摘要/Abstract

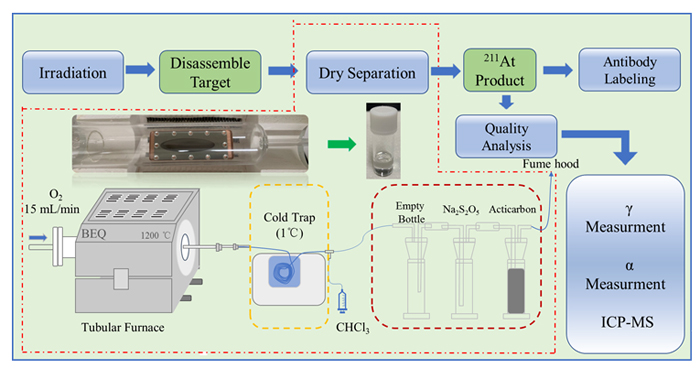

211At, 半衰期7.2 h, 发射的α粒子具有很高的线性传能密度, 是一种理想的靶向α治疗核素. 利用中国科学院近代物理研究所强流超导直线加速器提供的α束流辐照Bi靶生产211At, 系统考察了加速器生产211At的整个流程, 包括加速器辐照、干蒸馏分离、质量分析以及单抗标记. 研究结果表明, 干蒸馏分离211At的总收率最高达78.53%, 获得的固体211At产品具有极高的比活度、核纯度以及化学纯度, 其中杂质元素Bi、Cu、Zn、Al含量均低于100 ng/GBq, 且入射粒子能量低于28.2 MeV时, N(210At)/N(211At)值低于10–5, 研究也实现了211At在尼妥珠单抗上的标记, 标记率高达94.86%. 基于以上研究我们确立了一套简单、高效的分离方法, 为后续我国211At的生产和应用奠定了良好基础.

关键词: 加速器, 医用同位素, 干蒸馏法, 211At, 标记

211At, with a half-life of 7.2 h, is an excellent radionuclide being investigated for use in targeted alpha therapy as the result of very high linear energy transfer. However, the production of 211At is limited by 210At, because 210At decays to produce long half-life (138.4 d) extremely toxic daughter 210Po. The production of 211At via 209Bi(α,2n) nuclear reaction and 210At via 209Bi(α,3n) nuclear reaction, as the energy of incident α-particle increases, the ratio of N(210At)/N(211At) increases. In this research, the α-particle is provided by the Chinese Accelerator Driven Sub-critical System (ADS) Front-end Demo Linac at Institute of Modern Physics, Chinese Academy of Sciences. The technical process of 211At produced was studied systematically, including accelerator irradiation, separation by dry distillation method, quality analysis, and monoclonal antibody labeling. The bismuth targets were irradiated with α-particle by 28.18, 28.34, 28.48 28.92 MeV, and the target chamber adopts an inclined target with water cooling to improve the cooling effect. The dry distillation separation was carried out at a high temperature of 850 ℃, oxygen as the carrier gas, chloroform and ethanol as eluent, and the chloroform solution containing 211At was blow dry with nitrogen. The results showed that the total recovery of dry distillation separation of 211At reached 78.53%. After separation, the quality analysis of 211At was performed using a high-purity Ge-detector, alpha energy spectrometer, and mass spectrometer. The obtained solid 211At had high specific activity, radionuclide purity and chemical purity, where the content of impurity elements Bi, Cu, Zn, and Al was less than 100 ng/GBq, and the ratio of N(210At)/N(211At) was less than 10–5 when the incident particle energy is below 28.2 MeV. Finally, the labeling of 211At-nimotuzumab was realized through N-succinimidyl-3-(trimethylstannyl)benzoate, and the labeling rate was 94.86%. Based on this research, a set of simple and efficient separation methods was established, which laid a good foundation for the subsequent production and application of 211At in China.

Key words: accelerator, medical isotope, dry distillation method, 211At, labeling

PDF全文下载地址:

点我下载PDF