, 林晓青, 陈彤, 李晓东

, 林晓青, 陈彤, 李晓东

, 岑可法

, 岑可法能源清洁利用国家重点实验室, 浙江大学热能工程研究所, 杭州 310027

收稿日期: 2017-11-29; 修回日期: 2017-12-30; 录用日期: 2017-12-30

基金项目: 国家自然科学基金(No.51706201);国家重点研发计划项目(No.2017YFC0703100)

作者简介: 徐帅玺(1992-), 男, 博士研究生, E-mail:xushuaixi@zju.edu.cn

通讯作者(责任作者): 李晓东, 男, 教授、博士生导师, 主要从事能源与废弃物无害化能源化利用等基础理论和工程应用研究, 特别是从事废弃物燃烧及污染控制的基础研究和技术开发.先后负责承担了“973”子课题、“863”、国家自然科学基金、环保公益项目及企业重大科研项目等40余项.撰写出版著作3本(合著), 译著1本, 作为第一、二作者发表论文100余篇, 获得发明专利9项, 国家科技进步二等奖2项.E-mail:lixd@zju.edu.cn

摘要: 钢铁行业是我国二

英的第一大排放源,但对不同钢铁生产过程二

英的第一大排放源,但对不同钢铁生产过程二 英的生成排放认识有所欠缺.本文系统探究了钢铁行业不同物料的二

英的生成排放认识有所欠缺.本文系统探究了钢铁行业不同物料的二 英生成能力和同系物分布特征.结果表明,烧结飞灰的二

英生成能力和同系物分布特征.结果表明,烧结飞灰的二 英生成能力最强,而烧结生料生成二

英生成能力最强,而烧结生料生成二 英能力最弱.3种污泥(连铸、热轧、冷轧)和烧结生料的二

英能力最弱.3种污泥(连铸、热轧、冷轧)和烧结生料的二 英生成途径相似,4种飞灰(电炉、转炉、高炉一次、高炉二次)之间也有相似的二

英生成途径相似,4种飞灰(电炉、转炉、高炉一次、高炉二次)之间也有相似的二 英生成途径,而烧结飞灰则与其他物料均不同.所有物料中,有毒2,3,7,8-PCDD同系物之间存在极强的相关性,且氯酚合成二

英生成途径,而烧结飞灰则与其他物料均不同.所有物料中,有毒2,3,7,8-PCDD同系物之间存在极强的相关性,且氯酚合成二 英路径也被发现存在于钢铁生产过程中.

英路径也被发现存在于钢铁生产过程中.关键词:钢铁行业污泥飞灰二

英生成

英生成PCDD/F formation and distribution of various materials from steel industry

XU Shuaixi

, LIN Xiaoqing, CHEN Tong, LI Xiaodong

, LIN Xiaoqing, CHEN Tong, LI Xiaodong

, CEN Kefa

, CEN Kefa State Key Laboratory of Clean Energy Utilization, Institute for Thermal Power Engineering, Zhejiang University, Hangzhou 310027

Received 29 November 2017; received in revised from 30 December 2017; accepted 30 December 2017

Supported by the National Natural Science Foundation of China(No.51706201)and the National Key Research and Development Program of China (No.2017YFC0703100)

Biography: XU Shuaixi(1992—), male, Ph.D. candidate, E-mail:xushuaixi@zju.edu.cn

*Corresponding author: LI Xiaodong, E-mail:lixd@zju.edu.cn

Abstract: In China, integrated iron and steel industry is the main source of polychlorinated dibenzo-p-dioxins (PCDD) and dibenzofurans (PCDF) or, more briefly, of dioxins. However, studies about the PCDD/F formation on the whole process of steel making are rather less abundant. The aim with this study is to experimentally investigate the PCDD/F formation and distribution of various materials from steel industry. The experiments results show that sintering fly ash generates the most PCDD/F, and PCDD/F-yield of sintering raw material is the least. Three kinds of sludge (continues casting, cold rolling and hot rolling) and sintering raw material lead to a similar pathway for PCDD/F formation. Four fly ash (blast furnace 1&2, basic oxygen furnace and electric arc furnace) also presents the similar PCDD/F distribution, which is totally different from that of sintering fly ash. In this study, a fairly good internal correlation among 2, 3, 7, 8-substituted PCDD is observed. In addition, chlorophenol routes for PCDD/F formation in thermal metallurgical processes is also investigated.

Key words: steel industrysteel rolling sludgefly ashPCDD/F formation

1 引言(Introduction)二

钢铁的基本生产工艺流程:首先利用烧结工艺和炼焦工艺将铁矿石和焦煤转变为烧结矿和焦炭等原料, 然后利用高炉炼铁工艺将其制成生铁.下一步再以生铁为原料, 利用不同炼钢炉将其冶炼成钢.之后, 钢被铸成钢锭或连铸胚形状, 送到轧钢机进行轧制加工, 或经过锻造, 最终成为各种形状的钢材.目前, 人们对二

我国钢铁行业二

基于钢铁行业二

2 实验材料及方法(Materials and methods)2.1 实验材料实验所用的材料均来自国内某钢铁厂, 包括各种飞灰、烧结生料和轧钢污泥.其中飞灰包括高炉一次灰、高炉二次灰、电炉灰、转炉灰和烧结灰, 而轧钢污泥包括热轧污泥、冷轧污泥和连铸污泥.轧钢污泥是轧钢废水在经过污水处理后所产生的固体沉淀物质, 污泥中主要含有轧钢过程中用水喷淋冷却轧机轧辊辊道和轧制钢材的表面产生的氧化铁皮, 机械设备上的油类物质, 固体杂质等废弃物.高炉一次灰是由重力除尘器捕集的干粉尘, 粒径相对较大, 而高炉二次灰是由文氏管捕集的泥浆状粉尘经过滤后形成的泥饼, 其余的飞灰则均收集自各生产过程的静电除尘器中.所有飞灰和轧钢污泥均在105 ℃烘箱进行24 h干燥处理.烧结生料则由铁矿石(68.6%)、烧结返矿(15.0%)、焦炭(3.8%)、石灰石(3.0%)、熟石灰(3.0%)、白云石(3.0%)、蛇纹石(1.0%)、水(2.5%)和氯化铜(0.1%)组成.由于烧结生料生成二

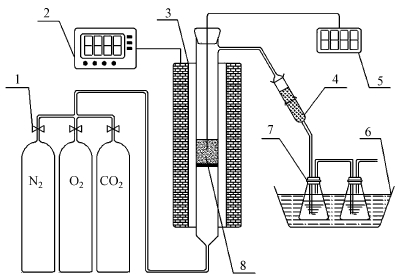

2.2 实验装置和工况本次研究采用小型管式炉完成污泥焚烧和飞灰及烧结生料从头合成二

图 1(Fig. 1)

|

| 图 1 立式管式炉反应系统 (1.气瓶, 2.管式炉温控装置, 3.管式炉和石英管, 4. XAD-Ⅱ树脂, 5.热电偶, 6.冰浴, 7.甲苯吸收液, 8.样品床) Fig. 1The vertical tube furnace system (1. Gas cylinder and mass flow meter, 2. Temperature controller, 3. Tubular furnace and tubular reactor, 4. XAD-Ⅱ resin, 5. Thermocouple, 6. Ice bath, 7. Toluene, 8. Quartz tube and sample) |

为了尽可能拟合现场实验条件, 不同物料所采用的实验工况有所差异, 具体详见表 1.3种污泥焚烧实验均在850 ℃, 标准空气的工况下完成, 而飞灰和烧结物料从头合成二

表 1(Table 1)

| 表 1 实验工况 Table 1 Experimental conditions | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

表 1 实验工况 Table 1 Experimental conditions

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2.3 样品采集及分析实验中, 吸附在XAD-Ⅱ树脂和甲苯中的气相二

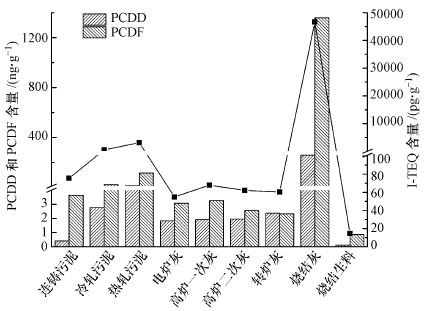

3 结果与讨论(Results and discussion)3.1 不同物料PCDD/Fs生成能力对比钢铁行业不同物料二

图 2(Fig. 2)

|

图 2 不同样品二 |

对比3种高温焚烧的轧钢污泥, 其同样展示了完全不同的二

如表 2所示, 对比5种飞灰的元素分布可以发现, 烧结飞灰的氯含量远远高于其余4种飞灰.其元素含量达到24.8%, 而其余4种飞灰中氯元素含量最高的是电炉灰, 其含量只有1.1%.众所周知, 二

表 2(Table 2)

| 表 2 5种飞灰的元素分布(质量分数) Table 2 Ultimate analysis of five fly ash samples | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

表 2 5种飞灰的元素分布(质量分数) Table 2 Ultimate analysis of five fly ash samples

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

如表 3所示, 3种轧钢污泥和烧结生料的PCDF/PCDD比值介于7和8之间, 而5种飞灰则相对较低.值得注意的是, 除烧结飞灰外, 其余飞灰的PCDF/PCDD比值都小于2, 其中转炉飞灰该比值略小于1.这说明除转炉飞灰外, 其余物料二

表 3(Table 3)

| 表 3 不同样品的PCDF/PCDD比值和PCDD/F氯化度对比 Table 3 The PCDD/PCDF-ratio and Cl-PCDD/F-values of all samples | ||||||||||||||||||||||||||||||||||||||||||||||||||

表 3 不同样品的PCDF/PCDD比值和PCDD/F氯化度对比 Table 3 The PCDD/PCDF-ratio and Cl-PCDD/F-values of all samples

| ||||||||||||||||||||||||||||||||||||||||||||||||||

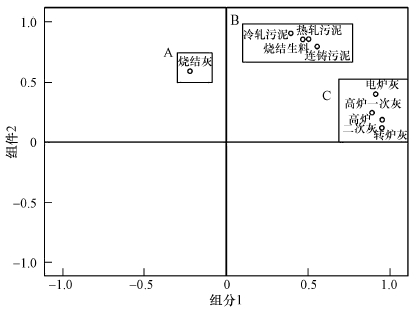

3.2 PCDD/Fs同系物组分布特征在本研究中, 主成分分析被采用以研究不同样品同系物组分布的相似和异同, 从而探究不同物料生成二

图 3(Fig. 3)

|

图 3 不同样品二 |

由主成分分析可知, 3种污泥和烧结生料的二

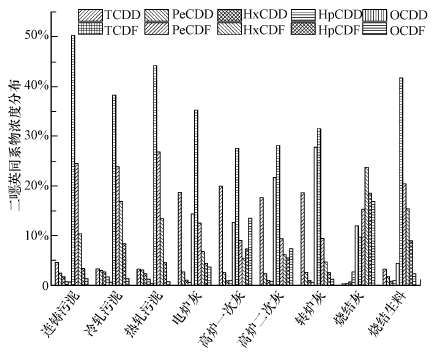

图 4(Fig. 4)

|

图 4 不同样品的二 |

3.3 PCDD/Fs内部关联众多研究关注于2, 3, 7, 8-PCDD/F的生成和分布规律, 这是由于2, 3, 7, 8位同时被氯原子取代的PCDD/F具有毒性.在本研究中, 采用Hagenmaier表来进行17种2, 3, 7, 8-PCDD/F同系物之间的关联分析.二

表 4(Table 4)

| 表 4 Hagenmaier同系物分布 Table 4 Hagenmaier profile | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

表 4 Hagenmaier同系物分布 Table 4 Hagenmaier profile

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

通过分析所有样品的Hagenmaier同系物分布可以发现, 2, 3, 7, 8-TCDD和其他2, 3, 7, 8-PCDD有较强的正相关(r):2, 3, 7, 8-TCDD (1.00), 1, 2, 3, 7, 8-PeCDD(五氯代二

|

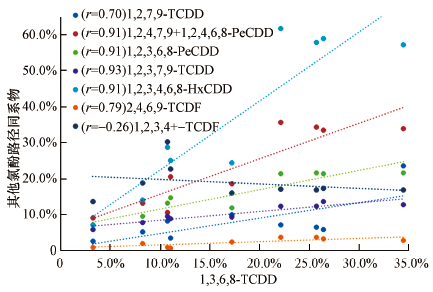

国外****的研究表明, 7种PCDD同系物包括1, 3, 6, 8-, 1, 3, 7, 9-TCDD, 1, 2, 4, 6, 8+1, 2, 4, 7, 9-, 1, 2, 3, 6, 8-, 1, 2, 3, 7, 9-PeCDD, 1, 2, 3, 4, 6, 8-HxCDD以及两种PCDF同系物1, 2, 3, 4+1, 2, 3, 6+1, 2, 3, 8+1, 4, 6, 9+1, 6, 7, 8+2, 3, 6, 8-TCDF和2, 4, 6, 8-TCDF极易由冷凝的氯酚或氯苯氧自由基直接合成而来, 例如2, 4, 6-三氯苯酚, 这些PCDD/F的生成路径被统称为氯酚路径(Luijk et al., 1994; Addink et al., 1995; Ryu et al., 2005).通过分析所有样品的氯酚路径同系物分布可得(图 4), 除1, 2, 3, 4+-TCDF外, 1, 3, 6, 8-TCDD与其他所有的氯酚路径同系物均有很强的正相关性.其中1, 2, 4, 6, 8+1, 2, 4, 7, 9-, 1, 2, 3, 6, 8-, 1, 2, 3, 7, 9-PeCDD, 1, 2, 3, 4, 6, 8-HxCDD这4种同系物展示出与1, 3, 6, 8-TCDD的超强相关性, 其r值均大于0.9, 而1, 3, 7, 9-TCDD和2, 4, 6, 8-TCDF的r值也均大于0.7.这说明氯酚路径在钢铁行业的二

图 5(Fig. 5)

|

| 图 5 氯酚路径同系物与1, 3, 6, 8-TCDD相关性 Fig. 5Congeners of chlorophenol condensation route as a function of 1, 3, 6, 8-TCDD |

通过PCDD/F的同系物相互关联性分析可以推测不同物料二

4 结论(Conclusions)本文借助实验室小型管式炉, 系统地探究了钢铁行业不同物料生成二

1) 钢铁行业的不同物料展示了完全不同的二

2) 利用主成分分析, 对比不同物料二

3) 有毒2, 3, 7, 8-PCDD之间有强相关性, 而有毒2, 3, 7, 8-PCDF之间的相关性不明显, 推测出一条钢铁行业的有毒二

参考文献

| Addink R, Cunbben P, Olie K. 1995. Formation of polychlorinated dibenzo-p-dioxins/dibenzofurans on fly ash from precursors and carbon model compounds[J]. Carbon, 33(10): 1463–1471.DOI:10.1016/0008-6223(95)00100-R |

| Altarawneh M, Dlugogorski B, Kennedy E M, et al. 2009. Mechanisms for formation, chlorination, dechlorination and destruction of polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/Fs)[J]. Progress in Energy and Combustion Science, 3(35): 245–274. |

| Buekens A, Stieglitz L, Hell K, et al. 2001. Dioxins from thermal and metallurgical processes:recent studies for the iron and steel industry[J]. Chemosphere, 42(5): 729–735. |

| Fujimori T, Takaoka M, Takeda N. 2009. Influence of Cu, Fe, Pb, and Zn chlorides and oxides on formation of chlorinated aromatic compounds in MSWI fly ash[J]. Environmental Science & Technology, 43(21): 8053–8059. |

| Gullett B K, Sarofim A F, Smith K A, et al. 2000. The role of chlorine in dioxin formation[J]. Process Safety and Environmental Protection, 1(78): 47–52. |

| Huang H, Buekens A. 1995. On the mechanisms of dioxin formation in combustion processes[J]. Chemosphere, 9(31): 4099–4117. |

| 刘国瑞, 郑明辉. 2013. 非故意产生的持久性有机污染物的生成和排放研究进展[J]. 中国科学:化学, 2013, 3(1): 265–278. |

| Lu S, Yan J, Li X, et al. 2007. Effects of inorganic chlorine source on dioxin formation using fly ash from a fluidized bed incinerator[J]. Journal of Environmental Sciences, 19(6): 756–761.DOI:10.1016/S1001-0742(07)60126-0 |

| Luijk R, Akkerman D, Slot P, et al. 1994. Mechanism of formation of polychlorinated dibenzo-p-dioxins and dibenzofurans in the catalyzed combustion of carbon[J]. Environmental Science & Technology, 28(2): 312–321. |

| Nakano M, Hosotani Y, Kasai E. 2005. Observation of behavior of dioxins and some relating elements in iron ore sintering bed by quenching pot test[J]. ISIJ International, 45(4): 609–617.DOI:10.2355/isijinternational.45.609 |

| Nakano M, Morii K, Sato T. 2009. Factors accelerating dioxin emission from iron ore sintering machines[J]. ISIJ International, 49(5): 729–734.DOI:10.2355/isijinternational.49.729 |

| Ooi C T, Lu L. 2011. Formation and mitigation of PCDD/Fs in iron ore sintering[J]. Chemosphere, 85(3): 291–299.DOI:10.1016/j.chemosphere.2011.08.020 |

| Ryu J, Mulholland J, Kim D, et al. 2005. Homologue and isomer patterns of polychlorinated dibenzo-p-dioxins and dibenzofurans from phenol precursors:Comparison with municipal waste incinerator data[J]. Environmental Science & Technology, 12(39): 4398–4406. |

| Stieglitz L, Bautz H, Roth W, et al. 1997. Investigation of precursor reactions in the de-novo-synthesis of PCDD/PCDF on fly ash[J]. Chemosphere, 34(5): 1083–1090. |

| Sun Y, Liu L, Fu X, et al. 2016. Mechanism of unintentionally produced persistent organic pollutant formation in iron ore sintering[J]. Journal of Hazardous Materials, 306(10): 41–49. |

| Suzuki K, Kasai E, Aono T, et al. 2004. De novo formation characteristics of dioxins in the dry zone of an iron ore sintering bed[J]. Chemosphere, 54(1): 97–104.DOI:10.1016/S0045-6535(03)00708-2 |

王存政, 李建萍, 李烨. 2011. 我国钢铁行业二 英污染防治技术研究[J]. 环境工程, 2011, 5(1): 75–79. 英污染防治技术研究[J]. 环境工程, 2011, 5(1): 75–79. |

| Xu S, Chen T, Zhang M, et al. 2018. Hot rolling sludge incineration:Suppression of PCDD/Fs by spent anion exchange resins[J]. Journal of Hazardous Materials, 1(343): 149–156. |

| Yan M, Li X, Chen T, et al. 2010. Effect of temperature and oxygen on the formation of chlorobenzene as the indicator of PCDD/Fs[J]. Journal of Environmental Sciences, 22(10): 1637–1642.DOI:10.1016/S1001-0742(09)60300-4 |

| Yang Y, Ryu C, Goodfellow J, et al. 2004. Modelling waste combustion in grate furnaces[J]. Process Safety and Environmental Protection, 82(3): 208–222.DOI:10.1205/095758204323065975 |

俞勇梅, 何晓蕾, 李咸伟. 2009. 烧结过程中二 英的排放和生成机理研究进展[J]. 世界钢铁, 2009, 6(1): 1–6. 英的排放和生成机理研究进展[J]. 世界钢铁, 2009, 6(1): 1–6. |

| Zhang M, Buekens A. 2016. De novo synthesis in iron ore sintering[J]. International Journal of Environment & Pollution, 60(1): 111–135. |

张苏, 董慧芹, 王文利. 2015. 钢铁行业二 英减排技术分析[J]. 能源与环境, 2015, 6(1): 70–71. 英减排技术分析[J]. 能源与环境, 2015, 6(1): 70–71. |