1120–1131.DOI:10.1299/jpes.2.1120 |

| [2] | Kataoka H, Shinkai Y, Hosokawa S, et al. Swirling annular flow in a steam separator[J].Journal of Engineering for Gas Turbines and Power, 2009, 131(3):1–7. |

| [3] | Kataoka H, Shinkai Y, Tomiyama A. Pressure drop in two-phase swirling flow in a steam separator[J].Journal of Power and Energy Systems, 2009, 3(2):382–392.DOI:10.1299/jpes.3.382 |

| [4] | Kataoka H, Shinkai Y, Tomiyama A. Effects of swirler shape on two-phase swirling flow in a steam separator[J].Journal of Power and Energy Systems, 2009, 3(2):347–355.DOI:10.1299/jpes.3.347 |

| [5] | Fryer P J, Whalley P B. The effect of swirl on the liquid distribution in annular two-phase flow[J].International Journal of Multiphase Flow, 1982, 8(3):285–289.DOI:10.1016/0301-9322(82)90037-4 |

| [6] | Bas H, Ozceyhan V. Heat transfer enhancement in a tube with twisted tape inserts placed separately from the tube wall[J].Experimental Thermal and Fluid Science, 2012, 41(3):51–58. |

| [7] | Chang L M, Wang L B, Song K W, et al. Numerical study of the relationship between heat transfer enhancement and absolute vorticity flux along main flow direction in a channel formed by a flat tube bank fin with vortex generators[J].International Journal of Heat and Mass Transfer, 2009, 52(7):1794–1801. |

| [8] | Song K W, Wang Y, Zhang Q, et al. Numerical study of the fin efficiency and a modified fin efficiency formula for flat tube bank fin heat exchanger[J].International Journal of Heat and Mass Transfer, 2011, 54(11):2661–2672. |

| [9] | Li J, Wang S F, Chen J F, et al. Numerical study on a slit fin-and-tube heat exchanger with longitudinal vortex generators[J].International Journal of Heat and Mass Transfer, 2011, 54(9):1743–1751. |

| [10] | Molina R, Wang S, Gomez L E, et al. Wet gas separation in gas-liquid cylindrical cyclone separator[J].Journal of Energy Resources Technology, 2008, 130(4):130–134. |

| [11] | Hewitt G F, Hall-Taylor N. Annular two-phase flow[M].Oxford: Pergamon, 1970: 110-117. |

| [12] | Miesen R, Beijnon G, Duijvestijn P E M, et al. Interfacial waves in core-annular flow[J].Journal of Fluid Mechanics, 1992, 238(5):97–117. |

| [13] | Liu L, Bai B F. Interfacial stability in vertical swirling annular two-phase Flow[C]//NURETH-16, Chicago, IL UAS, Aug 29-Sep 6, 2015. |

| [14] | Matas J P, Hong M, Cartellier A. Stability of a swirled liquid film entrained by a fast gas stream[J].Physics of Fluids, 2014, 26(4):042108.DOI:10.1063/1.4871395 |

| [15] | Jeon J, Hong M, Han Y M, et al. Experimental study on spray characteristics of gas-centered swirl coaxial injectors[J].Journal of Fluids Engineering, 2011, 133(12):121303.DOI:10.1115/1.4005344 |

| [16] | Im J H, Cho S, Yoon Y, et al. Comparative study of spray characteristics of gas-centered and liquid-centered swirl coaxial injectors[J].Journal of Propulsion and Power, 2010, 26(6):1196–1204.DOI:10.2514/1.48436 |

| [17] | Barnea D, Taitel Y. Kelvin-Helmholtz stability criteria for stratified flow:viscous versus non-viscous (inviscid) approaches[J].International Journal of Multiphase Flow, 1993, 19(93):639–649. |

| [18] | Ishii M, Hibiki T. Thermo-fluid dynamics of two-phase flow[M].Springer Berlin, 2011: 48-52. |

| [19] | Rosenthal D K. The shape and stability of a bubble at the axis of a rotating liquid[J].Journal of Fluid Mechanics, 1962, 12(03):358–366.DOI:10.1017/S0022112062000269 |

| [20] | Hocking L M. The stability of a rigidly rotating column of liquid[J].Mathematika, 1960, 7(01):1–9.DOI:10.1112/S0025579300001510 |

| [21] | Pedley T J. The stability of rotating flows with a cylindrical free surface[J].Journal of Fluid Mechanics, 1967, 30(1):127–147.DOI:10.1017/S0022112067001338 |