张云峰1,罗兴柏1,孙华刚2,施冬梅1,张玉令1,刘国庆1

(1. 陆军工程大学,石家庄 050000;2. 陆军装备研究院,石家庄 050000)

摘要:

为研究Zr41Ti14Ni12.5Cu10Be22.5非晶合金的冲击压缩响应及物态方程,利用平板冲击试验,测试了受到速度为350 m/s~550 m/s的铜板冲击时,非晶合金试样的自由面粒子速度;采用阻抗匹配法得到了材料的雨贡纽参数,并利用理想混合物模型对材料的雨贡纽参数进行预估,分析对比了理论计算结果与实验结果;将求材料格林艾森物态方程转化为非线性最优化问题,提出了基于模拟退火算法的材料格林艾森物态方程计算方法,设计了退火参数表,并采用解析法计算了材料的布里希-默纳罕物态方程和三项式物态方程,对比研究了三种物态方程与实验结果.理论和实验结果表明,5~10 GPa压力范围内,Zr41Ti14Ni12.5Cu10Be22.5非晶合金的零压体积声速为4 267 m/s,D-u曲线斜率为4.376,曲线斜率远大于一般金属材料,其雨贡纽极限强度为5.60 GPa左右;理想混合物模型仅适用于计算高压区Zr基非晶合金的雨贡纽参数,低压区理论计算结果与实验结果误差较大;在5~10 GPa压力范围内,格林艾森物态方程、三项式物态方程与实验结果吻合度较高,而布里希-默纳罕物态方程误差较大,不适用于计算材料状态参量.

关键词: Zr基非晶合金 物态方程 平板冲击 数值法 模拟退火算法

DOI:10.11918/j.issn.0367-6234.201804141

分类号:O347

文献标识码:A

基金项目:

Theoretical and experimental research of shock compressive behavior of Zr41Ti14Ni12.5Cu10Be22.5 amorphous alloy

ZHANG Yunfeng1,LUO Xingbai1,SUN Huagang2,SHI Dongmei1,ZHANG Yuling1,LIU Guoqing1

(1. Army Engineering University, Shijiazhuang 050000, China;2. Army Equipment Research Institution, Shijiazhuang 050000, China)

Abstract:

The plate-impact experiment was used to measure the response of shock pressure and the equation of state (EOS) of Zr41Ti14Ni12.5Cu10Be22.5 amorphous alloy. The particle velocities of free surface were tested under impact from copper plate with the velocity from 350 m/s to 550 m/s. The Hugoniot parameters of the material were calculated by using impedance matching method, and the experimental results were compared with the computational results calculated by ideal mixture model. The problem to solve the Gruneisen EOS of the material was turned into nonlinear optimization. A novel numerical method based on simulated annealing algorithm was developed to analyze the Gruneisen EOS of the material, and the annealing scheme was designed. The Birch-Murnaghan equation and the Trinomial equation of the material were proposed by analytical method, and compared with Gruneisen EOS and the experimental results. The experimental and theoretical results show that within the pressure between 5 GPa and 10GPa, the zero-pressure volume velocity of Zr41Ti14Ni12.5Cu10Be22.5 amorphous alloy was 4267 m/s, the slope of D-u curve was 4.376, which is much larger than normal metal, and the Hugoniot limit of the material was around 5.6 GPa. The ideal mixture model is only applicable to calculate the Hugoniot parameters of Zr-based amorphous alloy in high-pressure phase, whereas considerable errors will be caused under low pressure. The Gruneisen EOS and Trinomial EOS matched the experimental results well within the pressure between 5 GPa and 10 GPa, while there were major errors between the experimental results and the Birch-Murnaghan equation.

Key words: Zr-based amorphous alloy equation of state (EOS) plate-impact numerical method simulated annealing algorithm

张云峰, 罗兴柏, 孙华刚, 施冬梅, 张玉令, 刘国庆. Zr41Ti14Ni12.5Cu10Be22.5非晶合金冲击压缩行为理论与实验研究[J]. 哈尔滨工业大学学报, 2019, 51(5): 94-99. DOI: 10.11918/j.issn.0367-6234.201804141.

ZHANG Yunfeng, LUO Xingbai, SUN Huagang, SHI Dongmei, ZHANG Yuling, LIU Guoqing. Theoretical and experimental research of shock compressive behavior of Zr41Ti14Ni12.5Cu10Be22.5 amorphous alloy[J]. Journal of Harbin Institute of Technology, 2019, 51(5): 94-99. DOI: 10.11918/j.issn.0367-6234.201804141.

作者简介 张云峰(1990—),男,博士研究生;

罗兴柏(1962—),男,教授,博士生导师;

孙华刚(1979—),男,高级工程师,博士生导师 通信作者 孙华刚,shg_neu@scut.edu.com 文章历史 收稿日期: 2018-04-19

Contents -->Abstract Full text Figures/Tables PDF

Zr41Ti14Ni12.5Cu10Be22.5非晶合金冲击压缩行为理论与实验研究

张云峰1, 罗兴柏1, 孙华刚2

, 施冬梅1, 张玉令1, 刘国庆1

, 施冬梅1, 张玉令1, 刘国庆1 1. 陆军工程大学,石家庄 050000;

2. 陆军装备研究院,石家庄 050000

收稿日期: 2018-04-19

作者简介: 张云峰(1990—),男,博士研究生;

罗兴柏(1962—),男,教授,博士生导师;

孙华刚(1979—),男,高级工程师,博士生导师

通信作者: 孙华刚,shg_neu@scut.edu.com

摘要: 为研究Zr41Ti14Ni12.5Cu10Be22.5非晶合金的冲击压缩响应及物态方程,利用平板冲击试验,测试了受到速度为350 m/s~550 m/s的铜板冲击时,非晶合金试样的自由面粒子速度;采用阻抗匹配法得到了材料的雨贡纽参数,并利用理想混合物模型对材料的雨贡纽参数进行预估,分析对比了理论计算结果与实验结果;将求材料格林艾森物态方程转化为非线性最优化问题,提出了基于模拟退火算法的材料格林艾森物态方程计算方法,设计了退火参数表,并采用解析法计算了材料的布里希-默纳罕物态方程和三项式物态方程,对比研究了三种物态方程与实验结果.理论和实验结果表明,5~10 GPa压力范围内,Zr41Ti14Ni12.5Cu10Be22.5非晶合金的零压体积声速为4 267 m/s,D-u曲线斜率为4.376,曲线斜率远大于一般金属材料,其雨贡纽极限强度为5.60 GPa左右;理想混合物模型仅适用于计算高压区Zr基非晶合金的雨贡纽参数,低压区理论计算结果与实验结果误差较大;在5~10 GPa压力范围内,格林艾森物态方程、三项式物态方程与实验结果吻合度较高,而布里希-默纳罕物态方程误差较大,不适用于计算材料状态参量.

关键词: Zr基非晶合金 物态方程 平板冲击 数值法 模拟退火算法

Theoretical and experimental research of shock compressive behavior of Zr41Ti14Ni12.5Cu10Be22.5 amorphous alloy

ZHANG Yunfeng1, LUO Xingbai1, SUN Huagang2

, SHI Dongmei1, ZHANG Yuling1, LIU Guoqing1

, SHI Dongmei1, ZHANG Yuling1, LIU Guoqing1 1. Army Engineering University, Shijiazhuang 050000, China;

2. Army Equipment Research Institution, Shijiazhuang 050000, China

Abstract: The plate-impact experiment was used to measure the response of shock pressure and the equation of state (EOS) of Zr41Ti14Ni12.5Cu10Be22.5 amorphous alloy. The particle velocities of free surface were tested under impact from copper plate with the velocity from 350 m/s to 550 m/s. The Hugoniot parameters of the material were calculated by using impedance matching method, and the experimental results were compared with the computational results calculated by ideal mixture model. The problem to solve the Gruneisen EOS of the material was turned into nonlinear optimization. A novel numerical method based on simulated annealing algorithm was developed to analyze the Gruneisen EOS of the material, and the annealing scheme was designed. The Birch-Murnaghan equation and the Trinomial equation of the material were proposed by analytical method, and compared with Gruneisen EOS and the experimental results. The experimental and theoretical results show that within the pressure between 5 GPa and 10GPa, the zero-pressure volume velocity of Zr41Ti14Ni12.5Cu10Be22.5 amorphous alloy was 4267 m/s, the slope of D-u curve was 4.376, which is much larger than normal metal, and the Hugoniot limit of the material was around 5.6 GPa. The ideal mixture model is only applicable to calculate the Hugoniot parameters of Zr-based amorphous alloy in high-pressure phase, whereas considerable errors will be caused under low pressure. The Gruneisen EOS and Trinomial EOS matched the experimental results well within the pressure between 5 GPa and 10 GPa, while there were major errors between the experimental results and the Birch-Murnaghan equation.

Keywords: Zr-based amorphous alloy equation of state (EOS) plate-impact numerical method simulated annealing algorithm

非晶态合金是指内部结构中原子呈长程无序排列的合金[1].Zr基非晶合金具有易成型、高强度、高硬度、低杨氏模量、高弹性极限、断裂韧性高等一系列优异的物理力学性能,因而得到广泛的研究和应用[2-3].尤其在军事领域,独特的物理力学性能使其具有光明的应用前景[4-6],因而,对Zr基非晶合金冲击压缩行为及其物态方程的研究显得尤为重要.

在非晶合金的物态方程及冲击压缩性能研究方面,Li Gong[7]研究了Ni77P23非晶合金的压缩行为,并计算了材料的布里希-默纳罕(Birch-Murnaghan)物态方程.Masaru[8]总结了多种非晶合金体积模量与压力间的关系,研究了高压材料的结构预弛现象.J.Q.Wang[9]研究了Yb基非晶合金的压缩性能,结果表明压力对该材料的摩尔比容、体积模量、泊松比等参数的影响显著大于它种非晶合金;对Zr基非晶合金的研究方面,Wei等[10-11]测量了多种Zr基非晶合金的热力学参数,并从热力学参数出发计算了材料的Murnaghan方程.Zhang[12],Pan[13]等依据材料的热力学参数,分别计算了两种Zr基非晶合金基于Debye模型的物态方程.Martin[14],Mashimo等[15]分别研究了Zr57Nb5Cu15.4Ni12.6Al10、Zr55Al10Ni5Cu30两种非晶合金的冲击压缩行为,并发现了Zr基非晶合金冲击压缩曲线的分区现象.目前,国内外学者对非晶合金的高压响应研究成果较为丰硕,但尚无针对Zr41Ti14Ni12.5Cu10Be22.5非晶态合金的冲击响应及其冲击物态方程的相关工作.

本文采用平板冲击实验,研究了Zr41Ti14Ni12.5Cu10Be22.5非晶合金5 GPa~10 GPa压力范围内的冲击压缩行为.求得了材料的雨贡纽(Hugoniot)参数及Hugoniot极限强度,并与理论分析结果对比,得出了理论计算结果的适用范围;提出了基于模拟退火算法计算材料格林艾森(Gruneisen)物态方程的方法,并与解析法计算结果、Birch-Murnaghan物态方程、三项式物态方程结果做了对比研究.

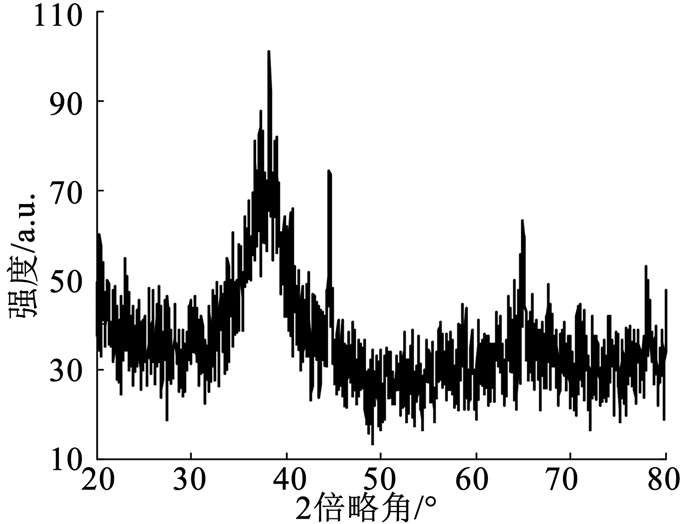

1 试验概况 1.1 材料制备实验对象为Zr41Ti14Ni12.5Cu10Be22.5非晶态合金,选用纯度高于99.5%的Zr,Ti,Ni,Cu,Be高纯金属,清除金属表面氧化膜后,按原子分数进行配置,分别在石油醚溶液,无水乙醇溶液中进行超声波清洗,以去除金属表面的油污以及在配料过程中附着的杂质.在高纯Ar气(99.99 mass%)气氛保护下,采用真空电弧炉熔炼,每个合金锭至少翻转熔炼4次,保证成分的均匀性良好,最终采用铜模喷铸法得到块体Zr基非晶合金,并利用线切割将材料制备成20 mm×20 mm×4 mm的长方体试样.图 1为制得试样的XRD图像,可以看到38°左右有一较宽的弥散峰且没有结晶峰,表明材料为典型的非晶结构.

Fig. 1

图 1 Zr41Ti14Ni12.5Cu10Be22.5非晶合金的XRD图像 Fig. 1 XRD pattern of Zr41Ti14Ni12.5Cu10Be22.5

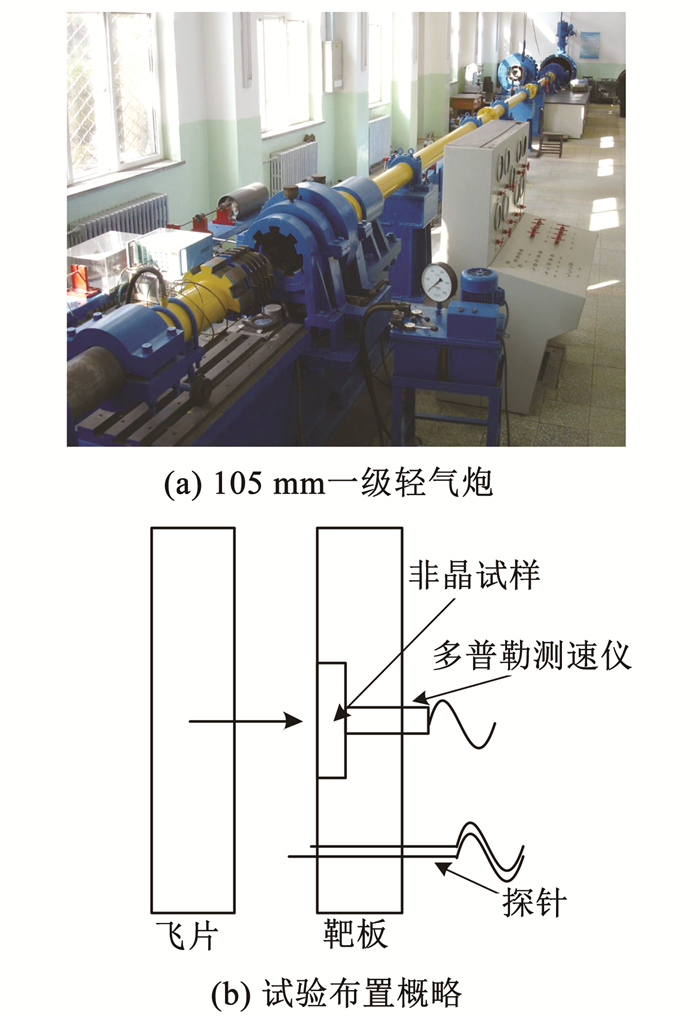

图 1 Zr41Ti14Ni12.5Cu10Be22.5非晶合金的XRD图像 Fig. 1 XRD pattern of Zr41Ti14Ni12.5Cu10Be22.5 1.2 平板冲击实验平板冲击实验在中科院力学研究所的一级轻气炮上进行,见图 2(a).采用阻抗匹配法测量Zr基非晶合金的Hugoniot曲线,阻抗匹配法的基本原理为用冲击绝热线已知的材料做标准,将待测样品材料的冲击压缩特性与该标准材料进行比较,获得待测材料冲击绝热线.实验飞片材料为超导电无氧铜,其密度为8.93 g/cm3,Hugoniot参数C0为3.940 km/s,λ为1.489.Zr基非晶合金试样镶嵌在环氧树脂内,并与铝制靶环组成靶板,试验布置见图 2(b).

Fig. 2

图 2 实验布置概略 Fig. 2 Schematic diagram of the experimental setup

图 2 实验布置概略 Fig. 2 Schematic diagram of the experimental setup 采用长短探针测量飞片的撞击速度V,长短探针头部距离与飞片撞击探针头部时间差的比值即为飞片速度.利用全光纤光子多普勒测速仪(PDV),根据多普勒频移效应测量试样自由面速度ufs.当被测物体向探头运动时,从被测物体表面反射回来的信号光fs,相对于激光器从探头发出的探测光fo,会有微小的多普勒频移fd

${f_{\rm{d}}} = {f_{\rm{s}}} - {f_{\rm{0}}} = \frac{{2{u_{{\rm{fs}}}}}}{{{\lambda _0}}} = \frac{{2{f_0}}}{c}{u_{{\rm{fs}}}}.$ (1)

式中:λ0为探测光的中心波长,c为光速,通过对干涉光时频分析提取多普勒频移fd,代入式(1)即可求得试样自由面速度ufs.

2 实验结果与讨论 2.1 材料D-u曲线在流体模型近似下,冲击波从自由面反射的卸载过程为等熵过程,当冲击波加载过程不太高时,冲击波后粒子速度u与自由面粒子速度ufs的近似关系为[14]

$u \approx \frac{1}{2}{u_{{\rm{fs}}}}.$ (2)

式(2)的推导过程可见文献[16].对于大部分固体,尤其在中压条件下,其冲击波速D与粒子速度u呈线性关系,在波前静止坐标系中,D-u关系为[17]

$D = {C_0} + \lambda u.$ (3)

式中C0理论上等于固体的零压体积声速.

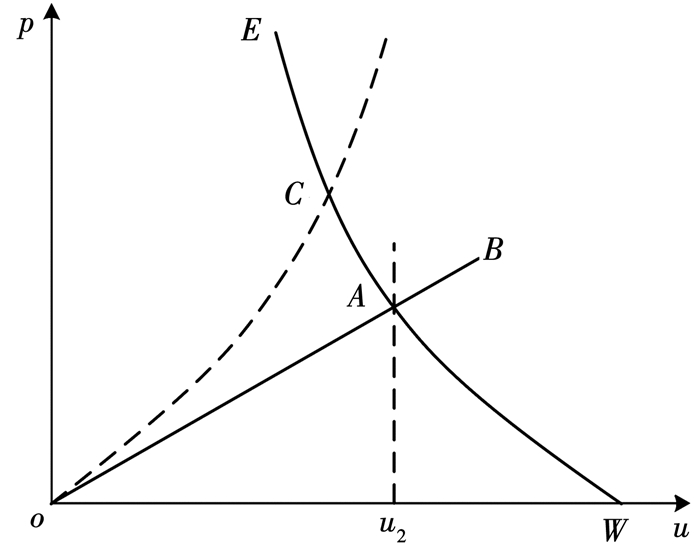

图 3为飞片撞击样品的p-u图,曲线OC为飞片(标准材料)的冲击绝热线,EAW为飞片冲击绝热线过速度W的镜像,待测样品的波直线OB与EAW相交于A点,波直线公式为[18]

$p = {\rho _0}Du.$ (4)

Fig. 3

图 3 飞片撞击试样p-u Fig. 3 p-u diagram of flyer impacting sample

图 3 飞片撞击试样p-u Fig. 3 p-u diagram of flyer impacting sample 已知飞片撞击非晶合金试样时压力平衡,根据图 2,由(3)(4)可得

${D_2} = \frac{{{\rho _{01}}\left[ {{C_{01}} + {\lambda _1}\left( {W - {u_2}} \right)} \right]\left( {W - {u_2}} \right)}}{{{\rho _{02}}{u_2}}}.$ (5)

式中:下标1代表标准材料,下标2代表非晶合金.由冲击波阵面质量守恒关系[16],可得

$\rho = {\rho _0}D/\left( {D - u} \right).$ (6)

将标准材料的Hugoniot参数、测试数据代入式(4)~(6)即可得到压力p、冲击波速D及材料密度ρ,表 1为材料的实测及计算数据.

表 1

1 350 190(6.00) 5.97(0.32) 6.36(0.021) 5 129.9(64.55)

2 390 210(10.59) 6.76(0.68) 6.38(0.042) 5 258.7(136.00)

3 439 239(7.38) 7.57(0.55) 6.42(0.028) 5 170.3(109.35)

4 502 270(7.18) 8.88(0.48) 6.45(0.026) 5 368.7(94.94)

5 550 290(8.61) 10.05(0.57) 6.46(0.031) 5 656.2(114.62)

表 1 实测及计算数据 Tab. 1 Experimental and computational data

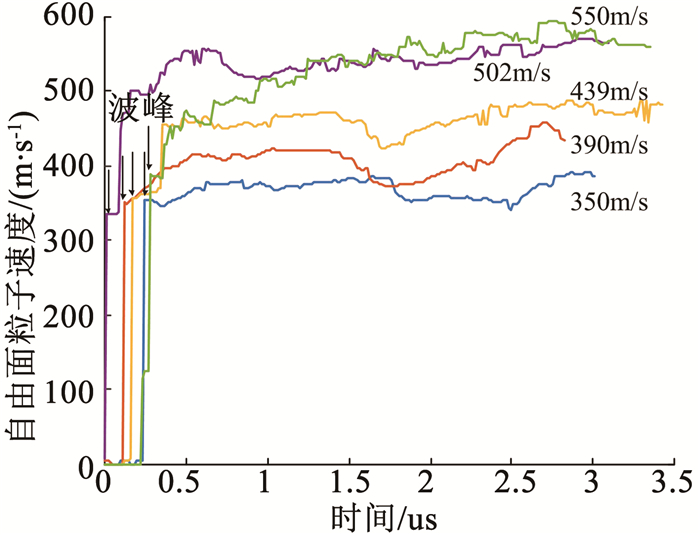

图 4为采用多普勒频移法测得的自由面速度曲线,可以看到材料明显的弹-塑性响应,曲线首先直线上升,到达材料的Hugoniot弹性极限时出现小波峰,随后塑性波到达,曲线继续上升一段高度后达到稳定.Hugoniot弹性极限(HEL)表示材料在单轴冲击载荷下的弹性响应极限,将弹性波波峰处的粒子速度代入式(4),即可求得Hugoniot弹性极限强度分别为5.59 GPa、5.65 GPa、5.66 GPa、5.51 GPa、6.75 GPa,舍弃最后一个明显偏大的值求平均,取材料的Hugoniot弹性极限强度σHEL为5.60 GPa.

Fig. 4

图 4 自由面速度 Fig. 4 Velocity of free surface

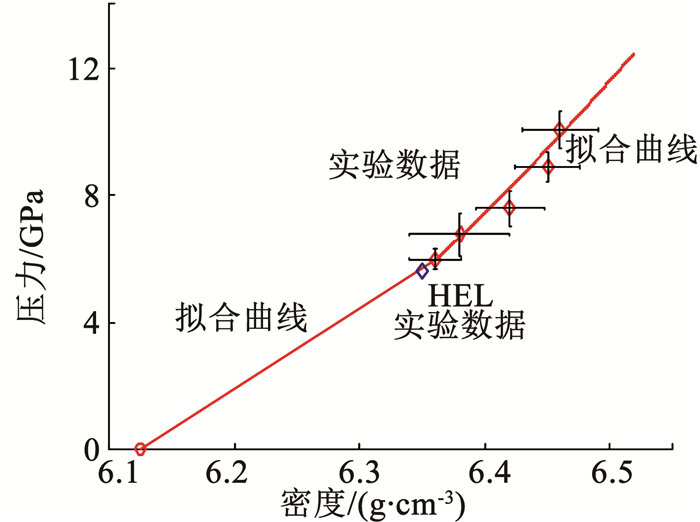

图 4 自由面速度 Fig. 4 Velocity of free surface 图 5为最小二乘法拟合的Zr41Ti14Ni12.5Cu10Be22.5非晶态合金D-u曲线,在5~10 GPa压力范围内,材料的Hugoniot参数C0为4.267 km/s,λ0为4.376,远大于一般固体1.0~1.5的斜率值,Martin[14],Mashimo等[15]观测到Zr57Nb5Cu15.4Ni12.6Al10、Zr55Al10Ni5Cu30两种Zr基非晶合金也具有类似现象.图 6为材料的P-ρ曲线,已知Hugoniot弹性极限下为材料的弹性响应阶段[17],故可通过σHEL得到材料在0~6 GPa内的P-ρ响应.

Fig. 5

图 5 材料的D-u曲线 Fig. 5 D-u curves of the material

图 5 材料的D-u曲线 Fig. 5 D-u curves of the material Fig. 6

图 6 材料P-ρ的曲线 Fig. 6 P-ρ curves of the material

图 6 材料P-ρ的曲线 Fig. 6 P-ρ curves of the material 2.2 冲击绝热线的理论预估假设Zr41Ti14Ni12.5Cu10Be22.5非晶态合金为理想混合物,由文献[18],当各组元的冲击波速度与粒子速度满足式(3)所示线性关系时,混合物的Hugoniot参数可由式(7)、(8)求得:

$\frac{1}{{C_0^2}} = \frac{1}{{V_0^2}}\sum\limits_i {\frac{{{x_i}V_{0i}^2}}{{C_{0i}^2}}} ,$ (7)

$\frac{1}{{\lambda _0^2}} = \frac{1}{{V_0^2}}\sum\limits_i {\frac{{{x_i}V_{0i}^2}}{{\lambda _{0i}^2}}} .$ (8)

式中xi为组元i的质量分数,理论计算所需参数及计算结果见表 2.

表 2

Zr 6.505 3.757 1.018 40

Ti 4.528 5.220 0.767 22

Ni 8.874 4.602 1.437 28

Cu 8.930 3.940 1.489 29

Be 1.851 7.998 1.124 4

Zr41Ti14Ni12.5Cu10Be22.5 6.125 4.147 0.925 26.78

表 2 计算参数及结果 Tab. 2 Parameters and computational results

可见,理论计算所得Hugoniot曲线斜率远小于实验所得结果.Martin[14]对Zr57Nb5Cu15.4Ni12.6Al10非晶合金高压物态方程的研究结果表明,材料的冲击Hugoniot曲线为低压区、混合区、高压区三部分的组合,而低压区部分的冲击Hugoniot曲线斜率远大于一般材料,而高压区Hugoniot曲线斜率与一般金属材料类似,在1.0~1.5之间.因此,推测采用理想混合物模型的计算结果更接近非晶合金高压区Hugoniot参数,为验证该假设,采用相同方法计算Zr57Nb5Cu15.4Ni12.6Al10非晶合金Hugoniot参数,理论计算所需参数及计算结果见表 3(括号内为混合法理论计算结果).

由表 3可知,采用理想混合物模型计算高压区Zr57Nb5Cu15.4Ni12.6Al10非晶合金Hugoniot参数与实验结果相近,从而证实了假设,即Zr基非晶合金的高压区Hugoniot参数可通过理想混合物模型进行计算.对于Zr41Ti14Ni12.5Cu10Be22.5非晶态合金,其Hugoniot曲线低压区、混合区的拐点压力大于10 GPa,高压区Hugoniot参数约为C0=4.147 km/s,λ=0.925.

表 3

Nb 8.586 4.438 1.207 41

Al 2.71 5.38 1.337 13

Zr57Nb5Cu15.4Ni12.6Al10 3.83(3.848) 1.21(1.055) 34.144

表 3 计算参数及结果 Tab. 3 Parameters and computational results

2.3 冲击物态方程在流体模型和谐振子模型近似下,忽略自由电子项的影响,由Gruneisen物态方程和Rankin-Hugoniot能量方程得出固体冲击物态方程计算模型[19].

$p = \frac{{\frac{V}{\gamma }{p_{\rm{C}}} - {E_{\rm{C}}}}}{{\frac{V}{\gamma } - \frac{1}{2}\left( {{V_0} - V} \right)}}.$ (9)

式中:pC为材料冷压,EC为材料冷能,γ为Gruneisen系数.为方便计算,通常利用波恩-迈耶势,冷能EC和冷压pC化为Q、q形式[20]:

${E_{\rm{C}}} = \frac{{3Q}}{{{\rho _{{\rm{0K}}}}}}\left\{ {\frac{1}{q}\exp \left[ {q\left( {1 - {\delta ^{ - 1/3}}} \right)} \right] - {\delta ^{ - 1/3}} - \left( {\frac{1}{q} - 1} \right)} \right\}.$ (10)

${p_{\rm{C}}} = Q{\delta ^{ - 2/3}}\left\{ {\exp \left[ {q\left( {1 - {\delta ^{ - 1/3}}} \right)} \right] - {\delta ^{ - 1/3}}} \right\}.$ (11)

式中:ρ0K为材料在0 K时的密度,

${\gamma _{{\rm{D}} - {\rm{M}}}} = \frac{1}{6}\frac{{{q^2}{\delta ^{ - 1/3}} \cdot \exp \left[ {q\left( {1 - {\delta ^{ - 1/3}}} \right)} \right] - 6\delta }}{{q \cdot \exp \left[ {q\left( {1 - {\delta ^{ - 1/3}}} \right)} \right] - 2\delta }}.$ (12)

将式(10)~(12)代入式(9)即为材料物态方程的Q、q形式.波后比容可由式(6)导出,将实验得到的D-u形式的Hugoniot曲线代入式(4)(6)即可得到一组压力、比容值记为pfit-Vfit.将pfit-Vfit代入式(9)~(12),通过数学迭代可得到数值法的目标函数为

$f = \sqrt {\sum {{{\left[ {p\left( {Q,q} \right) - {p_{fit}}} \right]}^2}} } .$ (13)

式(13)将求材料物态方程参数的问题转化为非线性优化问题,模拟退火算法适合解决这类问题.

模拟退火算法(Simulated annealing algorithm, SA)是依据统计物理学原理,模仿固体退火过程的随机优化算法.模拟退火算法特别适用于求解组合优化问题,它的核心为Metropolis算法.Metropolis算法产生一个马尔可夫链,它的转移概率确实收敛到一个独立平稳的Gibbs分布,当温度时,系统能量将收敛到全局极小点.Metropolis算法如式(14)所示

${X_{n + 1}} = \left\{ \begin{array}{l}{Y_n},\Delta E < 0;\\{Y_n},\Delta E > 0,\xi < {{\rm{e}}^{\left( { - \Delta E/T} \right)}};\\{X_n},\Delta E > 0,\xi \ge {{\rm{e}}^{\left( { - \Delta E/T} \right)}}.\end{array} \right.$ (14)

式中:Xn为n时刻状态,Yn为随机生成的新状态,ΔE为系统从状态Xn到Yn的能量差,T为当前温度,ξ为(0, 1)间的随机数.若ΔE为负,则新状态系统能量更低,该次转移被接受;若ΔE为正,则Yn以概率e(-ΔE/T)被接受,对于求解材料参数Q、q的问题,系统能量差即为目标函数(13)的新旧状态之差,算法的具体细节本文不再赘述.参数设置如下,其中Tini=1032为初始温度,Tend=10-20为终止温度,k=0.995为温差系数,温度依据式(15)进行迭代.

${T_{n + 1}} = k{T_n}.$ (15)

图 7为退火过程,横坐标采用对数形式,可以看到,高温时,曲线波动范围较大,以此跳出局部最小值;低温时,曲线快速收敛,以提高计算速度.经多次试验,算法稳定性较高.

Fig. 7

图 7 退火过程 Fig. 7 Annealing process

图 7 退火过程 Fig. 7 Annealing process 将所求参数Q、q代入式(9),即得Zr41Ti14Ni12.5Cu10Be22.5非晶态合金的Gruneisen冲击物态方程.最终求得Q=6.829 6×109 GPa,q=2.047 8,所得物态方程数据与实验数据均方差为0.376 1 GPa,而通过解析法[20, 22]求得Q=7.869 5×109 GPa,q=44.846 7,代入实验数据解得负压力值,与事实不符,表明提出方法较适用于Zr基非晶合金Gruneisen物态方程的计算,而传统解析法误差较大.

2.4 多项式物态方程实际应用过程中,也常采用Birch-Murnaghan物态方程[7, 14]和三项式物态方程表示材料的p-V关系,Birch-Murnaghan物态方程为

$p = \frac{{3{K_0}}}{2}\left[ {{{\left( {\frac{{{V_0}}}{V}} \right)}^{\frac{7}{3}}} - {{\left( {\frac{{{V_0}}}{V}} \right)}^{\frac{5}{3}}}} \right]\left\{ {1 + 3\left( {\frac{{{{K'}_0}}}{4} - 1} \right)\left[ {{{\left( {\frac{{{V_0}}}{V}} \right)}^{\frac{2}{3}}} - 1} \right]} \right\}.$ (16)

式中:K0为材料的零压体积模量.Zr41Ti14Ni12.5Cu10Be22.5非晶态合金的K0为114.4 GPa,K′0为体积模量对p的导数,其解析式为[14]

${{K'}_0} = 4{\lambda _0} - 1.$ (17)

三项式物态方程为

$p = {A_1}\mu + {A_2}{\mu ^2} + {A_3}{\mu ^3}.$ (18)

式中:A1为材料零体积应变下的体积模量,A2、A3为材料常数,μ=ρ/ρ0-1为材料的体应变,由最小二乘法得,A1=114.4 GPa,A2=705.2 GPa,A3=7 651 GPa.

材料三种形式的物态方程曲线见图 8,曲线与实验数据走势契合,在实验压力范围内,Gruneisen物态方程、Birch-Murnaghan物态方程、三项式物态方程均可较好地表现材料性质.三种物态方程计算结果与实验数据的均方差分别为0.376 1 GPa、0.363 5 GPa、0.980 8 GPa,表明在5~10 GPa冲击压力范围内,Gruneisen物态方程、三项式物态方程对材料性质的描述更为精准.

Fig. 8

图 8 材料物态方程曲线 Fig. 8 EOS curves of the material

图 8 材料物态方程曲线 Fig. 8 EOS curves of the material 3 结论1) 采用匹配阻抗法,利用长短探针、PDV等手段实验测定了Zr41Ti14Ni12.5Cu10Be22.5非晶合金的冲击Hugoniot曲线,得到了材料Hugoniot参数及Hugoniot曲线,在5 GPa~10 GPa范围内,曲线的斜率远大于一般固态金属及合金.

2) 采用理想混合物模型理论计算Zr基非晶合金的高压区Hugoniot参数,计算结果适应性较好,但该方法不适用于计算材料低压区Hugoniot参数.Zr41Ti14Ni10Cu12.5Be22.5非晶态合金Hugoniot曲线的低压区、混合区拐点压力大于10 GPa.

3) 提出了基于模拟退火算法计算材料Gruneisen物态方程的方法,并得到了Zr41Ti14Ni12.5Cu10Be22.5非晶合金的Gruneisen物态方程,该方法较传统解析法更适用于Zr基非晶合金Gruneisen物态方程的计算;与三项式物态方程、Birch-Murnaghan物态方程对比结果表明,在5~10 GPa冲击压力范围内,Gruneisen物态方程、三项式物态方程对材料性质的描述更为精准.

参考文献

[1] 惠希东, 陈国良. 块体非晶合金[M]. 北京: 化学工业出版社, 2007: 1.

HUI Xidong, CHEN Guoliang. Bulk amorphous alloy[M]. Beijing: Chemical Industry Press, 2007: 1.

[2] WANG G Y, LIAW P K, MORRISON M L. Progress in studying the fatigue behavior of Zr-based bulk-metallic glasses and their composites[J]. Intermetallics, 2009(17): 579. DOI:10.1016/j.intermet.2009.01.017

[3] DAI L H, YAN M, LIU L F, et al. Adiabatic shear banding instability in bulk metallic glasses[J]. Applied Physics Letters, 2005(87): 14916. DOI:10.1063/1.2067691

[4] CONNER R D, DANDLIKER R B, SCRUGGS V, et al. Dynamic deformation behavior of tungsten fiber/metallic glass matrix composites[J]. International Journal of Impact Engineering, 2000(24): 435. DOI:10.1016/S0734-743(99)00176-1

[5] RONG G, HUANG D W, YANG M C. Penetrating behaviors of Zr-based metallic glass composite rods reinforced by tungsten fibers[J]. Theoretical and Applied Fracture Mechanics, 2012(58): 21. DOI:10.1016/j.tafmec.2012.02.003

[6] KIM G S, SON C Y, LEE S B, et al. Ballistic impact properties of Zr-based amorphous alloy composites reinforced with woven continuous fibers[J]. Metallurgical and Materials Transactions A, 2012(43): 870. DOI:10.1007/s11661-011-0915-5

[7] LI G, GAO Y P, SUN Y N, et al. Compression behavior and equation of state of Ni77P23 amorphous alloy[J]. Chinese Science Bulletin, 2007, 52(4): 440. DOI:10.1007/s11434-007-0067-6

[8] MASARU A. Elastic constants, equation of state and mechanical relaxations of some metallic glasses at high pressure[J]. Materials Science Forum, 2012, 706: 1305. DOI:10.4028/www.scientific.net/MSF.706-709.1305

[9] WANG J Q, BAI H Y. High-pressure behaviors of Yb-based bulk metallic glass[J]. Scripta Materialia, 2009, 61: 453. DOI:10.1016/j.scriptamat.2009.04.044

[10] WANG W H, LI F Y, PAN M X, et al. Elastic property and its response to pressure in a typical bulk metallic glass[J]. Acta Materialia, 2004, 52: 715. DOI:10.1016/j.actamat.2003.10.008

[11] WANG W H, WEN P, WANG L M, et al. Equation of state of bulk metallic glasses studied by an ultrasonic method[J]. Applied Physics Letters, 2001, 79(24): 3947. DOI:10.1063/1.1426272

[12] ZHANG Y, PAN M X, WANG W H. Mie potential and equation of state of Zr48Nb8Cu14Ni12Be18 bulk metallic glass[J]. Chinese Physics Letters, 2001, 18(6): 805. DOI:10.1088/0256-307X/18/6/331

[13] PAN M X, WANG W H, ZHAO D Q, et al. The equation of state and potential function of Zr41Ti14Cu12.5Ni10Be22.5 bulk metallic glass[J]. Journal of Physics: Condensed Matter, 2002, 14: 5665. DOI:10.1088.0953-8984/14/23/302

[14] MARTIN M, SEKINE T, KOBAYASHI T, et al. High-pressure equation of the state of a zirconium-based bulk metallic glass[J]. Metallurgical and Materials Transactions, 2007, 38(11): 2689. DOI:10.1007/s11661-007-9263-x

[15] MASHIMO T, TOGO H, Zhang Y, et al. Hugoniot-compression curve of Zr-based bulk metallic glass[J]. Applied Physics Letters, 2006, 89: 241094-1. DOI:10.1063/1.2403931

[16] 经福谦. 实验物态方程导引[M]. 2版. 北京: 科学出版社, 1999: 209.

JING Fuqian. Experimental state equation guidance[M]. Second Edition. Beijing: Science Press, 1999: 209.

[17] ROSENBERG Z, DEKEL E.终点弹道学[M].钟方平, 译.北京: 国防工业出版, 2012: 9

ROSENBERG Z, DEKEL E. Terminal ballistics[M]. ZHONG Fangping translate Beijing: National Defence Industry Press, 2012: 9

[18] 谭华. 实验冲击波物理导引[M]. 北京: 国防工业出版社, 2007: 15.

TAN Hua. Experimental shockwave physics guidance[M]. Beijing: National Defence Industry Press, 2007: 15.

[19] 史安顺, 张先锋, 乔良, 等. 多功能含能结构材料冲击压缩特性的理论计算[J]. 爆炸与冲击, 2013, 33(2): 148.

SHI Anshun, ZHANG Xianfeng, QIAO Liang, et al. Theoretical calculation on shock compression characteristics of multifunctional energetic structural materials[J]. Explosion and Shock Waves, 2013, 33(2): 148. DOI:10.11883/1001-1455(2013)02-148-08

[20] 汤文辉, 张若棋. 物态方程理论及计算概论[M]. 北京: 高等教育出版社, 2008: 212.

TANG Wenhui, ZHANG Ruoqi. Introduction to theory and computation of equations of state[M]. Beijing: Higher Education Press, 2008: 212.

[21] HAYKIN S.神经网络与机器学习[M].申富饶, 译.北京: 机械工业出版社, 2011: 374

HAYKIN S. Neural networks and learning machines[M]. Shen Furao, translate. Beijing: China Machine Press, 2011: 374

[22] 胡金彪, 经福谦. 用冲击压缩数据计算物质结合能的一个简便解析方法[J]. 高压物理学报, 1990, 4(3): 175.

HU Jinbiao, JING Fuqian. A simplified analytical method for calculations of equation-of-state of materials from shock compression data[J]. Chinese Journal of High Pressure Physic, 1990, 4(3): 175.